10

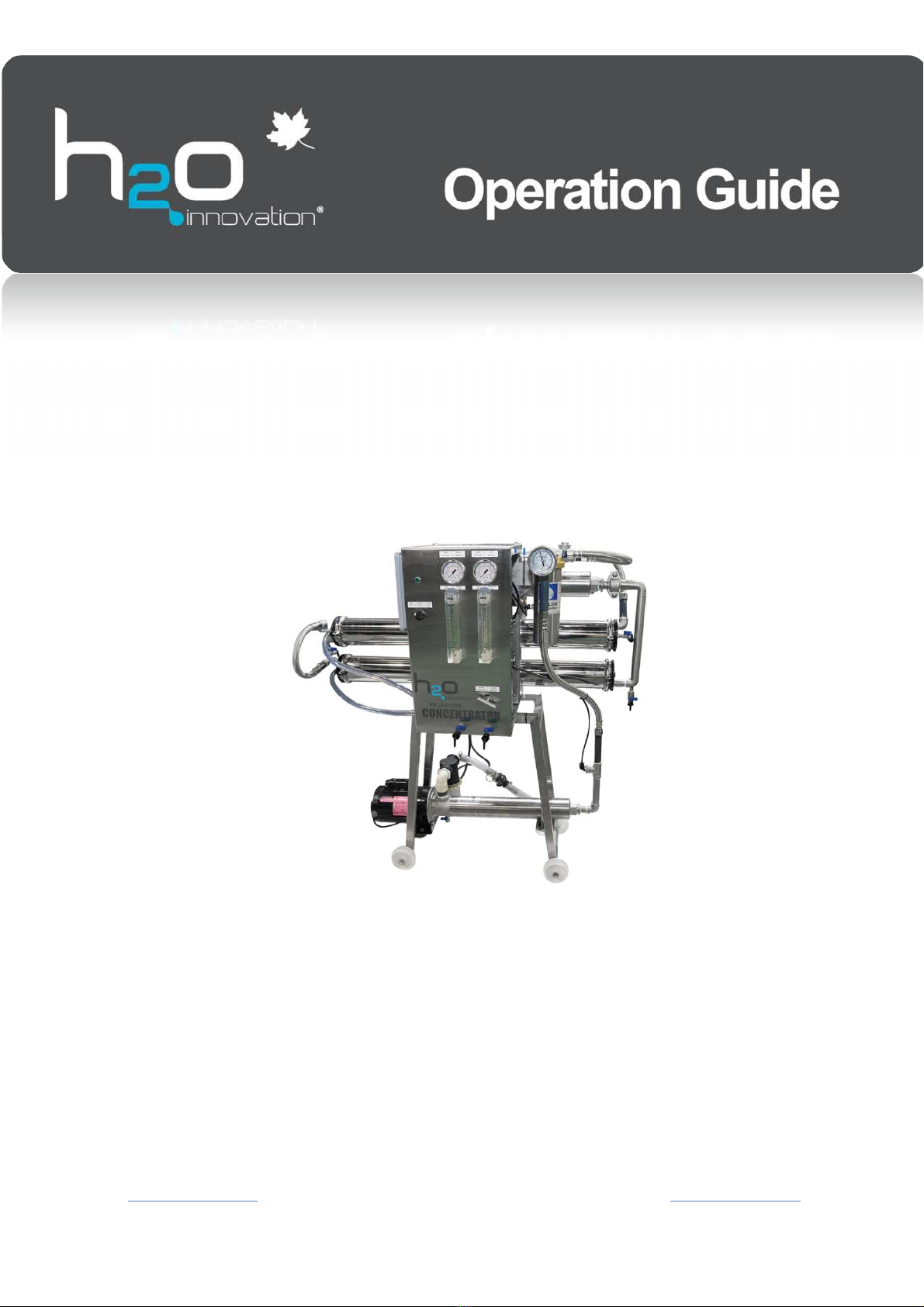

B.Maple Sap Concentration Process Cycle

(General sap water removal operation)

The purpose of maple sap concentration cycle is to remove water from the sap.

The maple sap concentration cycle is accomplished by following the next 7 steps.

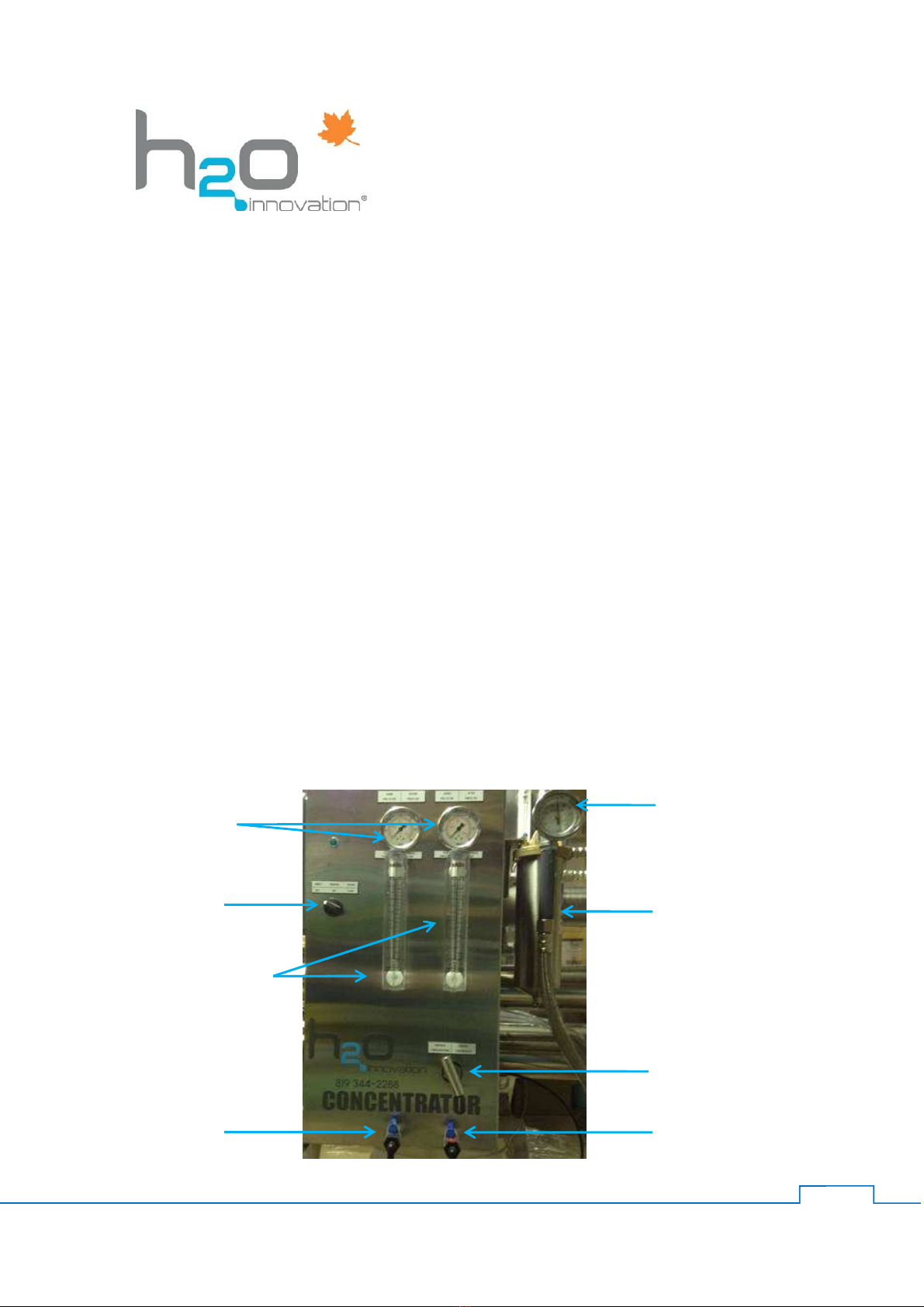

1. Back off the concentrate control valve 2 turns prior to starting the Concentrator.

2. Open the valve in the sap feed line to the Concentrator.

3. Close the valve in the permeate line to the Concentrator.

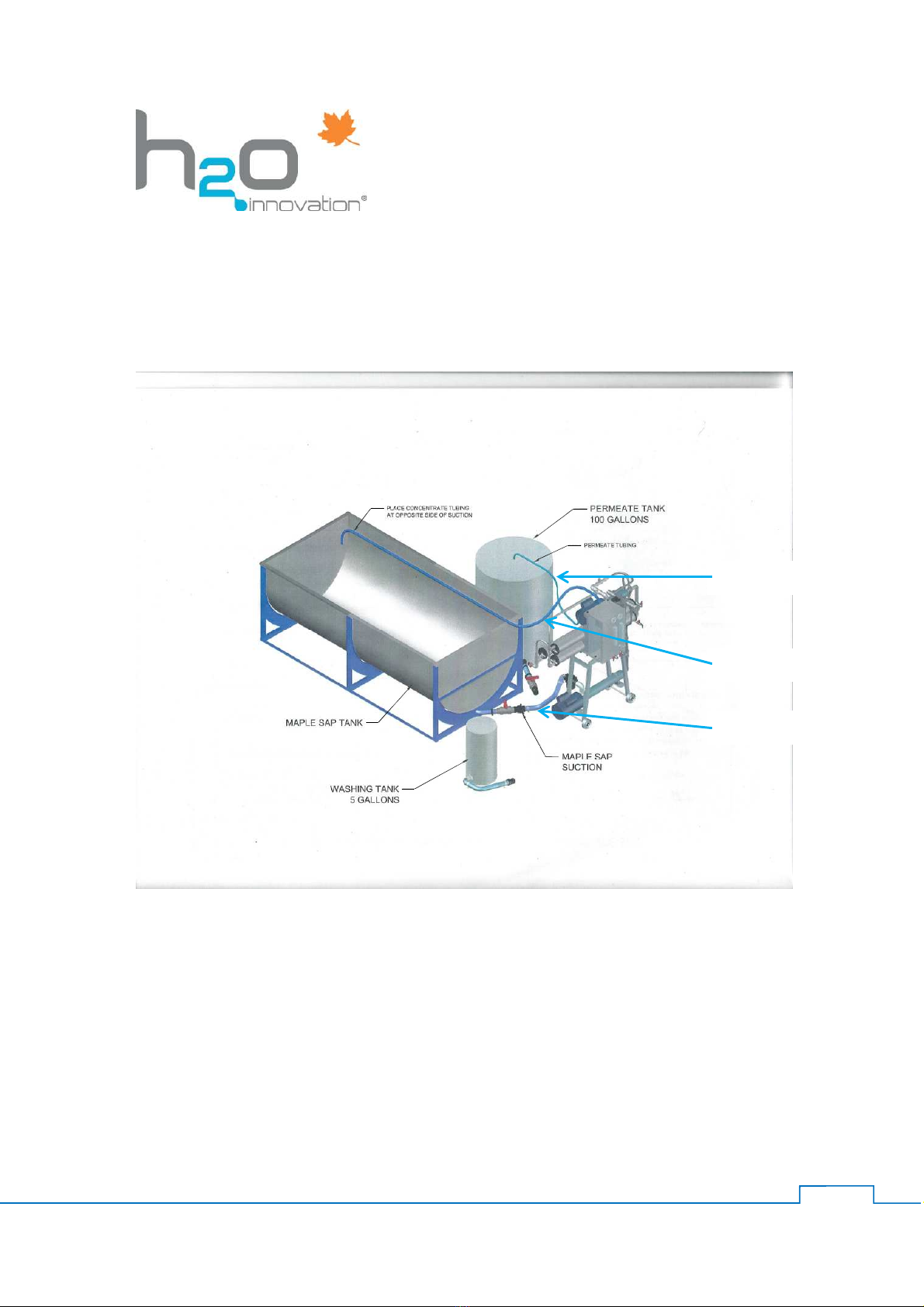

4. Place the concentrate and permeate lines to their respective storage tanks.

5. Start the Concentrator and adjust the CV concentrate valve in such that the flow meters

for the permeate fluid and concentrate fluid flow rates are both 50%.

6. Take a sample of fluid from the concentration sample valve and check the sugar

concentration using a refractometer or hydrometer, after 15 minutes of operation. The

concentration should have doubled.

Note: It is good practice to occasionally check the permeate fluid for sugar content to

insure the Concentrator is working properly.

7. Continue concentrating the sap for 3 hours until the next scheduled rinse cycle.

C. 3 Hour Rinse Cycle

The 3 hour rinse cycle is necessary after every 3-hour increment of continuous

concentration operation. The purpose of the process is to rinse/flush the membranes

using permeate or mineral free water by redirecting the flow of rinsing water into the

Concentrator. Under these conditions the fluid exiting the Concentrator will be waste.

The 3 hour rinse cycle can be accomplished by following the next 6 steps.

1. Back off the concentrate control valve 2 turns prior to starting the Concentrator.

2. Close the valve in the sap feed line to the Concentrator.

3. Open the valve in the permeate line to the Concentrator.

4. Place the concentrate and permeate lines to the drain.

Note: Roughly, the first three minutes of the rinse will contain about 15 gallons of

concentrated sap which can be saved prior to moving the concentrate line to the drain in

step 4. A refractometer or hydrometer can be used to monitor the sugar content by

sampling at the concentrate flow meter.

5. Start the Concentrator and adjust the pressure in pressure gauge M2, after the pre-filter,

to 100 PSI. Then adjust the pressure down to a minimum of 60 PSI using the CV

concentrate valve.

6. Continue rinsing the membranes with 50 to 100 gallons of permeate water.