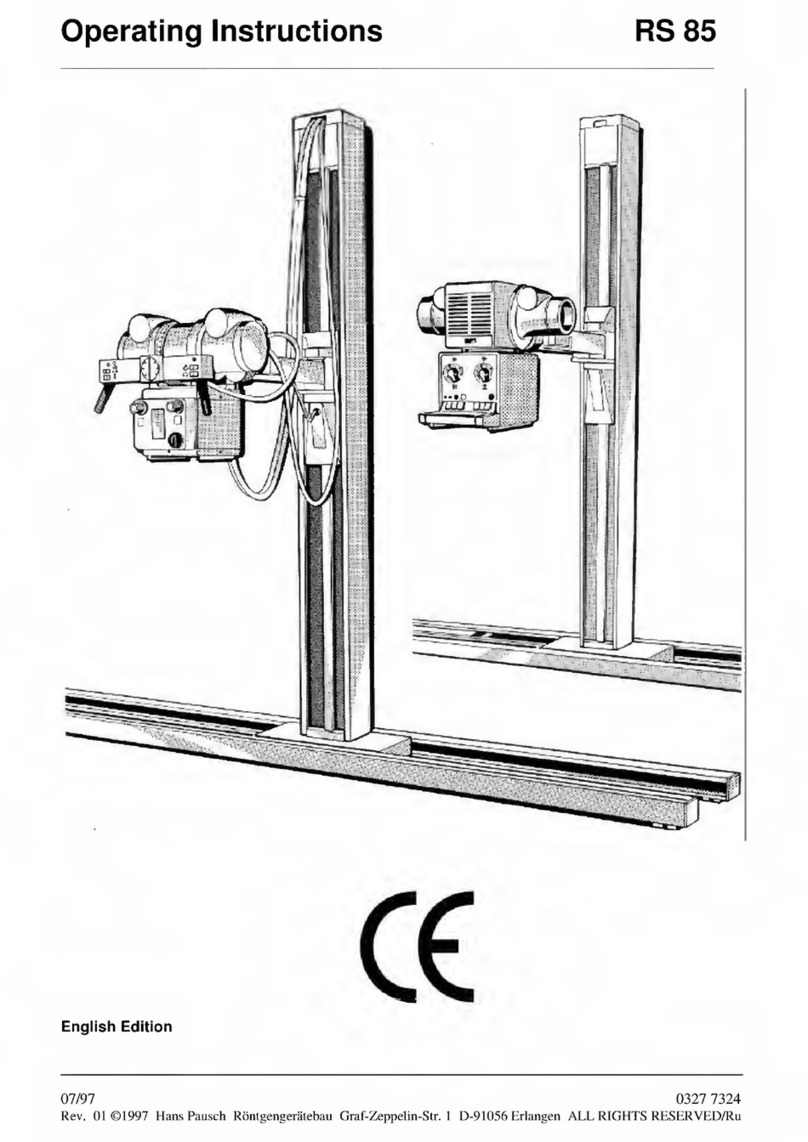

Hans Pausch COSMOS-2 User manual

MOUNTING

INSTRUCTIONS

COSMOS-2

0125

English

Edition

07/99

-1

of

34-

0380

7224

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

TABLE

OF

CONTENTS

Page

1

.

Specification

1.1

General

Safety

Notes

3

1.2.

Weight

of

Components

3

1.3.

Dimensions

of

Components

3

1.4

Shipping

Weight

and

Dimensions

3

1.5

Component

Designation

4

1.6.

Dimensional

Drawings

5

1.7

Power

Connection

6

1.8

Special

Tools

Required

6

1.9.

Schematics

7

1.10

Wiring

Diagram

8

1.11

Physical

Location

of

Electrical

Components

9

1.12

Component

Numbers

and

Designation

9

1.13

Component

check

list

10

2.

Mounting

of

Unit

2.1

Site

Preparation

11

2.2

Uncrating

11

2.3

Unit

preparation

12

2.4

Unit

mounting

2.5

Leveling

the

unit

13

2.5.1

Loading

of

counter

weights

14

2.6

Mounting

of

Bucky

Support

14

2.7

Mounting

of

Controls

14

2.8

Mounting

of

X-Ray

Tube

and

Collimator

14

2.9

Mounting

of

Bucky

15

2.10

Release

the

vertical

drive

15

2.11

Electrical

Connections

16

3.

Adjustments

3.1

Bucky

Tilt

Adjustment

17

3.2

Adjustment

of

Rotation

17

3.3

Adjustment

of

Vertical

Movement

17

3.4

Adjustment

of

Rotational

Lock

18

3.5

Vertical

Lock

18

3.6

SID-Pointer

18

3.7

SID-Drive

Clutch

19

3.8

SID

End

Switch

19

4.0

4.1

Technical

Maintenance

Mechanical

and

Electrical

Checks

21

4.2

Functional

Checks

25

4.3

Spare

Parts

26

4.4

Spare

Parts

List

28

4.5

Name

Plate

Location

32

4.6

Maintenance

documentation

33

0380

7224

-

2

of

34

-

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

12

07/99

ALL

RIGHTS

RESERVED

Ru

1

.

Specifications

1.1.

General

Safety

Notes

In

the

Federal

Republic

of

Germany,

the

electrical

installation

of

rooms

used

for

medical

purposes

must

conform

to

the

provisions

of

VDE

Standard

0107.

Consult

installation

lay¬

out

plan.

During

installation

it

is

important

that

all

protective

ground

wire

connections

provided

by

the

manufacturer

properly

made

before

the

equipment

is

started

up.

The

pro¬

tective

ground

wires

between

the

individual

system

components

and

the

power

supply

are

connected

as

shown

in

the

wiring

diagram.

Regulations

of

professional

associations

concerning

safety

and

accident

prevention

must

be

observed.

No

work

may

be

performed

on

parts

carrying

a

voltage

higher

than

42V

(Peak

Voltage).

If

it

is

necessary

to

turn

on

the

power

for

execution

of

movements

of

the

equipment

in

the

mode

of

installation

procedure,

it

must

be

shut

down

immediately

after

completion

of

these

movements.

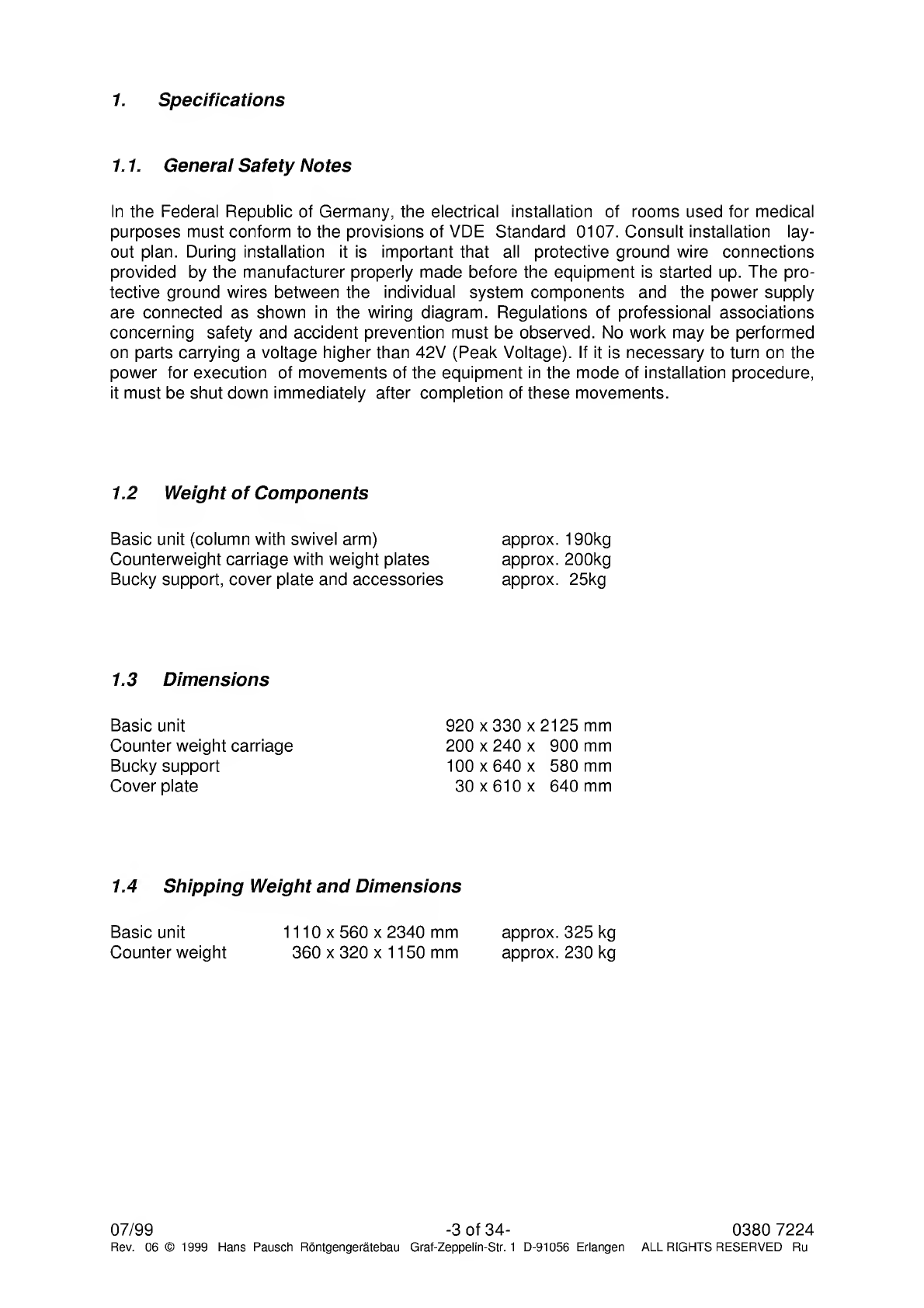

1.2

Weight

of

Components

Basic

unit

(column

with

swivel

arm)

Counterweight

carriage

with

weight

plates

Bucky

support,

cover

plate

and

accessories

approx.

190kg

approx.

200kg

approx.

25kg

1.3

Dimensions

Basic

unit

920

x

330

x

2125

mm

Counter

weight

carriage

200

x

240

x

900

mm

Bucky

support

100

x

640

x

580

mm

Cover

plate

30

x

610

x

640

mm

1.4

Shipping

Weight

and

Dimensions

Basic

unit

1110

x

560

x

2340

mm

Counter

weight

360

x

320

x

1150

mm

approx.

325

kg

approx.

230

kg

07/99

-3

of

34-

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

0380

7224

ALL

RIGHTS

RESERVED

Ru

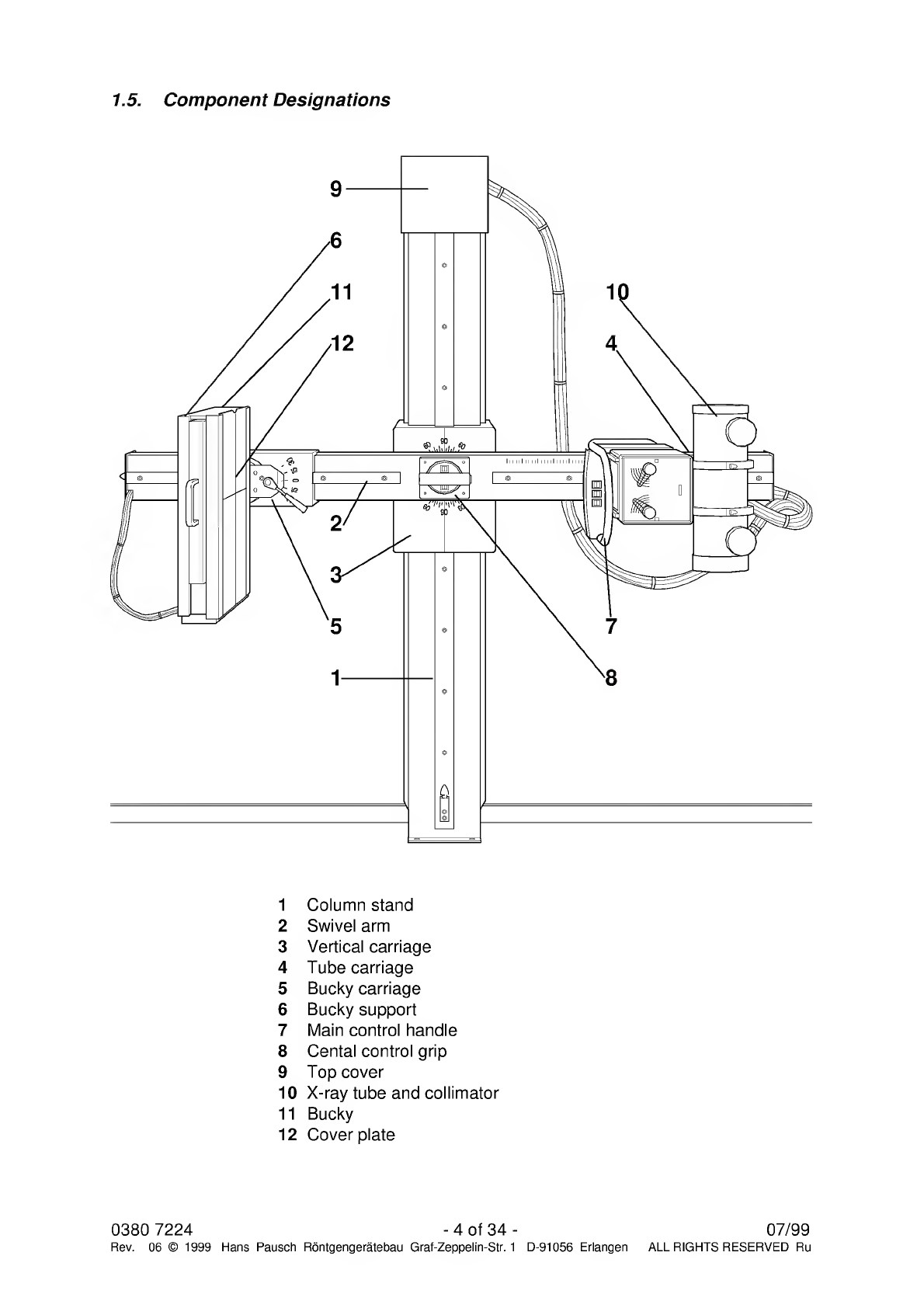

1.5.

Component

Designations

1

Column

stand

2

Swivel

arm

3

Vertical

carriage

4

Tube

carriage

5

Bucky

carriage

6

Bucky

support

7

Main

control

handle

8

Cental

control

grip

9

Top

cover

10

X-ray

tube

and

collimator

11

Bucky

12

Cover

plate

0380

7224

-

4

of

34

-

07/99

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

min.

440

*10

-

max.

1635

*ftf

ca.

2850

*

07/99

-5

of

34-

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

I_I

0380

7224

ALL

RIGHTS

RESERVED

Ru

1.7

Power

Connection

Requirement:

At

the

beginning

of

mounting

the

unit

all

electrical

connections

and

in¬

stallations

must

been

carried

out

according

to

the

ordering

contract

about

voltage

and

frequency.

Nominal

voltage:

Frequency:

Nominal

current:

Power

ratings:

115/230

VAC

50/60

Hz

2

/1

slow

blow

fuse

230

VA

1.8

Special

Tools

and

Measuring

Instruments

Required

Machinist's

water

level

Masonry

drill,

12

mm

(.472")

diameter

1

spring

scale

200

N

0380

7224

-

6

of

34

-

07/99

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

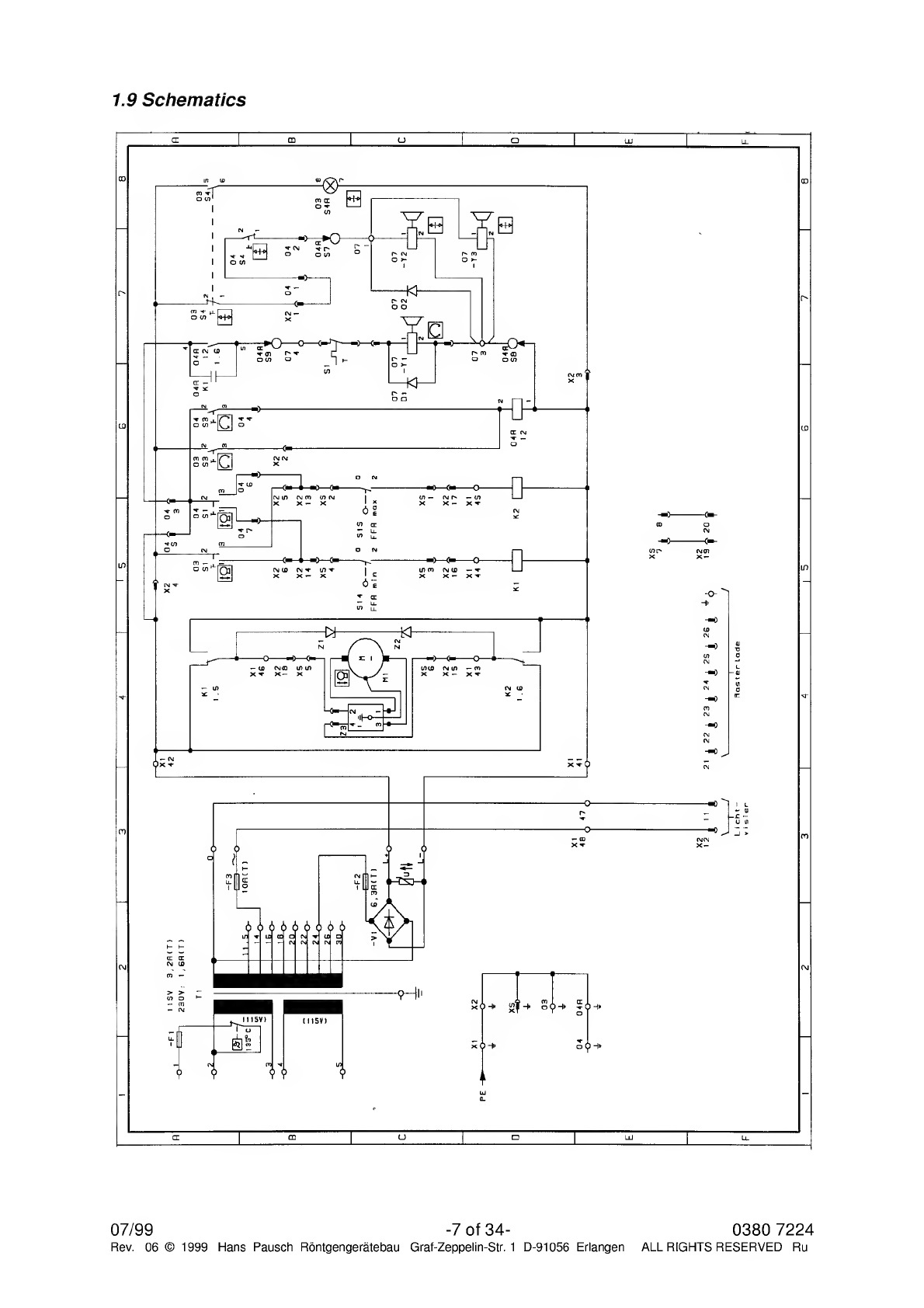

07/99

-7

of

34-

0380

7224

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

1.10

Wiring

Diagram

0380

7224

Rev.

06

©

1999

-

8

of

34

-

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

07/99

ALL

RIGHTS

RESERVED

Ru

1.11

Physical

Location

of

Electrical

Components

Component

Numbers

and

Designation

XI

Power

supply

X2

Terminal

strip

03

Main

control

handle

04

Cental

control

grip

X5

SID

drive

07

vertical

carriage

07/99

-9

of

34-

0380

7224

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

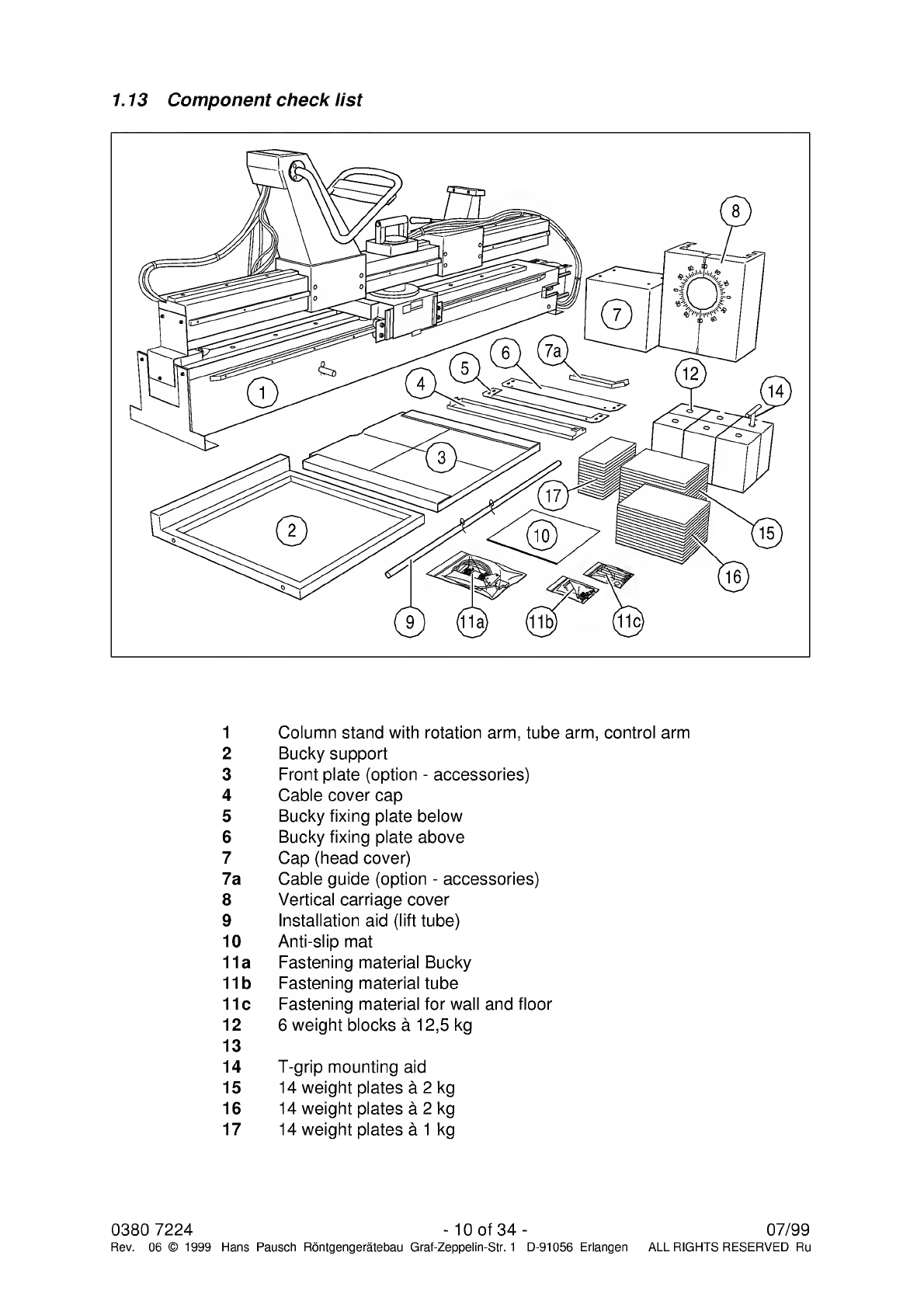

1.13

Component

check

list

1

Column

stand

with

rotation

arm,

tube

arm,

control

arm

2

Bucky

support

3

Front

plate

(option

-

accessories)

4

Cable

cover

cap

5

Bucky

fixing

plate

below

6

Bucky

fixing

plate

above

7

Cap

(head

cover)

7a

Cable

guide

(option

-

accessories)

8

Vertical

carriage

cover

9

Installation

aid

(lift

tube)

10

Anti-slip

mat

11a

Fastening

material

Bucky

11b

Fastening

material

tube

11c

Fastening

material

for

wall

and

floor

12

6

weight

blocks

a

12,5

kg

13

14

T-grip

mounting

aid

15

14

weight

plates

a

2

kg

16

14

weight

plates

a

2

kg

17

14

weight

plates

a

1

kg

0380

7224

-

10

of

34

-

07/99

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

2

.

Mounting

of

Unit

2.1

Site

Preparation

Make

unit

site

preparation

according

to

dimensional

drawing

on

page

5.The

bore

diameter

must

be

12

mm.

To

assure

all

movements

of

the

equipment

pay

attention

to

all

movement

possibilities.

Note:

The

mounting

points

must

be

suitable

for

tensile

strength

of

1000

N

pull.

For

example:

Liebig-safety

bolts

SI

2/65

for

concrete

floor

tensile

strength

classification

DIN

1045

B

15.

2.2

Uncrating

Remove

top

and

side

walls

of

the

crate

(not

necessary

with

just

protection

packing).

Take

out

the

Bucky

support

and

accessories

and

unpack

completely.

Check

the

contents

of

each

box

with

dispatch

note

or

order

to

assure

that

all

items

are

located.

Pay

also

attention

to

page

10

1.13

Component

check

list.

Fig.

1

Fig.

2

Mount

low

voltage

unit

(Fig.

27)

onto

the

rope

return

block

with

the

four

stay

bolts.

Move

equipment

with

the

transport

palette

to

the

installation

place

and

assure

that

foot

end

of

the

palette

is

approx.

1,5

m

away

from

the

installation

wall.

07/99

-11

of

34-

0380

7224

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

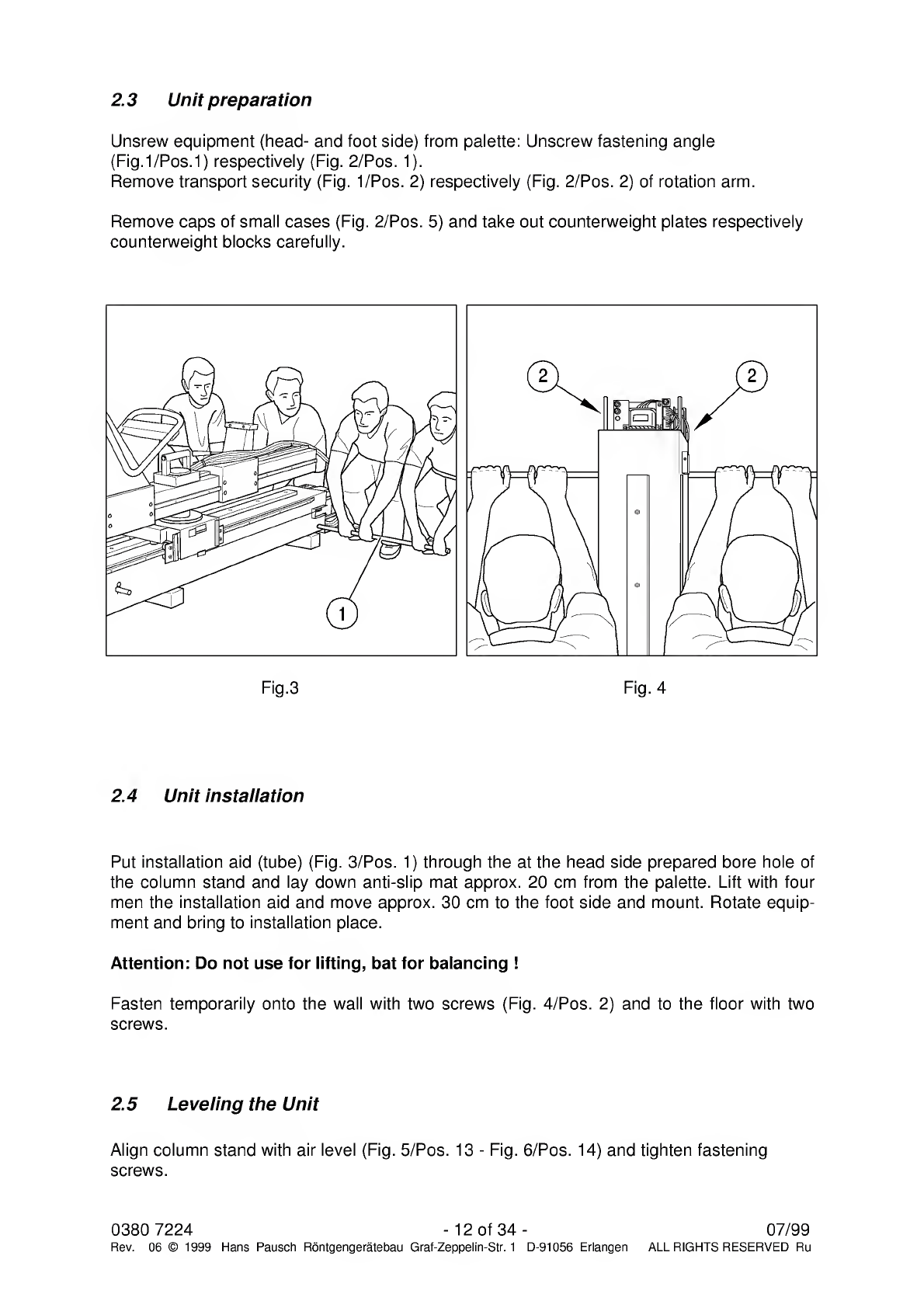

2.3

U

nit

preparation

Unsrew

equipment

(head-

and

foot

side)

from

palette:

Unscrew

fastening

angle

(Fig.l/Pos.1)

respectively

(Fig.

2/Pos.

1).

Remove

transport

security

(Fig.

1/Pos.

2)

respectively

(Fig.

2/Pos.

2)

of

rotation

arm.

Remove

caps

of

small

cases

(Fig.

2/Pos.

5)

and

take

out

counterweight

plates

respectively

counterweight

blocks

carefully.

Fig.3

Fig.

4

2.4

U

nit

installation

Put

installation

aid

(tube)

(Fig.

3/Pos.

1)

through

the

at

the

head

side

prepared

bore

hole

of

the

column

stand

and

lay

down

anti-slip

mat

approx.

20

cm

from

the

palette.

Lift

with

four

men

the

installation

aid

and

move

approx.

30

cm

to

the

foot

side

and

mount.

Rotate

equip¬

ment

and

bring

to

installation

place.

Attention:

Do

not

use

for

lifting,

bat

for

balancing

!

Fasten

temporarily

onto

the

wall

with

two

screws

(Fig.

4/Pos.

2)

and

to

the

floor

with

two

screws.

2.5

L

eveling

the

Unit

Align

column

stand

with

air

level

(Fig.

5/Pos.

13

-

Fig.

6/Pos.

14)

and

tighten

fastening

screws.

0380

7224

-

12

of

34

-

07/99

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

2.5.1

Loading

of

counterweights

Remove

cover

(Fig.

8/Pos.

18)

from

column

stand

and

strap

(Pos.

19)

from

counter

weight

carriage.

Insert

counter

weight

blocks

(Fig.

7/Pos.

19)

with

screwed

in

support

grip

(Pos.

20)

in

counter

weight

carriage.

Attention:

Insert

on

three

levels

2

counter

weight

blocks

each

and

7

counter

weight

plates

each.

Fig.

7

Fig.

8

07/99

-13

of

34-

0380

7224

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

The

adjustment

will

be

done

with

counter

balance

plates.

Ref.

to

section

3.3

Mount

strap

(Fig.

8/Pos.

19)

on

counter

weight

carriage

and

reinstall

cover

(Pos.18).

2.6

M

ounting

of

Bucky

Support

Put

swivel

arm

in

upright

position,

so

that

the

Bucky

carriage

(Fig.

10/

Pos.

27)

is

at

the

bottom

(Fig.

10/Pos.

28).

Mount

Bucky

support

(Pos.

27)

and

lining

plate

(Pos.

28a)

with

4

screws

to

Bucky

carriage

(Pos.

28).

Fig.

9

Fig.

10

2.7

M

ounting

of

Control

arm

Release

the

rotation

brake

while

pushing

onto

the

armature

(Fig.

9/Pos.

30)

and

rotate

rota¬

tion

arm

about

90°carefully.

Dismount

cover

(Fig.

11/Pos.

31+29)

from

the

tube

support

(Pos.

32).

Dismount

control

arm

(Pos.

33)

and

remount

again

180°

rotated.

2.8

M

ounting

of

X-Ray

Tube

and

Collimator

Lift

rotation

brake

while

pushing

onto

the

armature

(Fig.

9/Pos.

30)

and

rotate

rotation

arm

carefully

by

90°.

Bring

tube

(Fig.

11/Pos.

34)

to

the

tube

support

(Pos.

32)

and

fasten

with

4

screws.

Put

collimator

(Pos.

36)

onto

the

tube

(Pos.

34)

and

fasten.

Rotate

again

rotation

arm

by

180°.

Attention:

The

weight

counterbalance

of

the

rotation

arm

is

not

counterbalanced.

There

is

a

risk

of

accident!

0380

7224

-

14

of

34

-

07/99

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

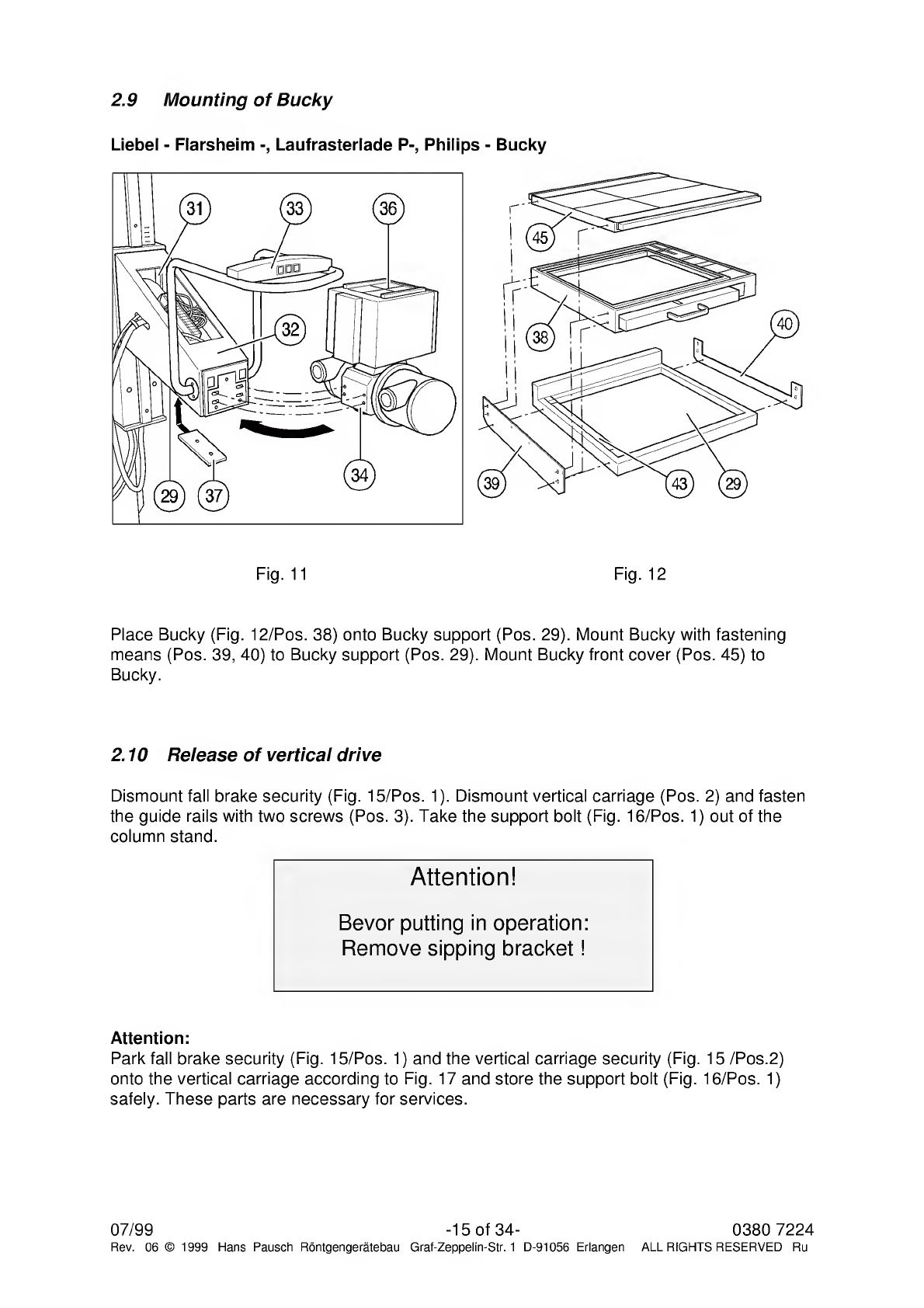

2.9

Mounting

of

Bucky

Liebel

-

Flarsheim

Laufrasterlade

P-,

Philips

-

Bucky

Fig.

11

Fig.

12

Place

Bucky

(Fig.

12/Pos.

38)

onto

Bucky

support

(Pos.

29).

Mount

Bucky

with

fastening

means

(Pos.

39,

40)

to

Bucky

support

(Pos.

29).

Mount

Bucky

front

cover

(Pos.

45)

to

Bucky.

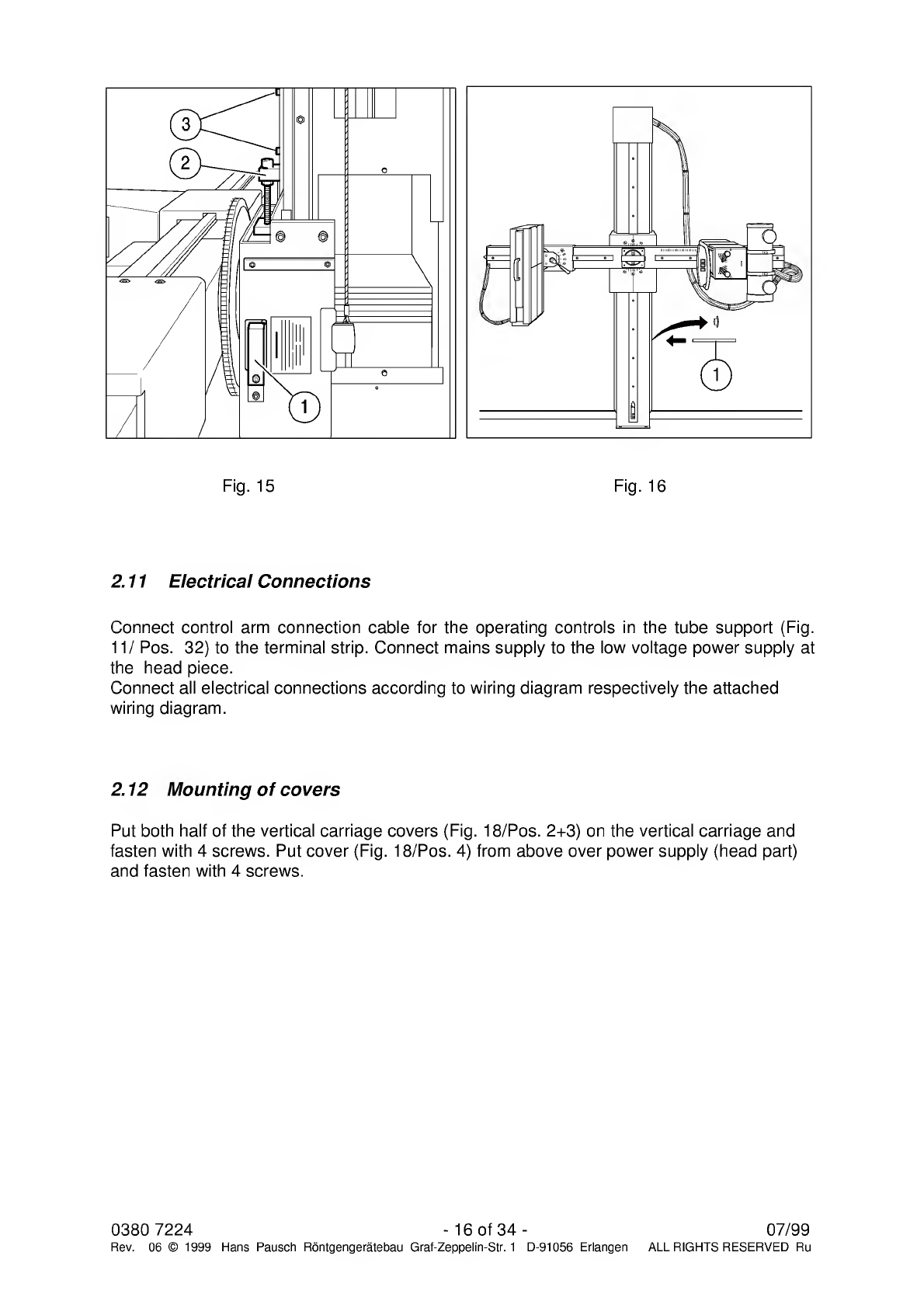

2.10

Release

of

vertical

drive

Dismount

fall

brake

security

(Fig.

15/Pos.

1).

Dismount

vertical

carriage

(Pos.

2)

and

fasten

the

guide

rails

with

two

screws

(Pos.

3).

Take

the

support

bolt

(Fig.

16/Pos.

1)

out

of

the

column

stand.

Attention!

Bevor

putting

in

operation:

Remove

sipping

bracket!

Attention:

Park

fall

brake

security

(Fig.

15/Pos.

1)

and

the

vertical

carriage

security

(Fig.

15

/Pos.2)

onto

the

vertical

carriage

according

to

Fig.

17

and

store

the

support

bolt

(Fig.

16/Pos.

1)

safely.

These

parts

are

necessary

for

services.

07/99

-15

of

34-

0380

7224

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

2.11

Electrical

Connections

Connect

control

arm

connection

cable

for

the

operating

controls

in

the

tube

support

(Fig.

11/

Pos.

32)

to

the

terminal

strip.

Connect

mains

supply

to

the

low

voltage

power

supply

at

the

head

piece.

Connect

all

electrical

connections

according

to

wiring

diagram

respectively

the

attached

wiring

diagram.

2.12

Mounting

of

covers

Put

both

half

of

the

vertical

carriage

covers

(Fig.

18/Pos.

2+3)

on

the

vertical

carriage

and

fasten

with

4

screws.

Put

cover

(Fig.

18/Pos.

4)

from

above

over

power

supply

(head

part)

and

fasten

with

4

screws.

0380

7224

-

16

of

34

-

07/99

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

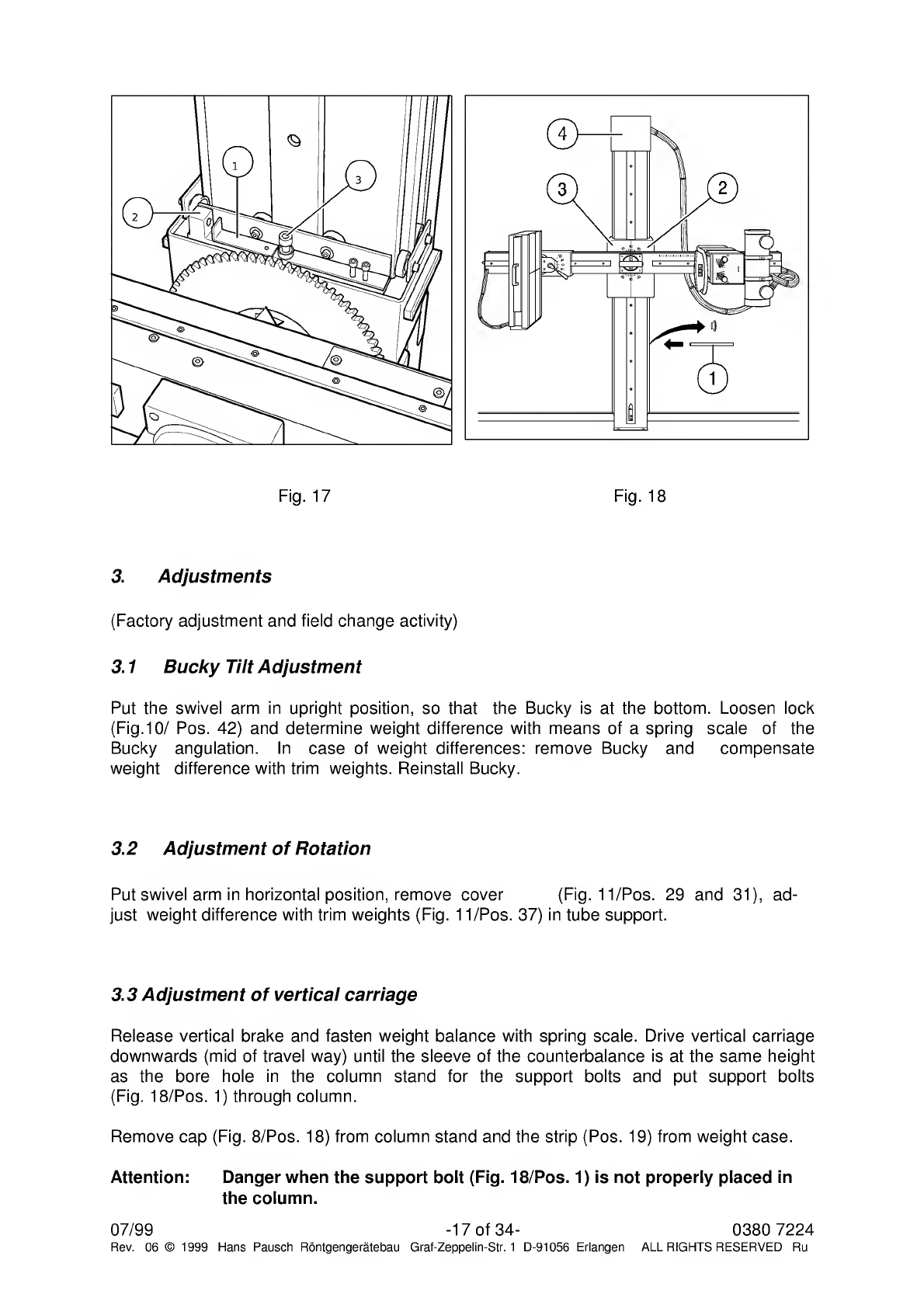

3.

Adjustments

(Factory

adjustment

and

field

change

activity)

3.1

B

ucky

Tilt

Adjustment

Put

the

swivel

arm

in

upright

position,

so

that

the

Bucky

is

at

the

bottom.

Loosen

lock

(Fig.10/

Pos.

42)

and

determine

weight

difference

with

means

of

a

spring

scale

of

the

Bucky

angulation.

In

case

of

weight

differences:

remove

Bucky

and

compensate

weight

difference

with

trim

weights.

Reinstall

Bucky.

3.2

A

djustment

of

Rotation

Put

swivel

arm

in

horizontal

position,

remove

cover

(Fig.

11/Pos.

29

and

31),

ad¬

just

weight

difference

with

trim

weights

(Fig.

11/Pos.

37)

in

tube

support.

3.3

A

d

justment

of

vertical

carriage

Release

vertical

brake

and

fasten

weight

balance

with

spring

scale.

Drive

vertical

carriage

downwards

(mid

of

travel

way)

until

the

sleeve

of

the

counterbalance

is

at

the

same

height

as

the

bore

hole

in

the

column

stand

for

the

support

bolts

and

put

support

bolts

(Fig.

18/Pos.

1)

through

column.

Remove

cap

(Fig.

8/Pos.

18)

from

column

stand

and

the

strip

(Pos.

19)

from

weight

case.

Attention:

Danger

when

the

support

bolt

(Fig.

18/Pos.

1)

is

not

properly

placed

in

the

column.

07/99

-17

of

34-

0380

7224

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

Switch

off

power

supply.

Adjust

weight

difference

with

weight

plates

and

insert

in

counter¬

weight

box.

Install

security

sleeve

(Fig.

8/Pos.

19)

onto

counterweight

box

and

lock

column

with

cap

(Pos.

18).

Remove

support

bolt

(Fig.

18/Pos.

1)

from

column.

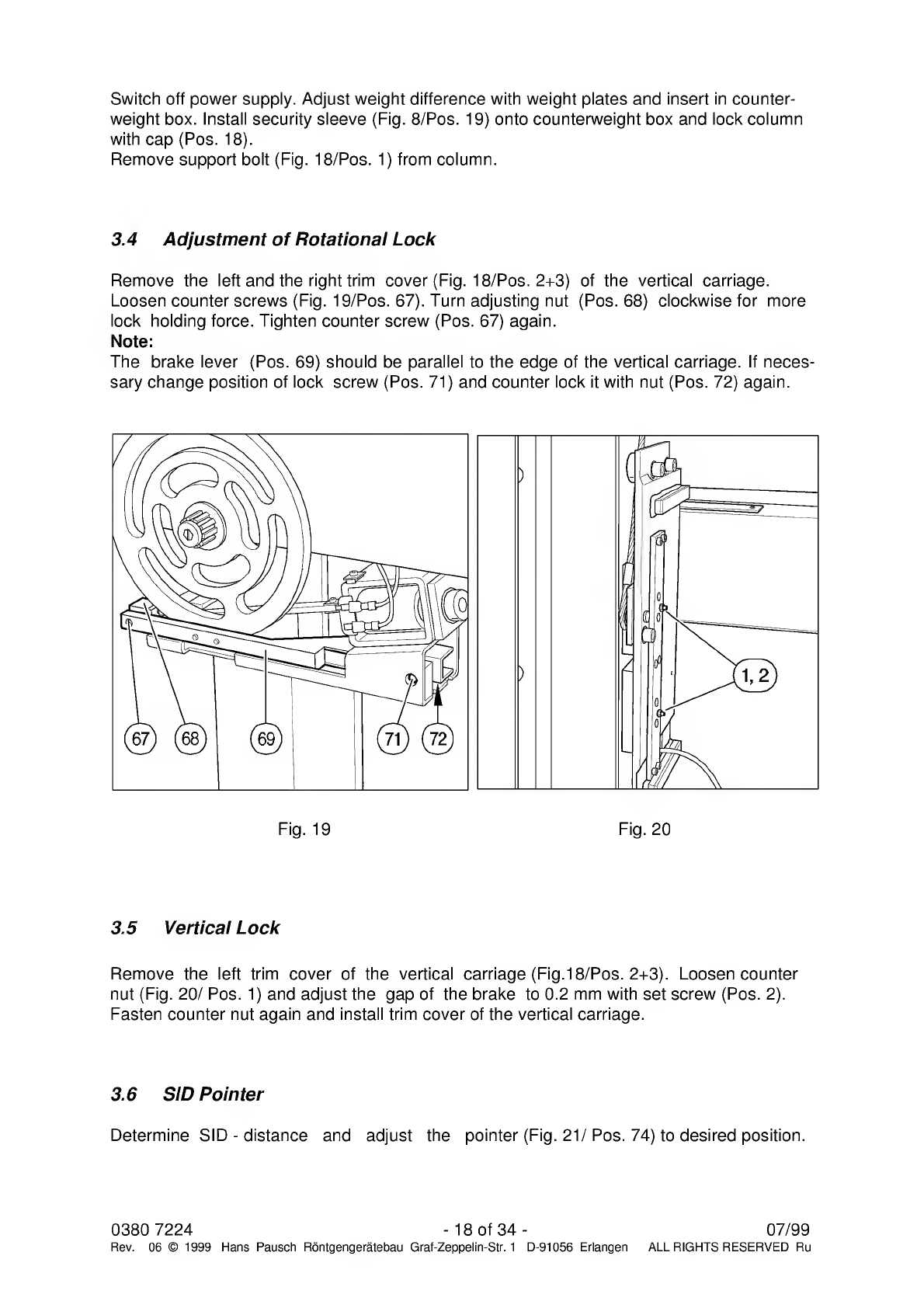

3.4

A

djustment

of

Rotational

Lock

Remove

the

left

and

the

right

trim

cover

(Fig.

18/Pos.

2+3)

of

the

vertical

carriage.

Loosen

counter

screws

(Fig.

19/Pos.

67).

Turn

adjusting

nut

(Pos.

68)

clockwise

for

more

lock

holding

force.

Tighten

counter

screw

(Pos.

67)

again.

Note:

The

brake

lever

(Pos.

69)

should

be

parallel

to

the

edge

of

the

vertical

carriage.

If

neces¬

sary

change

position

of

lock

screw

(Pos.

71)

and

counter

lock

it

with

nut

(Pos.

72)

again.

)

(

1

rp

i#

0

(I

0

\

=

o

)

/

0

0

(.•>)

0/[

ir\_

3.5

V

ertical

Lock

Remove

the

left

trim

cover

of

the

vertical

carriage

(Fig.18/Pos.

2+3).

Loosen

counter

nut

(Fig.

20/

Pos.

1)

and

adjust

the

gap

of

the

brake

to

0.2

mm

with

set

screw

(Pos.

2).

Fasten

counter

nut

again

and

install

trim

cover

of

the

vertical

carriage.

3.6

S

ID

Pointer

Determine

SID

-

distance

and

adjust

the

pointer

(Fig.

21/Pos.

74)

to

desired

position.

0380

7224

-

18

of

34

-

07/99

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

3.7

SID

Drive

Clutch

Remove

cover

(Fig.22/Pos.

76).

Adjust

the

torque

with

means

of

the

3

screws

(Pos.

77).

For

higher

torque

turn

screws

(Pos.

77)

clockwise.

Note:

The

stop

motion

force

of

the

Bucky-

or

tube

carriage

should

be

set

to

150

N

max.

Secure

screws

with

locking

dye

and

mount

cover

again.

Fig.

21

Fig.

22

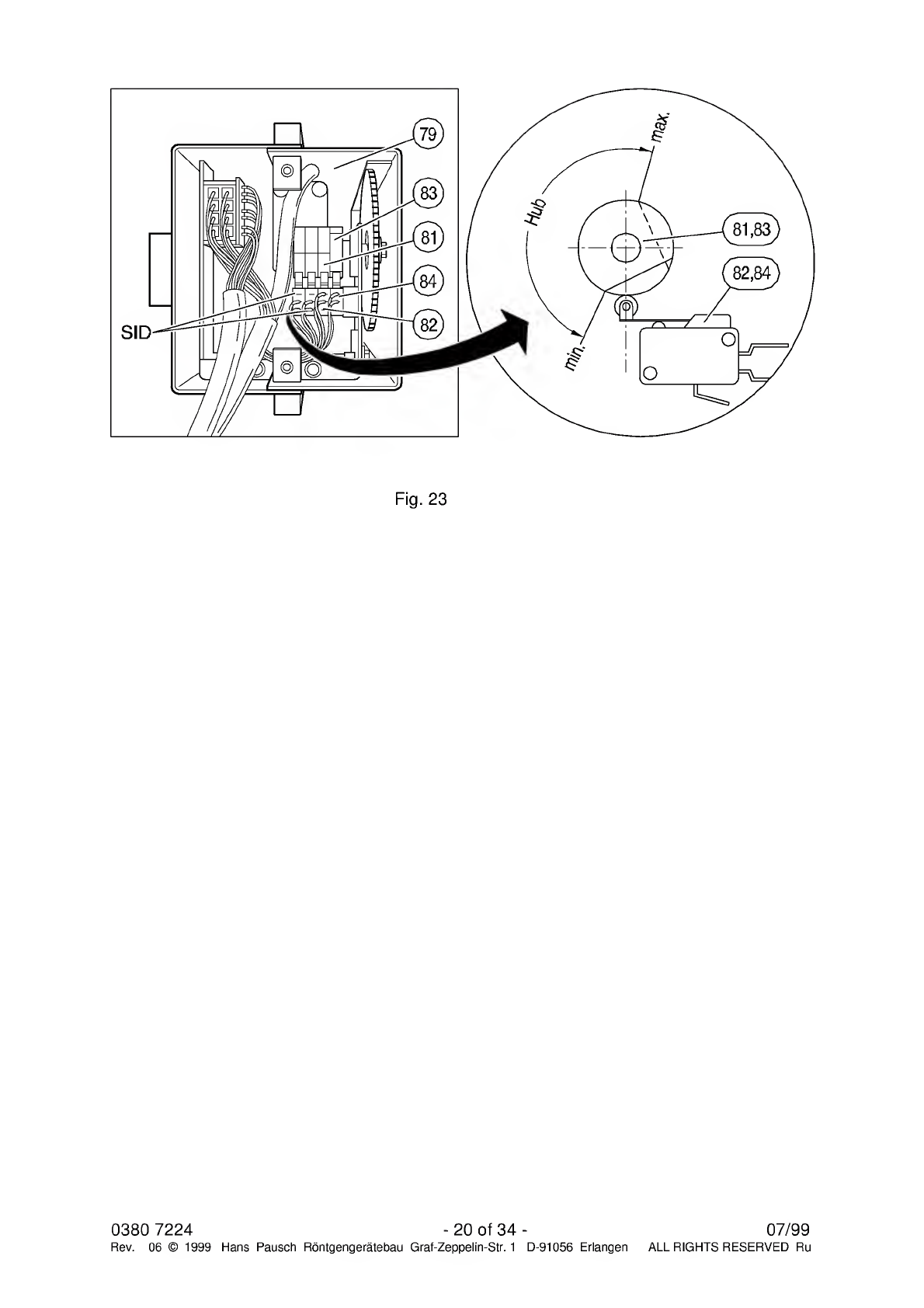

3.8

SID

End

Switch

Remove

end

cover

of

swivel

arm

(Fig.23/Pos.

79).

Drive

SID

to

minimum

distance

possi¬

ble.

Loosen

trip

cam

(Pos.

81)

with

socket

wrench

and

turn

the

cam

until

switch

(Pos.

82)

is

actuated.

Tighten

trip

cam.

Put

SID

to

maximum

distance,

loosen

trip

cam

(Pos.

83)

and

turn

it

until

switch

(Pos.

84)

is

actuated.

Fasten

trip

cam

again.

Note:

The

SID

is

variable

from

1

m

to

2

m

distance

but

can

be

limited

in

any

intermediat

distance.

Install

trim

cover

(Pos.

79)

again.

07/99

-19

of

34-

0380

7224

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

Fig.

23

0380

7224

-

20

of

34

-

07/99

Rev.

06

©

1999

Hans

Pausch

Rontgengeratebau

Graf-Zeppelin-Str.

1

D-91056

Erlangen

ALL

RIGHTS

RESERVED

Ru

Table of contents

Other Hans Pausch Industrial Equipment manuals