© 2022 WEINZIERL ENGINEERING GmbH Seite 2/30

Content

1Application .........................................................................................................................3

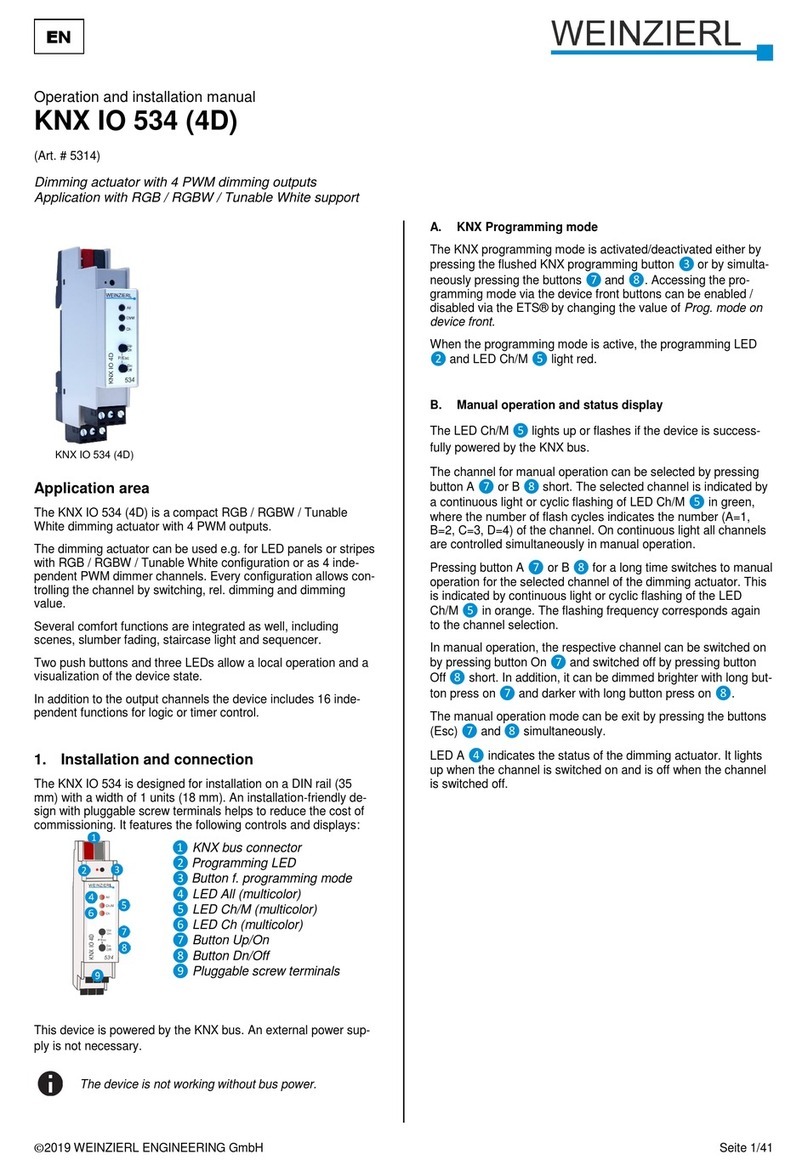

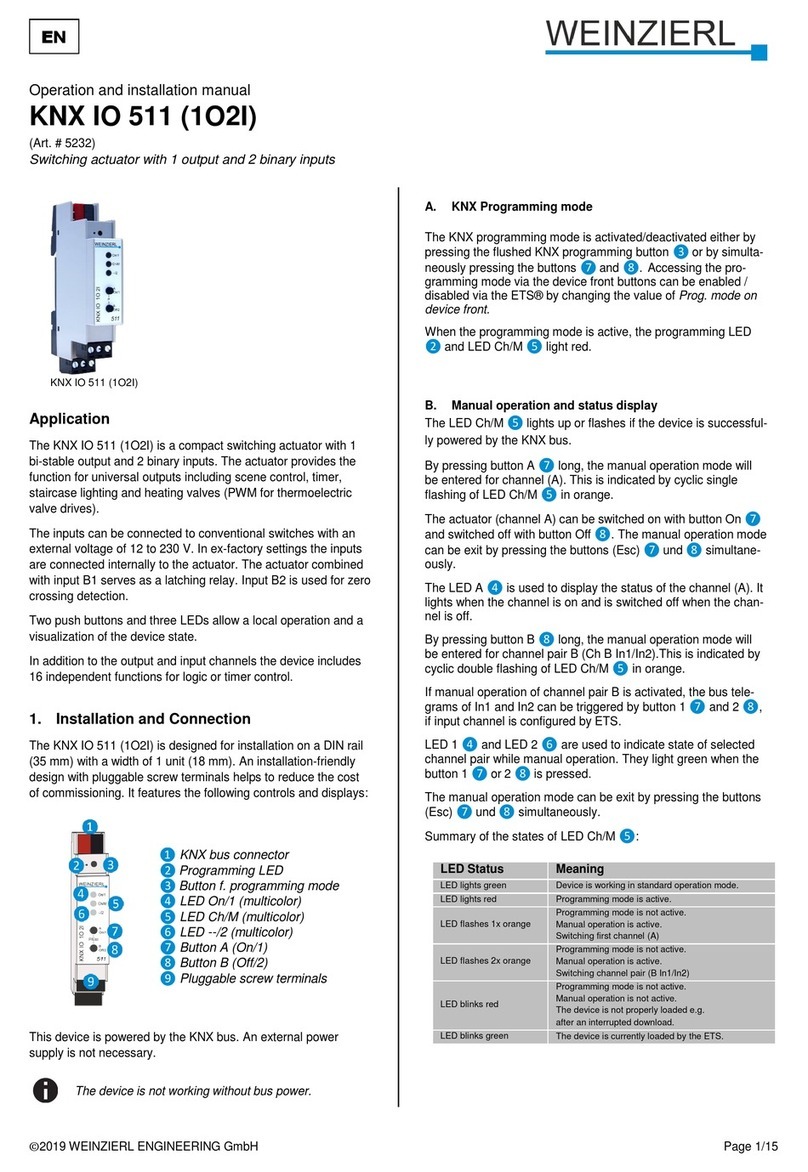

2Installation and connection...............................................................................................3

2.1 KNX programming mode......................................................................................................4

2.2 Manual operation and status display....................................................................................4

3Reset to factory default settings.......................................................................................5

4Wiring scheme ...................................................................................................................5

4.1 Pluggable screw terminals ...................................................................................................5

4.2 Pin assignment ....................................................................................................................6

5KNX Security......................................................................................................................7

6ETS database .....................................................................................................................8

6.1 Secure commissioning.........................................................................................................8

6.2 Secure group communication............................................................................................. 10

6.3 Description.........................................................................................................................12

6.4 General settings.................................................................................................................12

6.5 Actuator A / B: General......................................................................................................14

6.6 Actuator A / B: Lock function..............................................................................................17

6.7 Actuator A / B: Universal output.........................................................................................19

6.8 Actuator A / B: Scene function ...........................................................................................19

6.9 Actuator A / B: On/Off delay...............................................................................................20

6.10 Actuator A / B: Staircase function.......................................................................................21

6.11 Actuator A / B: Valve actuator (PWM for thermal servo).....................................................22

6.12 Logic / Timing.....................................................................................................................25

6.13 Function 1 –16: Timer.......................................................................................................26

6.14 Function 1 –16: Logic........................................................................................................28