10

APM-001e

AUG 2015

DIGITAL READOUT FLASHING 2222

LOSS OF FOUL GAS PRESSURE. This usually means

the pressure in the air separator chamber is below 80 psig

(5.5 bar). Pressure gauge on the purger reads near suction

pressure. The purger will not allow noncondensible gases

to be released from the purger. However, the purger will

continue to operate normally in all other functions.

REASON 1:A burned-out purge point solenoid coil.

Check: Check the remote purge point solenoid 3 amp

fuse for continuity. Replace if necessary. Advance

purge points one at a time with the purge point advance

button, waiting approximately 2 minutes before advancing

again. Wait until the fuse opens or the digital readout

again flashes 2222. The faulty coil or wiring is now

pinpointed.

Action: Replace the coil or repair the wire, and replace

the 3 amp fuse (p/n 20-1698).

REASON 2: A remote purge point solenoid valve is jammed

closed.

Check: Inspect the remote purge point solenoid valve

which caused the diagnostic code to appear. Manually

open the solenoid valve and recheck the pressure.

Action: If the coil is energized, clean and replace any

solenoid valve parts as necessary. See also the Caution

section on page 14.

REASON 3: Foul gas line restricted.

Check: Inspect the Foul gas line for a closed shut-off

valve(s) or the plastic shipping cap still in foul gas line

flange.

Action: Open shut-off valves and/or remove the shipping

cap. See also Caution section, page 14.

REASON 4: Faulty pressure transducer.

Check: With the purger in any operational mode, check

the pressure gauge reading. If it is above 80 psig, check

pressure transducer plug-in connector terminals 27 &

30 for 10 volts DC. Then check terminals 28 & 29 for at

least 13 mV.

Action: If terminals 27 & 30 do not have 10 volts DC, check

for faulty wiring. If terminals 28 & 29 do not have at least

13 mV, replace the pressure transducer (p/n 20-1857)

with the purger at zero pressure. See also the Caution

section on page 14.

DIGITAL READOUT FLASHING 3333

PURGER TOO WARM. If the purger evaporator temperature

is 40°F (4.4°C) or warmer, the purger will not release

noncondensible gas from the purger because excessive

refrigerant would also escape. The purger will continue to

operate normally in all other functions. This code is also

displayed during initial start-up until the purger flooded

evaporator is cooled down.

REASON 1: Suction temperature too high.

Check: Verify the pressure at the purger suction line

connection.

Action: Connect to a lower-temperature suction.

REASON 2: Restriction in the suction line.

Check: Inspect the suction line and shut-off valves. These

should be a minimum size of ¾”. On new installations,

also make sure the plastic shipping cap in suction line

flange is removed.

Action: Eliminate the restriction. See also the Caution

section on page 14.

REASON 3: The flooded evaporator inside the purger is

not filled with refrigerant.

Check: Look for a closed liquid line shut-off valve,

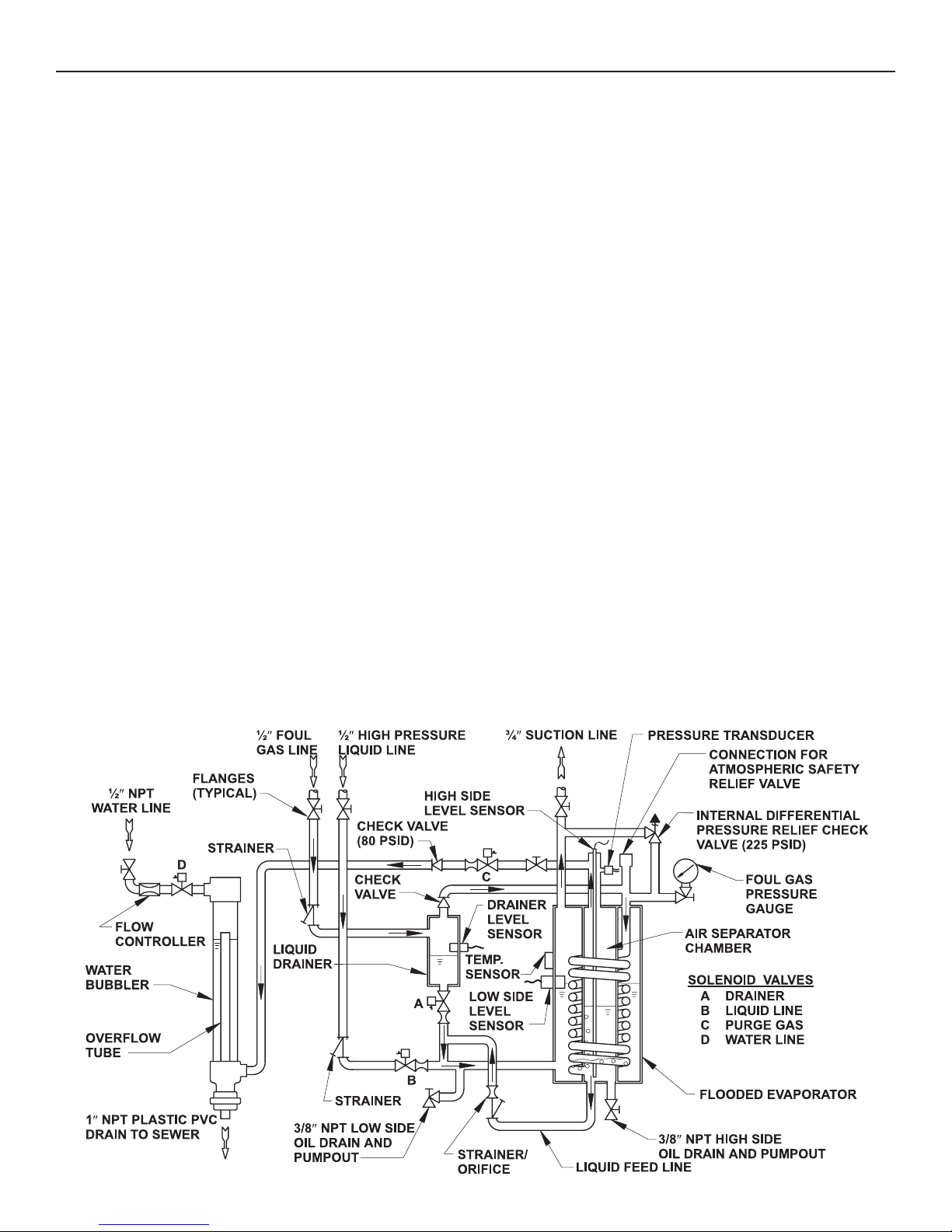

Also, check that the liquid line solenoid valve (B) is

energized.

Action: Open the liquid line shut-off valve. If not energized,

check for voltage at the liquid line solenoid valve coil.

Replace the coil if it is burned-out.

REASON 4: Faulty temperature sensor.

Check: With the temperature sensor plug-in connector

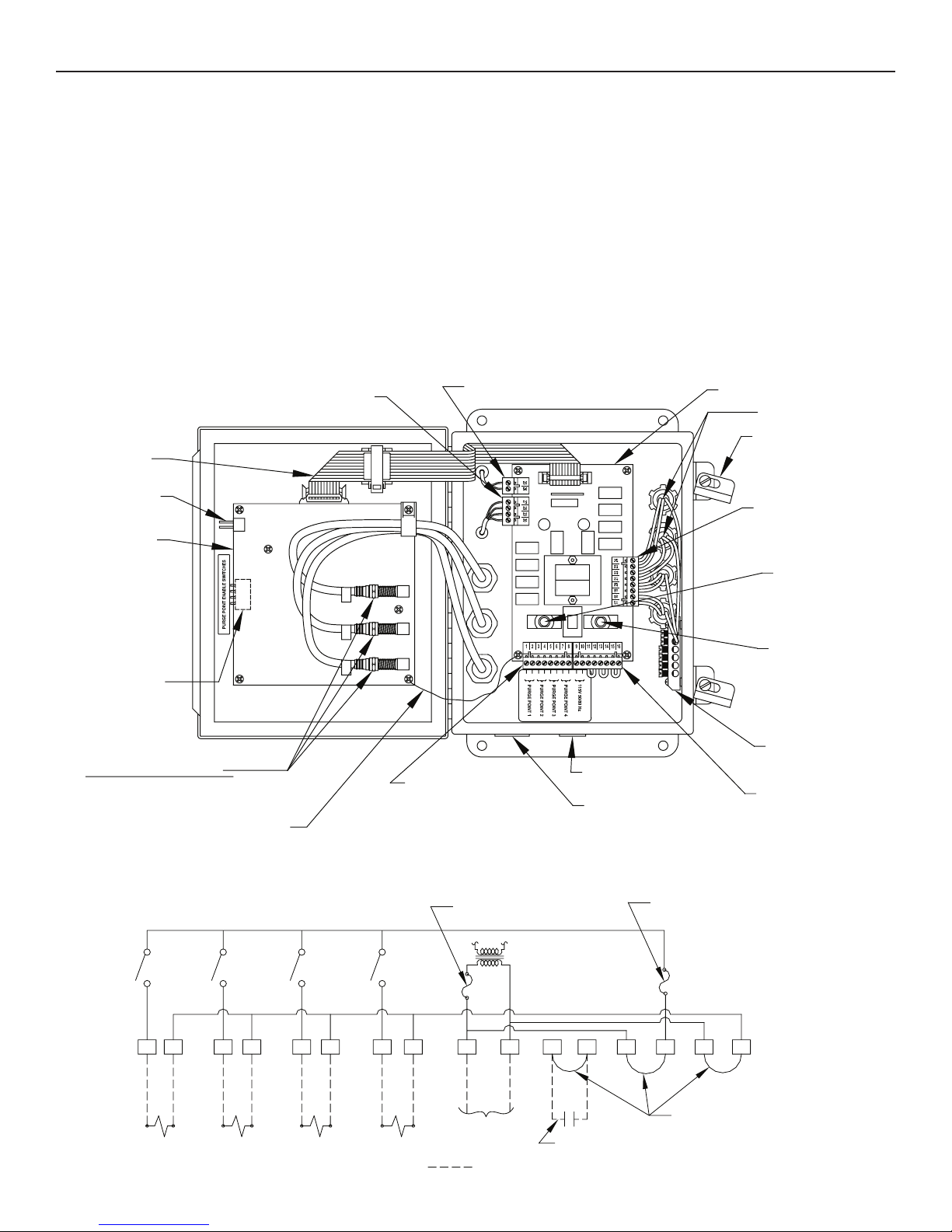

disconnected from power board (see Figure 4), check

the electrical resistance of the sensor across the wire

leads.

Action: If the resistance is not between 30 K ohms and 486

K ohms, replace the temperature sensor (p/n 20-2303).

See also Caution section on page 14.

DIGITAL READOUT FLASHING 4444

PURGED OVER 60 MINUTE TIME LIMIT. If noncondensibles

are released from the purger for 60 minutes continuously, a

time delay will close the purge gas solenoid valve (C). This

limits the possibility of a substantial amount of refrigerant

inadvertently being released into the water bubbler in the

unlikely event of purger malfunction.

REASON 1: A large volume of noncondensibles is

continuously being removed from system.

Action: Reset the time delay by momentarily turning the

APM to Purger Switched Off and back to the desired

operation mode. Delay is now reset for up to another

hour of continuous purging. Otherwise, put the purger

in New System Start-up mode for continuous purging

without the 60 minute time limit.

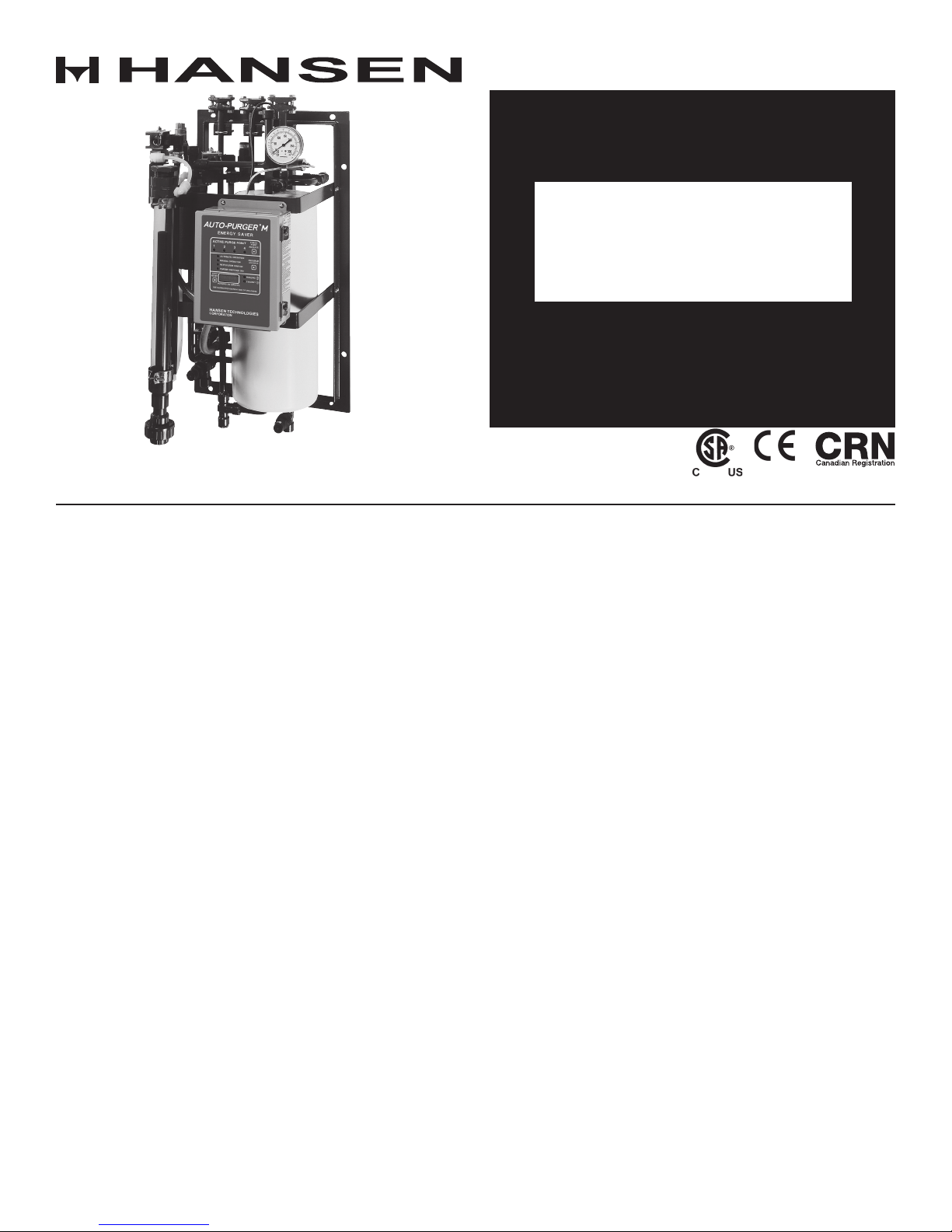

REASON 2: Purge gas solenoid valve (C) is not opening

or the removable seat/orifice is blocked.

Check: Make sure purge gas solenoid valve (C) is energized.

If not, check for voltage at solenoid coil.

Action: Replace the coil if it is burned-out, otherwise clean

or replace the removable seat/orifice inside the solenoid

valve body. See also the Caution section on page 13.

REASON 3: The shut-off valve located before the purge

gas solenoid valve (C) is closed.

Check: Verify that purge gas is not being sent to the

bubbler.

Action: Open the valve.

SECTION 4 TROUBLE SHOOTING PURGER OPERATION