Field of Application

Before using the HarkenNinjaMultiAscend, read the instructions contained

in this manual thoroughly. This instruction manual is an integral part of the

product, and it supplies information for its correct safe use and maintenance.

If you do not understand any of the instructions, please contact Harken’s

authorizeddealer. Harken shall not be liable for damages, injuries, or

death caused by usage not covered in this manual or any non‑compliant or

unsafeactions.

This manual is intended for specialized personnel or expertusers.

Safety Information

General advice

Progress capture device for ascending rope, and short distance

ropedescents.

Intended use

• As a typeB rope adjustment

device compliant to the European

StandardEN12841:2006 (fully

rated and lockingchestascender)

up to a maximum ratedload of

140kg, that is a manuallyoperated

device which, when attached to

a workingline, locks under load

in one direction and slides freely

in the opposite direction, to be

used on ropeaccess systems and

relatedactivities.

• This product can be used for

haulingsystems: this use is to be

considered outside the scopes of

the Regulation2016/425.

• This product should only be

used by one person at a time;

this equipment should be a

personalissueitem.

• This product is intended to prevent

the risk of falls from a height during

acceptableactivities.

• As a rope clamp compliant to the

EuropeanStandard EN567:2013

to be used on mountaineering

and related activities, that is

a mechanicaldevice which, if

attached to a rope or an accessory

cord of appropriate diameter,

will clamp under load in one

direction and move freely in the

oppositedirection.

Improper use

• Do not use with wirerope.

• Do not use as a fallarrest device.

• Do not use this product outside

of its limitations, or for any other

purpose than that for which it is

intended.

• Do not alter, tamper, or add

to this equipment without the

manufacturer’s prior written

consent. Any repair shall only be

carried out in accordance with the

manufacturer’sprocedures.

• Do not use this rope clamp in

weather or environmentalextremes.

Personal protective equipment

• Harness, gloves, and helmet

that meet national and/

or localrequirements are

recommended.

• Follow your national and/or

local regulatory requirements

for Personal Protective

Equipment(PPE).

Risks

• This equipment shall only be used

by a person trained and competent

in its safeuse.

• Activities involving the use of the

NinjaMultiAscend are inherently

dangerous. You are responsible for

your own actions and decisions.

• Read and understand all

instructions before use

• Get specic training on the

NinjaMultiAscend’s properuse.

• Become acquainted with

MultiAscend’s capabilities

andlimitations.

• Understand and accept the risks

involved.

• Users must be medically t for

all activities the MultiAscend is

involved in. Users must be capable

of controlling their own safety in any

emergencysituation.

• Failure to heed any of these

warnings could result in severe

injury ordeath.

• Overloading or dynamic load on the

NinjaMultiAscend may damage the

anchorrope.

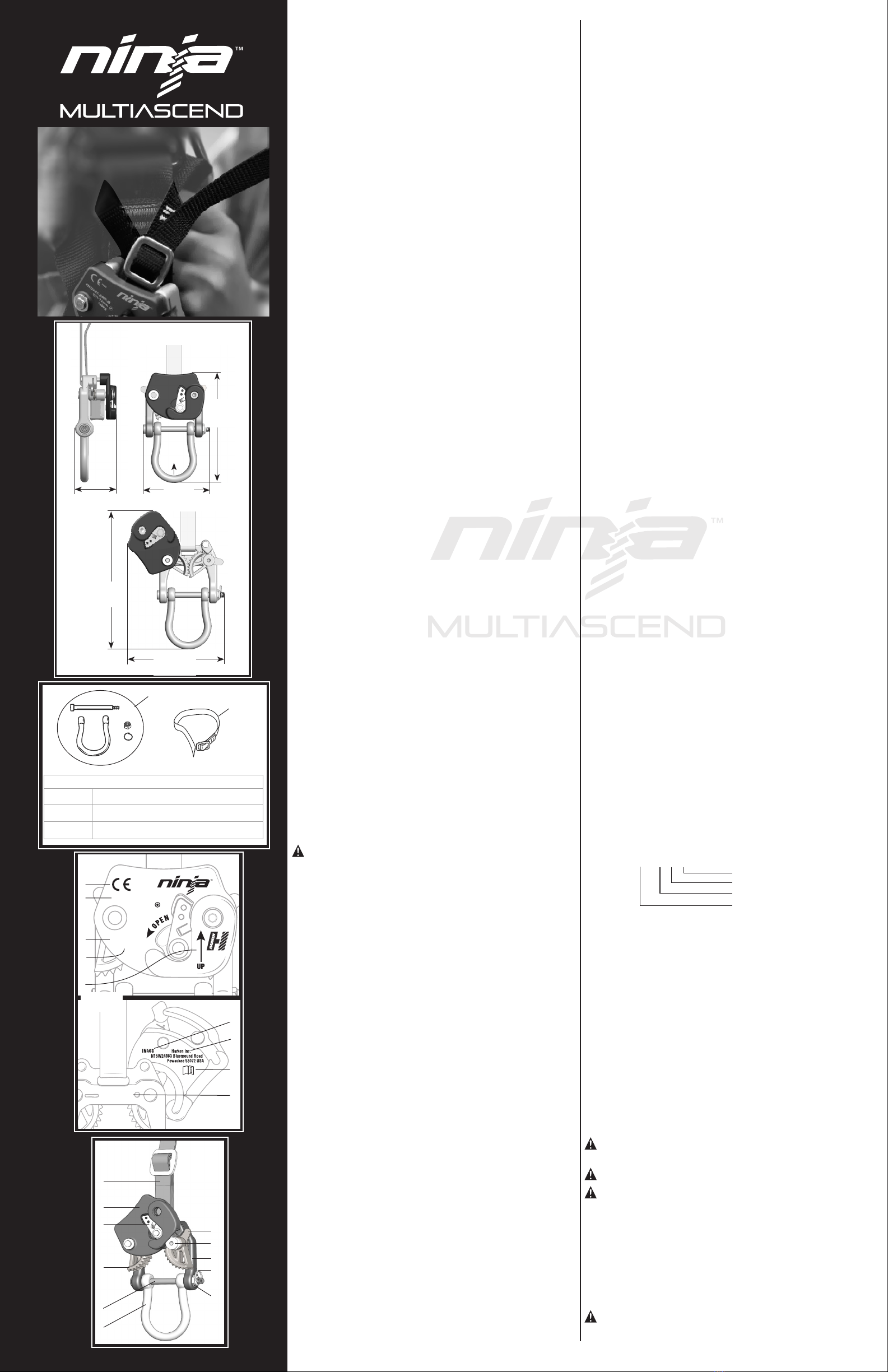

• Verify that the product markings are

legible. Fig 4

WARNINGS

Do not use as a fall arrest device.

Anchor ropes should be attached to the anchor above the user.

Slack between the anchor and the user should be avoided.

Any loading above the published recommendations or dynamic

loading on the MultiAscend may damage both the rope and the

device. Stay within the limitations of the specifications and

lengths documented.

Only competent personnel trained to use this equipment safely

may use it.

Be aware of any dangers that may occur due to the use of

combined items, in which the safe function of any one item is

affected by, or interferes with, the safe function of another.

Do not trail or loop this product over sharp edges. Trailing or

looping safety equipment in such a way may result in death

or injuries.

Do not make any alteration or additions to the equipment

without Harken’s prior written consent. All repairs should only

be carried out according to Harken procedures.

If the product is sold outside of its original country of

destination, the reseller must provide instructions for the

following: use, maintenance, periodic examination, and repair,

in the language of the country where the product is to be used.

Product descriptions/components

Materials: The product is made of aluminum body andswing plate; stainless

steel hardware, pawls, and harness connection; nylonwebbing for the strap;

stainless steel for the metal components of the strap.

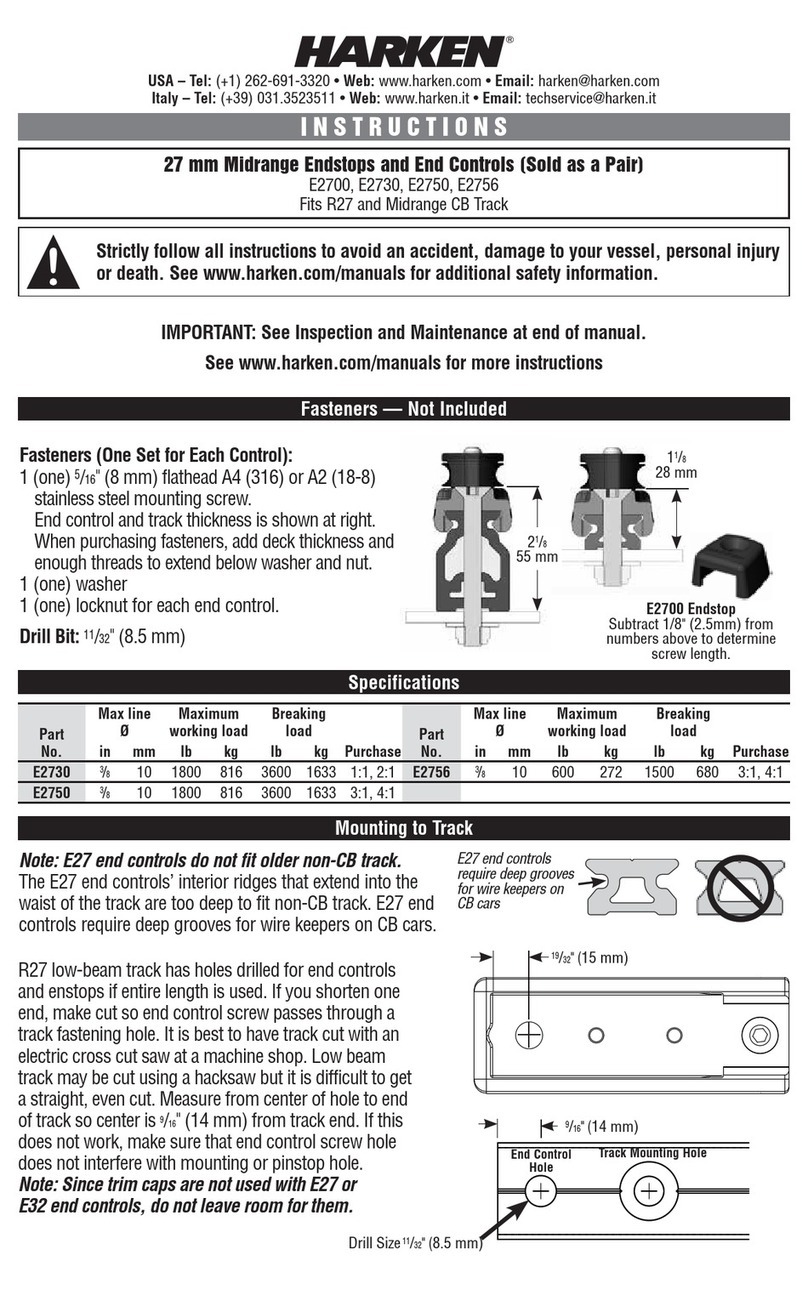

Dimensions - Fig 2

Fig 1

YYYYDDD-XXXX

6

7

8

9

2008

EN12841: 2006-B

Ø11 -13 mm

140kg

EN567: 2013

Ø9 -13mm

1

4

5

2

3

Fig 4

Nomenclature of parts - Fig 5

A. Top adjustment strap

B. Swing plate

C. Latch

D. Pawls

E. Capscrew

F. Bottom saddle bracket

G. Pawl triggers

H. M4 Tapped hole*

I. Body

J. Cotter ring

K. Nylon insert locknut

*for optional locking fastener

swingplate

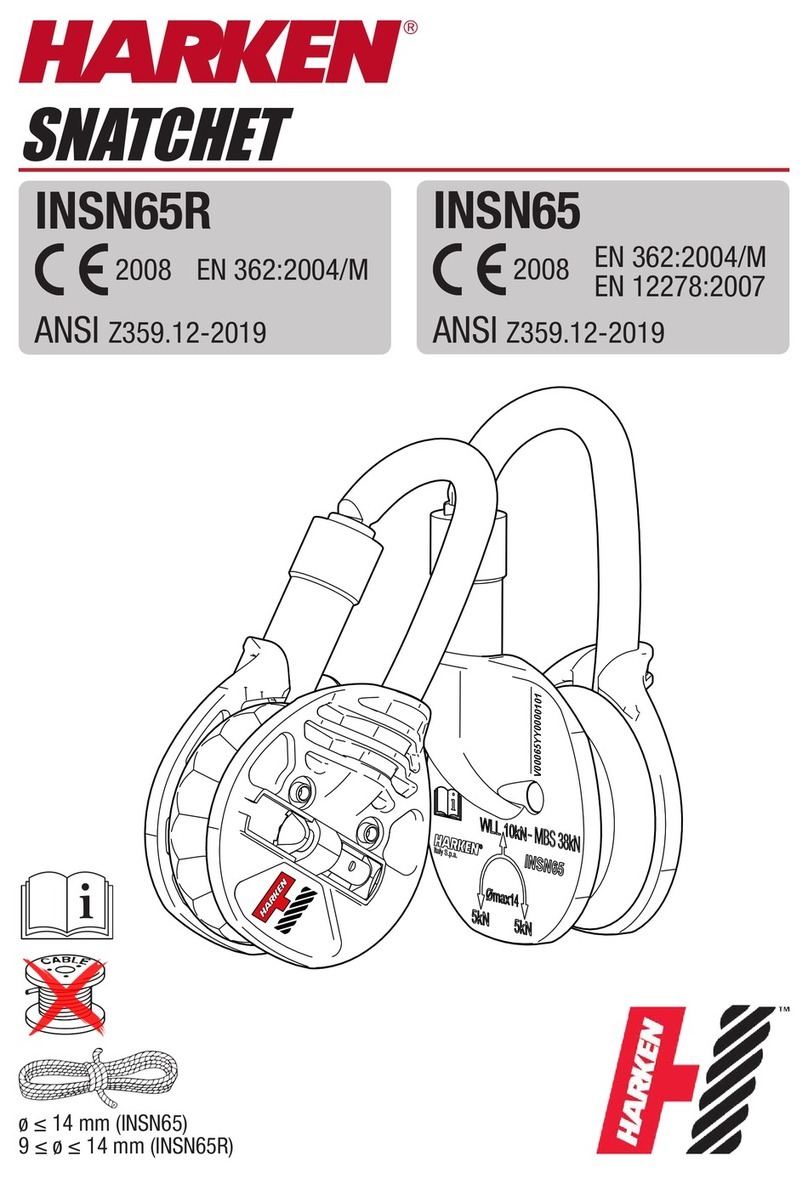

Certifications

The MultiAscend device complies with regulation (EU)2016/425 relating

toPPE.

EN567:2013 ‑ 9–13mm rope

Tested for certication purposes with the following models ofrope:

Tendon Canyon Dry Ø9mm

Bluewater Protac Ø9mm

Tendon Static Ø9mm

Teufelberger KMIII Ø9mm and Ø13mm

EN12841.2006 B ‑ Ø: 11–13mm, maximumrated load:140kg

Tested for certication purposes with the following models of rope (both

lowstretch kernmantel ropes according to EN1891, typeA):

Beal Access Ø11mm

Teufelberger KMIII Ø13mm

Note: This product has been approved for the use under the following

specic conditions, as indicated in the standard EN12841:2006: heat, cold,

wet, andoil.

Note: When the adjustable anchor line is loaded by the full weight of the

user this becomes a working line and an independently anchored safety line

should be used in addition for optimum safetyoftheuser.

Note: The primary function of TypeB rope adjustment devices is progression

along the working line, and they shall always be used in conjunction with,

and connected to, a TypeA rope adjustment when used in accordance with

EN12841:2006.

Note: When used as a rope adjustment device compliant with EN12841,

only low stretch TypeA kernmantle ropes compliant with EN1891 shall be

used. When used as a rope clamp compliant with EN567:2013, the device

can be used with any of the following options:

• Dynamic mountaineering ropes compliant to EN892

• Accessory cords compliant to EN564

• Low stretch kernmantle ropes compliant with EN1891

Note: The harness must be compliant with EN813 or EN12277.

Note: It is recommended to use this device only in conjunction with

CE‑markedPPE for compliance with2016/425.

The EU examination certicate and production control phase were carried

out by DolomiticertS.C.A.R.L. EUNotiedBody (N.B.2008, Villanova Zona

Industriale7/A, 32013Lonarone(BL)— Italy‑Tel.+390437573407).

The EUDeclaration of Conformity can be downloaded from the website

www.harken.com.

This manual can be changed without notice.

Consult the website for updated versions or other languages not in

thismanual.

Product labeling Fig 4

1. CE mark and number of the

notied body involved in the

control of the production

2. Certication information regarding

EN12841:2006

3. Certication information regarding

EN567:2013

4. Latch open direction

5. Correct loading direction

6. Manufacturer’s part number

7. Name and address of

manufacturer

8. Read the manual

9. Serial number of device

Unit Serial Number

Control

Day of Manufacture

Year of Manufacture

The Serialnumber is in the format YYYYDDD‑XXXX. Thisformat represents

the following: 4‑digityear, 3‑digitday (Julian calendar count), and a 4‑digit

individual identier. For example, in the Juliancalendar, the number234

represents August22.

Use

Connection to the harness: Connect the bottom saddlebracket to

an approved, rated, full‑strength point on the harness’ ventral (frontal)

attachmentFig 15. The MultiAscend is considered a full point of attachment

when properly connected to a full bodyharness:

1. Loop bottom saddle bracket

through harness.Fig 11

andFig 12

2. Screw in capscrew until lock

nut is tight. Capscrew andnut

should turn together free from

base.Fig 13

3. Loop cotterring in hole of

capscrew.

4. Connect upper webbingstrap

to sternal D‑ringconnection of

harness to hold up when not in

use.Fig 14

WARNING! Not all harnesses are compatible with this chest

ascender. Consult manufacturer for recommendations.

WARNING! Only use lock nut once, then replace.

WARNING! When using the MultiAscend as a chest ascender,

never connect the chest ascender to the harness attachment

point via an additional component (e.g., a connector or a

lanyard). Always connect the saddle bracket directly to the

harness attachment point.

Top adjustment strap

Attach as an alignment support per harness instructions. See Fig 1 diagram

of strap reeving. Ensure that the top adjustment strap cannot get caught in

thepawls.

WARNING! Strap not for load bearing, only for

alignment purposes

B

C

D

I

A

G

H

E

F

J

K

Fig 5

Harken Inc., USA - One Harken Way, N15W24983 Bluemound Rd., Pewaukee, WI 53072, USA M1033 10/23 Made in USA Printed in USA

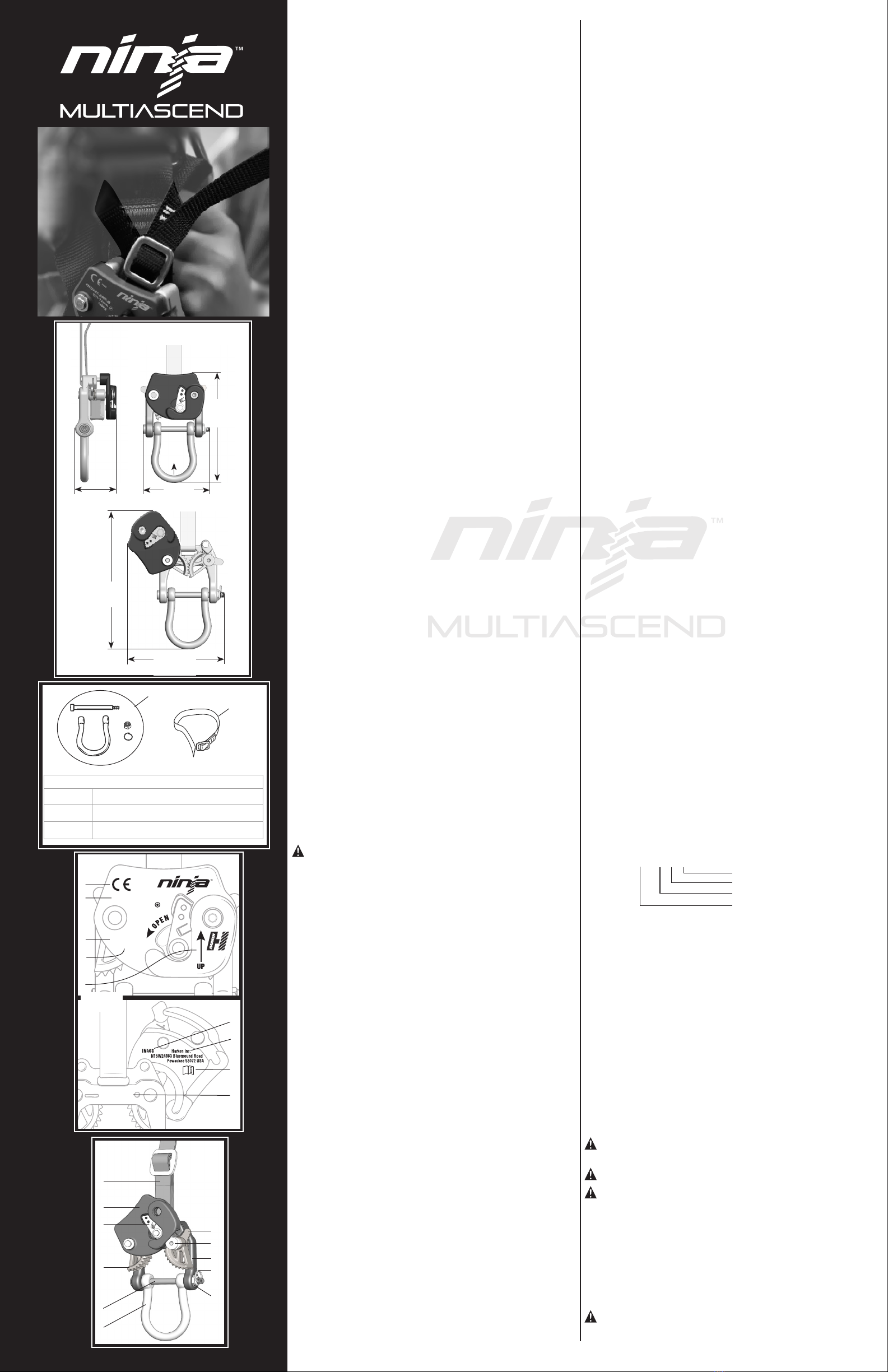

Replacement parts

Part no. Description

IN909 Pin, bottom saddle bracket, lock nut and cotter ring

IN910 Webbing strap replacement

IN909

IN910

Fig 3

40 mm

1.59"

120 mm

4.74"

DirectionDirection

ofof

TravelTravel

73 mm

2.87"

148 mm

5.84"

108 mm

4.25"

Fig 2