Hardy Instruments A Series Specification sheet

HI 1756-WS & HI 1756-2WS

WEIGH SCALE MODULE

Series A

OPERATION AND INSTALLATION

MANUAL

Corporate Headquarters

9440 Carroll Park Drive, Suite 150

San Diego, CA 92121

Phone: (858) 278-2900

FAX: (858) 278-6700

Web-Site: http://www.hardyinst.com

Hardy Instruments Document Number: 0596-0247-01 Rev K

Copyright November 2000 Hardy Instruments, Inc. All Rights Reserved. Printed in the U.S.A. (941028)

Local Field Service

Hardy has over 200 field technicians in the U.S., and more positioned throughout the

world to assist you in your support needs. We also have factory engineers who will

travel to your facility anywhere in the world to help you solve challenging applica-

tions. We're ready to support you with:

•Installation and start-up

•Routine maintenance and certification

•Plant audits and performance measurement

•Emergency troubleshooting and repair

To request Emergency Service and Troubleshooting, Start-up, Installation, Calibra-

tion, Verification or to discuss a Maintenance Agreement please call 800-821-5831

Ext. 1757 or Emergency Service after hours (Standard Hours 6:00 AM to 6:00 PM

Pacific Standard Time) and weekends Ext. 1111.

Outside the U.S

Hardy Instruments has built a network of support throughout the globe. For specific

field service options available in your area please contact your local sales agent or our

U.S. factory at +1 858-292-2710, Ext. 1757.

Table of Contents

i

Table of Contents

OVERVIEW - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-1

A Brief Description of Chapter 1- - - - - - - - - - - - - - - - - - -1-1

About This Manual - - - - - - - - - - - - - - - - - - - - - - - - -1-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

WAVERSAVER®- - - - - - - - - - - - - - - - - - - - - - - - - -1-3

C2® Calibration - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

IT®- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

Excitation Monitor - - - - - - - - - - - - - - - - - - - - - - -1-3

Digital Volt Meter (DVM) - Optional - - - - - - - - - - - - - - -1-4

Return to Zero Test - Optional - - - - - - - - - - - - - - - - -1-4

Weighing System Tests - Optional - - - - - - - - - - - - - - -1-4

Auto Zero Tracking - - - - - - - - - - - - - - - - - - - - - - - - -1-5

CHAPTER 2 - SPECIFICATIONS- - - - - - - - - - - - - - - - - -2-1

A Brief Description of Chapter 2- - - - - - - - - - - - - - - - - - -2-1

Specifications for a Standard HI 1756-WS (-2WS) Weigh

Scale Module- - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Channels- - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Conversion Rate - - - - - - - - - - - - - - - - - - - - - - - -2-1

Averages- - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Resolution - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Non-Linearity - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

WAVERSAVER®- - - - - - - - - - - - - - - - - - - - - - - -2-1

Excitation Monitor - - - - - - - - - - - - - - - - - - - - - - -2-1

Common-Mode Rejection- - - - - - - - - - - - - - - - - - - -2-1

Common-Mode Voltage Range - - - - - - - - - - - - - - - - -2-2

Backplane Input Voltage - - - - - - - - - - - - - - - - - - - -2-2

Backplane Current Load - - - - - - - - - - - - - - - - - - - -2-2

Backplane Power Load - - - - - - - - - - - - - - - - - - - - -2-2

C2 Calibration Input - - - - - - - - - - - - - - - - - - - - - -2-2

Cable lengths- - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Load Cell Excitation - - - - - - - - - - - - - - - - - - - - - -2-2

C2 Calibration Output- - - - - - - - - - - - - - - - - - - - - -2-2

Environmental Requirements - - - - - - - - - - - - - - - - - - - -2-2

Temperature Coefficient - - - - - - - - - - - - - - - - - - - -2-2

Operating Temperature Range - - - - - - - - - - - - - - - - -2-2

Storage Temperature Range - - - - - - - - - - - - - - - - - -2-2

Humidity Range - - - - - - - - - - - - - - - - - - - - - - - -2-2

Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Digital Voltmeter - - - - - - - - - - - - - - - - - - - - - - - -2-2

HI 1756-WS WEIGH SCALE MODULE

ii

Optional Equipment- - - - - - - - - - - - - - - - - - - - - - - - -2-3

1756 RTA (Remote Termination Assembly - - - - - - - - - - -2-3

RTA Cable Assemblies - - - - - - - - - - - - - - - - - - - - -2-3

HI 215IT Series Junction Box - - - - - - - - - - - - - - - - - -2-3

Default Parameters - - - - - - - - - - - - - - - - - - - - - - - - -2-3

CHAPTER 3 - INSTALLATION - - - - - - - - - - - - - - - - - - -3-1

A Brief Description of Chapter 3- - - - - - - - - - - - - - - - - - -3-1

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-1

Installing the HI 1756-WS (-2WS) into an Allen-Bradley

ControlLogix Processor or Allen-Bradley Remote Rack - - - - - - -3-1

Installing the HI 1756-WS (-2WS) into the ControlLogix Chassis -3-2

Removing the Module from the Chassis - - - - - - - - - - - - - - -3-3

Installing the Module I/O Connector - - - - - - - - - - - - - - - - -3-4

About the Module I/O Connector3-4

Load Cell Wiring Diagrams - - - - - - - - - - - - - - - - - - - - -3-6

Industry Standard Load Cells - - - - - - - - - - - - - - - - - -3-6

Hardy Load Sensor with C2- - - - - - - - - - - - - - - - - - -3-6

HI 1756 Remote Terminal Assembly (HI 1756-XX-RT)- - - - - -3-7

RTA Cable Assembly- - - - - - - - - - - - - - - - - - - -3-8

Hardy HI 215IT Junction Box - - - - - - - - - - - - - - - - - -3-9

CHAPTER 4 - SETUP4-1

A Brief Description of Chapter 4- - - - - - - - - - - - - - - - - - -4-1

Power Check - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-1

LEDS- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-2

Scale Data LEDs - - - - - - - - - - - - - - - - - - - - - -4-2

OK Module Status LED - - - - - - - - - - - - - - - - - - -4-2

Reset Module Message- - - - - - - - - - - - - - - - - - -4-2

Setting Up Communications Between the PLC and the

HI 1756-WS (-2WS) Weigh Scale Module - - - - - - - - - - - - - -4-2

Configuration Parameters for the HI 1765-WS Module- - - - - - - -4-4

Input Data - - - - - - - - - - - - - - - - - - - - - - - - -4-6

STATUSWORD - - - - - - - - - - - - - - - - - - - - - - - -4-6

Parameters for the HI 1756-WS (-2WS) Module - - - - - - - - - - -4-8

Commands- - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-11

Zero Command (ZEROCMD) - - - - - - - - - - - - - - - - - -4-12

Tare Command (TARECMD) - - - - - - - - - - - - - - - - - -4-12

Write Non-Volatile Command (WRITENONVOLATILE) - - - - -4-12

Reload Non-Volatile (RELOADNONVOLATILE) - - - - - - - - -4-13

Enable Calibration Button Command (ENABLEBUTTONCMD)- -4-13

Disable Calibration Button Command (DISABLEBUTTONCMD) -4-13

Set Default Parameters (SETDEFAULTPARAMS)- - - - - - - -4-13

Table of Contents

iii

Cal Low Command (CALLOWCMD) - - - - - - - - - - - - - -4-13

Cal High Command (CALHIGHCMD) - - - - - - - - - - - - - -4-14

C2 Cal Command (C2CALCMD) - - - - - - - - - - - - - - - -4-14

Read Weight Cal Command (READWEIGHTCAL) - - - - - - -4-15

Perform Integrated Technician Tests (WEIGHSYSTEST) - - - -4-15

Structure (ITECHTEST)- - - - - - - - - - - - - - - - - - -4-15

Search for C2 Load Sensors (C2SEARCH) - - - - - - - - - - -4-16

Read C2 Sensor Serial Number (READC2SERIALNUM) - - - -4-17

Read Status of Module (GETSTATUS) - - - - - - - - - - - - -4-18

Write Parameters (WRITEPARAM) - - - - - - - - - - - - - - -4-18

Read Parameters (READPARAM) - - - - - - - - - - - - - - -4-18

Read Live Weight (READLIVEWEIGHT) - - - - - - - - - - - -4-19

Command Table - - - - - - - - - - - - - - - - - - - - - - - -4-19

Output Table - - - - - - - - - - - - - - - - - - - - - - - - - -4-20

Error Code List - - - - - - - - - - - - - - - - - - - - - - - - -4-21

Timed Out Commands - - - - - - - - - - - - - - - - - - - - -4-21

Return Codes - - - - - - - - - - - - - - - - - - - - - - - - -4-21

Calibration Setup Procedures - - - - - - - - - - - - - - - - - - - -4-21

Setting the Unit of Measure - - - - - - - - - - - - - - - - - - -4-21

Setting the Motion Tolerance Value - - - - - - - - - - - - - - -4-22

Setting the Zero Tolerance Value - - - - - - - - - - - - - - - -4-22

Setting the Auto Zero Tolerance Value - - - - - - - - - - - - -4-22

Setting the Number of Readings Averages - - - - - - - - - - -4-22

Setting the Span Weight Value - - - - - - - - - - - - - - - - -4-22

Setting the WAVERSAVER® Value - - - - - - - - - - - - - - -4-22

CHAPTER 5 - CALIBRATION - - - - - - - - - - - - - - - - - - -5-1

A Brief Description of Chapter 5- - - - - - - - - - - - - - - - - - -5-1

Pre-Calibration Procedures - - - - - - - - - - - - - - - - - - - - -5-1

Electrical Check Procedures - - - - - - - - - - - - - - - - - - - -5-2

Load Cell/Point Input/Output Measurements- - - - - - - - - - -5-2

Load Check - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-3

C2 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - -5-4

About C2 Calibration - - - - - - - - - - - - - - - - - - - - - -5-4

“THE BUTTON” C2 Calibration - - - - - - - - - - - - - - - - -5-4

C2 Calibration Using Ladder Logic - - - - - - - - - - - - - - -5-6

Hard Calibration - - - - - - - - - - - - - - - - - - - - - - - - - -5-6

Hard Calibration Procedures - - - - - - - - - - - - - - - - - -5-6

Hard Calibration Ladder Logic Example - - - - - - - - - - - - -5-7

CHAPTER 6 - OPERATING PROCEDURES - - - - - - - - - - - -6-1

A Brief Description of Chapter 6- - - - - - - - - - - - - - - - - - -6-1

Input Data - - - - - - - - - - - - - - - - - - - - - - - - - - -6-1

HI 1756-WS WEIGH SCALE MODULE

iv

CHAPTER 7 - TROUBLESHOOTING- - - - - - - - - - - - - - - -7-1

A Brief Description of Chapter 7- - - - - - - - - - - - - - - - - - -7-1

Scale LED stays off when Performing a C2 Calibration with

The Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-1

Scale LED is Flashing Red - - - - - - - - - - - - - - - - - - - - -7-1

Return Codes- - - - - - - - - - - - - - - - - - - - - - - - - -7-1

Mechanical Inspection - - - - - - - - - - - - - - - - - - - - - - -7-5

Load Sharing and Load Sensor Checkout - - - - - - - - - - - - - -7-6

Guidelines for Instabilities on Formerly Operating Systems - - - - -7-7

Electrical - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-8

Mechanical Stability and Configuration Settings - - - - - - - - - - -7-9

INDEX

GLOSSARY OF TERMS

Table of Illustrations

I

Table of Illustrations

CHAPTER 3 - INSTALLATION - - - - - - - - - - - - - - - - - - -3-1

POSITIONING THE MODULE FOR INSTALLATION - - - - - - - -3-2

MODULE RELEASE(S)- - - - - - - - - - - - - - - - - - - - - - -3-3

MODULE INSTALLED IN CHASSIS- - - - - - - - - - - - - - - - -3-3

HI 1756-WS WITH DOOR OPEN - - - - - - - - - - - - - - - - - -3-5

HI 1756-2WS WITH DOOR OPEN - - - - - - - - - - - - - - - - -3-5

INDUSTRY STANDARD LOAD CELLS WIRING DIAGRAM - - - - -3-6

HARDY LOAD SENSOR/C2 WIRING DIAGRAM - - - - - - - - - -3-6

REMOTE TERMINAL ASSEMBLY - - - - - - - - - - - - - - - - -3-7

RTA WITH JUMPERS FOR LOAD CELLS WITHOUT

SENSE LINES - - - - - - - - - - - - - - - - - - - - - - - - - - -3-7

RTA CABLE ASSEMBLY - HI 1756WS SINGLE CHANNEL - - - - -3-8

RTA CABLE SCHEMATIC - HI 1756WS SINGLE CHANNEL - - - -3-8

RTA CABLE ASSEMBLY - HI 17562WS DUAL CHANNEL - - - - -3-8

RTA CABLE SCHEMATIC - HI 1756-2WS DUAL CHANNEL- - - - -3-9

HARDY HI 215IT JUNCTION BOX WIRING DIAGRAM - - - - - - -3-9

CHAPTER 4 - SETUP - - - - - - - - - - - - - - - - - - - - - - -4-1

MODULE LEDS SINGLE CHANNEL - - - - - - - - - - - - - - - -4-1

MODULE LEDS DUAL CHANNEL‘ - - - - - - - - - - - - - - - - -4-1

COMMUNICATION CONFIGURATION DIALOG BOX- - - - - - - -4-3

DISCRETE DATA - - - - - - - - - - - - - - - - - - - - - - - - -4-7

PARAMETERS DIALOG BOX - - - - - - - - - - - - - - - - - - -4-10

PARAMETERS DIALOG BOX (CONT’D) - - - - - - - - - - - - - -4-10

MESSAGE CONFIGURATION EXAMPLE- - - - - - - - - - - - - -4-11

CHAPTER 5 - CALIBRATION - - - - - - - - - - - - - - - - - - -5-1

PROPERLY INSTALLED LOAD CELL W/NO BINDING - - - - - - -5-2

MILLIVOLTS/WEIGHT SCALE - - - - - - - - - - - - - - - - - - -5-3

“THE BUTTON” C2 CALIBRATION - HI 1756-WS - - - - - - - - - -5-5

“THE BUTTON” C2 CALIBRATION - HI 1756-2WS - - - - - - - - -5-5

CHAPTER 6 - OPERATING PROCEDURES - - - - - - - - - - - -6-1

COMMUNICATION CONFIGURATION DIALOG BOX- - - - - - - -6-1

DISCRETE DATA - - - - - - - - - - - - - - - - - - - - - - - - -6-2

CHAPTER 7 - TROUBLESHOOTING- - - - - - - - - - - - - - - -7-1

COMMAND RETURN PROCESS- - - - - - - - - - - - - - - - - -7-2

COMMAND DEFINITIONS AND ACTIONS - - - - - - - - - - - - -7-3

MECHANICAL INSPECTION - - - - - - - - - - - - - - - - - - - -7-5

LOAD SHARING AND LOAD SENSOR CHECKOUT - - - - - - - -7-6

Chapter 1 - Overview

1-1

CHAPTER 1 - OVERVIEW

A BRIEF

DESCRIPTION OF

CHAPTER 1

This manual is designed for use by installers, opera-

tors, and service personnel. It provides specifications

and procedures for linking, configuring, operating,

maintaining, and troubleshooting the Hardy Instru-

ments HI 1756-WS and HI 1756-2WS ControlLogix®

I/O Weigh Scale Modules.

NOTE: Control/Logix®is a registered trademark of the Rock-

well Corporation.

Both modules come with WAVERSAVER®, C2®but-

ton-triggered calibration, INTEGRATED TECHNICIAN

(IT®) diagnostics, and ladder logic configurability.

NOTE: WAVERSAVER®, C2®, INTEGRATED TECHNICIAN®are

registered trademarks of Hardy Instruments Inc.

Before using the product, be sure you understand all

cautions, warnings, and safety procedures stated or

referenced in this manual. And, to get the best service

from this product, follow the practices recommended

in this manual.

Hardy Instruments appreciates your business. We

welcome all corrections or suggestions for improve-

ment of this manual. Should you not understand any

information in this manual or experience any prob-

lems with the product, please contact our Customer

Support Department at:

Phone: (858) 278-2900

FAX: (858) 278-6700

e-mail: support@hardyinst.com

Web: hardyinst.com

About This Manual Chapter 1 - Introduces the instruments and provides

an overview of the their capabilities

Chapter 2 - Provides a list of specifications

Chapter 3 - Contains instructions needed to install

the HI 1756-WS and HI 1756-2WS (both standard

and optional equipment) and the Remote Termination

Assembly (-RTA)

HI 1756-WS WEIGH SCALE MODULE

1-2

Chapter 4 - Provides hardware configuration instruc-

tions, including dip switch and jumper settings.

Chapter 5 - Provides firmware/software setup proce-

dures needed to operate and calibrate the instrument.

Chapter 6 - Provides calibration instructions.

Chapter 7 - Provides operating procedures.

Chapter 8 - Provides troubleshooting procedures.

Description Both the HI 1756-WS and HI 1756-2WS Weigh Scale

Modules are self-contained, microprocessor-based

ControlLogix I/O modules with control inputs and

outputs that plug into the backplane of an Allen-Brad-

ley ControLogix®programmable controller and/or

Remote Rack. The remote rack module connects to

the local chassis via a ControlNet link.

NOTE: The Allen-Bradley Control/Logix®manuals contain

useful information about their products that is not

provided in this manual. This manual assumes that

users have a basic understanding of process control

and can interpret ladder logic instructions as needed

to generate the electronic signals that control their

application(s).

The HI 1756-WS Weigh Scale Module Series A is

configured for single-channel operation while the HI

1756-2WS Weigh Scale Module Series A is config-

ured for dual-channel operation. Both modules can be

used for a wide variety of process weighing applica-

tions such as batching, blending, filling/dispensing,

check weighing, force measurement, level by weight

and weight rate monitoring.

The analog-to-digital converter in the weigh module

controller updates fifty times per second and is capa-

ble of 8,388,608 counts of display resolution. This is

enough to provide accurate weight measurement and

control and to tolerate large “dead” loads or over siz-

ing of load cells/sensors. To calibrate the module you

can simply push “The Button” to effect a C2 elec-

tronic calibration. C2, Hard (Traditional calibration

with weights) is also available for those not using

Hardy Instruments C2 certified load sensors.

Chapter 1 - Overview

1-3

WAVERSAVER®During the measurement of small weight changes, the

affects of mechanical vibration and noise from the

operating environment can introduce substantial inter-

ference. WAVERSAVER factors out vibration, noise,

and other interference-related signals from the load

cell so the rate controller can better decipher the

actual weight data.

WAVERSAVER®can be configured to ignore noise

with frequencies as low as 0.25 Hz. One of five higher

additional cut off frequencies may be selected to pro-

vide a faster instrument response time. The default

factory configuration is 1.00 Hz vibration frequency

immunity.

C2®Calibration Traditional calibration uses certified test weights.

C2® Electronic Calibration allows a scale to be cali-

brated without the need for test weights. It can be ini-

tiated by pressing “THE BUTTON®” located in the

front of the module, or via ladder logic.

A C2 weighing system consists of up to eight C2 load

sensors, a junction box, interconnect cable, and an

instrument with C2 capabilities (e.g., the HI 1756).

Each Hardy Instruments C2-certified load sensor out-

puts digital information used for the calibration. The

modules reads the sensor outputs and detects the num-

ber of active sensors. It then calibrates the scale based

on the load sensor’s output plus a user-supplied refer-

ence point value (from 0 to any known weight on the

scale).

IT® INTEGRATED TECHNICIAN™is a system diagnostics

utility which, in conjunction with an HI 215IT series

IT junction box, continuously monitors the excitation

circuit (with up to 4 load sensors) for possible mal-

functions. IT reads individual load sensor voltages

and weights and isolates individual system compo-

nents for quick and easy troubleshooting.

Excitation Monitor Continuously monitors a system’s excitation current

to check for open or shorted load sensors or damaged

or broken excitation wire(s), including the wires

HI 1756-WS WEIGH SCALE MODULE

1-4

between the module, Remote Terminal Assembly

(RTA) and the IT®Junction box. If the measured cur-

rent deviates more than a ± 10% tolerance, an “Exci-

tation Error” bit (Module Status Word bit 9) is set to

1.

Digital Volt Meter

(DVM) - Optional Requires the HI 215IT Series Junction Box to monitor

both mV and mV/V readings for the system and per

individual load sensor. Once a problem is detected by

the operator the DVM readings help the operator to

isolate the faulty component. Further, the DVM read-

ings can be used to level a system and to make corner

adjustments to platform scales. Accuracy is +/- 2% or

better of full scale.

NOTE: If you do not have the HI 215IT Junction Box con-

nected to the module, the mV/V reading as displayed

is the total for all the load cells on the system.

Return to Zero

Test - Optional Requires the HI 215IT Series Junction Box to monitor

individual load sensors. This test compares the origi-

nal voltage reading (saved at calibration) against the

current voltage reading of an empty vessel. The test

checks for damaged load sensorsdue to electrical zero

shift or abnormal mechanical forces that cause bind-

ing on one or all of the load sensors in the system.

Weighing System

Tests - Optional Requires the HI 215IT Series Junction Box for full

utilization. This test is used to diagnose drifting or

unstable weight reading problems. The Weighing Sys-

tem Test does the following:

1. Disconnects the controller and engages an inter-

nal reference signal to see if the problem is within

the instrument.

2. Disconnects the load sensors and engages an

internal (in the junction box) reference signal to

see if the cable between the instrument and the

Junction Box is causing the problem.

3. Reads the weight of each load sensor to see if the

load sensor might be causing the problem.

Chapter 1 - Overview

1-5

The ability to read the weight seen by each individual

load sensor allows use of this test to make cornering,

leveling and load sharing adjustments to the weighing

system.

AUTO ZERO

TRACKING Auto Zero Tracking automatically adjusts for zero

weight. This capability allows the module to ignore

material build-up in the weighing system within a pre-

set auto zero tolerance. For auto zeroing to work cor-

rectly, any “live weight” plus any weight previously

zeroed on the scale must be below the set Auto Zero

Tolerance value and the scale must not be in motion.

This is not used on all applications and should be

reviewed before use.

NOTE: The amount of weight zeroed off is cumulative. The

Autozero command will fail if the current gross weight

plus any previously zeroed amount exceeds the zero

tolerance value.

HI 1756-WS WEIGH SCALE MODULE

1-6

Chapter 2 - Specifications

2-1

CHAPTER 2 - SPECIFICATIONS

A Brief Description of

Chapter 2 Chapter 2 lists the specifications for the HI 1756-WS

and HI 1756-2WS Weigh Scale Modules. Specifica-

tions are listed for the standard instrument and for

optional equipment. The specifications listed are

designed to assist in the installation, operation and

troubleshooting of the instrument. All service person-

nel should be familiar with this section before

attempting an installation or repair of this instrument.

Specifications for a

Standard HI 1756-WS

(-2WS) Weigh Scale

Module

Channels 2 Channels

• Single Channel HI 1756-WS

• Dual Channel HI 1756-2WS

Conversion Rate 50 updates per second

Averages 1-255 User Selectable in single increments

Resolution Internal: 1:8,388,608

Input Up to eight (8) 350 ohm Full Wheatstone Bridge,

Strain Gauge Load Sensors/Cells (5 volt excitation)

on one vessel.

Non-Linearity 0.0015% of Full Scale

WAVERSAVER®User Selectable

• 7.50 Hz

• 3.50 Hz

• 1.00 Hz (Default)

• 0.50 Hz

• 0.25 Hz

Excitation Monitor Current less than +/- 10% expected

Common-Mode

Rejection 110dB at or below 60 Hz

HI 1756-WS WEIGH SCALE MODULE

2-2

Common-Mode

Voltage Range 2.5VDC maximum (with respect to earth ground)

Backplane Input

Voltage 5 VDC and 24 VDC

Backplane Current

Load <1 Amp at 5 VDC

0.0125 Amps at 24 VDC (with 4-350 Ohm Load Cells

Backplane Power

Load < 5W at 5 VDC

< .3W at 24 VDC with 4-350 Ohm Load Cells

C2 Calibration

Input Isolation from digital section 1000 VDC minimum.

Cable lengths 1000 feet maximum of C2 authorized cable

250 feet maximum of C2 authorized cable (Maximum

of 4 load sensors) with IT Junction box.

Load Cell

Excitation 5 VDC +/- 1.15 W maximum.

Isolation from digital section 1000 VDC minimum

C2 Calibration

Output Isolation from digital section 1000 VDC minimum

Environmental

Requirements

Temperature

Coefficient Less than 0.005% of full scale per degree C for Cal-

LO and Cal-HI reference points

Operating

Temperature

Range

0oC to 60oC (32oF to 140oF)

Storage

Temperature

Range

-40oC to 85oC (-40oF to 185oF)

Humidity Range 0-90% (non-condensing)

Approvals CE Approval

UL, CUL (pending)

Digital Voltmeter Accuracy +/- 2% of full scale

Resolution

Chapter 2 - Specifications

2-3

• mV/V 4 digits to the right of the decimal

Optional Equipment

1756 RTA (Remote

Termination

Assembly

Hardy Part # -RTA (HI-1756-XX-RTA if ordered sep-

arately) Remote Termination supports two (2) sepa-

rate HI 1756-WS weigh scale modules or one (1) HI

1756-2WS weigh scale module. Unit includes DIN

rail mounting for 35mm x 15mm DIN rail.

RTA Cable

Assemblies Hardy Part # -C6 (HI 1756-XX-C6)

• Cable Length: 6 ft. (1.525 meters) from

the single channel module to the RTA.

Hardy Part # -C6 (HI 1756-XX-DC6)

• Cable Length: 6 ft. (1.525 meters) from

the dual channel module to the RTA.

HI 215IT Series

Junction Box NEMA rated waterproof enclosure which sums from

one to four load sensors load sensors.

• -PS1 NEMA 4 Painted Steel

• -SS1 NEMA 4X Stainless Steel

• -FG1 NEMA 4X Fiberglass

Default Parameters

Parameter Default Setting

ChanActive 1On

calyear*

calmonth*

calday*

calid[2]*

Calib Type

tareweight 0.0 lbs

Table 2-1: Default Parameters

HI 1756-WS WEIGH SCALE MODULE

2-4

NOTE: * The HI 1756 modules do not have a real time clock,

so the year; month; day and calid must be set by the

operator.

Metric lbs 0

WAVERSAVER®1 Hz 3

SpanWeight 10,000.00

CalLowWeight lbs 0

Num Averages 10

ZeroTrackEnable False 0

ROCTimeBase 10

ZeroTolerance 10

AutoZeroTolerance 10.0 lbs

MotionTolerance 5.0 lbs

Parameter Default Setting

Table 2-1: Default Parameters

Chapter 3 - Installation

3-1

CHAPTER 3 - INSTALLATION

A Brief Description of

Chapter 3 Chapter 3 provides the recommended procedures for

unpacking, cabling, interconnecting, configuring and

installing the Weigh Scale Module. Users and service

personnel should be familiar with this information

before installing or operating the Weigh Scale mod-

ule. If you experience any problems installing this

equipment, contact Hardy Instruments Inc., Customer

Support for assistance.

Unpacking Step 1. Before signing the packing slip, inspect

the packing for damage of any kind, and

report any damage to the carrier company

immediately.

Step 2. Check to see that everything in the pack-

age matches the bill of lading. You should

normally have:

• HI 1756-WS or HI 1756-2WS Weigh

Scale Module

• Operation and Installation Manual

Step 3. Write down the Model and Serial number

of the module. You may need this informa-

tion when contacting The Customer Sup-

port Department for parts or service.

Installing the

HI 1756-WS (-2WS)

into an Allen-Bradley

ControlLogix

Processor or Allen-

Bradley Remote Rack

WARNING ELECTROSTATIC DISCHARGE MAY DAM-

AGE SEMICONDUCTOR COMPONENTS IN

THE MODULE. DO NOT TOUCH THE CON-

NECTOR PINS.

Observe the following handling precautions:

• Wear an approved wrist-strap ground-

ing device when handling the module.

HI 1756-WS WEIGH SCALE MODULE

3-2

• Touch a grounded object or surface to

rid yourself of any electrostatic dis-

charged prior to handling the module.

• Handle the module from the bezel in

front away from the connector. Never

touch the connector pins.

• Do not install the module right next to

an AC or high voltage DC module.

• Route all the load voltage cables

away from high voltage cables.

Installing the

HI 1756-

WS (-

2WS)

into the

ControlL

ogix

Chassis

Step 1. Make sure that the module is oriented cor-

rectly for installation. (See Fig. 3-1)

FIG. 3-1 POSITIONING THE MODULE FOR

INSTALLATION

Step 2. Gently slide the module into the Chassis.

Step 3. Slide the digital board between the PCB

Guides on the top plate and bottom plate

of the chassis to line up the module con-

nector with the backplane connector.

Step 4. When the module connector is touching

the backplane connector, firmly but care-

fully push toward the chassis until the pins

are plugged in and the Processor Releases

(both top and bottom) are snapped into

place. (See Fig. 3-2 & 3-3)

This manual suits for next models

2

Table of contents

Popular Control Unit manuals by other brands

Homelife

Homelife CT2 24 UNI DL Instructions and warnings for installation, use and maintenance

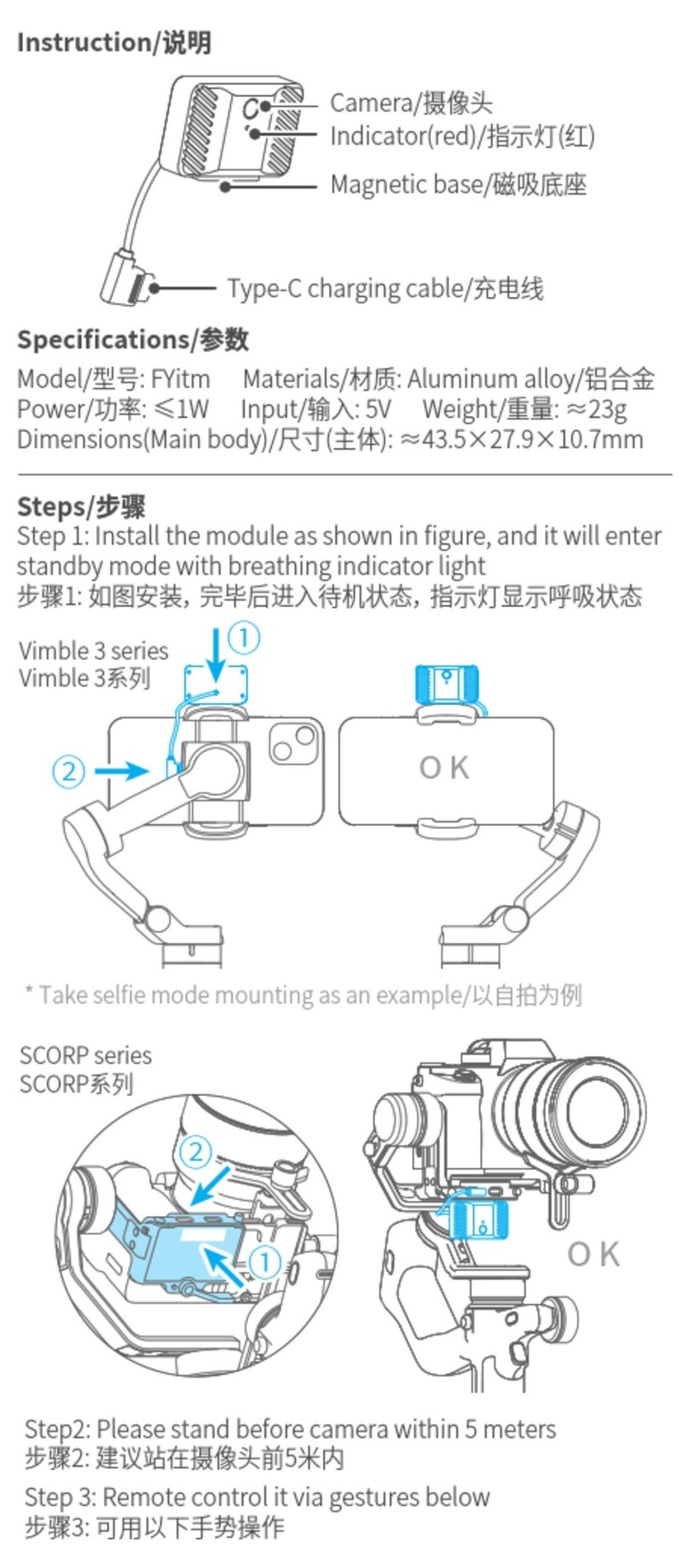

FeiYu Tech

FeiYu Tech FYitm instructions

Paradox

Paradox PCS265 Installation and programming guide

Krom Schroder

Krom Schroder DG 17VC operating instructions

Exor

Exor CDW10U2UL installation instructions

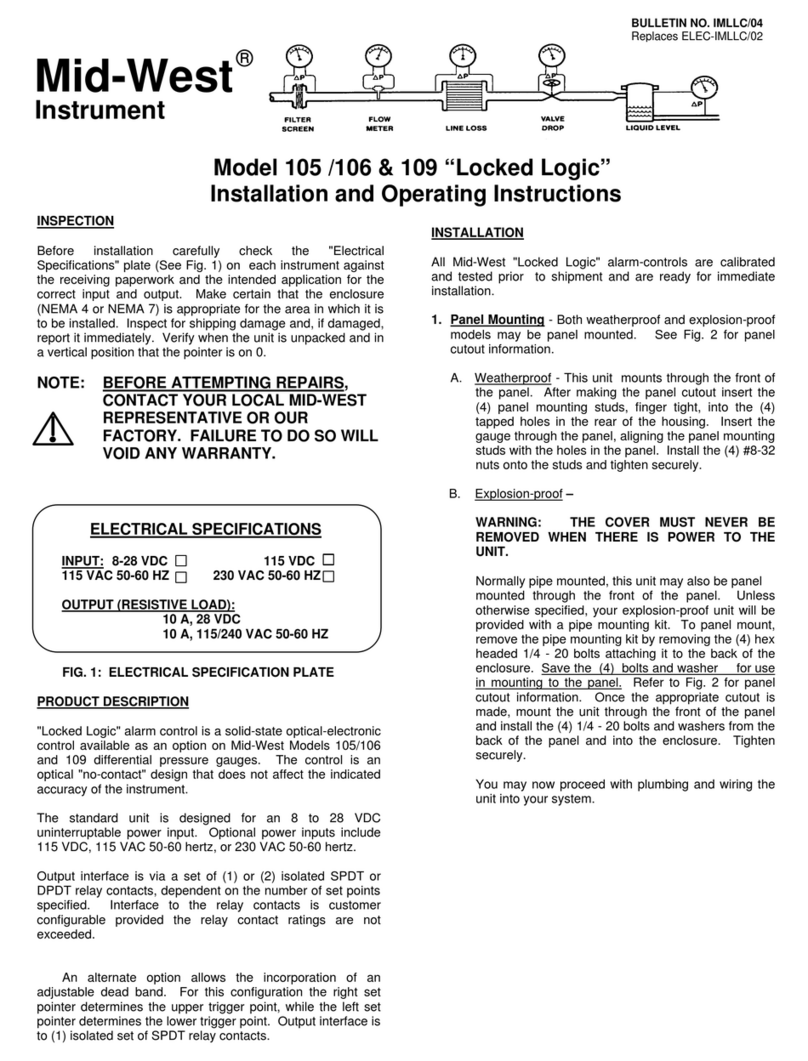

Midwest

Midwest 105 Locked Logic Installation and operating instructions