HARMSCO WaterBetter WBC 170SC-2 User manual

SPECIFICATION WBC 40SC-2 WBC 90SC-2 WBC 170SC-2

Flow rate (GPM) Up to 50 Up to 100 Up to 150

Recommended flow rate (GPM) 35 70 105

Filter area (pleated)* 40 sq. ft. 90 sq. ft. 170 sq. ft.

Pipe sizes, inlet & outlet 2” NPT 2” NPT 2” NPT

Pipe size, drain 1/2” NPT 1/2” NPT 1/2” NPT

Filter height 25-1/8” 35” 46-1/4”

Filter diameter 12” 12” 12”

Floor space required 15”x15” 15”x15” 15”x15”

Service height clearance 38” 58” 79”

Shipping weight (approx.) 36 lbs. 42 lbs. 48 lbs.

Temperature rating** 140° (60°C) 140° (60°C) 140° (60°C)

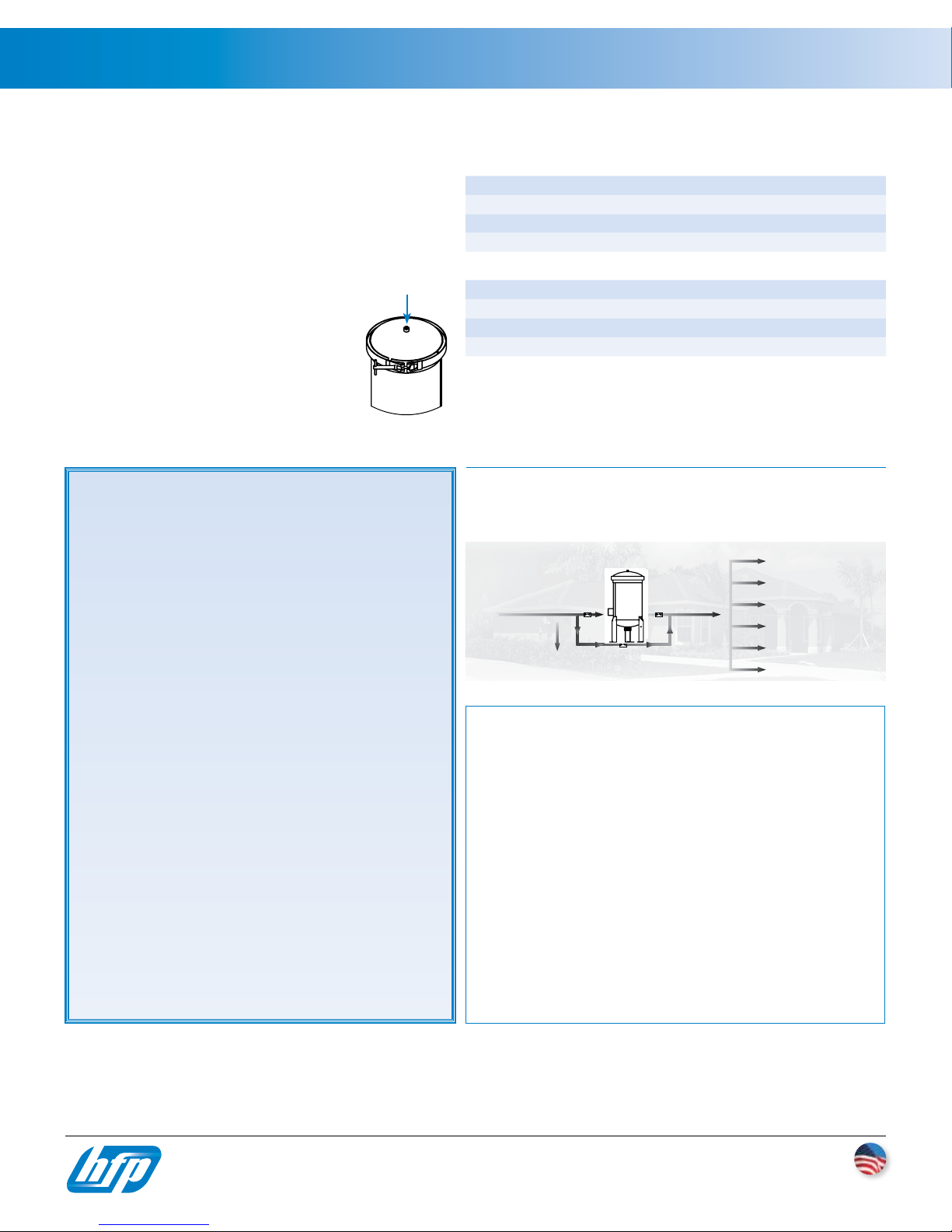

HOW THEY WORK

Up-flow Design

Air is automatically purged due to principle of up-flow filtration.

Filtered liquid exits the filter at the highest point. A secure lifting

handle prevents cross contamination of filtered and unfiltered

liquid. This patented up-flow design allows Harmsco®to utilize

100% of cartridge surface area, providing efficient filtration. Filter

efficiencies are dramatically improved to provide longer filter

runs and reduced filtration costs. Harmsco®Hurricane®filter

cartridges for the WBC filters are available in a wide range of micron

ratings and may be cleaned and re-used in most applications and

micron ratings.

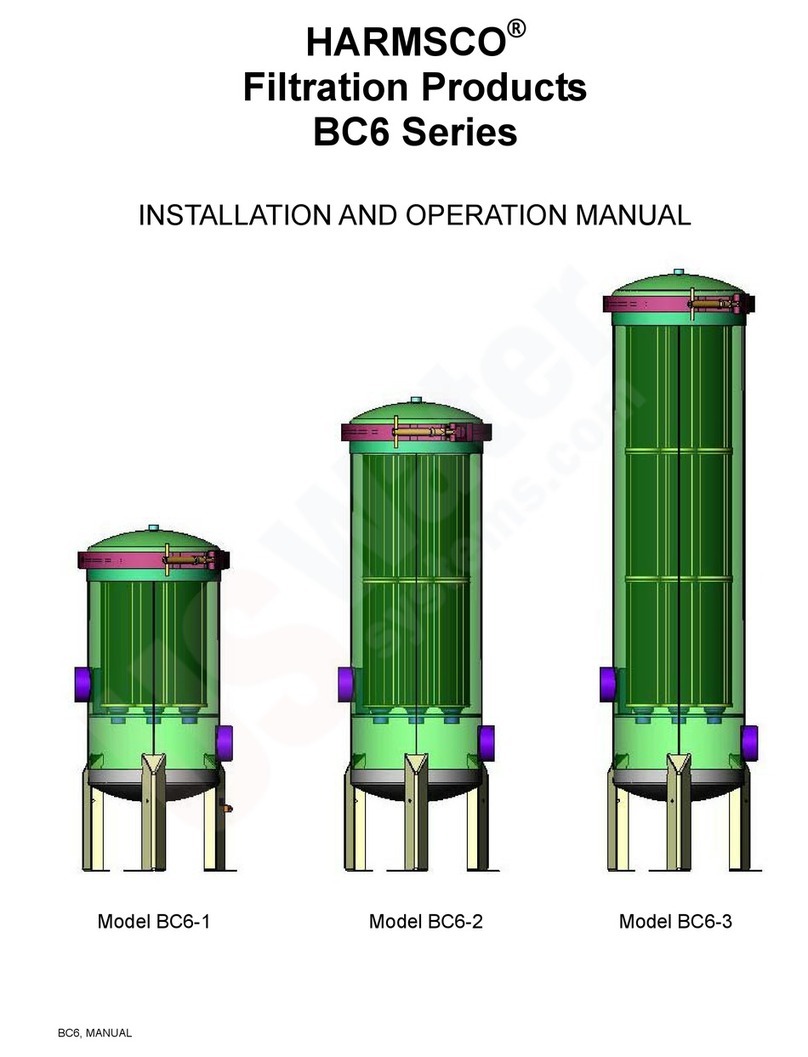

Three WBC Filter models are available for a wide range of applications.

* Specific cartridge models have various square footage.

** Varies based on pressure and time under load.

HARMSCO®WBC Filters

Installation & Operation Manual

Harmsco®WaterBetter®Band Clamp filters provide clamp band closure convenience.

Models & Specifications

Features

304 stainless steel filter housings

Electropolished for superior finish

Resistant coatings available

Band clamp closure to simplify maintenance

Drill in place legs

CPVC standpipe for up-flow design

World’s largest selection of filter cartridges

WBC 40SC-2

WBC 90SC-2

WBC 170SC-2

Maximum Flow Rate Recommended Flow Rate Model Pleated Filter Area

Up to 50 GPM 35 GPM WBC 40SC-2 40 sq. ft.

Up to 100 GPM 70 GPM WBC 90SC-2 90 sq. ft.

Up to 150 GPM 105 GPM WBC 170SC-2 170 sq. ft.

Up to 300 GPM 210 GPM WBC 170SC-2 (two filters*) 340 sq. ft. (two filters*)

Up to 450 GPM 315 GPM WBC 170SC-2 (three filters*) 510 sq. ft. (three filters*)

Up to 600 GPM 420 GPM WBC 170SC-2 (four filters*) 680 sq. ft. (four filters*)

Up to 750 GPM 525 GPM WBC 170SC-2 (five filters*) 850 sq. ft. (five filters*)

Filter Model Cartridge

Product Code

Nominal

Micron Rating

Cartridge Dimensions

L x OD x ID

Ship Wt./Ctn.

(One Cartridge)

WBC 40SC-2 HC/40-0.35 0.35 9-5/8” 7-3/4” 3” FPT 4 lbs.

HC/40-1 1 9-5/8” 7-3/4” 3” FPT 4 lbs.

HC/40-5 5 9-5/8” 7-3/4” 3” FPT 4 lbs.

HC/40-10 10 9-5/8” 7-3/4” 3” FPT 4 lbs.

HC/40-20 20 9-5/8” 7-3/4” 3” FPT 4 lbs.

HC/40-50 50 9-5/8” 7-3/4” 3” FPT 4 lbs.

HC/40-100 100 9-5/8” 7-3/4” 3” FPT 4 lbs.

HC/40-150 150 9-5/8” 7-3/4” 3” FPT 4 lbs.

HC/40-EZ-CLEAN NR* 9-5/8” 7-3/4” 3” FPT 4 lbs.

WBC 90SC-2 HC/90-0.35 0.35 19-1/2” 7-3/4” 3” FPT 7 lbs.

HC/90-1 1 19-1/2” 7-3/4” 3” FPT 7 lbs.

HC/90-5 5 19-1/2” 7-3/4” 3” FPT 7 lbs.

HC/90-10 10 19-1/2” 7-3/4” 3” FPT 7 lbs.

HC/90-20 20 19-1/2” 7-3/4” 3” FPT 7 lbs.

HC/90-50 50 19-1/2” 7-3/4” 3” FPT 7 lbs.

HC/90-100 100 19-1/2” 7-3/4” 3” FPT 7 lbs.

HC/90-150 150 19-1/2” 7-3/4” 3” FPT 7 lbs.

HC/90-EZ-CLEAN NR* 19-1/2” 7-3/4” 3” FPT 7 lbs.

WBC 170SC-2 HC/170-0.35 0.35 30-3/4” 7-3/4” 3” FPT 10 lbs.

HC/170-1 1 30-3/4” 7-3/4” 3” FPT 10 lbs.

HC/170-5 5 30-3/4” 7-3/4” 3” FPT 10 lbs.

HC/170-10 10 30-3/4” 7-3/4” 3” FPT 10 lbs.

HC/170-20 20 30-3/4” 7-3/4” 3” FPT 10 lbs.

HC/170-50 50 30-3/4” 7-3/4” 3” FPT 10 lbs.

HC/170-100 100 30-3/4” 7-3/4” 3” FPT 10 lbs.

HC/170-150 150 30-3/4” 7-3/4” 3” FPT 10 lbs.

HC/170-EZ-CLEAN NR* 30-3/4” 7-3/4” 3” FPT 10 lbs.

Model AHeight Inlet Outlet Drain

WBC 40SC-2 25-1/8” 2” MNPT 2” MNPT 1/2” FNPT

WBC 90SC-2 35” 2” MNPT 2” MNPT 1/2” FNPT

WBC 170SC-2 46-1/4” 2” MNPT 2” MNPT 1/2” FNPT

WBC Filters

are rated for pressures

to 150 psi

and temperatures

to 140°F.

Hurricane®

Replacement

Cartridges

Sizing

Use the chart shown below to size WBC Filters for your application:

*Parallel installation with valves to isolate filters for service while other filters are operational.

Note: Lower flow rates and pressures result in longer cartridge life. Designing to 70-80% of maximum flow will increase overall performance.

Pressure Drop

The total head loss data shown below was developed by NSF International and indicates pressure drop with

Waterbetter®Filter and one micron filter cartridge in clean water.

WBC Filter Housings Utilize Hurricane®Filter Cartridges

Temperature

&

Pressure

Ratings

Hurricane®replacement

cartridges are available in

a wide range of nominal

ratings, shown right.

Cartridges are rated for

temperatures to 140˚F

and may be used to

separate solids in liquids

with a pH of 3 to 11.

Packaged one cartridge

per carton.

Activated carbon and Poly-Pleat Hurricane®cartridges available. Please see catalog. * NR - not rated

Cartridge Cleaning Instructions

Hurricane®cartridges are made of Polyester Plus™,

a proprietary blend of polyester fibers which can be

cleaned in most applications and micron ratings to

make Waterbetter®filter elements reusable! For best

results, follow the directions described below:

When Cartridge Cleaning

is Possible

Clean cartridge when pressure differential is 12 psi

above startup differential.

Non-cleanable Applications

Replace cartridge when pressure differential is 30 psi

above start-up differential or when flow has diminished

to an unacceptable level, indicating cartridge is at

capacity.

Cartridge Removal

To remove filter cartridge, drain filter housing. Remove

lid. Hold lifting handle and pull upward to remove filter

cartridge from filter housing. Follow cleaning

instructions described herein.

Lid Replacement

Clean o-ring and contacting surfaces of tank and lid.

Reposition o-ring, lid and clamp band making sure that

clamp covers housing flange and lid flange. Tighten

clamp band slowly insuring proper engagement of

clamp to flanges. Continue tightening clamp closure

bolt and, if necessary, strike the clamp with a mallet in

an inward radial direction and all around its circumfer-

ence to prevent sticking between clamp and flanges.

When Cartridge Cleaning is Not Possible

For best results, clean

cartridges with pressure

nozzle using standard

hose. Direct spray at

an angle to remove

particulate (see photo).

Follow these directions

to remove oils, organic

matter, algae and mineral

deposits.

OILS: Soak cartridge in

a solution of tri-sodium

phosphate or similar

strong detergent (2 lbs. to

10 gallons of water). Soak

up to 12 hours for best

results. Rinse after bath.

ORGANIC MATTER, ALGAE: Use tri-sodium phosphate solution

as described above, plus 1 pint of liquid chlorine to kill organic matter

and algae. Soak cartridge one hour or longer until surface is no

longer “slippery.” Rinse after bath.

CALCIUM MINERAL DEPOSITS: Follow directions for “oils”

described above. Soak cartridge for approximately ten minutes in a

solution of one part of muriatic acid to twenty parts of water. Rinse

cartridge thoroughly with water.

Generally, it is not possible to clean Hurricane®filter cartridges when

filtering petroleum-base liquids, toxic substances, and one and

below micron applications.

Note: Pressure gauges are recommended to indicate when cartridge

cleaning or replacement is necessary.

Cartridge Care

Cartridge Cleaning in Aqueous Applications

Caution: Do not rinse cartridges with acid

until oils and organic matter are removed.

Use detergent first and follow with acid bath

for mineral removal. Flush cartridges with water

after muriatic or tri-sodium phosphate baths.

0

10

20 30

40 50

1.2

1.0

0.8

0.6

0.4

0.2

Flow Rate (GPM)

Pressure drop WBC 40SC-2

Total Head Loss (P.S.I.)

020 40 60 80 100

3.0

2.5

2.0

1.5

1.0

0.5

Flow Rate (GPM)

Pressure drop WBC 90SC-2

Total Head Loss (P.S.I.)

040 80 120 160 200

12.0

10.0

8.0

6.0

4.0

2.0

Flow Rate (GPM)

Pressure drop WBC 170SC-2

Total Head Loss (P.S.I.)

Clamp Band #1616

Lifting Handle #362-S

Housing Seal #1626-B

Lid #1602-C

Filter Cartridge

Filter Housing

WBC 90SC-2

(shown)

Cartridge Sub-assembly

Prior to installing cartridge,

thread on lifting handle

securely for proper seal.

Standpipe

4"

OUTLET

2" MNPT

10 1

2

"

55

8

"

DRAIN

1/2" FNPT

A

11 1

2

"

REF

10"

INLET

2" MNPT

1/4" FNPT

GAUGE PORT

41

16

"

31

2

"

30°

11 1

2

"

15°

120°

TYP

B

INLET

2" MNPT

OUTLET

2" MNPT

DRAIN

1/2" FNPT

3

8

"

TYP

3

4

"

TYP

LEG SLOT

DETAIL B, (2X)

Part No. Material Description

362-S Stainless steel Lifting handle for filter cartridge

1602-S Stainless steel Lid with vent

1616 Stainless steel Clamp band

1626-B Rim gasket to seal filter

Options:

1626-V Viton Rim gasket to seal filter

1901-C CPVC Standpipe for WBC 40SC-2

1902-C CPVC Standpipe for WBC 90SC-2

1903-C CPVC Standpipe for WBC 170SC-2

Installation

Install filter using 2” couplers for inlet and outlet with 1/2”

NPT coupler for drain pipe. Shut-off valves should be

installed on inlet, outlet and on drain pipe to be able to

service the filter and isolate it when necessary.

Pressure gauges are also recommended before and after

the filter to easily calculate the pressure differential and to

know when cartridge should be cleaned or replaced.

1/4” FPT Lid Fitting

One-quarter inch FPT fittings are installed

in WBC filter lids for a number of customer

supplied options, including petcock for

pressure relief, pressure gauge, sensor,

thermocouple, etc. This fitting should be

plugged at time of installation if one of these

options is not installed.

Part List

WBC filter parts and components are listed below:

Harmsco®Whole House Filtration Featuring

Harmsco®WBC 40SC-2 Filter

One Filter Covers it All!

Incoming City Water

Irrigation Tap

Cartridges HC/40-1 or HC/40-5 or HC/40-AC

To House

Drinking Water Faucets

Refrigerator / Icemaker

Hot Water Heater

Lavatory Sinks

Shower Heads

Laundry & Utilities

(bypass)

1 Micron

5 Micron

Activated

Carbon

Available From:

Harmsco, Inc. Industrial Filters

Limited Warranty

1. Harmsco, Inc. warrants its line of Industrial Filters to be free of defects in

material and workmanship for a period of one year from the date of

installation.

2. The warranty for Industrial Filters ordered with special coatings is limited

only to the recoating of the defective parts due to failure in materials or

workmanship for one year from date of installation.

3. This warranty does not cover any equipment purchased for use in

applications in which the product is not suited. It is the responsibility of

the buyer to determine if a product is suitable for a particular application.

4. THIS WARRANTY EXCLUDES THE FOLLOWING:

a. Any fresh water unit installed for salt water use.

b. Damage caused by improper installation, operation or care.

c. Chemical attack.

d. Rubber type parts and normal wear items, i.e. “o” rings, rim gaskets,

wing nuts, pipe caps, holding rods.

e. Any costs of labor or expenses incurred in the removal and/or

installation of Unit, or any surrounding device.

f. Damage caused by galvanic or electrolytic attack.

g. Altering or removing the Harmsco, Inc. information label.

h. Any unit not grounded.

5. Service under this warranty is to be provided by the dealer/distributor who

sold the unit to the distributor. If the dealer/distributor is unable to provide

warranty service, contact:

Harmsco, Inc. P.O. Box 14066

North Palm Beach, Florida 33408, U.S.A.

Phone (561) 848-9628 • Fax (561) 845-2474

A Returned Goods Authorization (RGA) number must be received from the

above office and placed on all shipments to and correspondence with

Harmsco, Inc. Please be prepared with the following information:

1. Model number and serial number

2. Date of installation

3. Name of installer

4. Nature of problem

5. Yo u r a d d r e s s , t e l e p h o n e n u m b e r a n d e m a i l a d d r e s s .

Lid Fitting

1 Micron

5 Micron

Activated

Carbon

Note: This publication is to be used as a guide. The data within has been obtained from many sources and is considered to be accurate. Harmsco does not assume liability for the accuracy and/or

completeness of this data. Changes to the data can be made without notification. Temperature, Pressure, Flow Rates, Differential Pressures, Chemical Combinations and other unknown factors can

affect performance in unknown ways. Limited Warranty: Harmsco warrants their products to be free of material and workmanship defects. Determination of suitability of Harmsco products for uses

and applications contemplated by Buyer shall be the sole responsibility of Buyer. The end user/installer/buyer shall be liable for the product’s performance and suitability regarding their specific intended

applications. End users should perform their own tests to determine suitability for each application.

HARMSCO EUROPE SRL

Via Salvo D’Acquisto 10a-12 46040 Guidizzolo (MN) Italy

Tel: +39 0376 818782 • Fax: +39 0376 818399 • E-mail: info@harmscoeurope.com © Harmsco, Inc. 05F 06 7/12

www.harmscoeurope.com

Made in USA

This manual suits for next models

2

Table of contents

Other HARMSCO Water Filtration System manuals