2

PRODUCT MANUAL

1800 358 101

sales.au@westlab.com

www.westlab.com.au

+64 9 553 3677

sales.nz@westlab.com

www.westlab.co.nz

646 568 5391

sales.us@westlab.com

www.westlab.com

1 877 822 1455

sales.ca@westlab.com

www.westlab.com

Australia New Zealand United StatesCanada

1. Product Description

1.1 Introduction

Westlab’s Precision Multichannel Channel Pipettes are designed to meet the liquid-

transfer requirements of the modern laboratory and to withstand chemical exposure.

The metal fabrication of the pipettes increases their liquid transfer precision and

accuracy. Additionally, the 8- and 12-channel variants of the multichannel pipettes offer

pipetting volume exibility.

With excellent calibration retention and a precise volume adjustment mechanism,

the pipettes ensure accurate volume dispensing. Coupled with the lockable counter

mechanism, the high precision volume adjustment of the pipettes commoditises

accurate and repeatable liquid dispensing.

Tailored to reduce the negative effects from repetitive strain injury, the well-balanced and

sturdy chassis reduces unnecessary weight without compromising the overall quality of

the pipette. Furthermore, the pipettes are manufactured from a heat-resistant material

allowing them to be safely autoclaved multiple times without a loss of quality. With a fully

autoclavable body, the transfer of contaminants during pipetting is reduced.

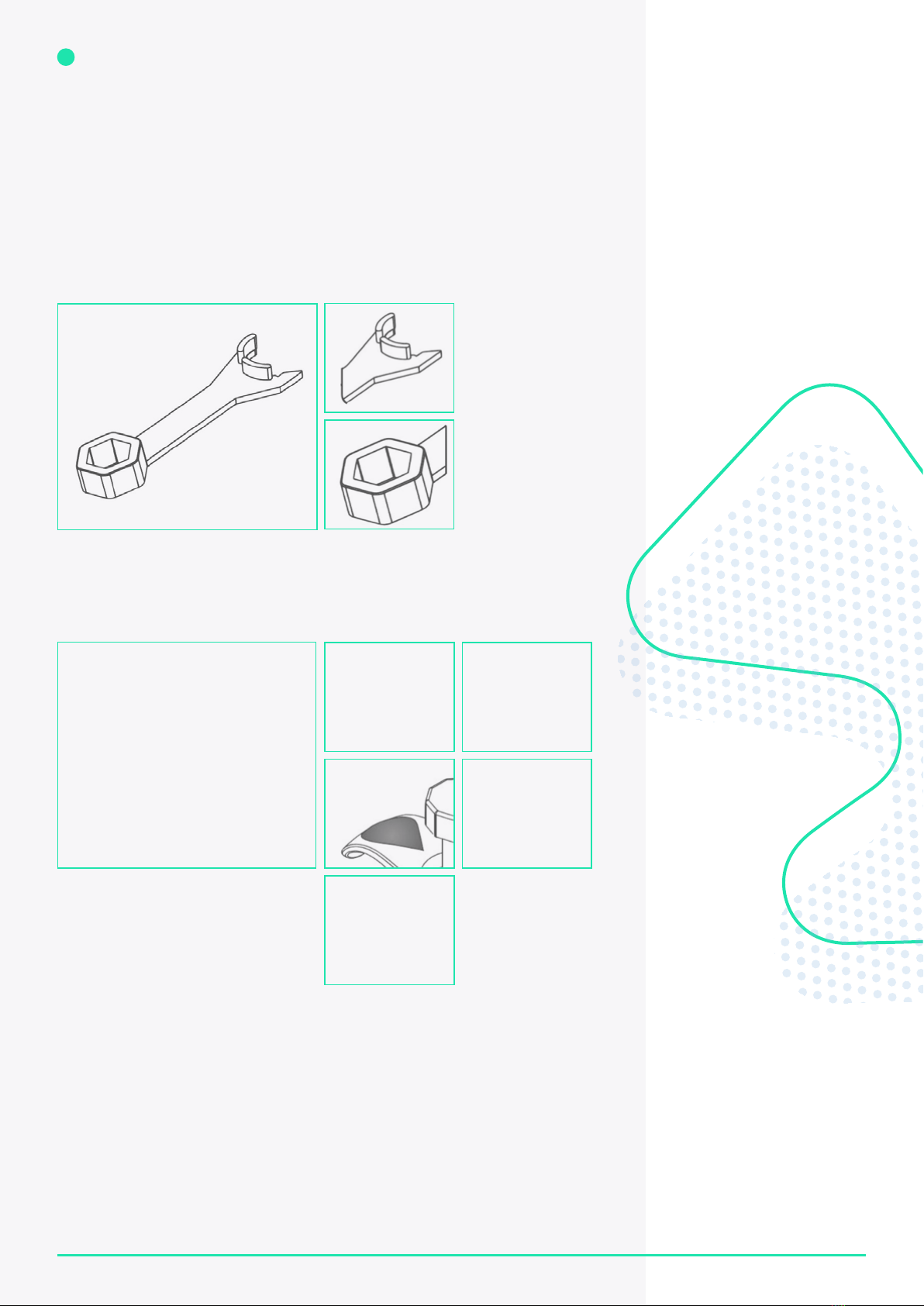

The pipettes are provided with exchangeable colour inserts for easy visual identication

of pipettes by user-dened or volume-dened categories. Each pipette can be individually

colour coded, using the included tool for drop removing.

The pipettes operate according to the air displacement principle and are produced and

tested according to EN ISO 8655.

1.2 Features

• Fully Autoclavable Pipette Body

• Soft Grip & Light Pipette Chassis

• Exchangeable Colour Inserts for Visual Identication

• Serial Number & Declaration of Conformity Supplied

• Accurate Liquid Dispensing Across All Channels

• Counter-Mechanism Prevents Accidental Turning

• Compatible With All Major Pipette Tip Brands

• Manufactured In Germany

TABLE OF CONTENT

1. Product Description

1.1 Introduction

1.2 Features

1.3 Accessories

2. Technical Specications

3. Safety Precautions

4. Maintenance & Cleaning

5. Installation

6. Operation

7. Troubleshooting

8. Product Disposal

PRODUCT CODE

665-259

665-260

665-261

665-262

665-263

665-264

PLEASE READ THESE INSTRUCTIONS BEFORE USE.

M

a

d

e

i

n

G

e

r

m

a

n

y