4

ADDITIONAL SATETY RULES FOR THIS PRODUCT

1. Be alert and think clearly. Never operate power tools when tired, intoxicated or when taking medications that

cause drowsiness.

2. Keep hands away from moving parts and cutting surfaces.

3. Feed work into blade or cutter against the direction of rotation.

4. Handle workpiece correctly. Protect hands from possible injury.

5. Make sure blades are aligned and properly attached to cutterhead.

6. Use quality lumber. Blades last longer and cuts are smoother with good quality wood.

7. Do not perform jointing/planing operations on material shorter than 8-1/8″, narrower than 3/4″, or less

than1/4″thick.

8. Never make jointing cut deeper than 1/8″.

9. Do not back the work toward the infeed table.

10. Support the workpiece adequately at all times during operation; maintain control of the workpiece.

11. Use push block/push stick for jointing material narrower than 3″or planing material thinner than 3″.

12. Take precautions against kickback. Do not permit any-one to stand or cross in line of cutterhead’s rotation.

Kickback or thrown debris will travel in this direction.

13. Replace or sharpen blades as they become damaged or dull.

ELECTRICAL REQUIREMENTS

POWER SUPPLY AND MOTOR SPECIFICATIONS

WARNING: To avoid electrical hazards, fire hazards, or damage to the tool, use proper circuit protection. Use a

separate electrical circuit for your tools. To avoid shock or fire, if power cord is worn or cut, or damaged in any

way, have it replaced immediately.

GROUNDING INSTRUCTIONS

WARNING: This tool must be grounded while in use to protect the operator from electrical shock.

IN THE EVENT OF A MALFUNCTION OR BREAKDOWN, grounding provides a path of least resistance for

electric current and reduces the risk of electric shock. This tool is equipped with an electric cord that has an

equipment-grounding conductor and a grounding plug. The plug MUST be plugged into a matching receptacle

that is properly installed and grounded in accordance with ALL local codes and ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not fit the receptacle, have the proper receptacle installed by

a qualified electrician.

IMPROPER CONNECTION of the equipment-grounding conductor can result in risk of electric shock. The

conductor with green insulation (with or without yellow stripes) is the equipment-grounding conductor. If repair

or replacement of the electric cord or plug is necessary, DO NOT connect the equipment-grounding conductor

to a live terminal.

CHECK with a qualified electrician or service person if you do not completely understand the grounding

instructions, or if you are not sure the tool is properly grounded.

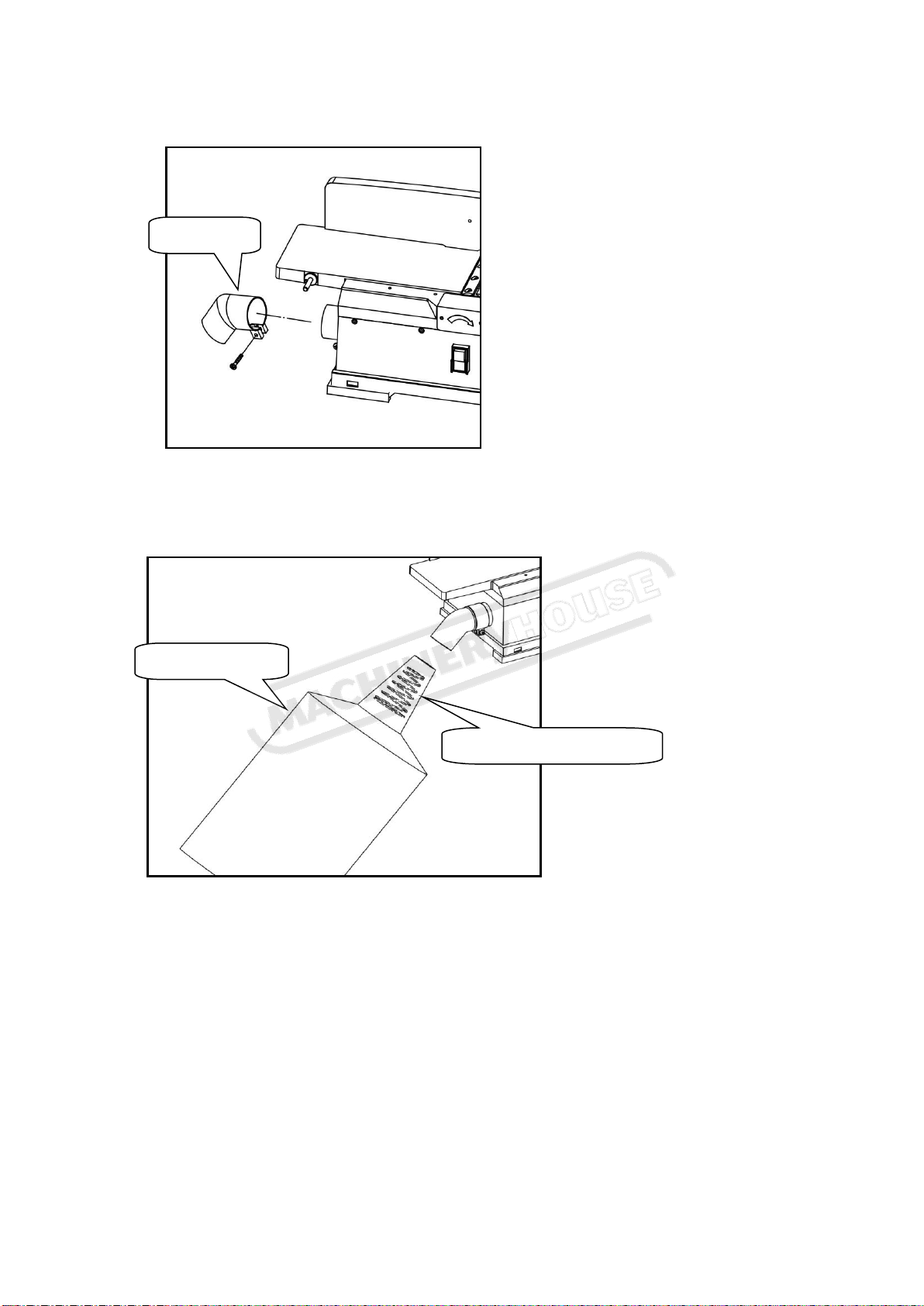

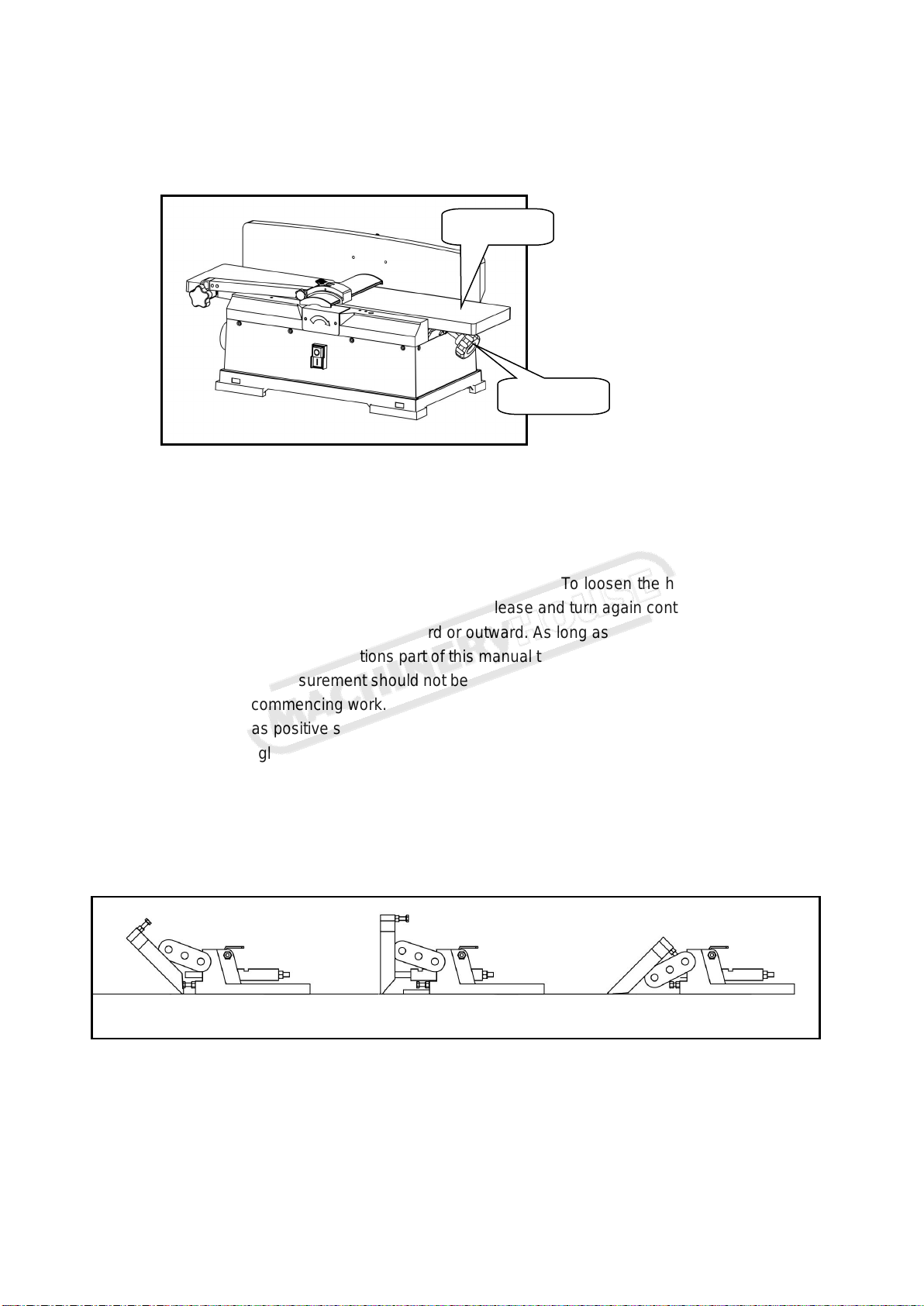

Refer to nether picture: