8 ENGLISH 16/01/2020

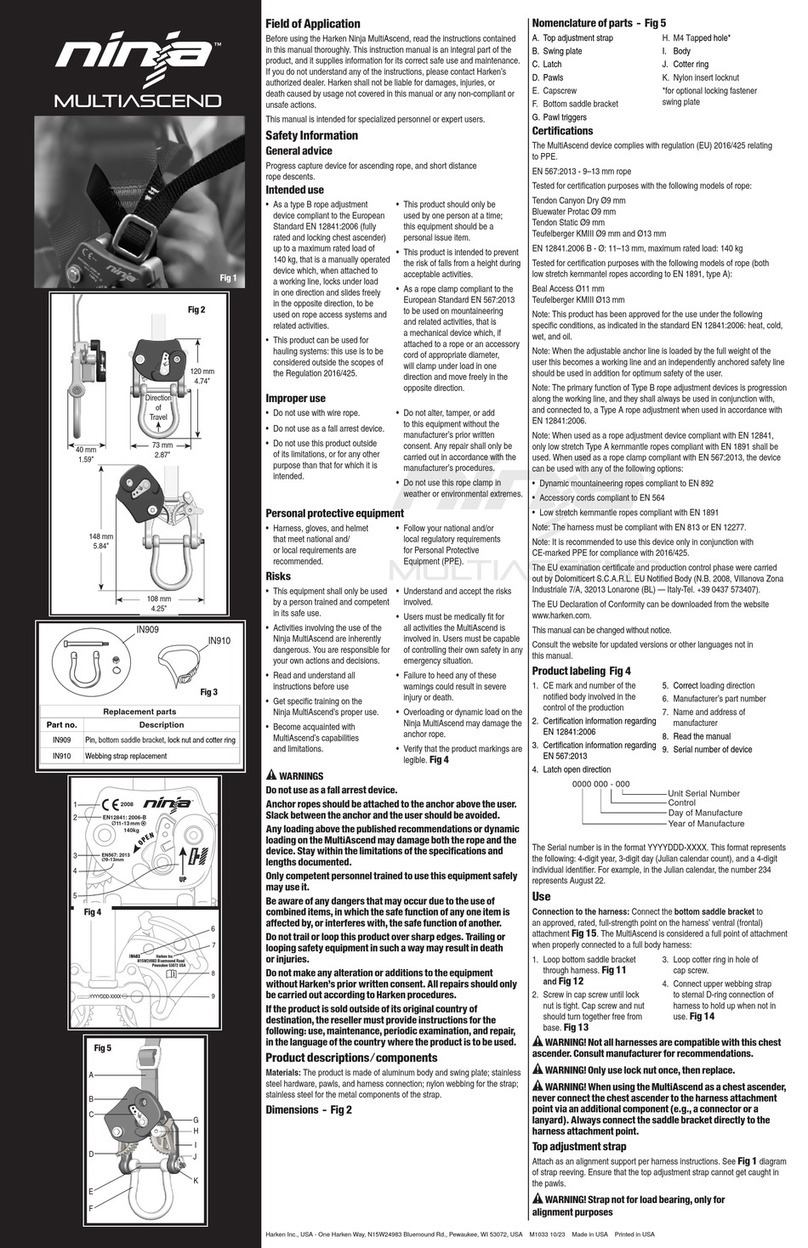

FEATURES OF THE ANCHORING DEVICES AND BRACKET ASSEMBLY

The materials and minimum thicknesses required according to the type of roof on which the anchoring

devices in the INBRKT.XNrange are installed are given below. The following table refers to the roof profile, on

which fixings must be done exclusively using the rivets supplied by HARKEN.

FEATURES

STEEL SANDWICH PANELS MINIMUM THICKNESS 0.4 mm

ALUMINIUM SANDWICH PANELS MINIMUM THICKNESS 0.6 mm

STEEL SHEET MINIMUM THICKNESS 0.6 mm

The INBRKT.XNbrackets are supplied with rivets and standard fixing feet and relative fixing bolts.

Using:

• standard fixing feet,

• the fixing bolts between these and the other components of the device,

• the rivets supplied by HARKEN,

on corrugated sheet and sandwich panels of suitable thicknesses, for which fixing between the anchoring

device and the corrugated sheet and sandwich panel is suitable.

Check the seal between the sandwich panel or corrugated sheet and the underlying structure, as well as the

ability of the latter to resist the forces transmitted by the anchoring system.

The system has been tested in compliance to:

- UNI 11578:2015 type D for use by 4 operators at the same time

- EN 795:2012 type D

- CEN/TS 16415:2013 type D for use by 4 operators at the same time.

For some corrugated sheet the standard fixing feet shape may not be suitable. In these cases it is possible to

design and use non-standard support bases/fixing feet: these must be sized by the designer qualified for

structural calculations as they are a part of the anchoring device fixing system. The project also includes the

calculation of the fixing sizes: the type of rivet/screw, their number and arrangement (in this case there is no

obligation to use rivets supplied by HARKEN as the sizing is done by an external designer).

The situation described below refers to the field tests for connection between sandwich panel/corrugated

sheet and the underlying structure.

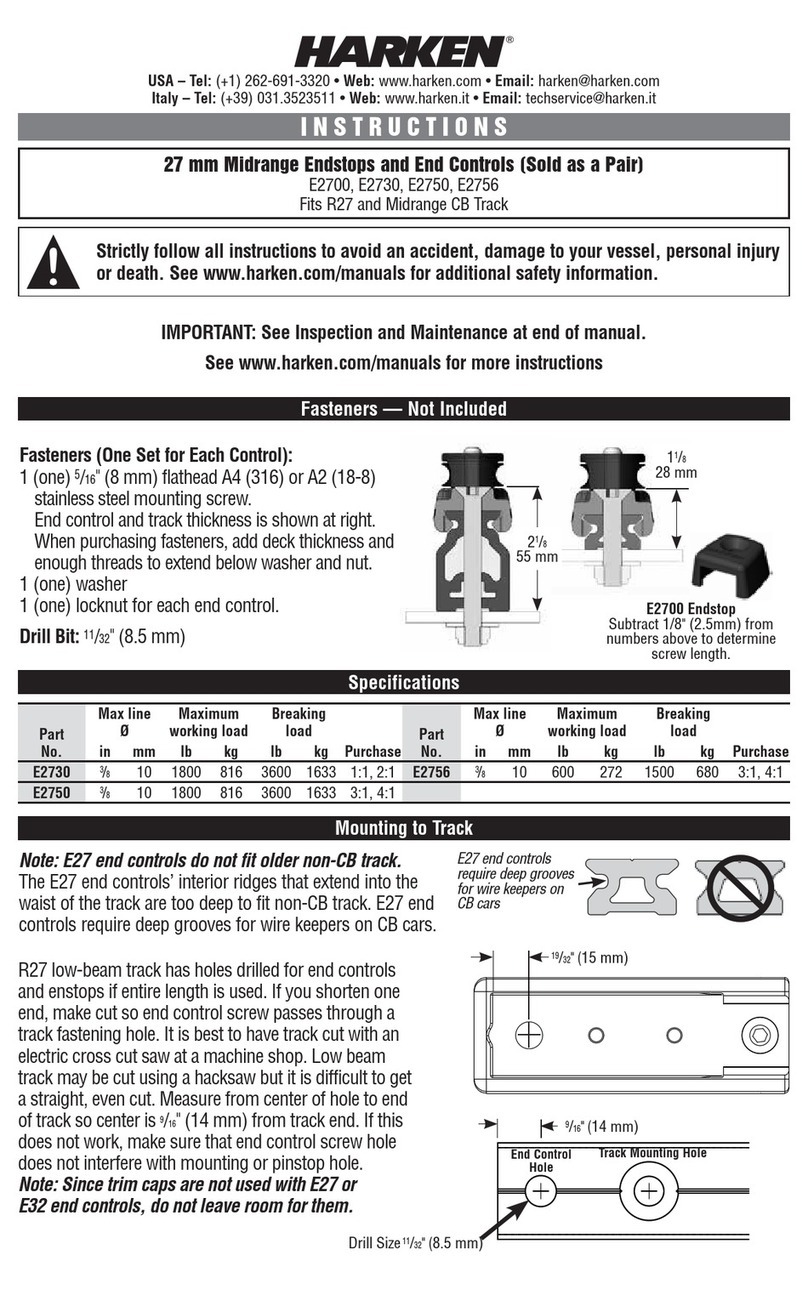

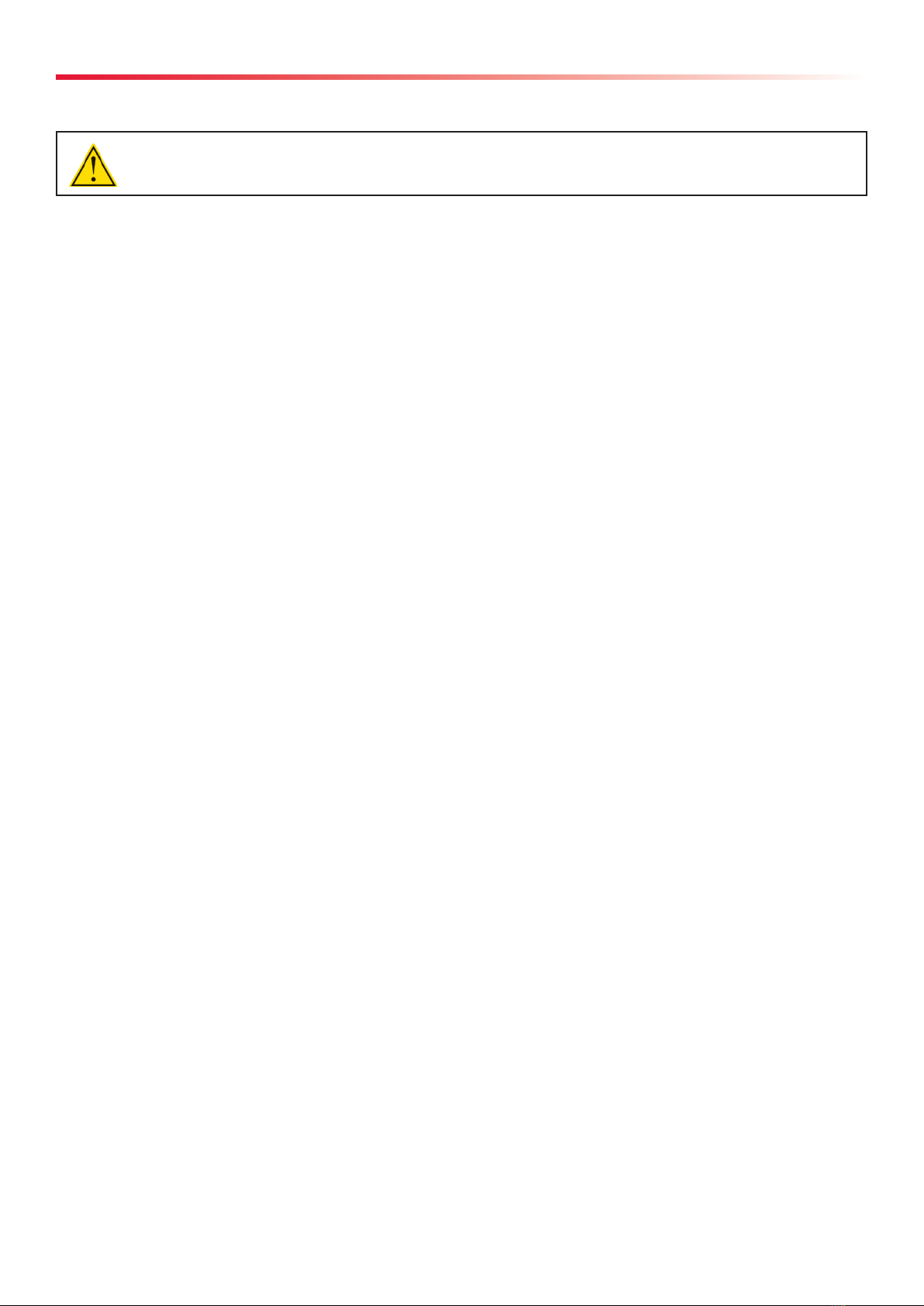

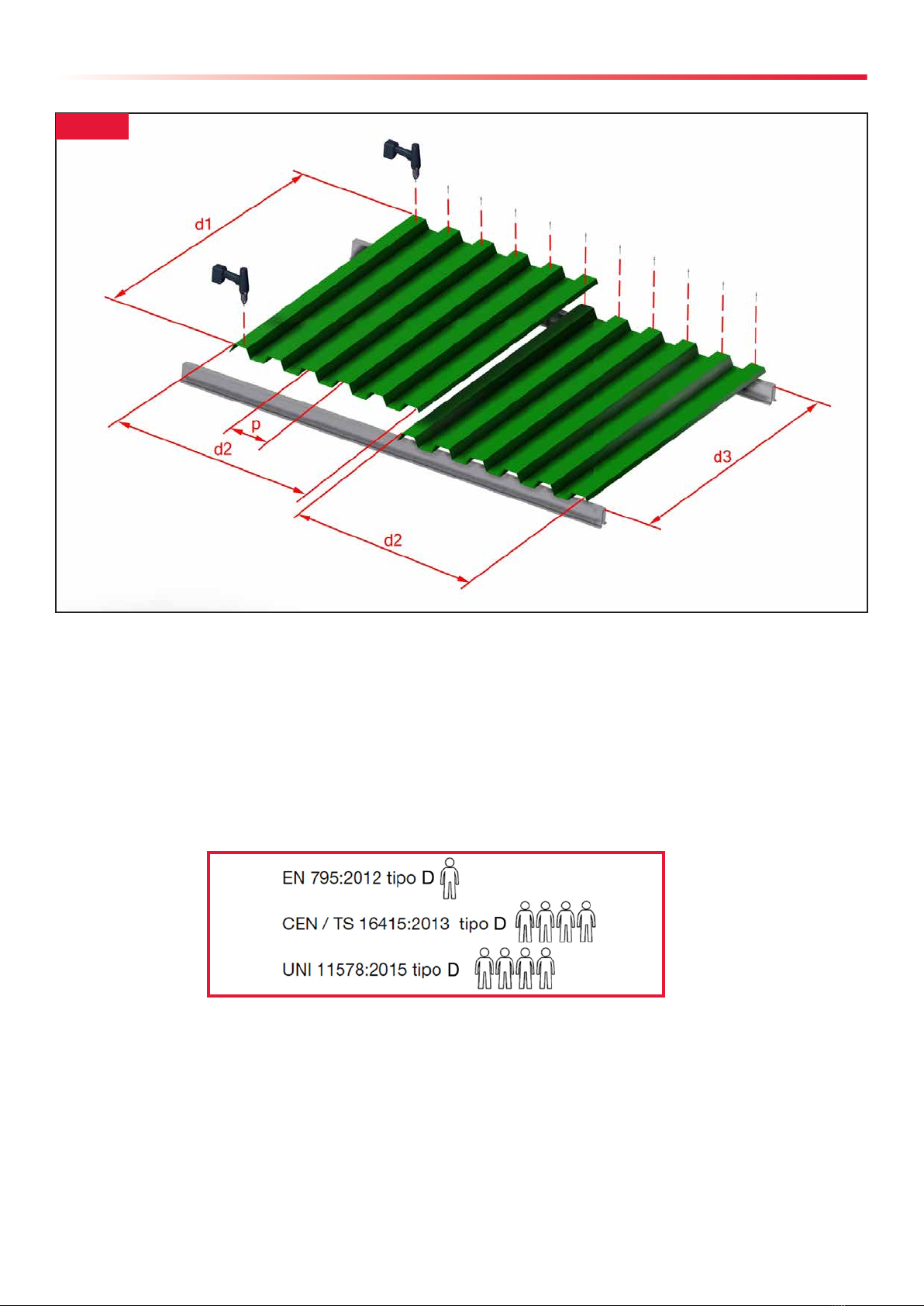

As shown in the following figure (Fig.1) the tests were carried out on 2 portions of roof, each measuring d1=

2 m and d2=1 m, coupled together to form a surface area of 2 m x 2 m. The distance between the fixing rows

was, for the purpose of safety, the maximum permitted by the corrugated roofing manufacturer, i.e. d3=1.5

m. The fixing used met the requirements of the corrugated roof manufacturer’s technical data sheet, for

fixings on iron omega profiles, as this was the type of underlying structure: the fixing was chosen according

to the underlying structure (wood, steel, reinforced concrete, etc., and their characteristics). A fixing was

installed on every corrugated angle, both in the upper and lower fixing row in relation to the device

positioning: during the test, the omega profiles were found to be solidly fixed to the test field structure. The

device fixed on the corrugated roof using the rivets supplied did not overlap or cross a fixing row.