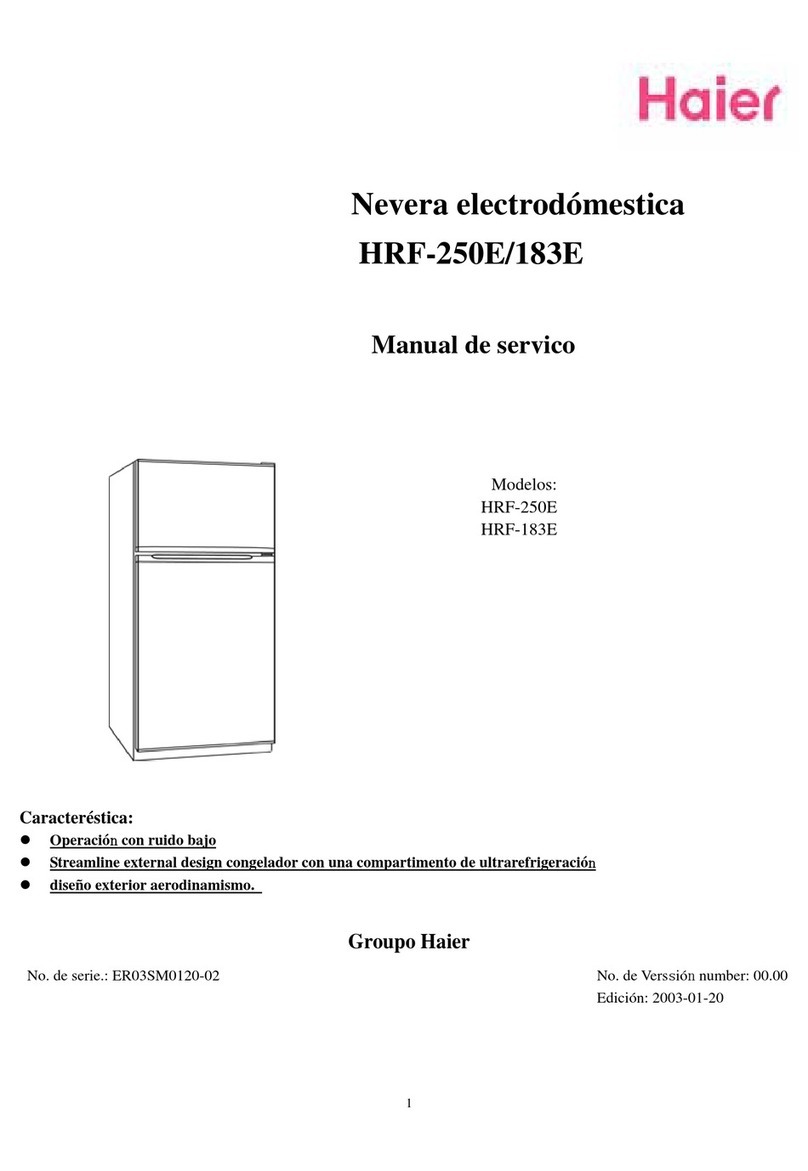

Haier RF-8888-39 User manual

Other Haier Refrigerator manuals

Haier

Haier FROST FREE REFRIGERATOR User manual

Haier

Haier HBC-150 User manual

Haier

Haier HYCD-282 User manual

Haier

Haier HB16WMAA User manual

Haier

Haier HRF-183 Instruction Manual

Haier

Haier HRF-800DGS8 User manual

Haier

Haier BC-117SS User manual

Haier

Haier HTD635WISS User manual

Haier

Haier HSP03WNAWW User manual

Haier

Haier HTMR315 User manual

Haier

Haier JR-N40C User manual

Haier

Haier HTR3619FN Series User manual

Haier

Haier REFRIGERATOR / FREEZER COMBO HRF-6631RG User manual

Haier

Haier HBX-IC User manual

Haier

Haier HRF-221FR/A User manual

Haier

Haier HC27SF22RB User manual

Haier

Haier JR-NF140A User manual

Haier

Haier AFL631CB User manual

Haier

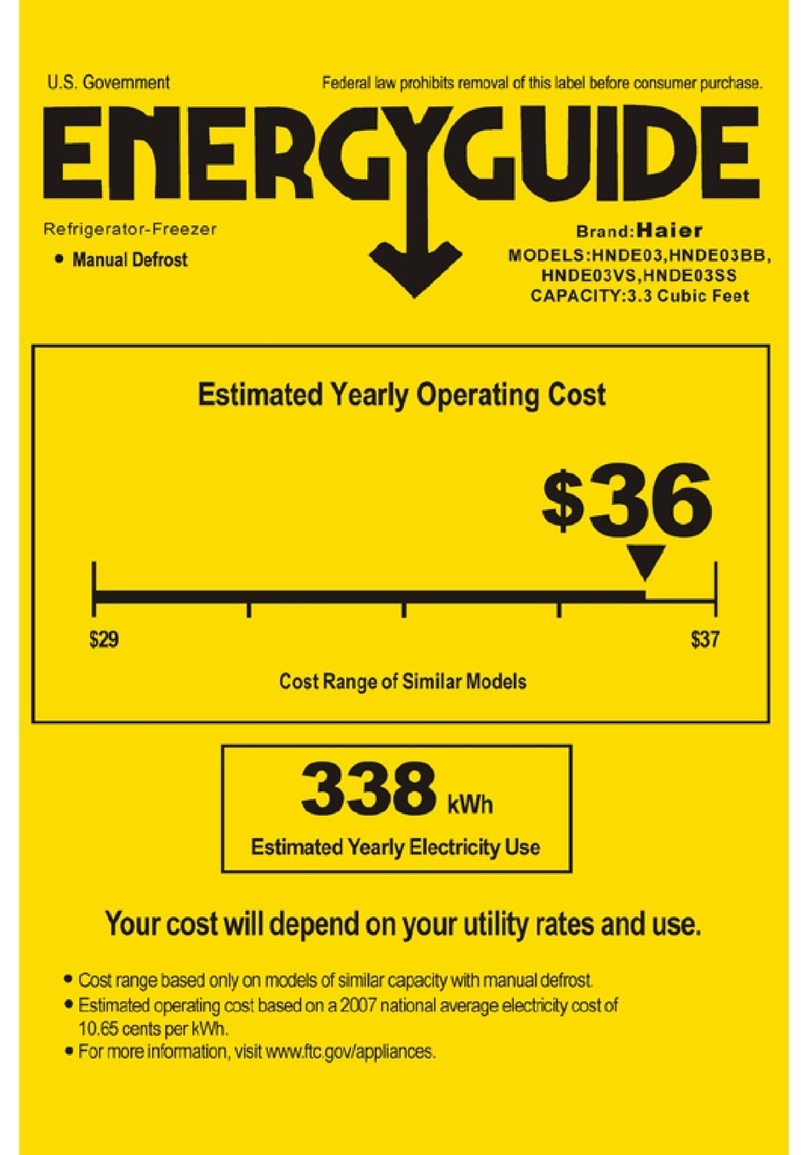

Haier HNDE03 Assembly instructions

Haier

Haier HSBS582AS User manual