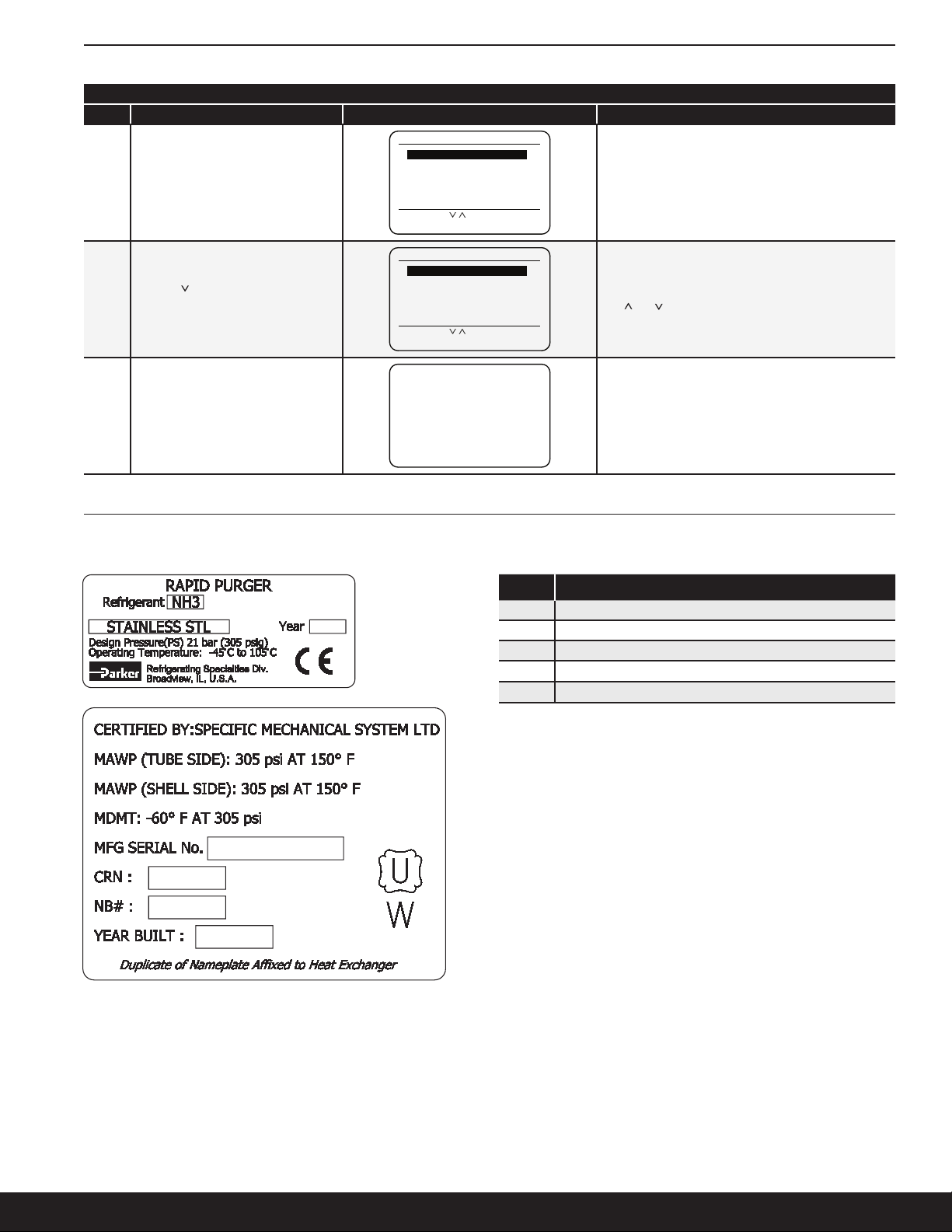

Bulletin 76-00 B

5

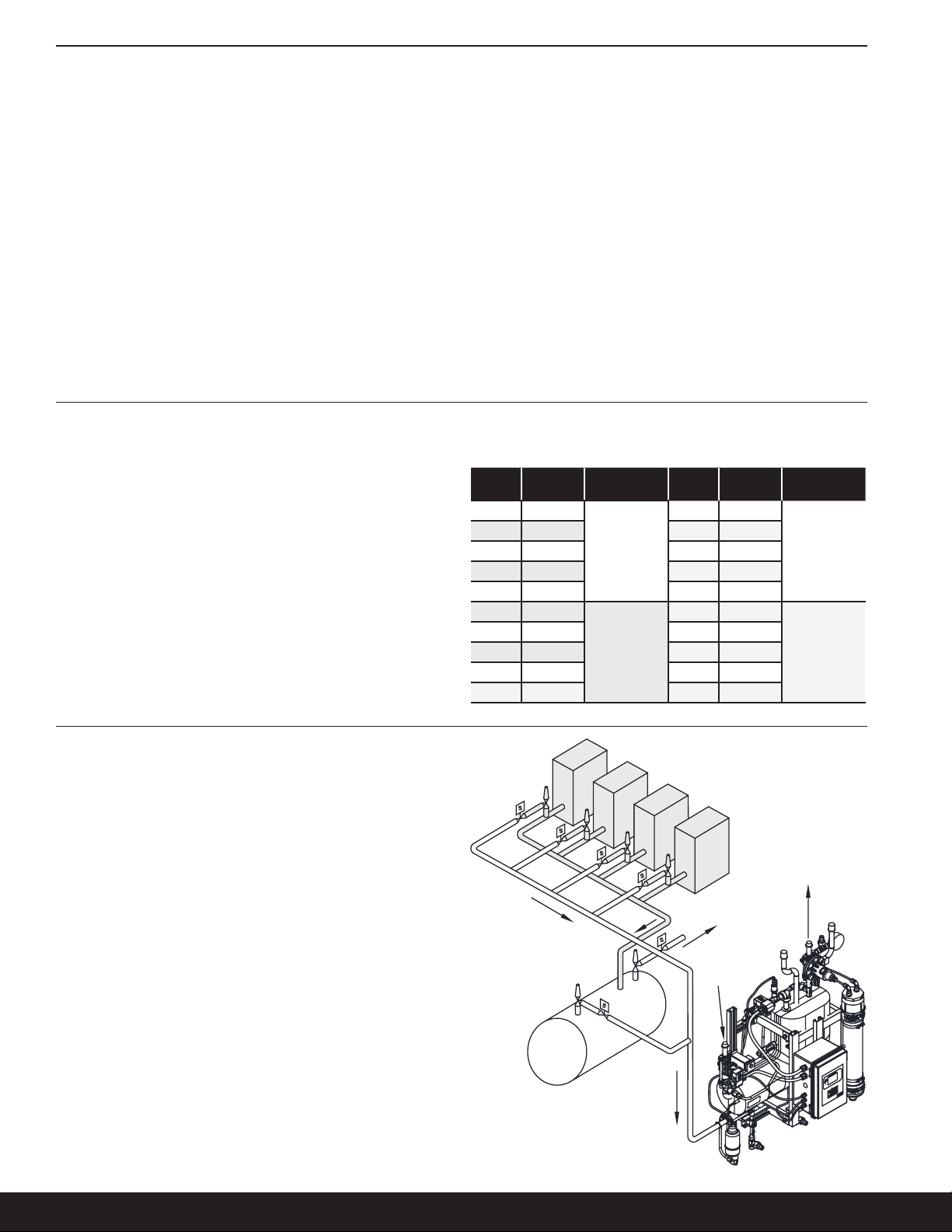

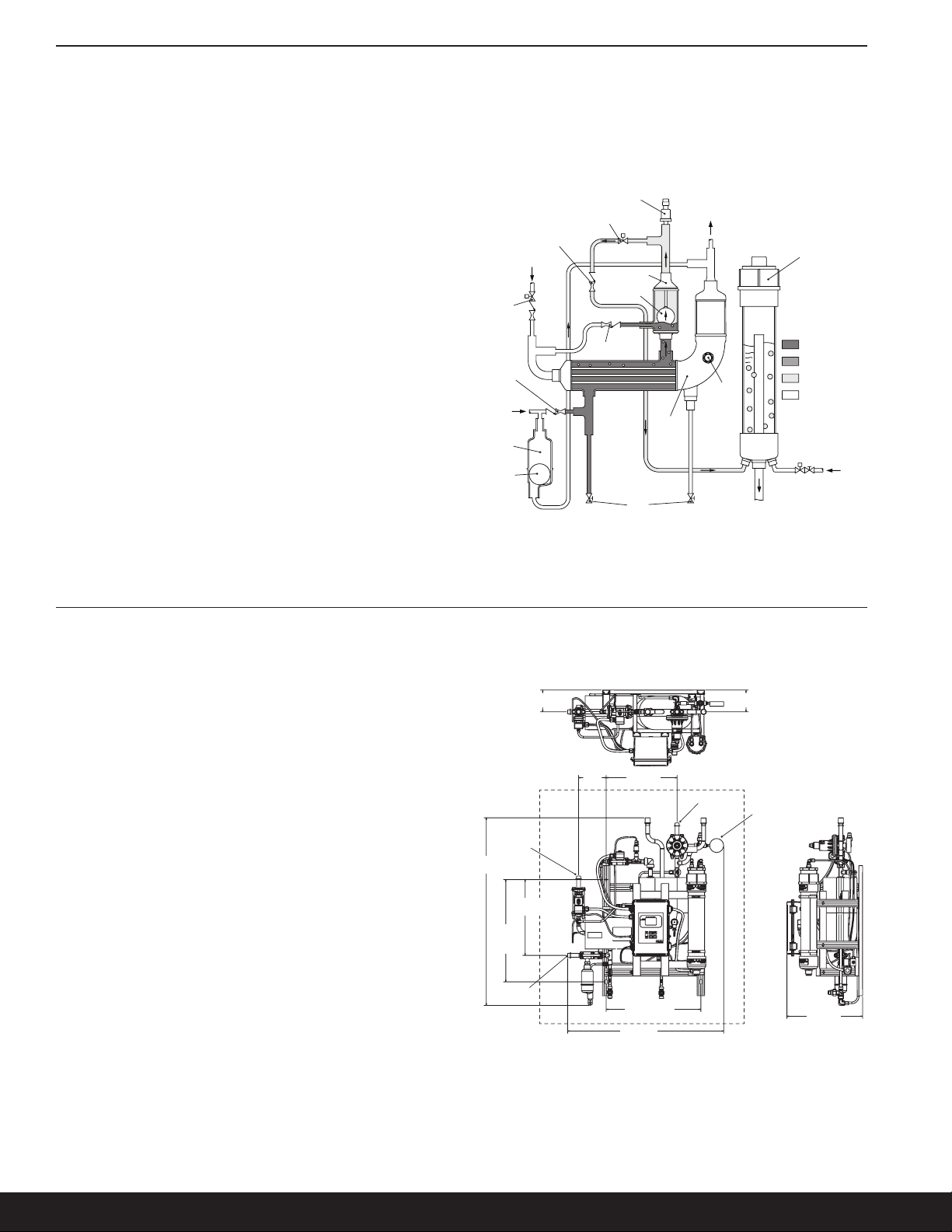

Foul Gas Line

Flange w/ Stub

High Pressure Liquid Line

Flange w/ Stub

Suction Line

Flange w/ Stub

1⁄2" SW

Shut-Off Valve

1⁄2" SW

Shut-Off Valve

1⁄2" SW

Shut-Off

Valve

Oil Drain Valve

(Shell Side)

Oil Drain Valve

(Tube Side)

Water

Line

1⁄4" NPT

Water Solenoid

Bubbler

3⁄4"-14 FPT

Water Drain Line

Under Side View: Water

line connected to the water

solenoid

WARNING

Do not trap the foul gas line prior to

entering the purger. is will cause

the foul gas to condense.

!

Figure 6: Purger Flange Line Connections

Figure 7: Water Line Connections

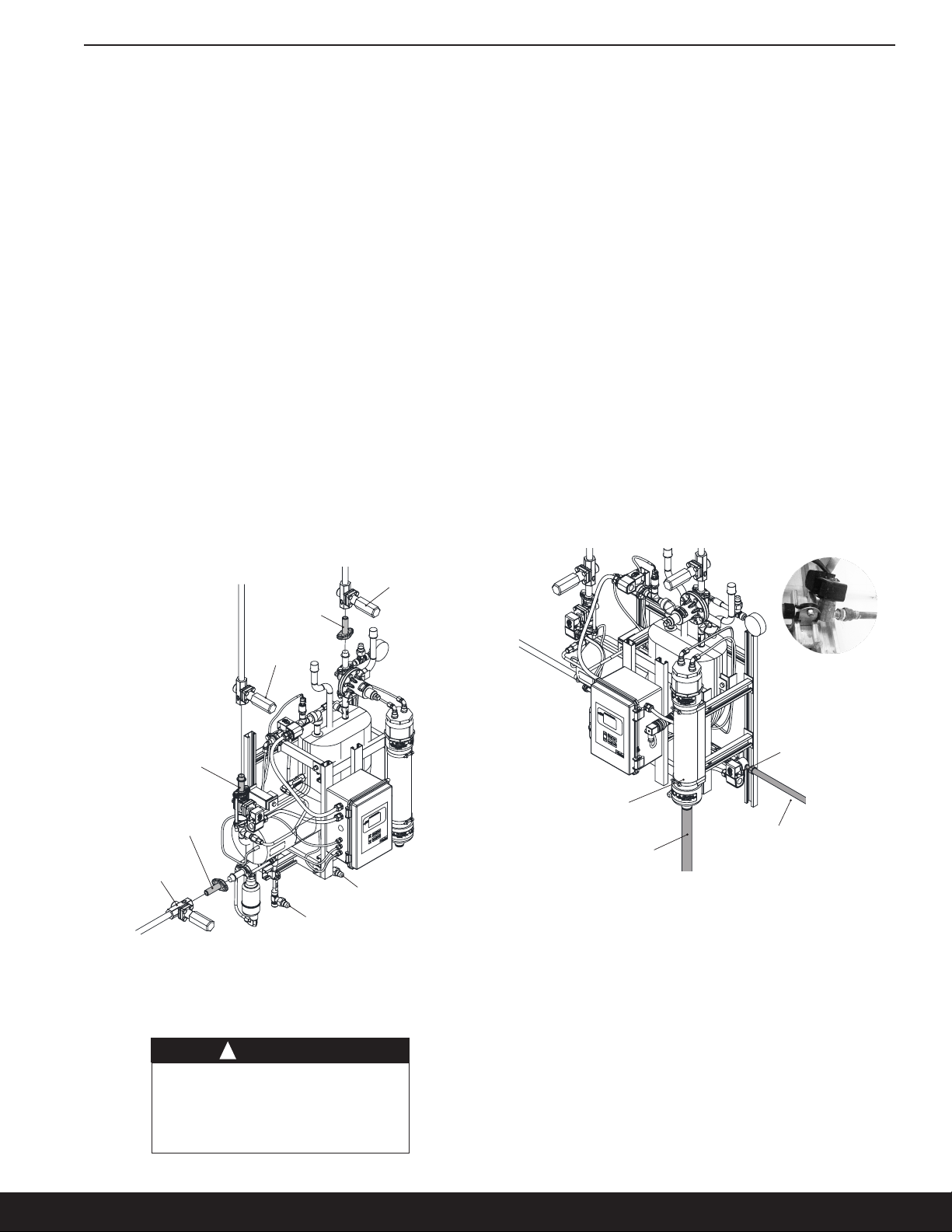

Make sure to leave access for servicing the unit if required. e

recommended clearance zone, as shown in Figure 5, is 254 mm

(10") for the top and sides. e bottom of the purger must be

free of obstructions to allow for water drain and oil removal.

2. Properly locate, support and align the systems high pressure

liquid, foul gas and suction lines with the purger.

Note: To prevent oil from entering the heat exchanger and

reducing performance of the purger, it is recommended to

tie the liquid line in from the side or top of the desired liquid

piping. We also recommended connecting the suction line

from the purger to the low side system suction. is will allow

setting of the A2 regulator for optimal performance down to a

minimum of 0.34 barg (5 psig).

3. Weld in the three 1⁄2" SW shut-off isolation valves. Make sure

the connections are free from debris and corrosion. For more

installation instruction on hand shut-off valves, refer to the

RSBHV safety bulletin located in the purger packet.

Before welding the system’s high pressure liquid, foul gas and

suction lines to the hand shut-off valves, they need to be in the

open position. Normally, it is not necessary to disassemble

valves for welding. However, if welding is prolonged enough

to overheat the body, a wet rag should be wrapped around

the valve bonnet and upper body during welding. e codes

applicable to the welding of socket weld valves require that

the pipe be inserted into the socket until bottomed against the

stop. e pipe is then to be backed out approximately 1⁄16 of an

inch before welding.

4. Remove the purger flange connections, with the welded stubs,

from the high pressure liquid, foul gas and suction line. e

anges are highlighted, in gray, in Figure 6.

5. Wait several minutes before welding the purger anges to

the hand shut-o valves. Be certain the mating surface of the

ange is parallel to the mating ange and perpendicular to the

pipe axis. Again, the hand shut-off valves must be in the open

position prior to welding. Check the connections to make sure

they are free from debris.

6. After the shut-o valves and purger anges have been installed

wait several minutes to cool down from the welding process.

e hand shut-o valves must be put in the closed position to

prevent any ammonia from entering the heat exchanger prior

to nishing the installation. If the valves are closed before the

heat dissipates from the welds, the seat can be damaged.

7. Using the same ange nuts and bolts, reconnect the anges

to the purger and tighten them progressively. For more

information on ange torque specication, please reference

the IIAR 2-2008 Section 10 documentation.

8. Purge the water line to remove any contaminants prior to

connecting it to the water feed solenoid, highlighted in gray in

Figure 7. is will prevent the solenoid valve, ow switch and

water lines from becoming plugged. Apply Teon tape/paste to

the 1⁄4" NPT threaded nipple prior to threading it into the water

solenoid.

9. Install a water drain line for the bubbler. e connection for

the drain line is 3⁄4"-14 FPT. Follow your local codes on how to

properly dispose of the water after a purge.

10. Check and verify both oil drain valves, shown in Figure 6, are

closed by removing the seal cap and turning the adjustment

stem clockwise. If the adjustment stem does not move it means

the valve is fully seated. Do not over tighten; it can damage the

seat and be a potential leak point.

11. Open the purger control panel to start wiring the purge points

and power supply, see Figure 8 for wiring diagram. All common

lines should tie together at the DIN rail terminal blocks.

Coil common, shown in Figure 8, on the purge point solenoids

connections are common to the relay. Incoming line power

(120/240 volts) should be supplied to these terminals. An

incoming neutral should be supplied to one of each of the coil