Bulletin 75-00 E / Page 7

Control Features Setup

is includes date, time, purge type

(automatic, manual, etc.), and the

number of purge points being sampled

1. Press and release the “Menu”

button on the keypad. e rapid

purger setup main menu will

appear.

2. When in the main operating

screen press and release the

“Menu” button. Use the Up/

Down arrow buttons to select the

“Setup” option. Press and release

the “Enter” button. Use the Up/

Down arrow keys to select the

“Purge Options” eld. Press and

release the “Enter” button, “Setup

Points” will be highlighted. Press

and release the “Enter” key on the

keypad. Using the Up/ Down arrow

keys, select how many purge points

are being used. When done, press

and release the “Enter” key. Now

we must enter the time (in minutes)

each purge point is sampled. is

setting is less important when the

“Automatic” purge mode is selected.

In this mode, sample times will

change up or down based on vent

cycle history. With the Point and

Duration highlighted (darkened

bar across the eld), press and

release the “Enter” key. An arrow

will appear to the left of the time to

be changed. Using the Up/ Down

arrow keys, select a time from 5 – 20

minutes in 5 minute increments.

Press and release the “Enter” key

when done. Use the Up/ Down

arrow key to select the next point

and duration to be set. Follow the

same procedure for each of the

purge points being used. When

done, press and release the “Menu”

key to return to the purge options

screen.

“Auto” To select “Auto”, press and

release the “Enter key. is is all

that is required to operate in the

“Auto” mode (as dened in this

manual). Press and release the

“Menu” key to return to the main

screen. If you need to terminate

the active point being sampled

and move to the next, press and

release the “Terminate” (TERM)

key. Terminate Active Point (1-20)

should be highlighted. Press and

release the “Enter” key to move to

the next purge point. If you need

to stop all Purging in the “Auto”

mode, select the Terminate Purge

Cycle by using the Up/ Down arrow

keys. Press “Enter” and release to

make your selection. In order to

release the system from Purge Hold,

re-select the “Auto” purge option

again as explained at the beginning

of this step.

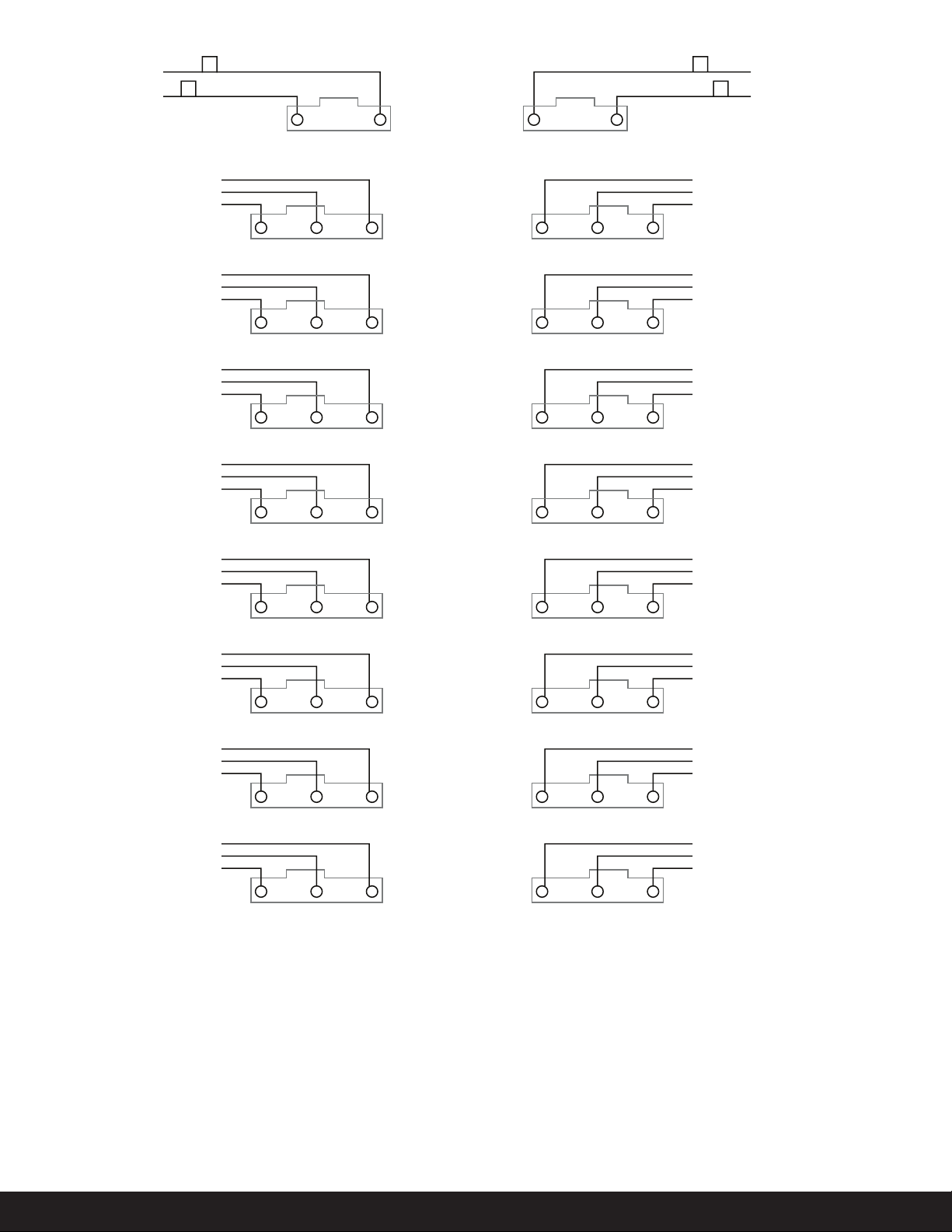

V

LIQUID SOL

SUCTION SOL

SOFT GAS SOL

HOT GAS SOL

EQUALIZE SOL

FAN

MAIN MENU

START UP

SETUP

HISTORY

OTHER SETTINGS

SELECT WITH V PRESS (ENTER)

PRESS (MENU) TO CANCEL

Main Menu Options

Use the Up/ Down arrow buttons to

select the “Setup” option. Press and

release the “Enter” key.

V

LIQUID SOL

SUCTION SOL

SOFT GAS SOL

HOT GAS SOL

EQUALIZE SOL

FAN

SETUP

SET TIME AND DATE

PURGE OPTIONS

CALIBRATE PRESURE INPUT

TRIM TEMPERATURE READING

CHANGE LIQUID FEED SETTINGS

SELECT WITH V PRESS (ENTER)

PRESS (MENU) TO CANCEL

Setup Menu

Press and release the “Enter” key

a second time to enter the current

date. Use the Up/ Down arrow keys

to select the correct month. Press

and release the “Enter” button to

move to the next eld. Repeat these

steps to enter the day and year.

When nished, press, and release

the “Enter” key. Enter the current

day of the week by again using the

Up/ Down arrow keys. Next, enter

the current time using the same set

of key strokes. Don’t forget to select

between AM and PM in this screen.

When you’re done, press the “Enter”

key to return to the main menu.

LIQUID SOL

SUCTION SOL

SOFT GAS SOL

HOT GAS SOL

EQUALIZE SOL

FAN

SET TIME/DAY

WHAT IS THE DAY? TUE

SELECT WITH V PRESS (ENTER)

PRESS (MENU) TO CANCEL

V

Time / Date Setup Screen

LIQUID SOL

SUCTION SOL

SOFT GAS SOL

HOT GAS SOL

EQUALIZE SOL

FAN

PURGEDURATION

01 05 MIN

02 05 MIN

SELECT WITH V PRESS (ENTER)

PRESS (MENU) TO CANCEL

V

Purge Point Duration Setup Screen

3. Use the Up/ Down arrow keys to

select the “Purge Type” option and

press and release the “Enter” key. 3

Purge Options are available to you

in this screen.

LIQUID SOL

SUCTION SOL

SOFT GAS SOL

HOT GAS SOL

EQUALIZE SOL

FAN

PURGE OPTION

AUTO

MANUAL

TIME BASED

SELECT WITH V PRESS (ENTER)

PRESS (MENU) TO CANCEL

V

Purge Option Menu

LIQUID SOL

SUCTION SOL

SOFT GAS SOL

HOT GAS SOL

EQUALIZE SOL

FAN

TERMINATE PURGE

TERMINATE ACTIVE POINT 1

TERMINATE PURGE CYCLE

SELECT WITH V PRESS (ENTER)

PRESS (MENU) TO CANCEL

V

Terminate Purge Menu

“Manual” To select the “Manual”

mode, use the Up/ Down arrow key

to highlight the manual option.

Press and release the “Enter” key

to save your selection. To initiate a

purge cycle in the Manual mode,

press and release the “Initiate”

(INIT) key. Using the Up/ Down

arrow keys, select the point that you

wish to purge. Press the “Enter” key.

e point selected along with the

duration of time this point will be

sampled is shown toward the top of

the display. To terminate a purge in

the manual mode, press and release

the “Terminate” (TERM) key. Using

the Up/ Down arrow key, select