BC297731816824en-000101 | 148R9643 | 3

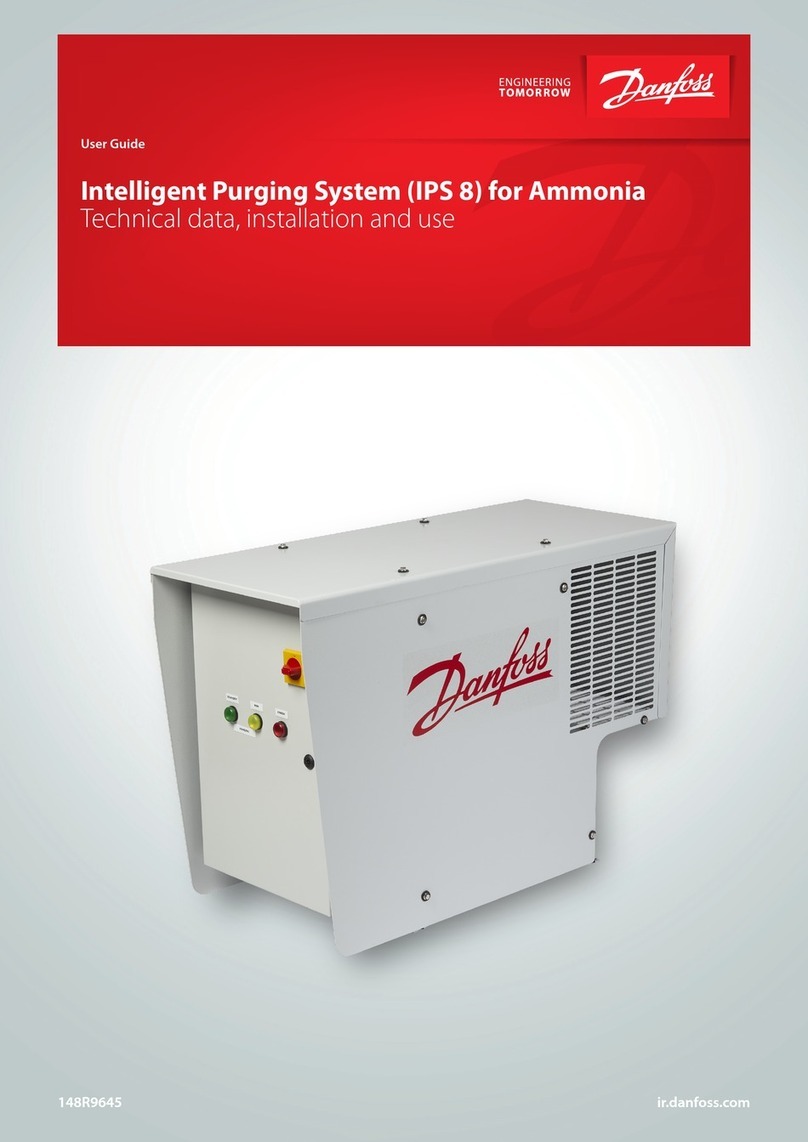

The Danfoss Intelligent Purger System (IPS)

is a stand-alone, self-contained purging unit

designed to remove non-condensable gases

(NC gases = air and other unwanted foreign

gases) from industrial ammonia refrigeration

systems.

The ingress of NC gases into a refrigeration

system is inevitable, regardless of the refrigerant,

pressures, or temperatures. NC gases in the

system will result in a decrease in system

efficiency, both in terms of an increase in power

consumption and reduced cooling capacity.

Due to having a different density than ammonia,

the ingressed air will accumulate in specific areas

of the system, where it can be removed using the

Danfoss IPS.

The accumulation areas are identified in the

Connection locations section, along with

recommended connection principles.

The purger unit is an electronic-controlled, self-

employed R404A refrigerant system that runs

independent of the main ammonia system and

with only one flange connection to the ammonia

plant.

This flanged opening allows access of the

ammonia gas/NC gas mix to the purger

evaporator, where it is divided into ammonia

condensate and NC gases. The ammonia

condensate is returned by gravity to the main

plant, while the NC gases are purged to the

atmosphere through a water bath.

Through the flanged opening, the purger unit

has access to all parameters from the ammonia

plant required for full electronic control.

The unit runs automatically in 24-hour cycles,

checking for the presence of NC gases and, if

present, removed.

To regain the design capacity of the main

ammonia system and prevent future air

accumulation, it is highly recommended to install

the Danfoss IPS.

Introduction

Features • State-of-the-art electronic controlled unit

based on the Danfoss MCX controller platform.

• Reduced power consumption.

• Automatic purging response to NC gases in the

refrigeration system.

• Continuous monitoring of differential pressure

between system refrigerant and purger

refrigerant.

• Electronic purging that minimizes refrigerant

(ammonia) relief to the environment.

• Self-contained unit operation, which functions

independently from the main plant.

• An operation log for easy purging cycle data

monitoring.

• Self-diagnostics for unit and system operation

to shut down in case of malfunction of air

purger components.

• Cost-effective installation with few mechanical

and electrical connection interfaces.

• A hermetic internal cooling system, which

minimizes leakage risks.

• A plug-and-play stand-alone design, which

eases installation and commissioning with low

risk of potential errors.

• No need for advanced settings.

• A compact and easy-to-handle design.

• Patent pending on IPS.