Required Tools for Installation

Procedure for Selecting the Location

than 10ft away depending on radio wave

conditions.)

•

Drill

•

Wire Snipper

•

Hole Saw 3/4”

•

Vacuum pump

•

Soap-and-water solution or gas leakage

detector

•

Torque wrench

• 17mm, mm, 6mm

•

Tubing cutter

•

Flaring tool

•

Razor knife

•

Measuring tape

•

Level

•

Micron gauge

•

Nitrogen

•

Mini-Split AD-87 Adapter (1/4” to 5/16”)

•

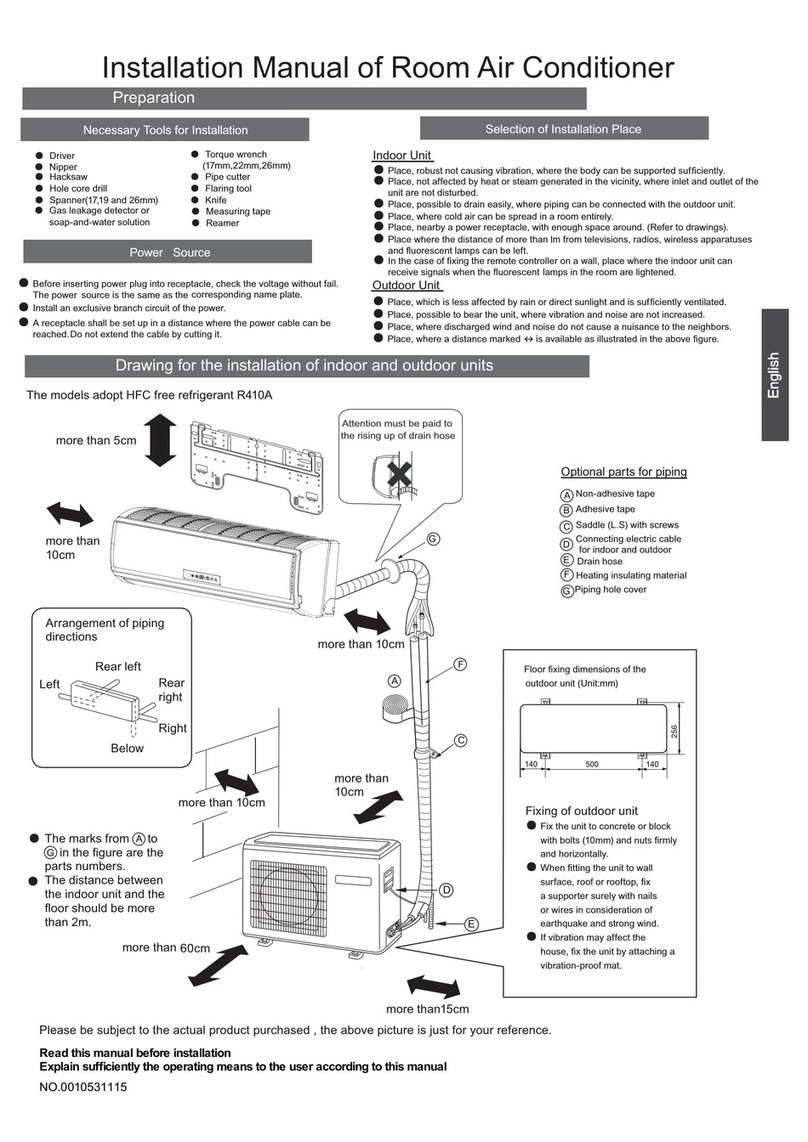

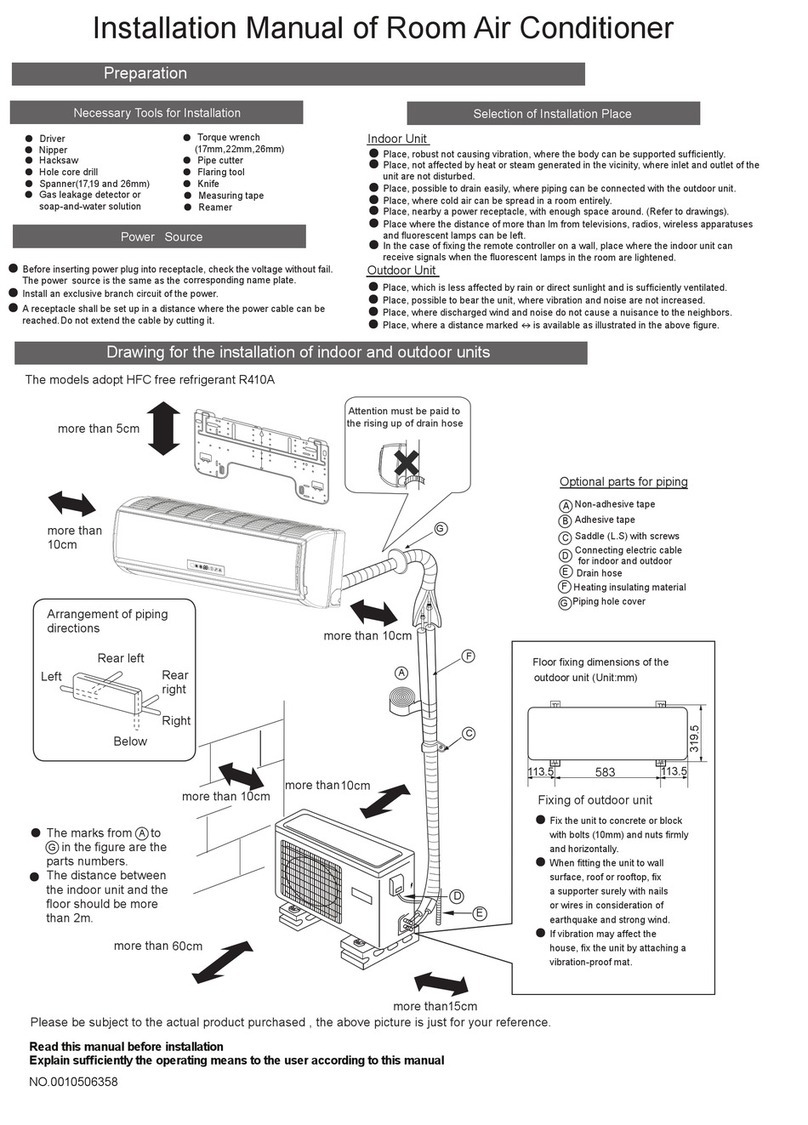

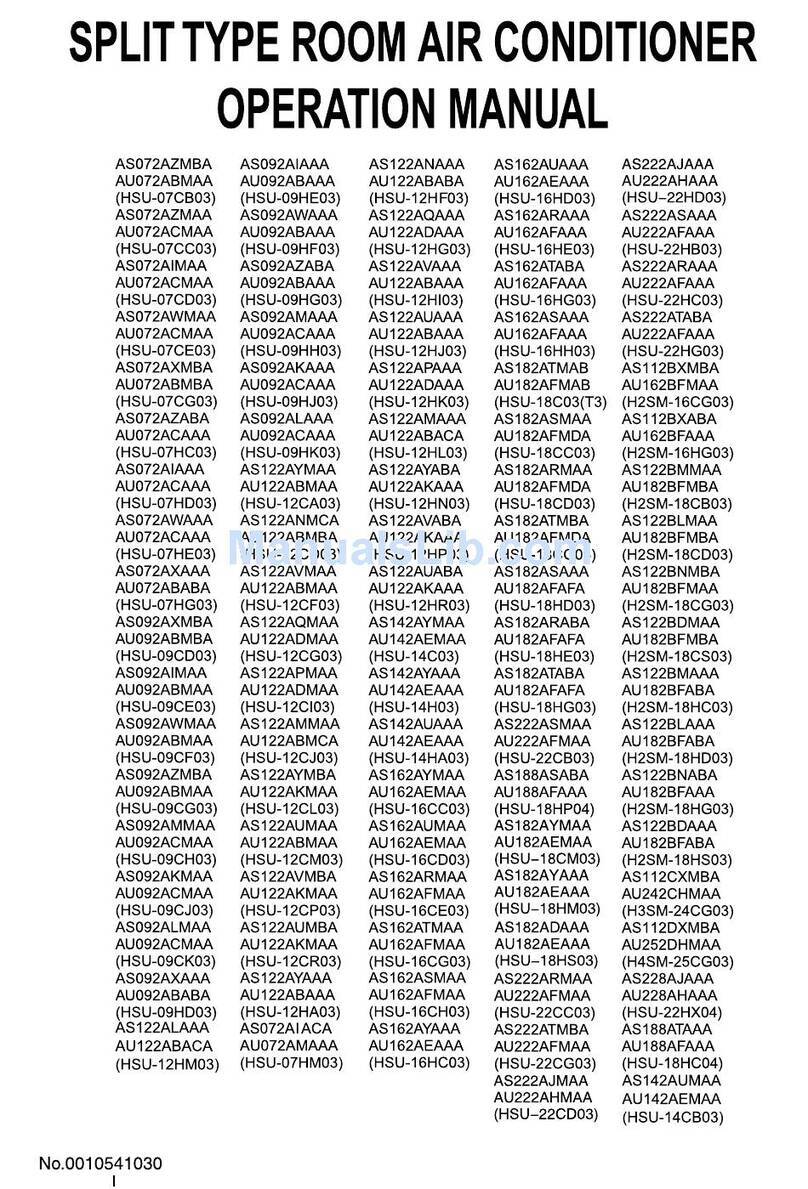

A - Non-adhesive Tape

•

B - Adhesive Tape

•

C - Saddle (L.S.) with screws

•

D - Electrical wiring

•

E - Drain hose (Included)

•

F - Insulation

•

G - Piping hole cover (Included)

•

Choose a place solid enough to bear the

weight and vibration of the unit and where

the operation noise will not be amplified.

•

Choose a location where the hot air

discharged from the unit or the operation

noise and will not cause a nuisance to the

neighbors of the user.

•

There must be sufficient space for

carrying the unit into and out of the site.

•

There must be sufficient space for air

passage and no obstructions around the

air inlet and air outlet.

•

The site must be free from the possibility

of flammable gas leakage in a nearby

place.

•

Locate the unit to avoid noise and

discharged hot air will not annoy the

neighbors.

•

Install units, power cords and inter-unit

cables at least 10ft away from television

and radio sets. This is to prevent

interference to images and sounds.

(Noise may be heard even if they are more

•

Since drain flows out of the outdoor unit,

do not place anything under the unit that

must be kept away from moisture.

Note:

1) Cannot be installed hanging from ceiling

or stacked.

)

If installing on a high place such as a roof,

with a fence or guard rail around it.

3)

If there is a potential for accumulated

snow to block the air inlet or heat ex-

changer, install the unit on a higher base.

4) R-410A refrigerant is a safe, nontoxic and

nonflammable refrigerant. However, if

there is a concern about a dangerous level

of refrigerant concentration in the case of

refrigerant leakage, add extra ventilation.

5)

Avoid installing the outdoor unit where

corrosive gases, such as sulfur oxides, am-

monia, and sulfurous gas, are produced. If

unavoidable, consult with an installation

specialist about using a corrosion-proof or

anti-rust additive to protect the unit coils.

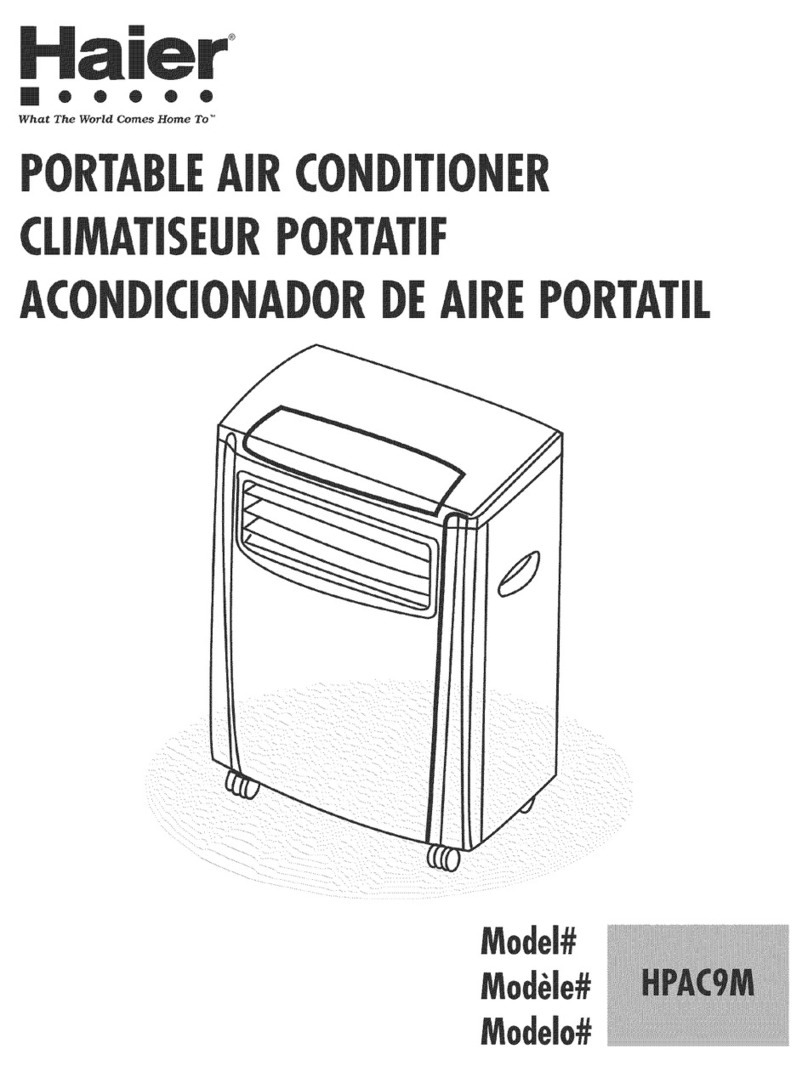

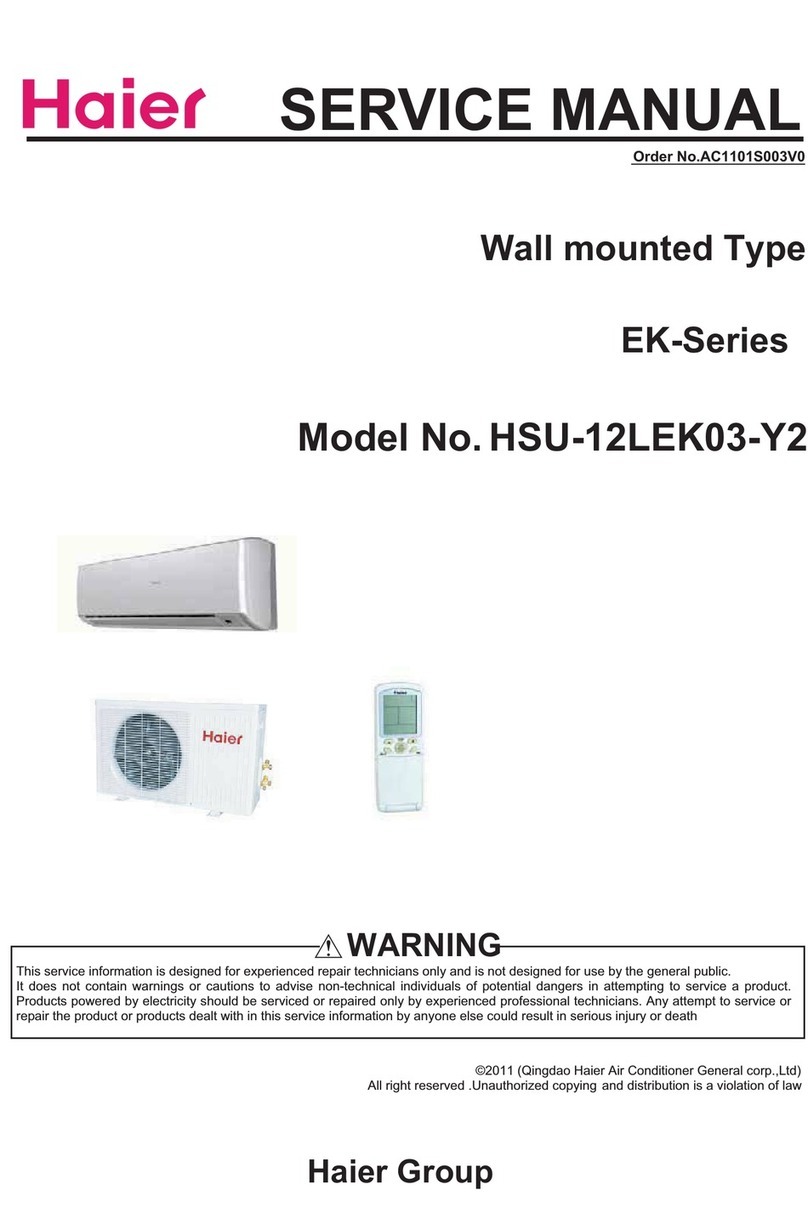

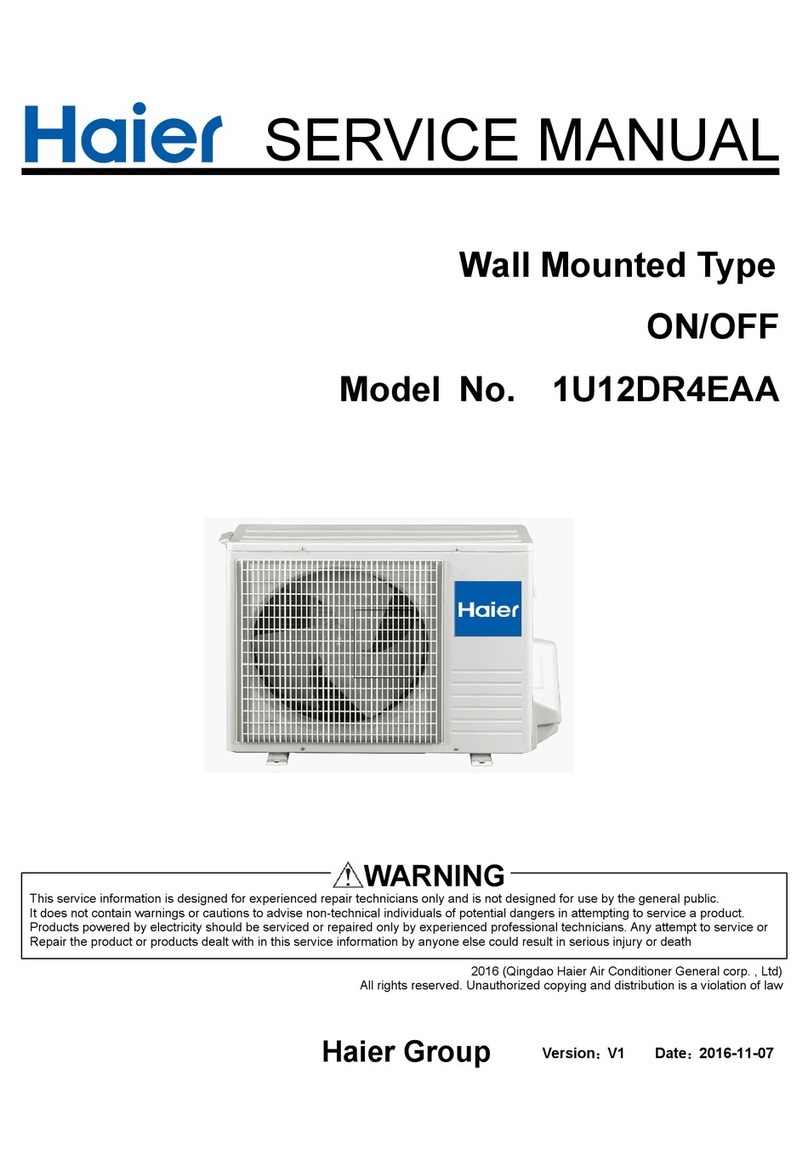

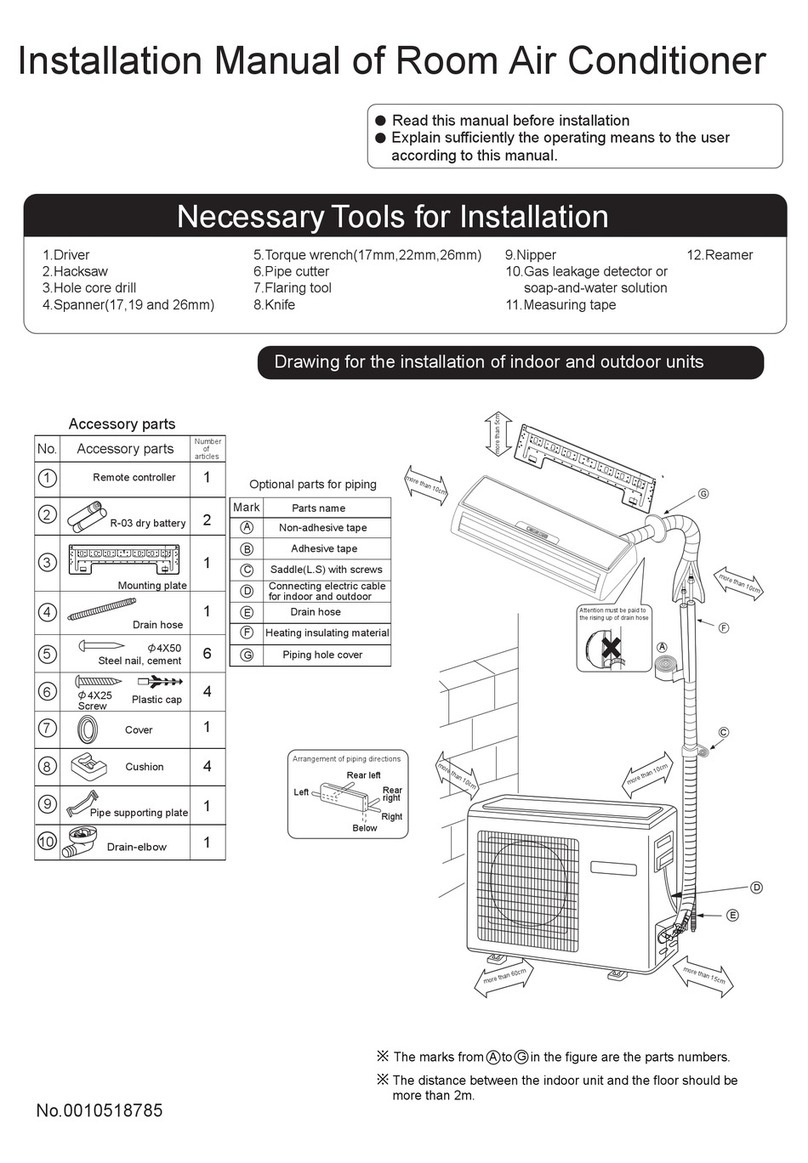

This picture is for reference only. Your product may look

different. Read this manual before installation. Explain the

operation of the unit to the user according to this manual.

The models adopt HFC free refrigerant R410A

more than 4 in.

Attention must be paid to

the rising up of drain hose

Outdoor unit mounting

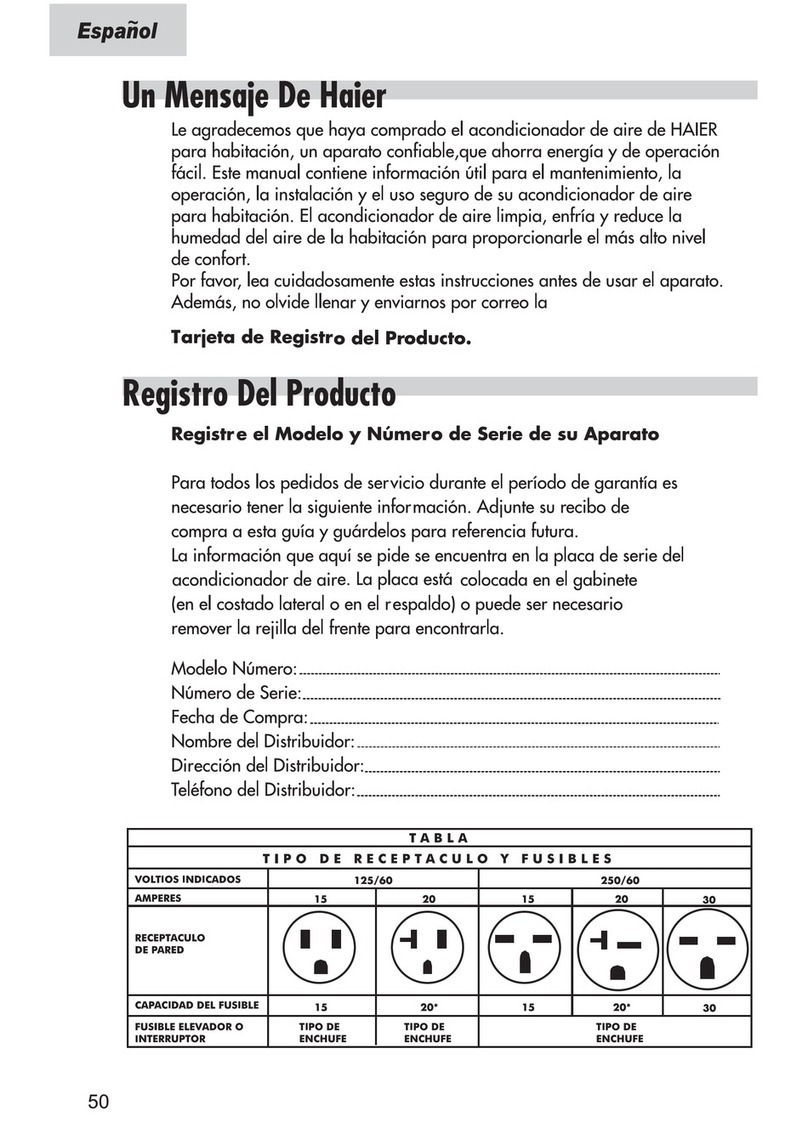

dimensions (Unit: mm/inch)

more than

G

4 in.

Arrangement of piping

directions

Rear left

Left Rear

right

more than 4 in.

F

A

Mounting the Outdoor Unit

•

Mount the unit to concrete or a block

Below

The marks from

A

to

Right

more than 8 in.

C

more than

6 in.

with bolts (10mm) and nuts firmly and

horizontally.

•

When mounting the unit to a wall or

roof, take strong winds and other

environmental conditions into

consideration when securing.

•

If vibrations effect the house, mount

the unit using a vibration-proof mat.

G

in the figure are the

parts numbers.

The distance between

the indoor unit and the

D

floor should be more

than 6.5 ft.

E

more than 24 in.

more than10 in.

Clearances of Indoor and Outdoor Units

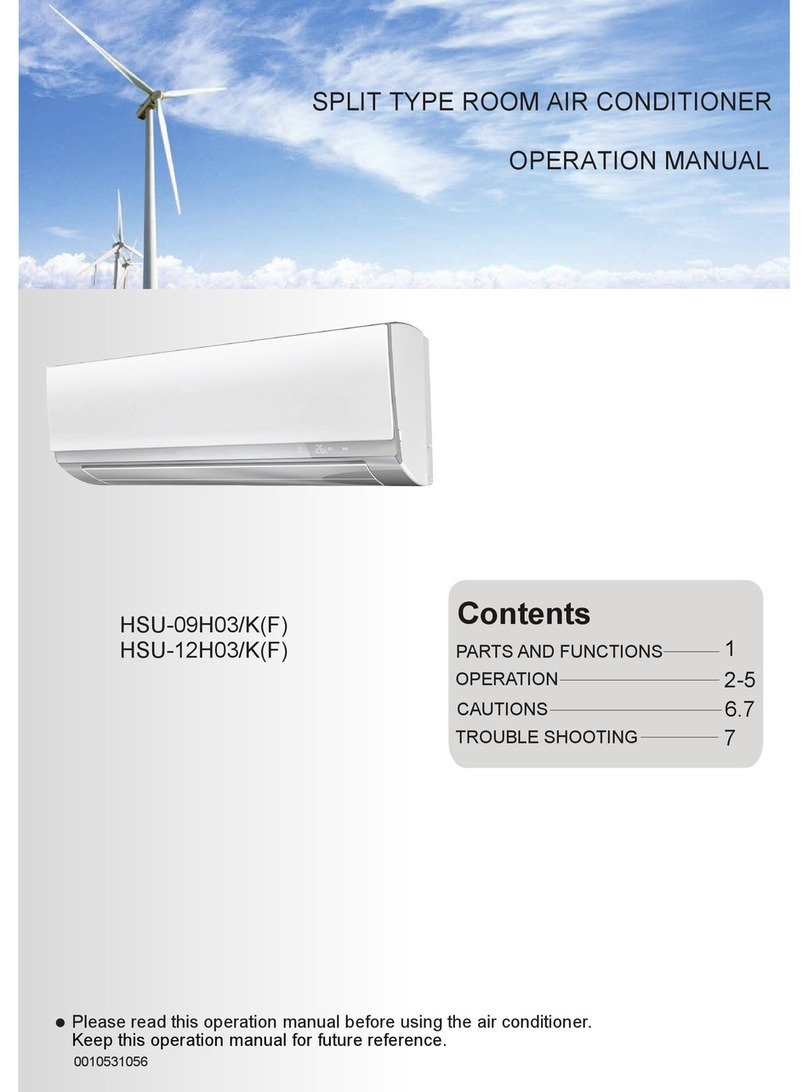

Step 1 Preparation

For:

12k 18k

Z

X

Y

X

X

Y

Z

12k

5 1/ ”

140

mm

19 11/16”

500

mm

10 1/16”

56

mm

18k

4 7/16”

113.5

mm

15/16”

583

mm

1 9/16”

319.5

mm