Please read through the instructions

carefully before using the unit and

carefully note the safety advice.

Always keep this manual accessible

to any users of the drill.

Area of Application

This device should only be used by

person who have completed a foot

care qualification. Before use the

operator should familiarize with the

device by reading this manual or

being instructed by another.

The device must only be used in

closed spaces. It may be used in

hospitals, in a commercial environ-

ment or in homes. The device is not

intended for use in operating rooms.

The control unit can be set up in a

cabinet or can be used as a porta-

ble unit (e.g. in a carry case). It is

suitable for the following scopes:

•foot care (milling, trimming and

polishing),

•manicure (grinding, milling and

polishing works).

The devise is determined of

operating rotating

instruments, which will not

penetrate the skin or

murcous membrane if used

appropriate, but could

evoke damages accidently.

Operation

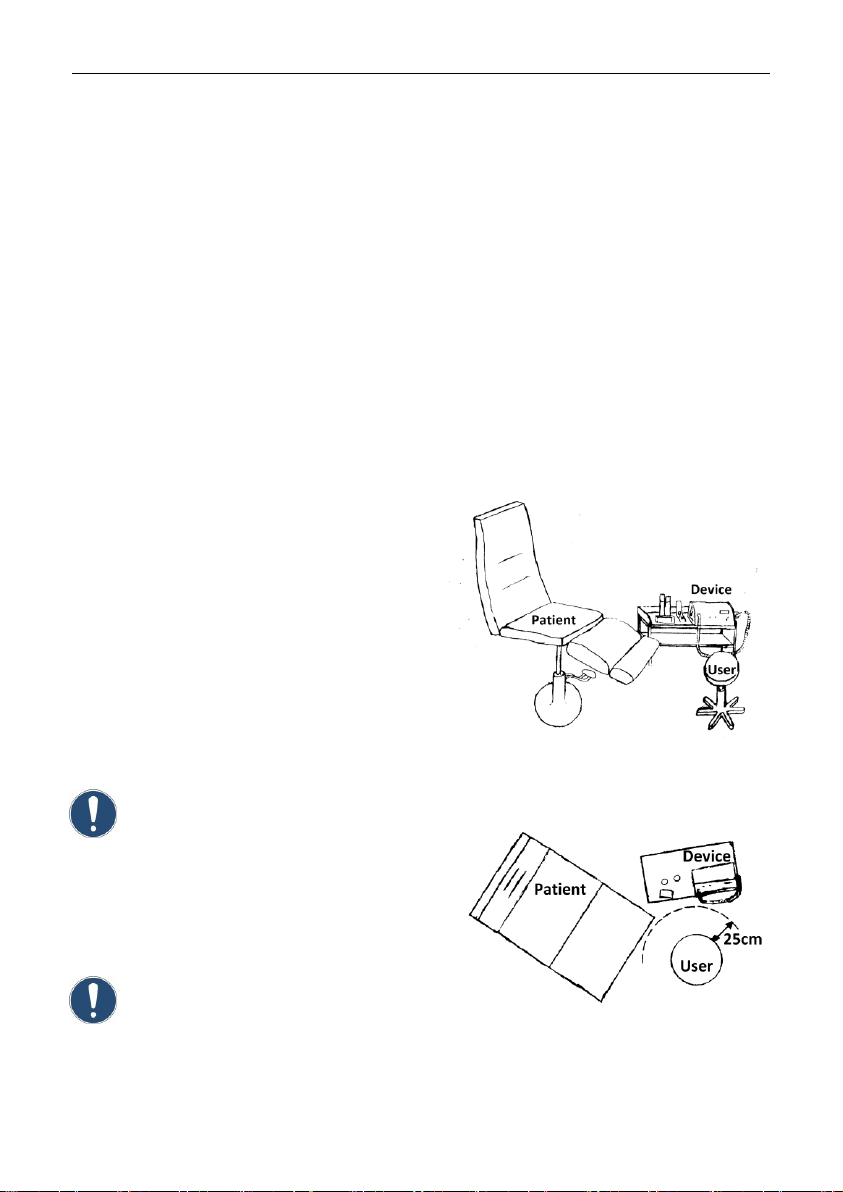

The working area must conform to

the conditions described. Set up the

unit in such a way, that the air slits

are not blocked and the extracted

air can escape well. To guarantee

unhindered air flow there must a

gap of at least 12 cm to the right of

the device.

Position the device so that the op-

erating buttons are easy to reach

and the outlet of the hose is a max-

imum distance of 60 cm from the

patient's foot. The unit should be

30 - 90 cm from the floor.

Image: Example of positioning of foot care unit

in treatment room

Image: Bird's eye view of work area