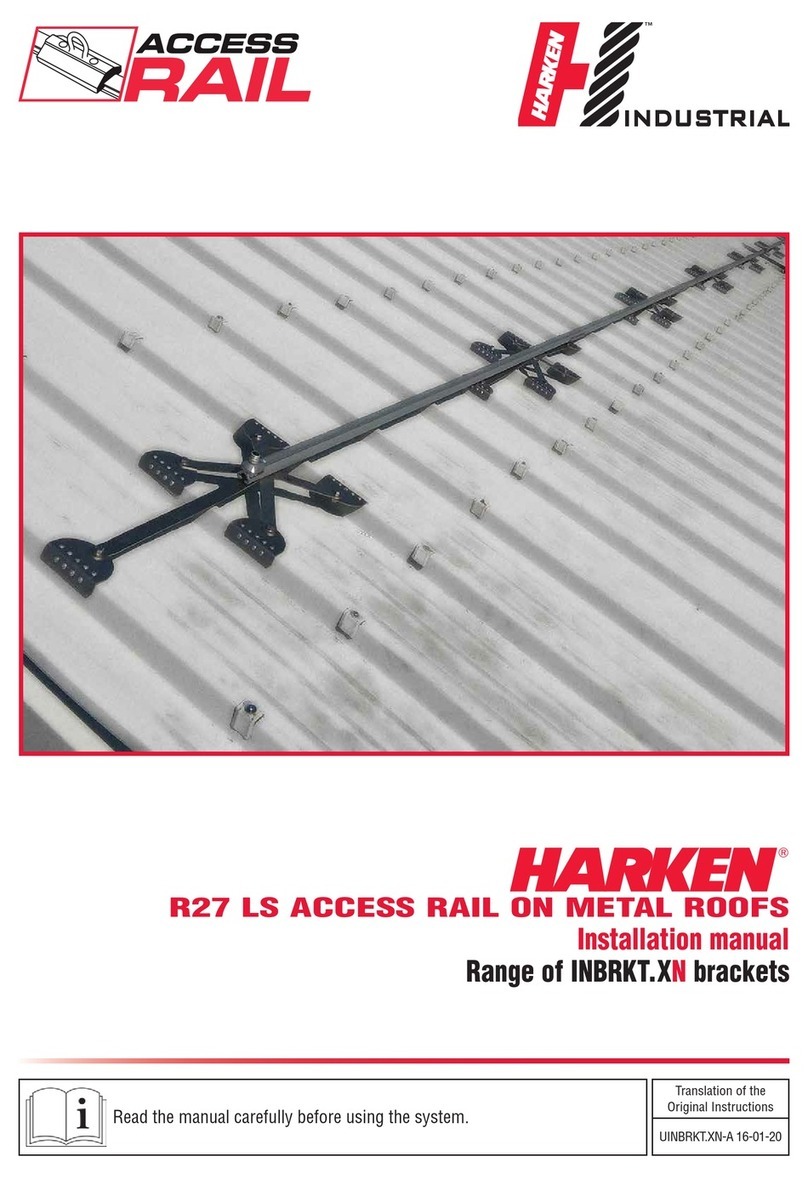

4 Access Rail System – R27

3) Installation

PLAN SYSTEM

Consider all factors that will affect safety during use of this equipment.

Rail must be laid out and positioned as determined by a naval architect

or other suitably qualified person.

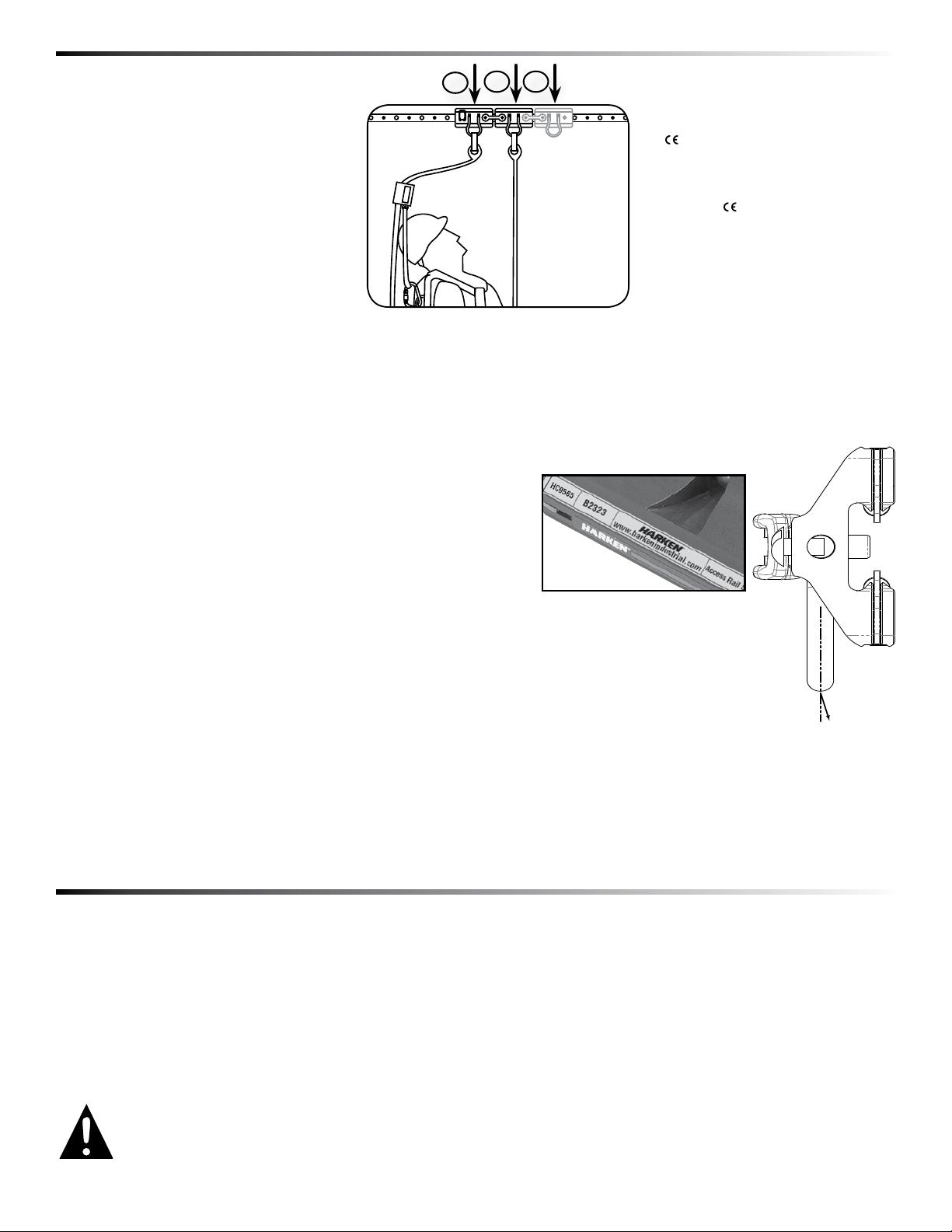

User must ensure that distance required to arrest fall is less than

obstruction below. Height of user plus extended safety lanyard length

must not be more than the height from rail to ground minus 2 m (6.5 ft).

Installer shall ensure suitability of base materials into which rail is fixed and that it is capable of sustaining test

force as detailed in standard EN 795:2012.

The following publications give detailed information to ensure safe and legally compliant installation. EN 795:2012

– Protection against falls from a height – Anchor devices – Requirements and Testing. BS 7883:2005 – Code of

practice for the design, selection, installation, use and maintenance of anchor devices conforming to BS EN 795.

MGN422 (M) – Use of Equipment to undertake work over the side on yachts and other vessels. (see Appendix A).

Harken External Access System – Installation and Proof Testing Advice. (see Appendix B).

Avoid attaching system components where suspension and/or fall arrest rope may come

in contact with, or abrade against, unprotected sharp edges.

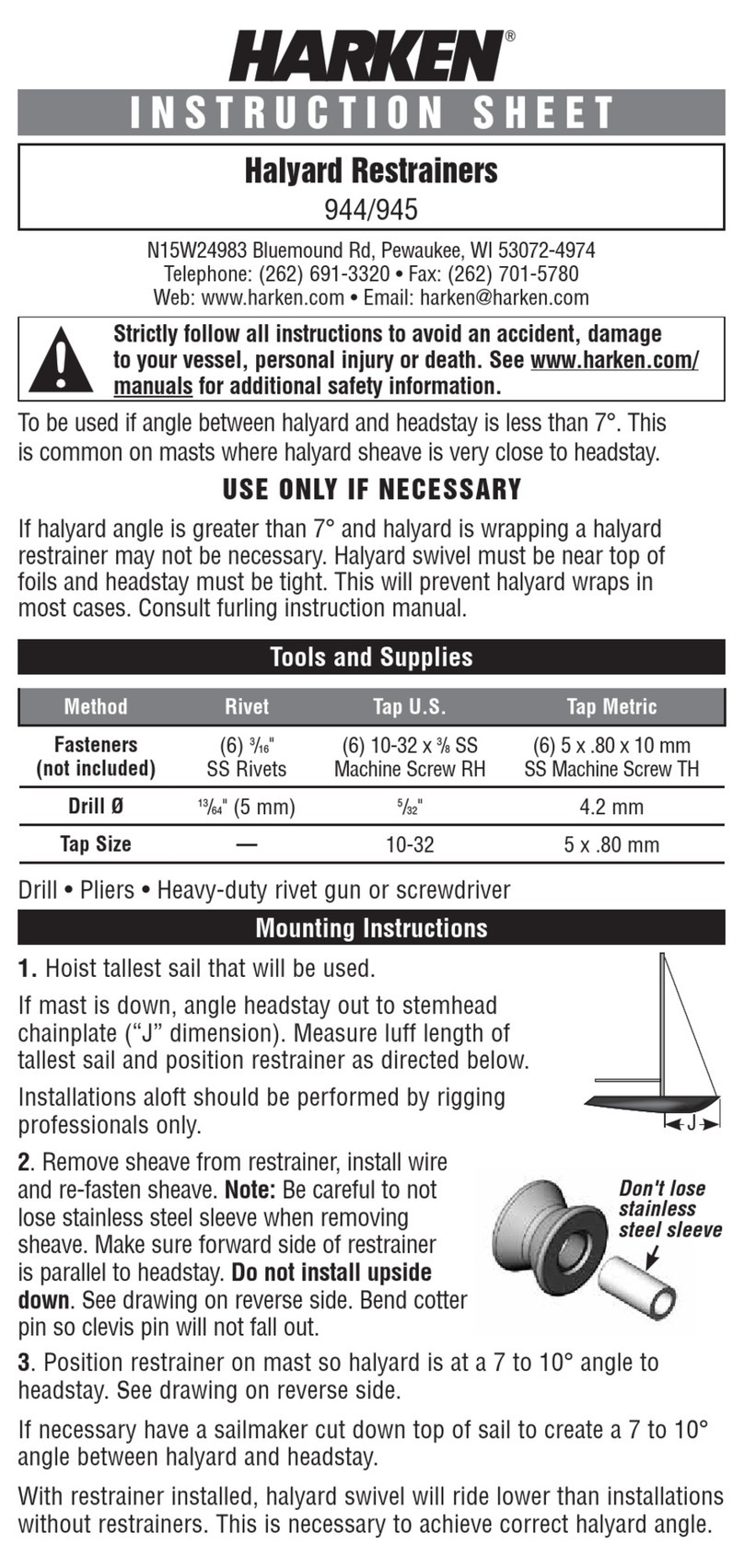

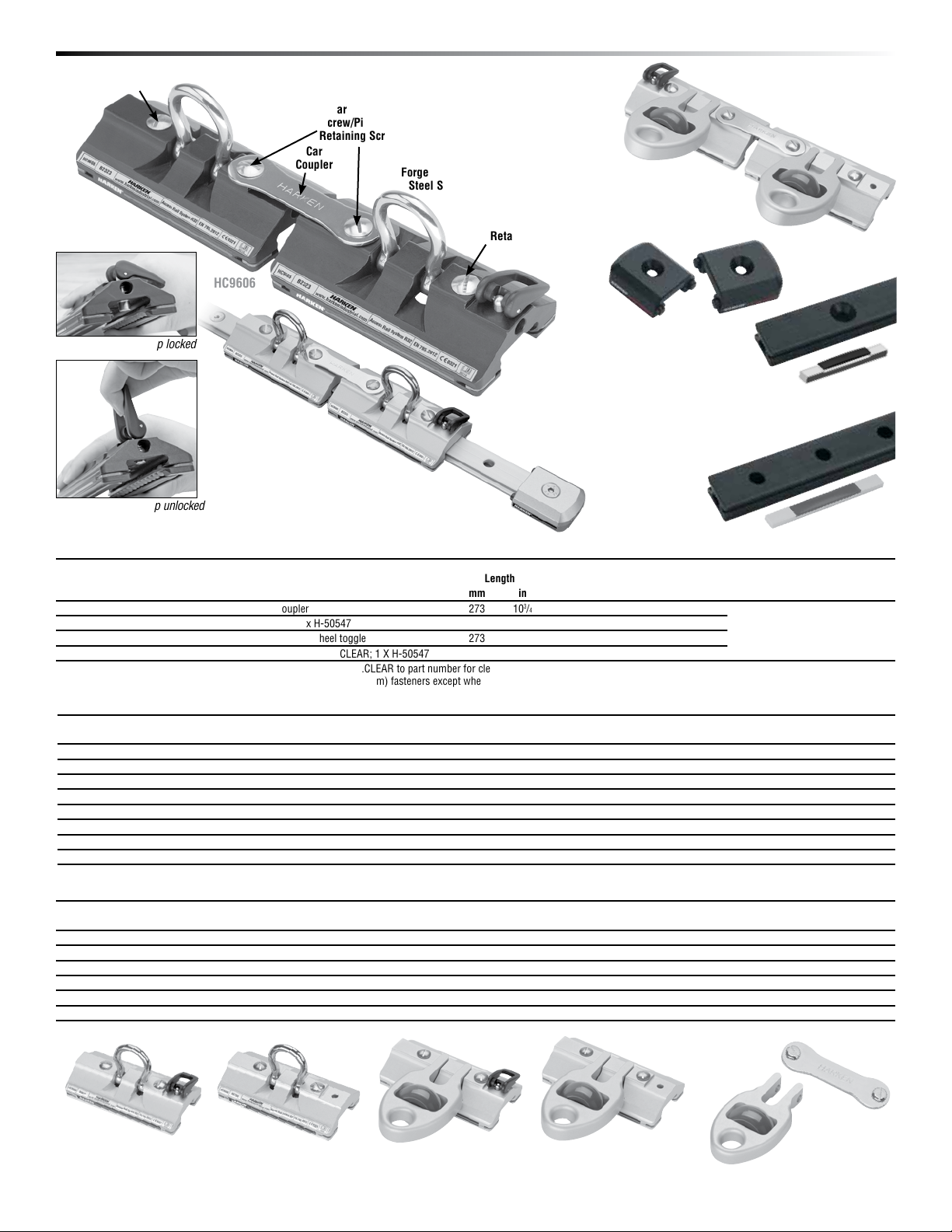

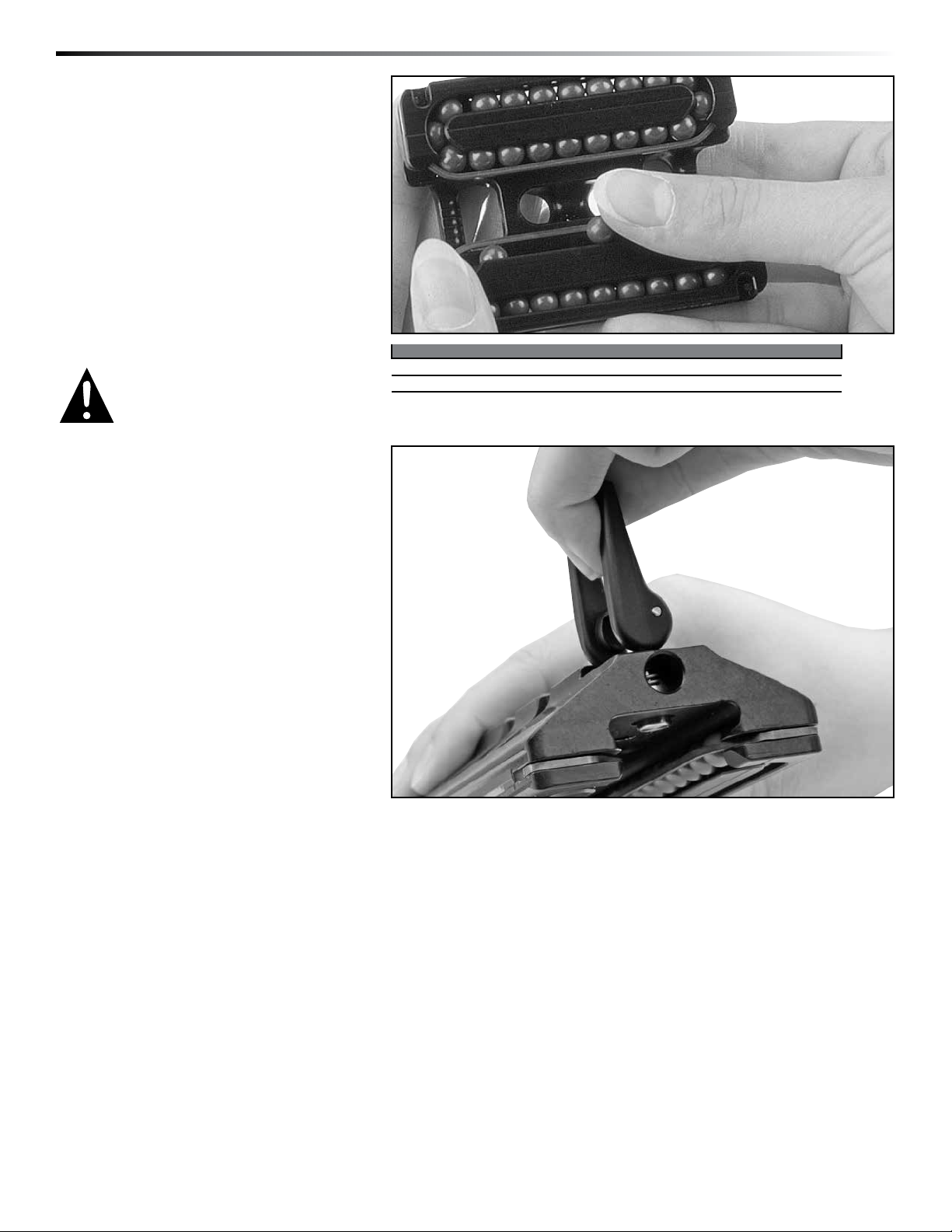

HC1057 CAR ASSEMBLY/WHEEL TOGGLE

This car is designed to run along a surface, mounted so that the toggle

overhangs the edge. Ensure that the whole wheel width is in good contact

with the surface to which the rail is attached. Ensure that the surface is

strong enough to sustain the expected working load and wear.

RAIL INSTALLATION

This Access Rail system should be installed only by a competent person or competent organization.

All rail listed in this manual is designed to use stainless steel fasteners. Attachment to vessel

must be in accordance with MGN 422(M). Harken does not recommend installing with aluminum

fasteners. Use of non stainless steel fasteners is at the liability of the installer and must be designed

to meet the requirements of MGN 422(M) in Appendix A and Proof Testing in Appendix B.

Always use threadlocking solution or locknuts.

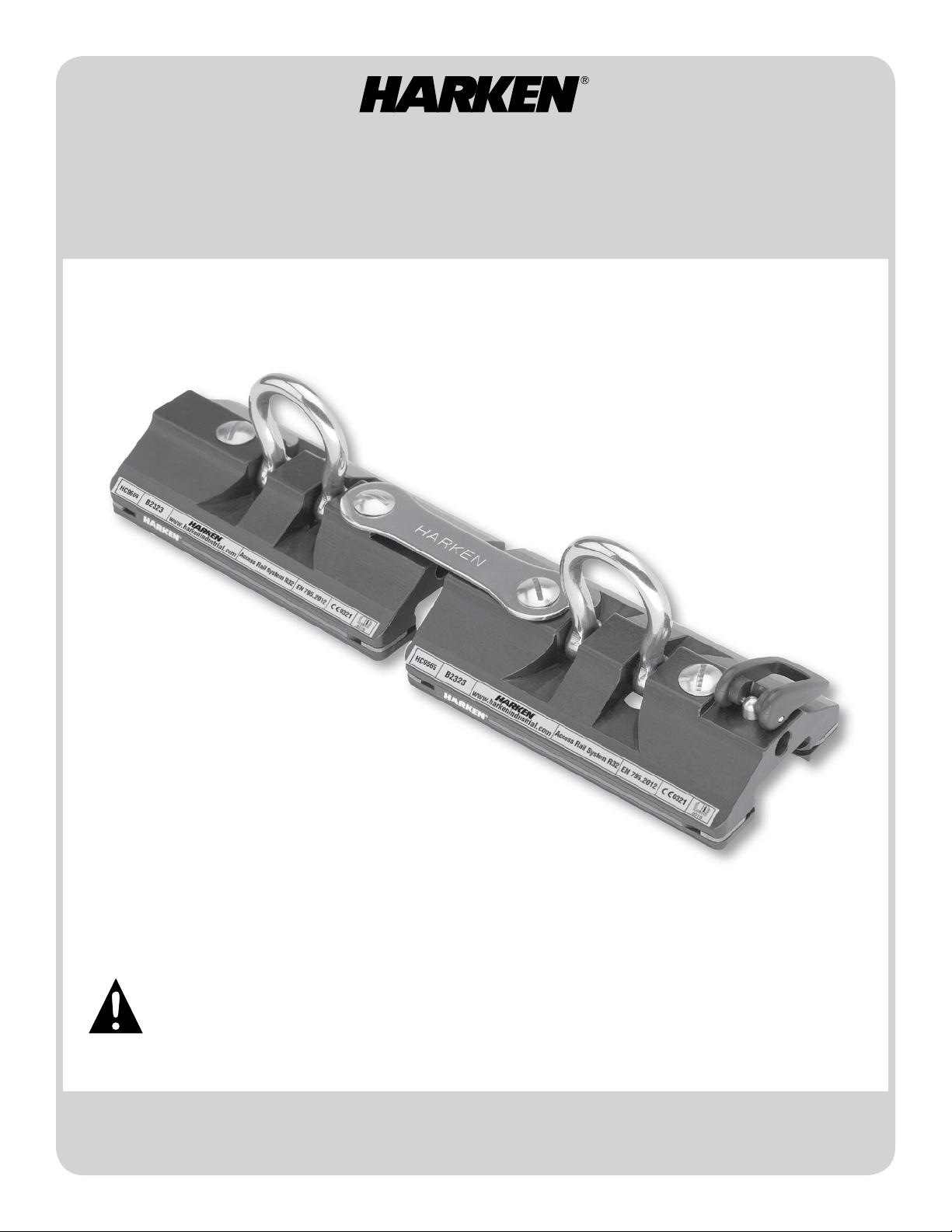

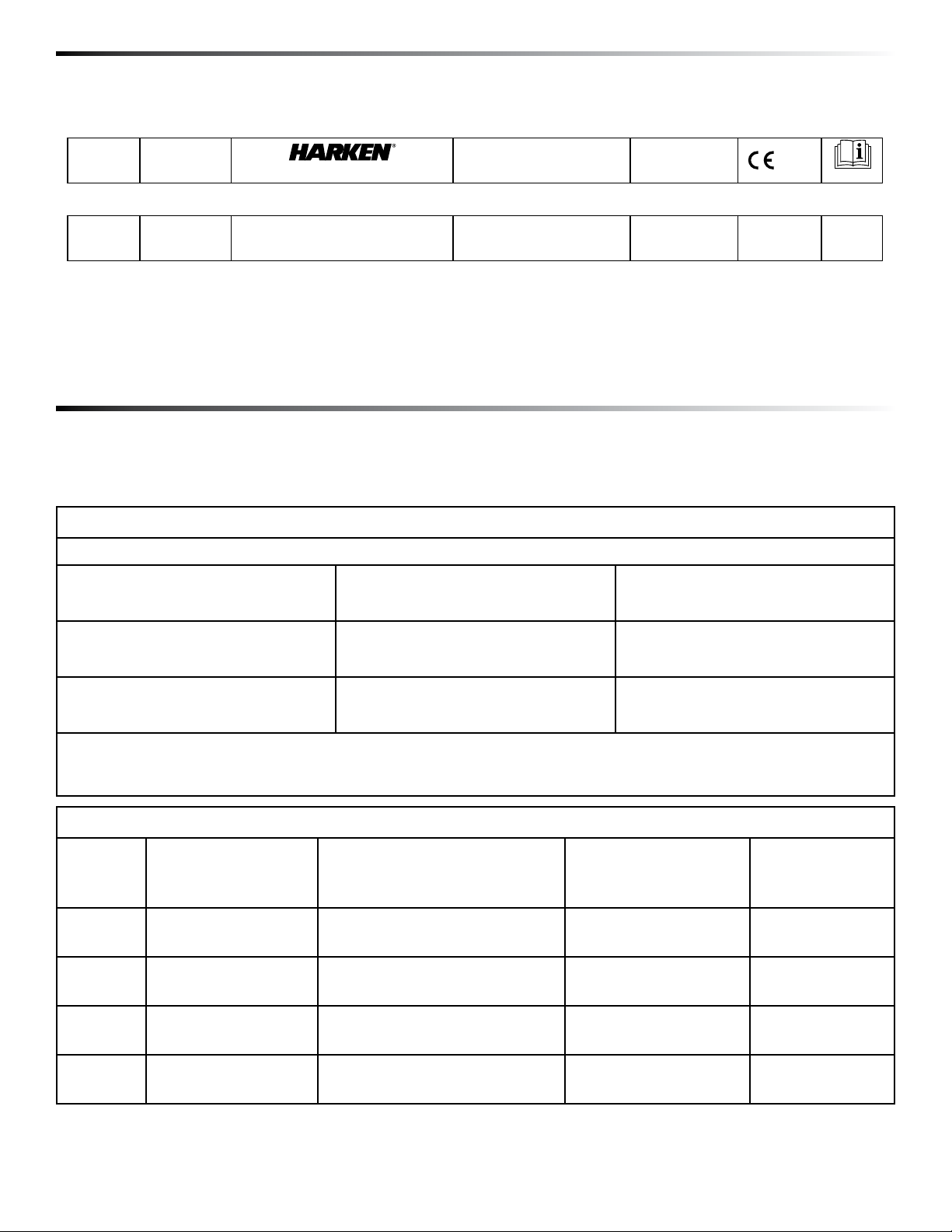

Precise rail alignment at joints is critical for smooth-running cars. Use Splice Links, Part

1649 (1643 rail) or Part 1651 (1650 rail), and round rods and spring clamps to align rail

during installation. Use transfer punch to mark hole centers. Keep rail in alignment, until

secured, with spring or "C" clamps when marking, drilling holes and inserting fasteners.

To prevent cars from rolling off rail, fasten endstops to rail ends using M8 (5/16")

stainless steel fasteners.

All rail and endstop fasteners must be coated with an anti-corrosion compound such as Tef-Gel®.

Installer must ensure that instructions and limitations of use are clearly displayed close to system. This should

include a statement that it is designed exclusively for use of personal protective equipment.

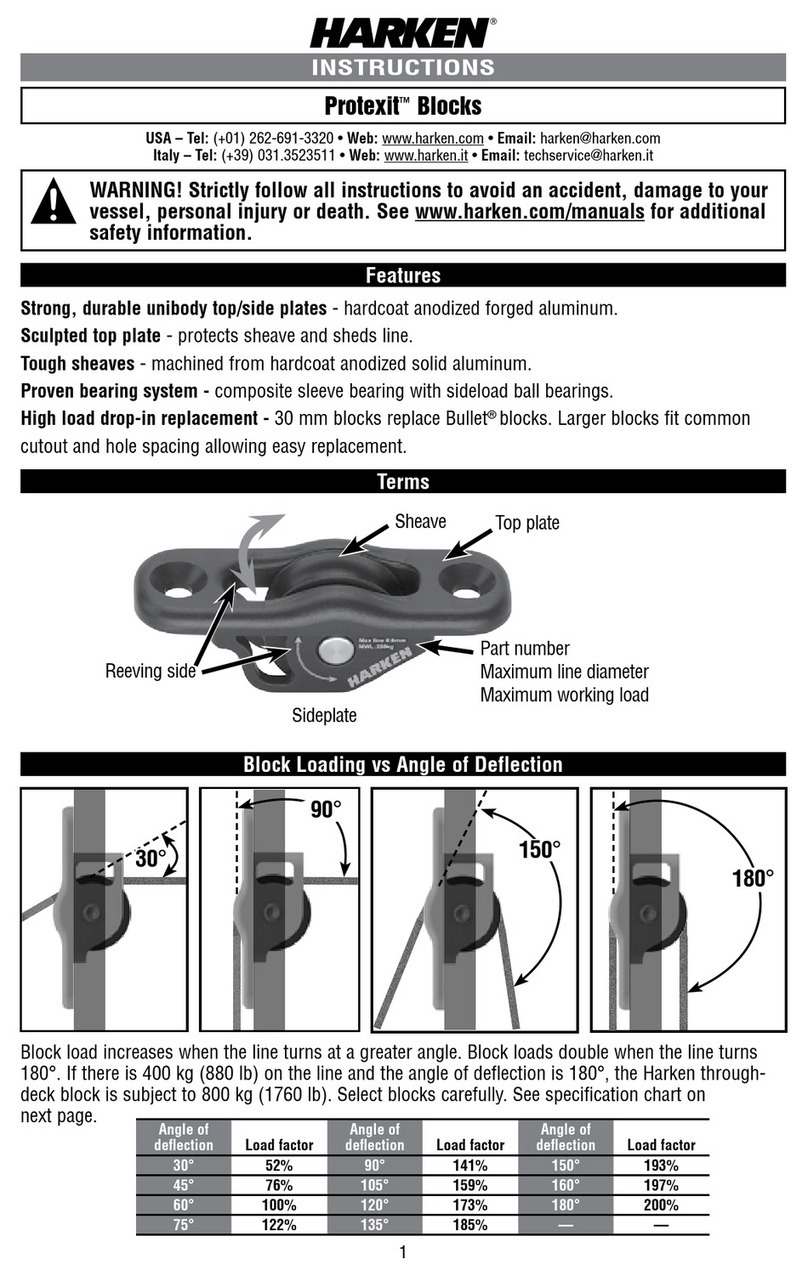

Rail should run horizontal to water plane, but can be mounted at various angles on this horizontal structure.

INCORRECT

CORRECT

Ceiling Mount Wall Mount

Mounted on angle:

cars with wheel

toggle face outward

Mounted in recess: cars with wheel

toggle for loading over an edge

Wheel Toggle Car

Use transfer punch to mark

hole centers. Hold rail in

alignment, until secured, with

spring or "C" clamps when

marking and drilling holes.