8

1. Retire el tapón del puerto de mantenimiento de la válvula de 3 vías, el tapón del

vástago de la válvula de 2 vías y 3 vías, y conecte el puerto de mantenimiento a

la manguera de proyección de carga (inferior) del colector. Conecte entonces la

manguera de proyección de carga (central) del colector a la bomba de vacío.

2. Abra la espita inferior del colector y accione la bomba de vacío. Si el indicador de

la escala (inferior) alcanza la condición de vacío por un momento, compruebe de

nuevo el punto 1.

3. Succione durante 15 minutos. Compruebe el nivel medido, que deberá ser de -0,1

Mpa (76 cm Hg) en el lado de baja presión. Tras finalizar la succión, cierre la espita

inferior del colector y detenga la bomba de vacío. Compruebe el funcionamiento

de las escala y manténgala durante 1-2 min. Si la escala retrocede a pesar de

ajustarse, realice de nuevo los trabajos de conicidad y vuelva al punto 3.

4. Abra el vástago de la válvula de 2 vías 90 grados hacia la izquierda. Después de 6

segundos, cierre la válvula de 2 vías e inspeccione si existen fugas de gas.

5. ¿No existen fugas de gas?

6. Desconecte la manguera de carga del puerto de mantenimiento y abra las válvulas

de 2 y 3 vías. Gire el vástago de la válvula hacia la izquierda hasta que golpee

ligeramente.

7. Para evitar fugas de gas, gire el tapón del puerto de mantenimiento y el tapón del

vástago de las válvulas de 2 y 3 vías un poco por encima del punto en el que la

torsión aumenta súbitamente.

8. Después de instalar los tapones, compruebe si existen fugas de gas a su alrededor.

-

Instalación de la fuente de alimentación

● La fuente de alimentación debe utilizarse exclusivamente con el aparato de aire

acondicionado. (Más de 10A)

● En caso de instalar el aire acondicionado en un lugar húmedo, instale un interruptor

de fugas de masa.

● Para realizar la instalación en otro lugar, utilice un interruptor de circuito situado lo

más lejos posible.

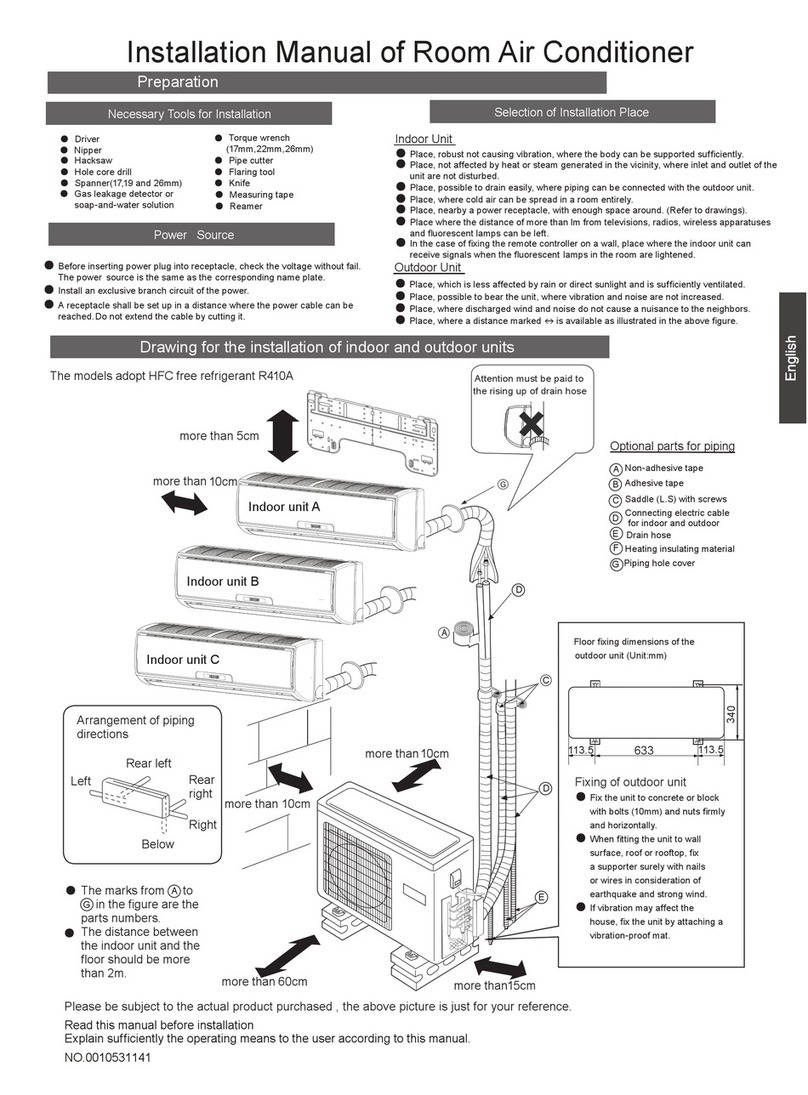

Trabajos de corte y conicidad de los tubos

● El corte del tubo se realiza con un cortador de tubos. Deberán eliminarse las

rebabas.

● Después de insertar la tuerca cónica deberá procederse a realizar los trabajos de

conicidad.

Herramienta de

conicidad para R410A Herramienta de conicidad convencional

De tipo acoplamiento De tipo acoplamiento

(tipo rígido) De tipo palometa

(tipo imperial)

A 0~0,5mm 1,0~1,5mm 1,5~2,0mm

Correcto Incorrecto

Delgado Daño de conicidad Grieta Parcial Demasiado fuera

Durante el drenaje

● Instale la manguera de drenaje formando una pendiente descendiente.

● No practique el drenaje como se muestra a continuación.

● Deposite agua en la bandeja de drenaje de la unidad interior y confirme que el

drenaje se realiza correctamente hacia fuera.

● En caso de que la manguera de drenaje se encuentre en una sala, asegúrese de

aplicar aislante de calor.

Etiqueta de carga de refrigerante

1

1+2= kg

R410A

2kg

2=

1=

B

C

D

FE

kg

A

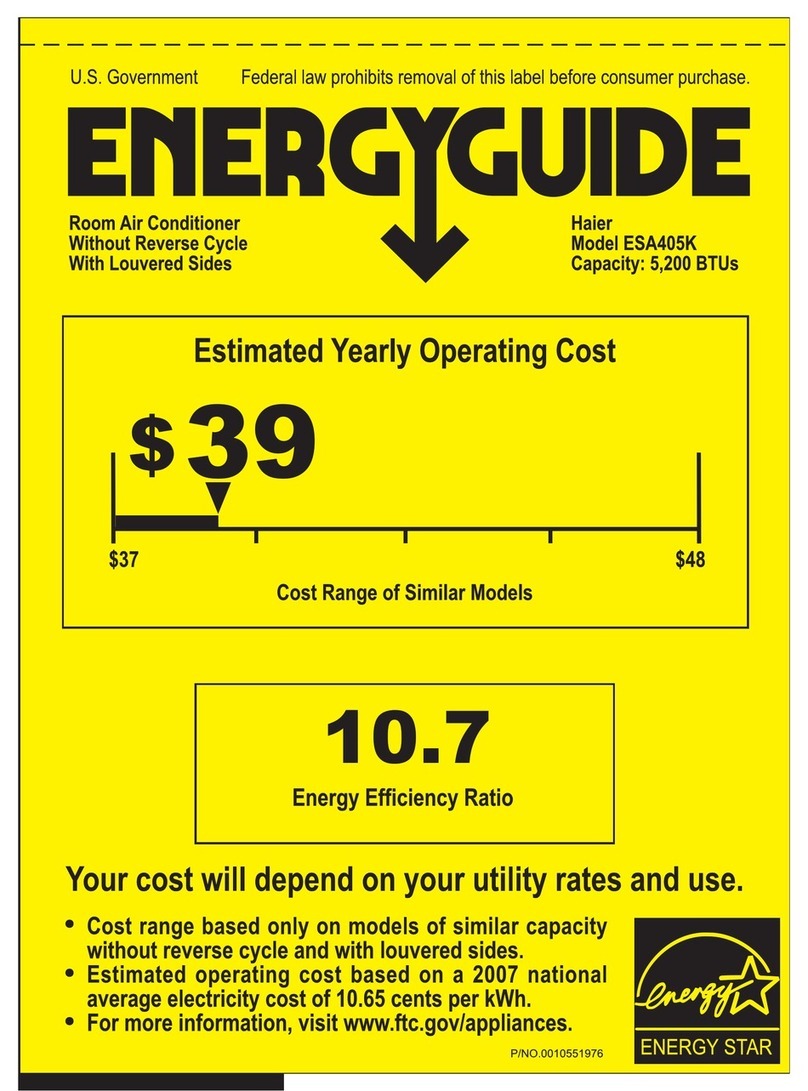

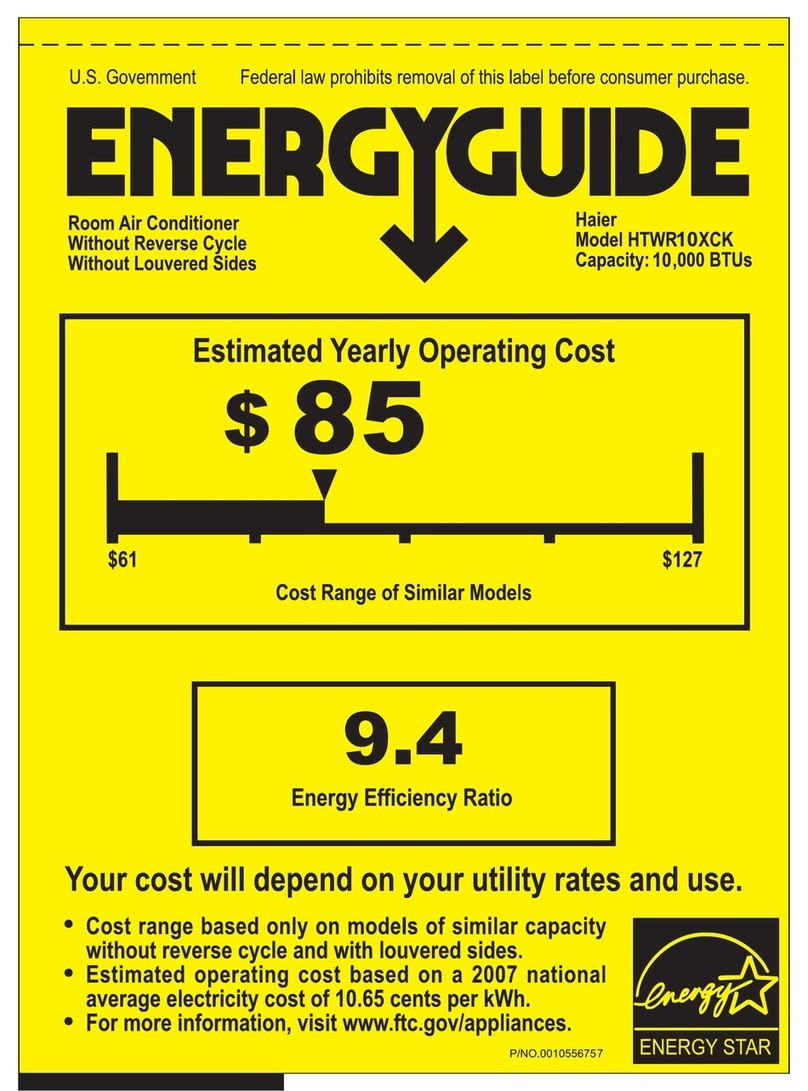

Este producto contiene gases fluorados de efecto invernadero regulados por el Protocolo de

Kioto. No los libere libremente a la atmósfera.

Tipo de refrigerante: R410A

Valor GWP*: 1975

GWP = Potencial de contribución al calentamiento global

Escriba con tinta indeleble:

• 1 La carga de refrigerante que contiene el producto de fábrica

• 2 La cantidad de refrigerante adicional cargada durante la instalación y

• 1+2 La carga total de refrigerante en la etiqueta de refrigerante suministrada con el producto.

Una vez escritos los datos correspondientes, la etiqueta deberá adherirse cerca de la conexión de

carga del producto (por ejemplo, sobre la parte interna de la cubierta de la válvula de retención).

A Contiene gases fluorados de efecto invernadero regulados por el Protocolo de Kioto.

B Carga de refrigerante que contiene el producto de fábrica: consulte la placa de características

de la unidad.

C Cantidad de refrigerante adicional cargada durante la instalación.

D Carga total de refrigerante.

E Unidad exterior.

F Botella de refrigerante y colector de carga.

Prueba de instalación y ejecución de la prueba

Explique al cliente cómo utilizar el aparato utilizando el manual de instrucciones.

Escriba una marca en los cuadros

¿Existe una fuga de gas en la conexión del tubo?

¿Aislamiento de calor de la conexión del tubo?

¿Están los cables de conexión interiores y exteriores firmemente insertados en el bloque de terminales?

¿Están los cables de conexión interior y exterior fijados firmemente?

¿Se ha realizado el drenaje correctamente?

¿Está la línea de tierra conectada con seguridad?

¿Está la unidad interior fijada con seguridad?

¿Cumple la normativa la fuente de voltaje?

¿Se aprecian ruidos?

¿Está la lámpara iluminada normalmente?

¿Se realizan normalmente las operaciones de calentamiento (con la bomba de calor) y refrigeración?

¿Funciona correctamente el regulador de temperatura de la sala?

En caso de que exista una fuga de gas, apriete las conexiones

de los tubos. Si la fuga se detiene, proceda al paso 6.

Si la fuga de gas no se detiene, descargue todo el refrigerante a

través del puerto de mantenimiento. Después de realizar de nuevo

la operación de conicidad y succión, rellene con el refrigerante

especificado desde el cilindro de gas.

Paso 1.

Paso 4.

Lateral de líquido de la válvula de 2 vías

Lateral de gas de la válvula de 3 vías

Colector (para R410A)

Junta de retención de contracorriente

Bomba de vacío (para R410A)

Tubo (para R410A)

Paso 2.

Paso 3.

Abrir

Cerrar

Paso 6. Válvula de 2 vías

Válvula de 3 vías

Válvula de 2 vías

Válvula de 3 vías

Abrir 90O

Válvula de 2 vías Válvula de 3 vías

Paso 7. Válvula de 2 vías

Válvula de 3 vías

Tapa del vástago de válvula

Tapa del vástago de válvula

Tapa del puerto de

mantenimiento

PRECAUCIÓN

● Si existen fugas de refrigerante en el aire acondicionado, será necesario

descargar todo el refrigerante. Succione primero, y cargue líquido

refrigerante en el acondicionador de aire de acuerdo con la cantidad

marcada en la placa de valores nominales.

● No permita que penetren otros medios de refrigeración (excepto el

especificado, R410A) o aire en el sistema de circulación del refrigerante.

Si ocurriese, se acumularía una presión anormalmente alta en el sistema

que podría provocar roturas y lesiones personales.

3. Insertar la tuerca cónica 4. Tubo cónico

Se alza por la

mitad. El extremo está

sumergido en agua. Está ondulado. La separación con el

suelo es

demasiado pequeña

Menos de

5cm

Se aprecia mal olor

de una acequia

Contiene gases fluorados de efecto invernadero

regulados por el Protocolo de Kioto.

Compruebe los siguientes

puntos de prueba

Cuchilla de conicidad 1. Cortar el tubo 2. Eliminar las rebabas