11.3 Replacing the load chain................................................................................................ 17

12 Inspection ......................................................................................... 17

12.1 Periodic checks...............................................................................................................17

12.2 Checking the load chain................................................................................................. 18

12.3 Checking the load hook..................................................................................................18

12.4 Checking - pawl...............................................................................................................19

12.5 Checking –Brake System .............................................................................................. 19

12.6 Checking –Suspension and load hook bolt.................................................................19

13 Service............................................................................................... 19

13.1 Load chain ....................................................................................................................... 19

13.2 Pulleys..............................................................................................................................20

13.3 Load hook ........................................................................................................................20

13.4 Gear ..................................................................................................................................20

13.5 Trolley............................................................................................................................... 20

13.6 Gear spring pressure brake ........................................................................................... 21

13.7 Overload protection ........................................................................................................ 21

13.8 Lubricant - Selection....................................................................................................... 21

13.9 Lubricant for food industry –Selection (as option*)....................................................21

14 Trouble .............................................................................................. 21

15 Remedy ............................................................................................. 22

16 Decommissioning ............................................................................ 22

16.1 Temporary decommissioning ........................................................................................ 22

16.2 Final decommissioning/disposal...................................................................................22

1 Information

The products meet European Union requirements, in particular the valided EU Machine Directive.

The entire company works acc. to a certified quality assurance system as per EN ISO 9001.

The production of components at our work is subject to strict, intermediate checks.

After assembly, the products are subject to a final test with overload.

For the operation of hoists, the national accident prevention apply in Germany, amongst others.

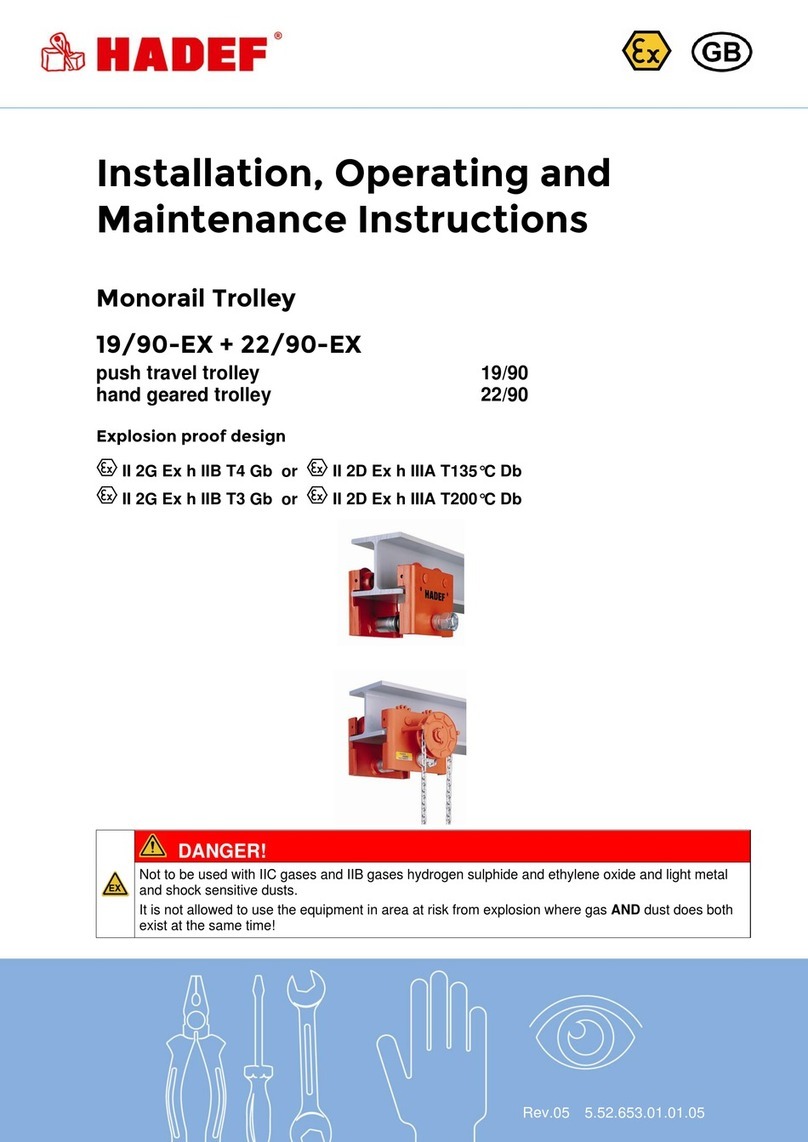

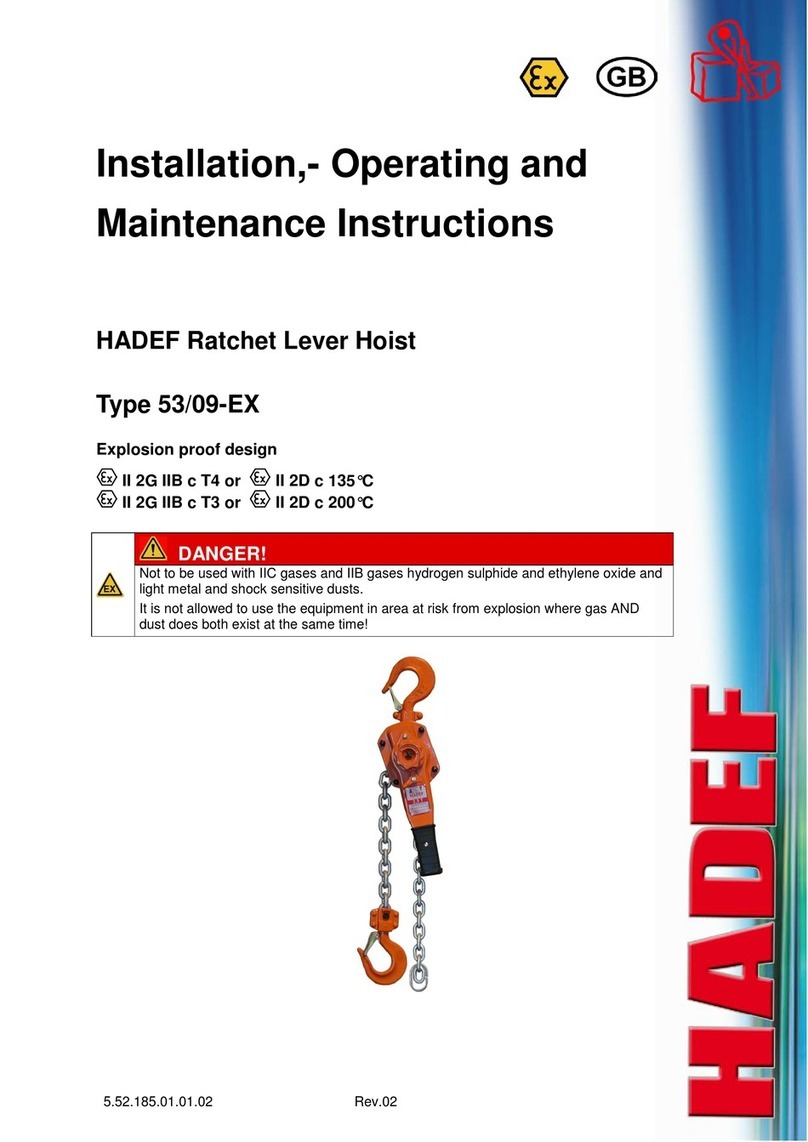

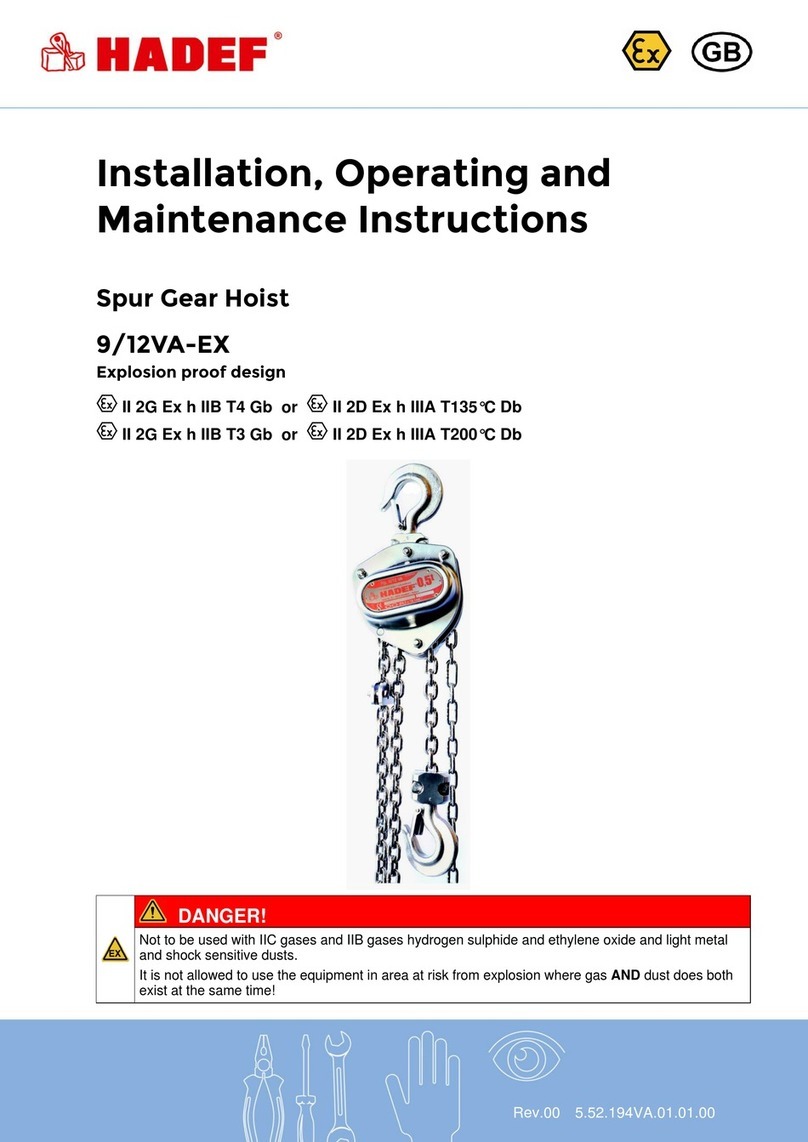

Lifting equipment for use in areas prone to explosion complies with current legislation, standards and

regulations and is classified in the applicable Ex-protection class.

The stated performance of the devices and meeting any warranty claims require adherence to all instructions

in this manual.

Before delivery, all products are packed properly. Check the goods after receipt for any damage caused

during transport. Report any damage immediately to the forwarding agent.

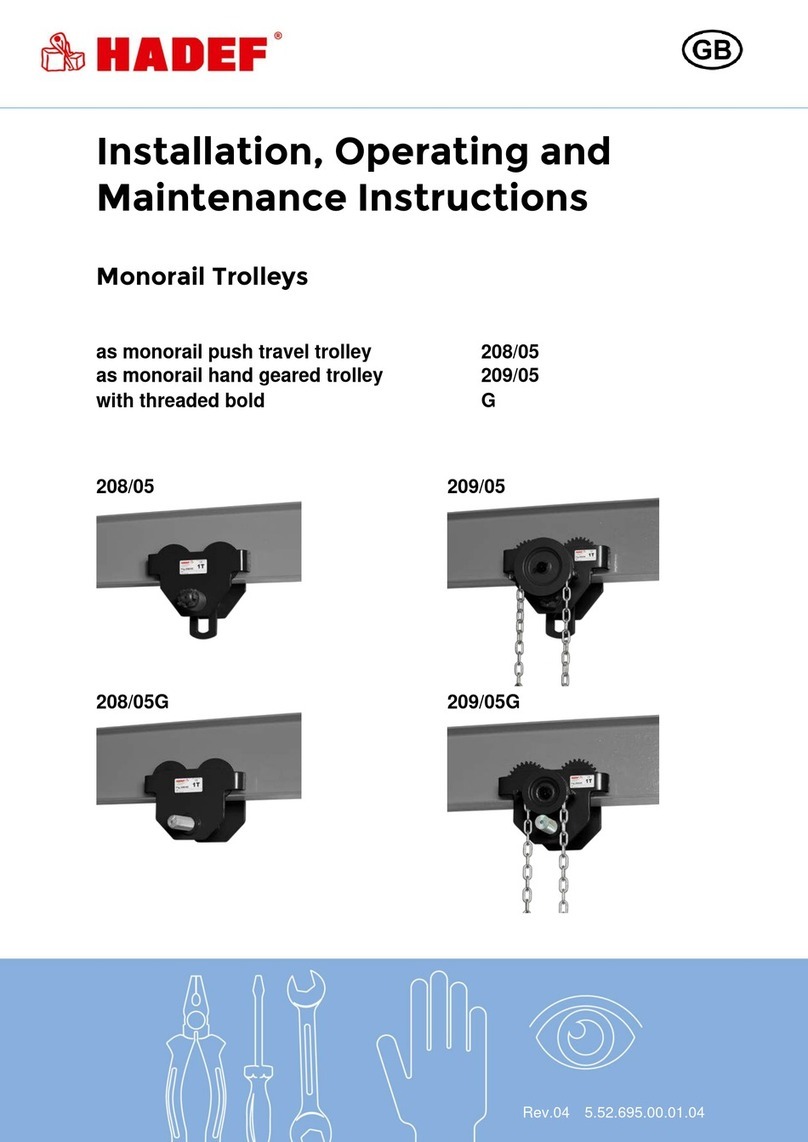

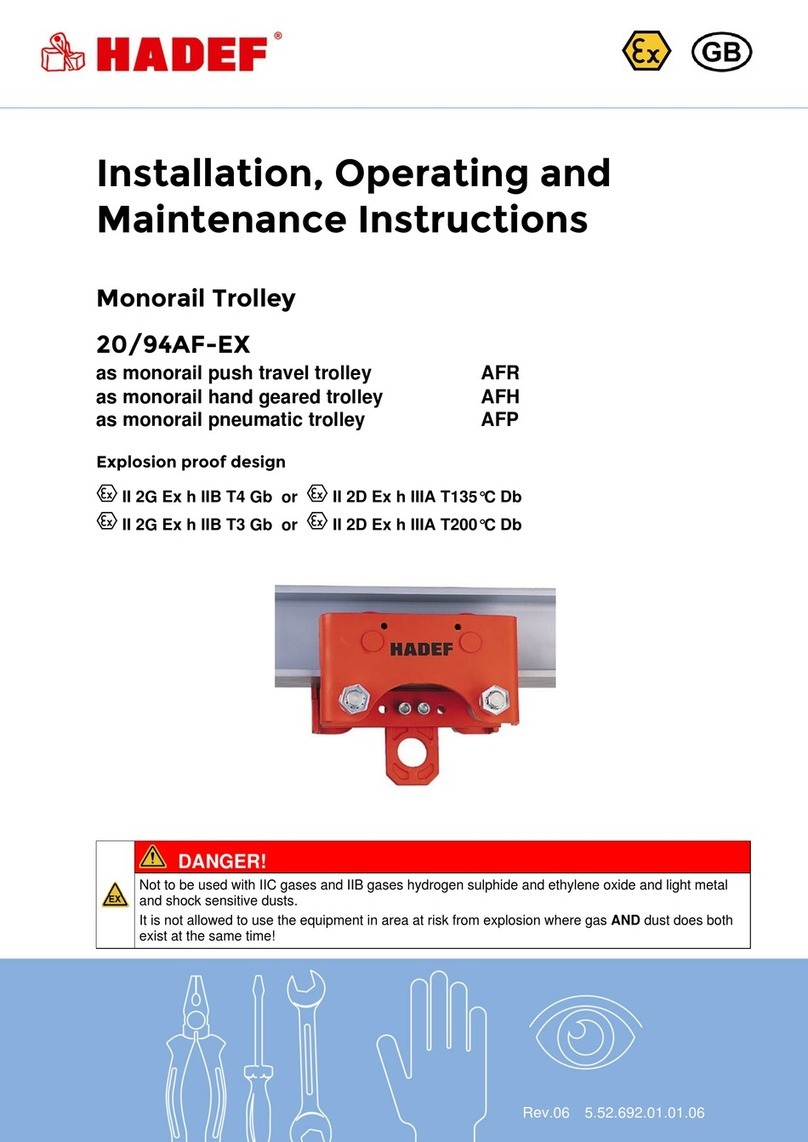

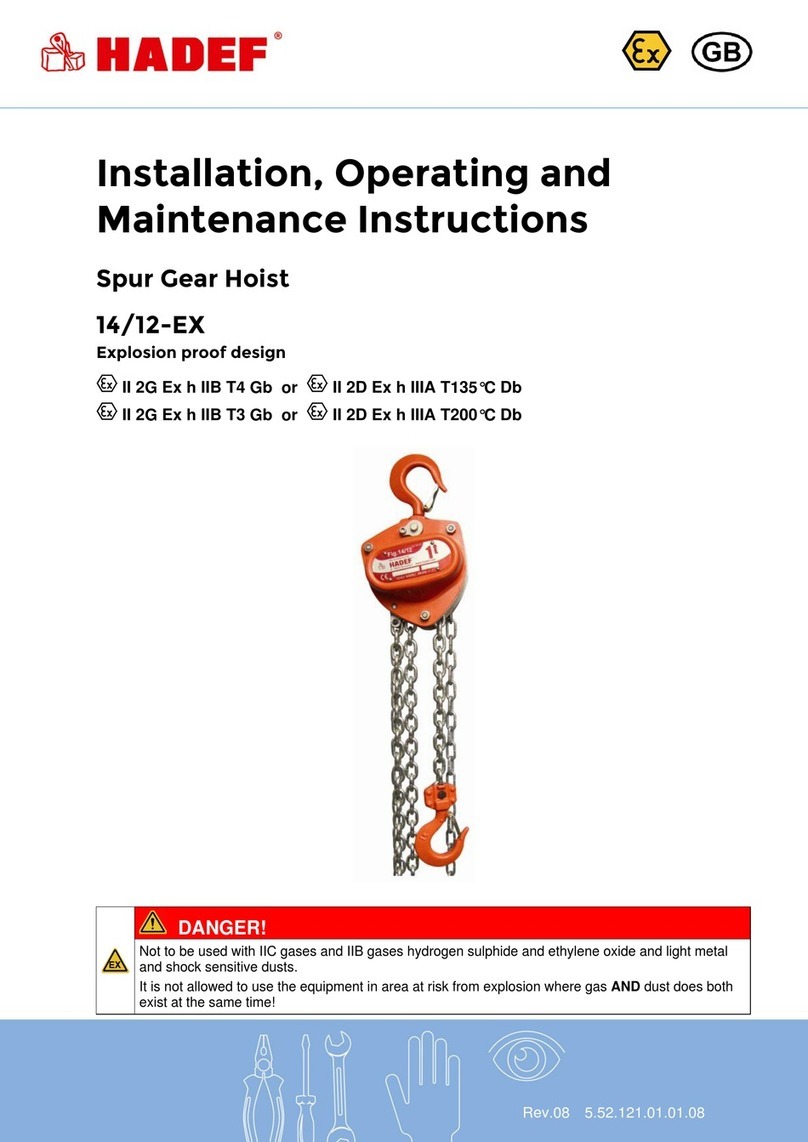

This manual serves for safe and efficient use of this hoist. Illustrations serve to explain something and may

differ from the illustration of the existing unit as they only serve as an example.

Documentation of component manufacturers that may be supplied additionally, must be observed, in case of

differences between these documentation and our manuals, the specification of the our manual must be

observed.

We refer to the prescribed equipment tests before initial start-up, before putting back into operation and the

regular periodic inspections.

In other countries any additional national regulations must be observed.

2 Safety

To assess the intended use of the devices correctly, the user must carry out an Ex-zone

classification.

The classification must be carried out in accordance with all current legislation, standards and

regulations for areas prone to explosion!