8

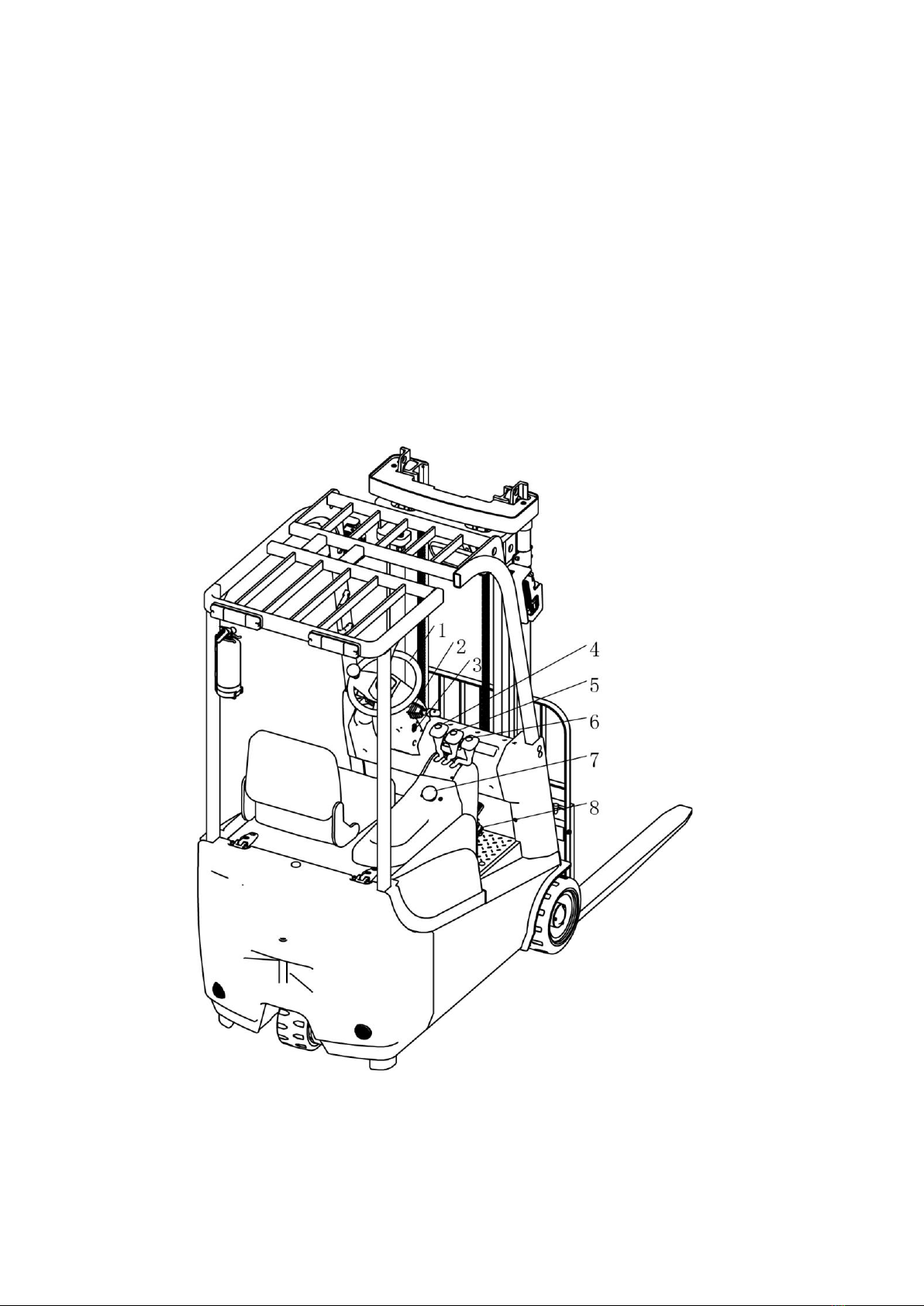

The main working part of the forklift is the forks. The forks recognize the

loading, unloading, stacking and short-distance transportation for pallets or

cargo.

The forks are mounted on the carriage, by chain drive or inner mast moving

up and down, the carriage and forks lifts the goods off the ground or to be

stacked on racks. The chain transmission and inner mast overall movement are

achieved by the extension of the lift cylinder. Forklift operation process is

achieved by extending of the control cylinders (including tilt action).

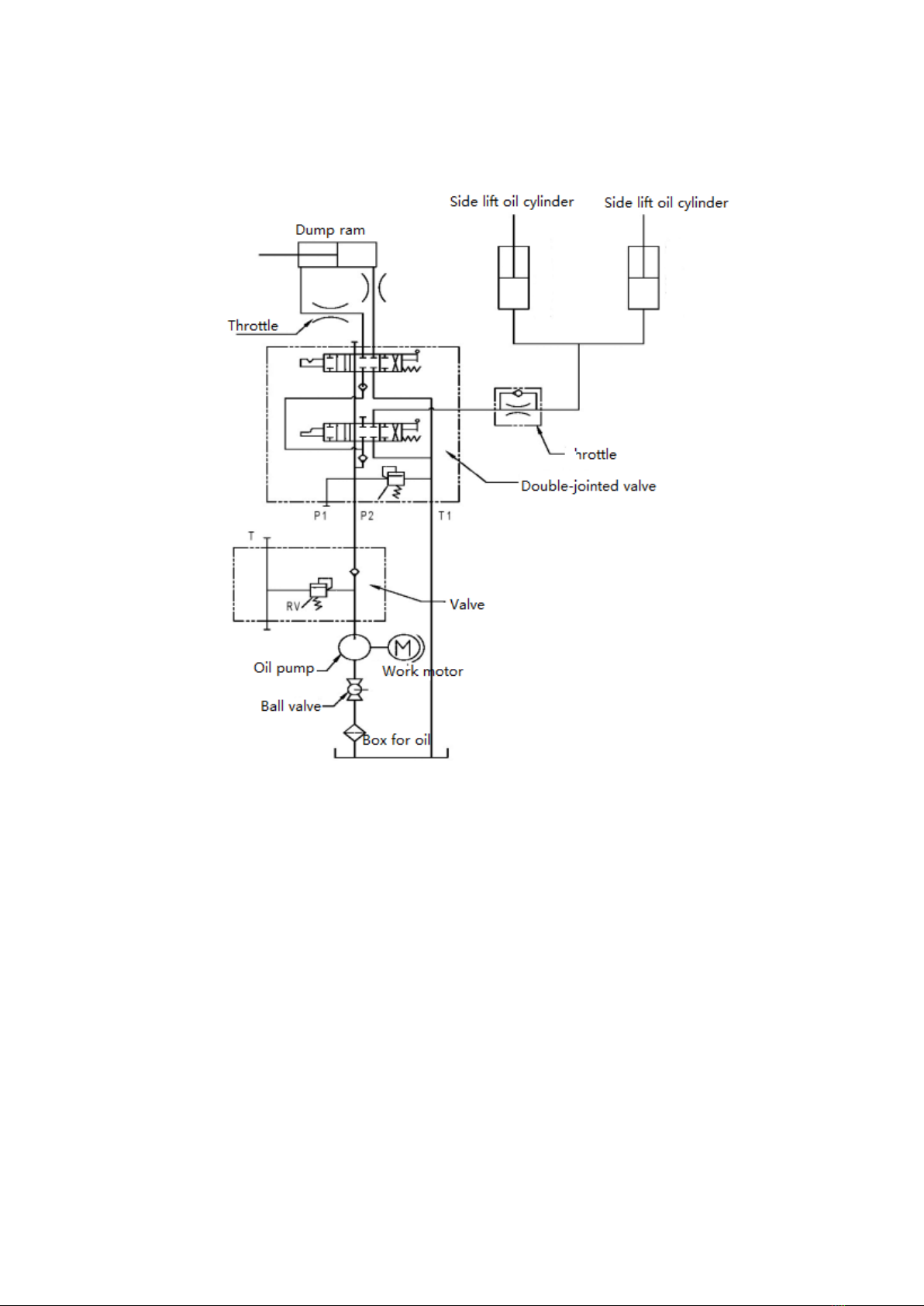

Cylinder movement is controlled by a physical valve stem, and the oil

pressure is provided by the hydraulic pump.

The controlled safety valves in the lifting cylinders and tilt cylinder will

slow down the speed of mast lifting, lowering or tilting to ensures safety.

2.3 Electrical principle

2.3.1 Electrical system

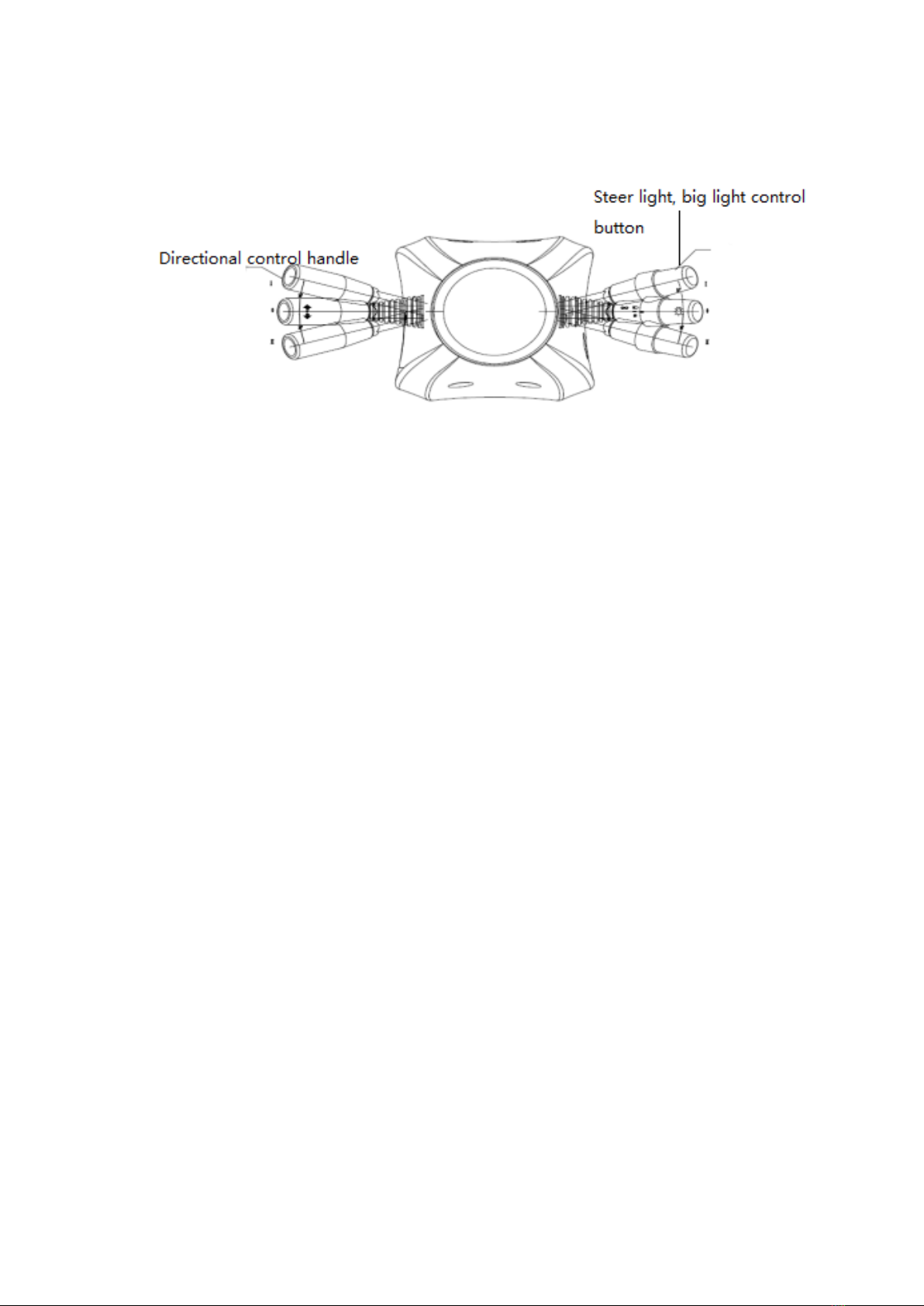

The forklift electrical system includes driving and operation control, and lighting.

The forklift implements Curtis Instrument Controllers and i.e. CURTIS1232 AC

control assembly.

The controller has the indicator for power display, slowing down of mast lifting,

parking and hour meter display function. When the battery power is may be low,

the power meter will cut off the control circuit of pump motor to protect its

battery life. The forklift will not lift however can still drive, which means the

forklift should be charged immediately.

The hydraulic pump motor is a DC motor therefore not recommended for long

continuous operations. The lifting movements should have intervals, should not

be continuous, otherwise it can cause the motor to overheat

Special Note: If the forklift is used for a continuous period, the pump motor may

lack performance. The lack of performance is that the starter may not lift

properly. The latter one is represented as no lifting with the multi-way valve

control lever, pump motor will keep turning. If this occurs the forklift should be

turned off. Disconnect the battery and allow time to dissipate the overload.