4

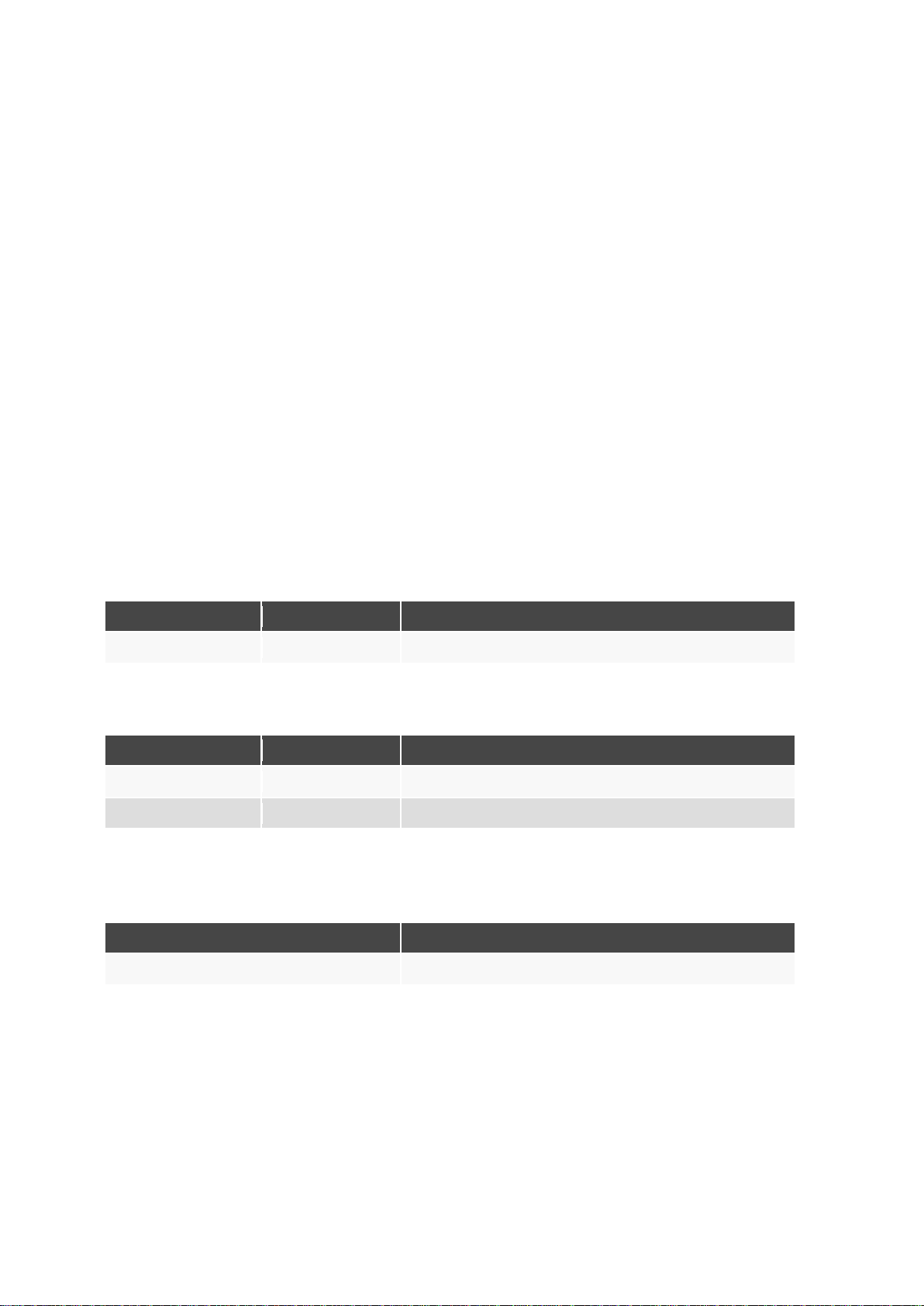

3Description of the Positioning clamping pin.............................................................................. 28

3.1 Overview ............................................................................................................................... 28

3.1.1 Overview of functional elements.............................................................................. 28

3.1.2 Type plate overview / inscription.............................................................................. 29

3.2 Functional description ........................................................................................................... 30

3.2.1 Optional accessories EH 23111 .............................................................................. 33

3.2.2 Material EH 23111 ................................................................................................... 33

3.2.3 Special parts ............................................................................................................ 34

3.2.4 Required tools.......................................................................................................... 34

3.3 Technical data....................................................................................................................... 35

3.3.1 Maximum load and number of permissible load cycles........................................... 36

3.3.2 Ambient conditions................................................................................................... 36

3.3.3 Intended service life................................................................................................. 36

4Transport and storage .................................................................................................................. 37

4.1 Controls at the time of acquisition by the recipient ............................................................... 37

4.2 Packaging.............................................................................................................................. 37

4.2.1 Unpacking................................................................................................................ 38

4.2.2 Re-packaging........................................................................................................... 38

4.3 Notes on hazards during transport........................................................................................ 38

4.4 Permitted aids for transport................................................................................................... 39

4.5 Scope of delivery................................................................................................................... 39

4.6 Interim storage ...................................................................................................................... 39

5Assembly........................................................................................................................................ 40

5.1 Notes on hazards during assembly....................................................................................... 40

5.2 Preparatory measures........................................................................................................... 40

5.3 Choice of location of use....................................................................................................... 40

5.3.1 Necessary operating and maintenance areas ......................................................... 40

5.3.2 Requirements for the location of use....................................................................... 41

6Commissioning.............................................................................................................................. 42

6.1 Safety measures before commissioning............................................................................... 42

7Operation........................................................................................................................................ 43

7.1 Safety measures during normal operation............................................................................ 43

7.2 Example application.............................................................................................................. 43

8Malfunctions .................................................................................................................................. 45

8.1 Malfunctions and corrective measures.................................................................................. 45

9Maintenance................................................................................................................................... 46

9.1 Safety measures during maintenance work.......................................................................... 46

9.2 Inspection and maintenance work......................................................................................... 47

9.2.1 Maintenance intervals.............................................................................................. 47

9.2.2 Maintenance - daily.................................................................................................. 47

9.2.3 Maintenance - weekly.............................................................................................. 48

9.2.4 Maintenance - annual .............................................................................................. 48

10 Dismantling and disposal............................................................................................................. 49

10.1 Disassembly.......................................................................................................................... 50

10.2 Disposal................................................................................................................................. 51