Harris Legacy 99-1300-0 User manual

Broadcast

Console

Operations

&

Technical

Manual

HARRIS 75-51

Revision B • 1/03

99-1300-0 (14-input mainframe)

99-1300-1 (22-input mainframe)

99-1300-2 (30-input mainframe)

BroadcastCommunicationsDivision

www.broadcast.harris.com

Revision B • 1/03

HARRIS CORPORATION

ii

Revision B • 1/03

HARRIS CORPORATION

iii

Contents

Safety Instructions ......................................... iv

Hazard/Warning Label Identification............. iv

Manual Revisions............................................ v

1- GENERAL INFORMATION

Product Overview ........................................1-1

Specifications ...............................................1-4

Warranty......................................................1-6

2- INSTALLATION

Console Installation......................................2-2

Mainframe Configuration ........................2-2

Connector Access ....................................2-3

Power Supply..........................................2-4

Grounding and Shielding ........................2-4

Installing Backup Batteries .....................2-4

Setting the Clock .....................................2-5

EventTimer ............................................2-6

Meter Setup ............................................2-6

Cabling andWiring ......................................2-7

Required Cables andWire .......................2-7

Wire Preparation ....................................2-7

CrimpTool Operation..............................2-8

Audio Connections .......................................2-9

Unbalanced Connections .......................2-10

Digital Clock Reference ..............................2-11

Logic Connections......................................2-11

Universal Input Logic Interface .............2-12

Setting DIP Switches.............................2-13

Quick Guides for Each Module...................2-16

Logic Connection Examples .......................2-50

Microphone Logic .................................2-50

Basic Peripheral Logic ..........................2-52

Complex Peripheral Logic.....................2-54

3- OPERATION

Module Overview .........................................3-1

Meter Panel Overview ..................................3-1

Microphone Preamplifier Module .................3-2

Universal Input Module................................3-3

Telco/Codec Module.....................................3-5

Remote Line Selector (RLS) Module ..........3-10

Meter Switcher Module ..............................3-11

Control Room Module................................3-12

Studio Module ...........................................3-13

Output 1 Module........................................3-14

Output 2 Module........................................3-14

Meter Panel................................................3-15

4- MAINTENANCE

Parts and Repair Services.............................4-1

Parts Ordering and Repair Information ...4-1

Spare and Replacement Parts..................4-2

Tool and Installation Kits........................4-3

Module Servicing .........................................4-3

Fader Servicing .......................................4-4

Clock and EventTimer .................................4-5

Backup Batteries..........................................4-5

Power Supply...............................................4-5

GeneralTroubleshootingTips .......................4-6

5- ACCESSORIES

Furniture and Cabinetry...............................5-1

Furniture-Mounted Panels............................5-1

Peripheral Panels .........................................5-2

Mic Remote Panels.......................................5-2

Headphone Distribution Amp ......................5-2

LogicWiring Diagrams & Cables ..................5-2

INDEX

Revision B • 1/03

HARRIS CORPORATION

iv

1. Read All Instructions. Read all safety and operating

instructions before operating the product.

2. Retain All Instructions. Retainallsafetyandoperating

instructions for future reference.

3. Heed AllWarnings.Youmustadheretoall warnings

on the product and those listed in the operating

instructions.

4. Follow All Instructions. Follow all operating and

product usage instructions.

5. Heat. This product must be situated away from any

heat sources such as radiators, heat registers,stoves,

or other products (including power amplifiers) that

produce heat.

6. Ventilation. Slots and openings in the product are

providedforventilation.Theyensurereliableoperation

of the product and keep it from overheating.Do not

block or cover these openings during operation.Do

not place this product into a rack unless proper

ventilation is provided and the manufacturer’s

recommended installation procedures arefollowed.

7. Water and Moisture. Do not use this product near

water such as a bathtub, wash bowl, kitchen sink, or

laundry tub,in a wet basement,or near a swimming

pool or the like.

8. Attachments. Do not use any attachments not

recommended by the product manufacturer as they

may cause hazards.

9. Power Sources.Youmustoperatethisproductusing

the type of power source indicated on the marking

label and in the installation instructions.If you are not

sure of the type of power supplied to your facility,

consult your local power company.

10. Grounding and Polarization. This product is

equippedwithapolarizedACplugwithintegralsafety

ground pin. Do not defeat the safety ground in any

manner.

11. Power Cord Protection.Powersupplycordsmustbe

routed so that they are not likely to be walked on nor

pinched by items placed upon or against them. Pay

particular attention to the cords at AC wall plugs and

convenience receptacles,and at the point where the

cord plugs into the product.

12. Lightning. For added protection for this product,

unplug it from the AC wall outlet during a lightning

storm or when it is left unattended and unused for

long periods of time.This will prevent damage to the

product due to lightning and power line surges.

13. Overloading. Do not overload AC wall outlets,

extensioncords,orintegralconvenienceoutletsasthis

can result in a fire or electric shock hazard.

14. Object and Liquid Entry. Never push objects of any

kind into this product through openings as they may

touch dangerous voltage points or short out parts,

whichcouldresultina fireorelectricshock.Neverspill

liquid of any kind on the product.

15. Accessories. Donotplacethis product onanunstable

cart, stand, tripod,bracket, or table.The product may

fall,causingseriousinjurytoachildoradultandserious

damagetotheproduct.Anymountingofthe product

must follow manufacturer’s installation instructions.

Safety Instructions16. Product and Cart Combination.Movethisproduct

with care. Quick stops, excessive force, and uneven

surfaces may cause the product and the cart

combination to overturn.

17. Servicing. Refer all servicing to qualified servicing

personnel.

18. Damage Requiring Service. Unplug this product

fromthewallACoutletandreferservicingtoqualified

service personnel under the following conditions:

a. When the AC cord or plug is damaged.

b. Ifliquidhas beenspilled orobjects havefallen into

the product.

c. If theproduct has been exposed to rain or water.

d. Iftheproductdoesnotoperatenormally(following

operating instructions).

e. If the product has been dropped or damaged in

any way.

f. When the product exhibits a distinct change in

performance.This indicates a need for service.

19. Replacement Parts. When replacement parts are

required, be sure the service technician has used

replacement parts specified by the manufacturer or

thathavethesamecharacteristicsastheoriginalparts.

Unauthorized substitutions may result in fire,electric

shock,or other hazards.

20. Safety Check.Uponcompletionof anyrepairsto this

product,ask the service technician to performsafety

checks to determine that the product is in proper

operating condition.

21. Cleaning. Do not use liquid or aerosol cleaners.Use

only a damp cloth for cleaning.

WARNING—This equipment generates,uses,and can radiate radio frequencyenergy.If not installed andused inaccordancewith the instructionsin this

manual it may cause interference to radio communications. It has been tested and found to comply with the limits for a Class A computing device

(pursuanttoSubpartJ ofPart 15FCCRules),which aredesignedto provide reasonableprotectionagainst such interferencewhenoperatedin acommer-

cial environment. Operation of this equipment in a residential area is likely to cause interference,in which case the user, at his own expense, will be

required to take whatever measures may be required to correct the interference.

Hazard/Warning Label Identification

TheLightning FlashWith

Arrowhead symbol,within an

equilateral triangle,alerts the user to

the presence of uninsulated

dangerous voltage within the

product’s enclosure that may be of

sufficient magnitude to constitute a

risk of electric shock.

TheExclamation Point symbol,

within an equilateral triangle,alerts the

user to the presence of important

operating and maintenance (servicing)

instructions in product literature and

instruction manuals.

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION

WARNING:SHOCK HAZARD - DO NOT OPEN

AVIS:RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR

CAUTION:TO REDUCETHE RISK OF ELECTRIC SHOCK DO NOT

REMOVE ANY COVER OR PANEL.NO USER SERVICEABLE PARTS

INSIDE.REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

WARNING: TO REDUCETHE RISK OF FIRE OR ELECTRIC SHOCK,

DO NOT EXPOSETHE POWER SUPPLY OR CONSOLETO RAIN OR

MOISTURE.

Revision B • 1/03

HARRIS CORPORATION

v

This page provides a quick reference of the

current document pages and their revision level. If

you receive a revision to this document from Harris,

replace the old manual pages with the new ones and

discardtheold pages.Replacethispagewiththenew

Manual Revisions page.

Revision Affected pages Comments

A All pages 2/02 First Release

B All pages 1/03 corrected various

installation & operation

descriptions. Added

accessory product

information.Condensed

manual page count.

Manual Revisions

Revision B • 1/03

HARRIS CORPORATION

vi

Revision B • 1/03

HARRIS CORPORATION

1-1

1

Thank you for joining the growing ranks of

broadcasters employing Harris Corporation prod-

ucts designed by Pacific Research & Engineering.

HarrisCorporationsuppliesaudioproductsandsys-

temstothe world’sleading broadcastfacilities.Our

mission is to provide the finest quality products,

systems,documentation,and after-salesupport.We

invitecommentsandsuggestionsforimprovements

to this documentation and to all of our services.

The Legacy is a very sophisticated console with

anextensiverangeof features contained in a com-

pact design.To obtain maximum benefit from the

console’s capabilities, read the

Installation

and

Operation

chapters prior to product installation.

PRODUCT OVERVIEW

Each Legacy console ships with the following

modules installed in the mainframe:

• Microphone Preamplifier module (one

5-inputMic Preamp PCAstandard,second

5-input Mic Preamp PCA optional)

• Universal Input modules (as ordered)

• Telco/Codec modules (up to 4,as ordered)

• Remote Line Selector (RLS) modules

(as ordered)

• Meter Switcher module (1 standard)

• Control Room module (1 standard)

• Studio module (1 optional)

• Output modules (2 standard)

Blank panels cover unused module positions.

The Legacy’s motherboard and module area is

completely contained within a sheet metal and

extruded aluminum chassis for strength and RFI

immunity.The meter panel is hinged at the rear,

closingovertheupperpart of themodulesto cover

theaudioandlogicconnectorsandtheLogicSetup

switches.The chassis bottom is open beneath the

meter panel for easy cable access.

ModuleDescriptions

Microphone Preamplifier Module

This module (PRE99-1151-2) can hold ten

high-performancepreamplifiers(fivearestandard

with an additional five optional).Each has a gain

trim control under a security cover. Phantom

power(+48VDC) is selectableforeachinput.Each

Mic Preamp boosts its mic-level inputs (from -65

dBu to -30 dBu) to a line level (+4 dBu),low-im-

pedance, balanced output for connection directly

to a Universal Input module or to outboard mic

processingequipment.

One module with a 5-input Mic Preamp PCA is

standard; a second optional 5-input PCA may be

installed.An additional 5-input Mic Preamplifier

module (PRE99-1151-2) or a 10-input Mic

Preamplifiermodule (PRE99-1151-1) maybein-

stalledintothe slot directly tothe right of thestan-

dard Mic Preamplifier module.

General

Information

Revision B • 1/03

HARRIS CORPORATION

1-2

1 General Information

EachTelco module includes the following con-

trolsorfeatures:channelon/offcontrol,faderlevel

control,cue control, modeselection with pan/bal-

ance control, Send control, record and monitor

controls, and output/Foldback selection to four

program buses and one off-line bus.Logic I/O is

available for logic wiring to/from the hybrid or

codec.

Remote Line Selector (RLS)

Module

This module (PRE99-1323) features twobanks

of eight selection buttons to independently route

the eight input signals to the two outputs. The

module switch either analog or digital signals,as

set by a DIP switch on the module.

Meter Switcher Module

This module (PRE99-1317) is located to the

right of the input module area.It provides control

of the digital timer and contains the meter source

selector buttons and the signal drivers for all the

meterdisplays.

The timer control section features stop, start,

hold, and reset controls, as well as whether the

modules automatically reset the timer.

Control Room Module

This module (PRE99-1318) contains the moni-

tor source selection and control facilities for the

console operator,and a co-host and a guest in the

control room.The module has parallel logic con-

trol (via a 14-pin connector) which provides ex-

ternal monitor dimming or muting, and warning

light control.The module includes four external

monitor inputs and six monitor and headphone

outputs.The outputs can simultaneously monitor

any combination of up to six analog sources (four

external inputs and Telco Record and Monitor)

andtwo digital sources (fourprograms and Send).

The Control Roommodulefeaturesmonitorand

headphonefader-levelcontrols,monitor-modecon-

Universal Analog/Digital Input

Module

The Universal Input modules (PRE99-1315)

feature two inputs (A and B), each of which can

acceptanalog or digital signals.Setup switcheson

the module set the source for each input. They

also set the source level (for analog signals) or the

attenuation amount (for digital signals). Each in-

put has its own fully independent parallel logic

control connector for remote control of the mod-

uleand/ormodulecontrol of the associatedsource

equipment.

Each Universal Input module includes the fol-

lowing controls or features: A/B input selection,

channel on/off control, fader level control, cue

control,mode selection with pan/balance control,

Sendcontrol,and output bus selectiontofour pro-

gram buses and one off-line bus.

Two 24-pin logic connectors connect logic wir-

ing to/from external control panels or peripher-

als. DIP switches set logic and module function

options for the A and B inputs.

Telco/Codec Input Module

Up to fourTelco/Codec (Telco) modules can be

installed into any of the input module slots on the

mainframe.The optionalTelco module (PRE99-

1316) has a single audio input (analog or digital)

from a remote send and receive device (like a tele-

phonehybrid,satellitetransceiver,ISDN interface,

or other stereo or mono Codec).

Eachmodulefeaturesmanual or automatic con-

trol of the Foldback signal returned to the hybrid

or codec.The Foldback signal for eachTelco mod-

ulecan be manually setto anyprogram oroff-line

bus.The Foldback signal can also follow theTelco

module’s on/off status when the Auto-Foldback

function is active. The Auto-Foldback function

automatically switches the feed to the caller be-

tween the off-line mix and the assigned bus with

the highest priority.For more information,see the

Telco Operation section on pages 3-7 to 3-9.

Revision B • 1/03

HARRIS CORPORATION

1-3

1 General Information

trol, cue and talkback level controls, and head-

phoneAuto-Cue select.

Studio Module

The optional Studio module (PRE99-1319) is

installedto the right of theControl Room module.

It provides a monitor and talkback-level control

for one studio or voice booth.The monitor source

can be any combination of 11 sources (four exter-

nalinputs,four programs,Send,andTelco Record

and Monitor) simultaneously.

The Studio module has a 14-pin parallel logic

connector for external dimming or muting of the

studio monitor speakers and control of a studio

warning light interface.Controls also provide the

ability to talk to or from a studio and an external

location.

Output Modules

Two Output modules ship standard with the

Legacy.

The Output 1 module (PRE99-1320) contains

the digital-to-analog converters and mix matrices

for creating mix-minus foldbacks to support up

to fourTelco/Codec modules. It also contains in-

dividually mixed outputs forTelco/Codec record-

ing.There is a mix-minus output for eachTelco/

Codecmodule.Digitaland analog outputs are pro-

vided for the mix-minus and recorder feed out-

puts. For digital outputs, sample rates of 48 kHz

and44.1 kHzare supported.The mix-minus ana-

log outputs are fixed at +4 dBu.This module fea-

tures output sample rate selectors for digital out-

puts and a gain trim control for the analogTelco

record mix output.

The Output 2 module (PRE99-1321) contains

the AES digital output drivers, digital-to-analog

converters,andanalog line amplifiersfor the Send

output and the four program outputs.The digital

output sample rate is 48 kHz.An output sample

rate of 44.1 kHz can be selected for the program

1 and 2 auxiliary outputs, the program 3 and 4

outputs,and the Send output. Gain trim controls

for the analog outputs are also provided.

PowerSupply

The separately packaged rack-mount power

supply assembly (PRE99-1202) uses keyed con-

nectorsto supply asingle +48 voltsDCto the con-

sole mainframe. There are two connectors from

thepowersupplyassemblytotheconsole:onecon-

nector supplies DC power and the other supplies

electrical signal information to the console.The

power supply module has an on/off switch and

an LED indicator on the front panel.The power

supplyis fully regulated and protectedagainst ex-

cessive current by internal fuses and electronic

safeguards.

Revision B • 1/03

HARRIS CORPORATION

1-4

1 General Information

SPECIFICATIONS

The specifications for the Legacy are signifi-

cantly more complete, and the related test condi-

tions are more defined, than those usually shown

for consoles in this class.Be sure to follow the test

conditions and measure in the units as stated.

The specifications arefor a fullyloaded Legacy-

30 input mainframe.

Test Conditions:

Specificationsare forthe basicsignal paths,per

channel, with >1k ohm loads connected to the

analog main outputs.

0 dBu corresponds to an amplitude of 0.775

volts RMS regardlessof the circuit impedance.This

is equivalent to 0 dBm measured into a 600 ohm

circuit for convenient level measurement with

meterscalibratedfor600ohm circuits.Noisespeci-

fications are based upon a 22 kHz measurement

bandwidth.The use of a meter with 30 kHz band-

width will result in a noise measurement increase

of approximately 1.7 dB.

Total Harmonic Distortion (THD+N) is mea-

sured at a +18 dBu output level using 1 kHz or a

swept signal with a 22 kHz low-pass filter.

FSD = Full Scale Digital, +24 dBu

Microphone Preamplifiers

Source Impedance: 150 ohms

Input Impedance: 5 k ohms minimum, balanced

Input Level Range: Adjustable, -65 to -30 dBu

Input Headroom: >20 dB above nominal input

Output Level: +4 dBu, nominal

Analog Line Inputs

Input Impedance: >40 k ohms, balanced

Input Level Range: Selectable; -10 dBv, +4 dBu,

+6 dBu, +8 dBu

Input Headroom: 20 dB above nominal input

Analog Main Outputs

Output Source Impedance: <3 ohms balanced

Output Load Impedance: 1 k ohms minimum

Nominal Output Levels: Program,Send,Telco/Codec

Mix-Minus,TelcoRecordMixFeed:+4 dBu,ad-

justable between +3 dBu and +9 dBu

Maximum Output Levels: Program, Send, Telco/

Codec Mix-Minus, Telco Record Mix Feed:

+24 dBu; +28 dBu with 100k output load im-

pedance and nominal output level adjusted to

+8 dBu

Digital Inputs and Outputs

Reference Level: +4 dBu (-20 dB FSD)

Digital I/O:Through digital input and digital Pro-

gram, Send,Telco/Codec Mix-Minus outputs

Signal Format: AES-3, S/PDIF (input only)

AES-3 Input Compliance:

24-bit sample rate conver-

sion available, individually switch selectable

AES-3 Output Compliance:

24-bit

Digital Reference:

Crystal (internal) or AES-3 (ex-

ternal) at 48 kHz ±100 ppm

Internal Sample Rate:

48 kHz

Output Sample Rates: Program 1 and 2 Main out-

puts 48 kHz;Program 1 and 2 Aux,Program 3

and4,Send,Telco/Codec Mix-Minus,andTelco

Record Mix outputs 48 kHz or 44.1 kHz, indi-

vidually switch selectable

Processing Resolution:

24-bit fixed with extended

precision accumulators

Conversions:

A/D 24-bit, Delta-Sigma, 128x

oversampling on all digital inputs; D/A 24-bit,

Delta-Sigma,128x oversampling

Latency:

<1.6 ms, mic in to monitor out

Revision B • 1/03

HARRIS CORPORATION

1-5

1 General Information

Monitor Outputs

Output Source Impedance: <3 ohms, balanced

Output Load Impedance: 1 k ohms minimum

Output Level: +4 dBu nominal,+24dBu maximum

Frequency Response

Microphone or Line Input to Program or Send Output:

+0 dB/-0.5 dB, 20 Hz to 20 kHz

Dynamic Range

Analog Input to Analog Output: 105 dB referenced to

FSD, 108 dB“A”weighted to FSD

Analog Input to Digital Output: 109 dB referenced to

FSD

Digital Input to Analog Output: 107 dB referenced to

FSD, 110 dB“A”weighted to FSD

Digital Input to Digital Output: 138 dB

Equivalent Input Noise

Microphone Preamp:-127 dBu, 150 ohm source

Total Harmonic Distortion + Noise

Mic Pre Input to Mic Pre Output: <0.005%, 20 Hz to

20 kHz, -38 dBu input, +18 dBu output, 100k

ohm load, 22 kHz filter bandwidth

Analog Input to Analog Output: <0.003% at 1 kHz,

+18 dBu input, +18 dBu output, 100 k ohm

load, 22 kHz filter bandwidth

Digital Input to Digital Output:

<0.00016%,20 Hzto

20 kHz, -20 db FSD input, -20 db FSD output,

20 kHz filter bandwidth

Digital Input to Analog Output:

<0.003% at 1 kHz,

-6 db FSD input, +18 dBu output, 100 k ohm

load, 22 kHz filter bandwidth

Crosstalk Isolation

Program-to-Program or to-Program or to-Send:

>95dB,

20 Hz to 20 kHz

A Input to B Input, B Input to A Input:

>110 dB,20 Hz

to 20 kHz

Stereo Separation

Analog Program Outputs:

>86 dB,20 Hz to 20 kHz

Console Power Requirements

Fully configured Legacy-14:185 watts at 115/230

VAC, ±12%, 50/60 Hz

Fully configured Legacy-22:250 watts at 115/230

VAC, ±12%, 50/60 Hz

Fully configured Legacy-30

:

285 watts at 115/230

VAC, ±12%, 50/60 Hz

Power SupplyVoltage

Console power: +48VDC at 8.34 Amp, redundant

operation optional

Power Supply Ground

Rack-mount power supply frame: grounded through

AC cord

Power Supply Connection

AC input: IEC power cord

DC output: two keyed multi-pin connectors

Dimensions

Legacy-14:9.75

"

x 41.13

"

x 33.38

"

(H,W, D)

Legacy-22:9.75

"

x 54.44

"

x 33.38

"

(H,W, D)

Legacy-30:9.75

"

x 67.24

"

x 33.38

"

(H,W, D)

Power Supply (Rack-mount power supply frame):

3.5

"

(2 RU) x 19.0

"

x 16.0

"

(H,W, D)

HarrisCorporation reserves the right to change

specifications without notice or obligation.

Revision B • 1/03

HARRIS CORPORATION

1-6

1 General Information

E) This Warranty is void for equipment which

has been subject to abuse, improper installa-

tion, improper operation, improper or omit-

ted maintenance, alteration, accident, negli-

gence(in use,storage, transportation,or han-

dling), operation not in accordance with

Seller’s operation and service instructions, or

operation outside of the environmental con-

ditions specified by Seller.

F) ThisWarranty is the only warranty made by

Seller, and is in lieu of all other warranties,

includingmerchantabilityandfitnessforapar-

ticularpurpose,whetherexpressed or implied,

except as to title and to the expressed specifi-

cations contained in this manual.Seller’s sole

liability for any equipment failure or any

breach of thisWarranty is as set forth in sub-

paragraph A) above; Seller shall not be liable

or responsible for any business loss or inter-

ruption,orotherconsequentialdamagesofany

nature whatsoever, resulting from any equip-

ment failure or breach of this warranty.

WARRANTY

The Legacy digital console carries a

manufacturer’s warranty which is subject to the

following guidelines and limitations:

A) Except as expressly excluded herein, Harris

Corporation (“Seller”) warrants equipment of

its own manufacture against faulty workman-

ship or the use of defective materials for a pe-

riod of one (1) year from date of shipment to

Buyer.The liability oftheSeller under thisWar-

rantyis limited to replacing,repairing,or issu-

ing credit (at the Seller’s discretion) for any

equipment, provided that Seller is promptly

notified in writing within five (5) days upon

discoveryofsuchdefects byBuyer,and Seller’s

examination of such equipment shall disclose

to its satisfaction that such defects existed at

the time shipment was originally made by

Seller, and Buyer returns the defective equip-

ment to Seller’s place of business in Mason,

Ohio, packaging and transportation prepaid,

with return packaging and transport guaran-

teed.

B) Equipment furnished by Seller, but manufac-

tured by another, shall be warranted only to

theextentprovided bythe othermanufacturer.

C) Thermal filament devices, such as fuses, are

expressly excluded from this warranty.

D) The warranty period on equipment or parts

repaired or replaced under warranty shall ex-

pire upon the expiration date of the original

warranty.

2

Revision B • 1/03

HARRIS CORPORATION

2-1

The Legacy mainframe is designed to

“drop into” a cutout (shown below) in the studio

furniture countertop. A minimum of 14 inches

(355.7 mm) of vertical clearance above the

countertop is required to fully open the meter

panel.The rear 2.5 inches (63.5 mm) of the main-

frame is open so wiring can be easily dressed up

throughthe mainframe to the module connectors,

which are hidden below the meter panel.

The Legacy console shipment consists of:

• The 14-, 22-, or 30-input mainframe with the

standard modules (Microphone Preamp,Meter

Switcher,ControlRoom,and Outputs) installed,

along with the other modules ordered (Univer-

salInput,Telco/Codec,RLS,Studio),and blank

panels to cover any unused positions.

• The rack-mount power supply assembly.

• The LegacyToolkit (3AA batteries,AMPMOD

IV crimp tool and contact removal tool, hex

driver,and module removal tool).

• Audio and Logic connector kit. The kit con-

tains all theAMP MOD IV connector housings

and receptacle contacts typically needed for

installation.

Installation

Console FrontView Console SideView,with dimensions (inches & [mm])

5.75"

[146.1]

11.79"

[299.5]

4.00"

[101.6]

0.75"

[19.1]

33.38"

[847.9]

4.00"

[101.6]

2.48"

[63.0]

14.00

"

[355.6]

2.50"

[63.5]

COUNTERTOP

1234567890123456789012345678901212345678

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1

23456789012345678901234567890121234567

8

1234567890123456789012345678901212345678

CONSOLE CUTOUT

(for recessed installations)

C

30.5"

[774.9]

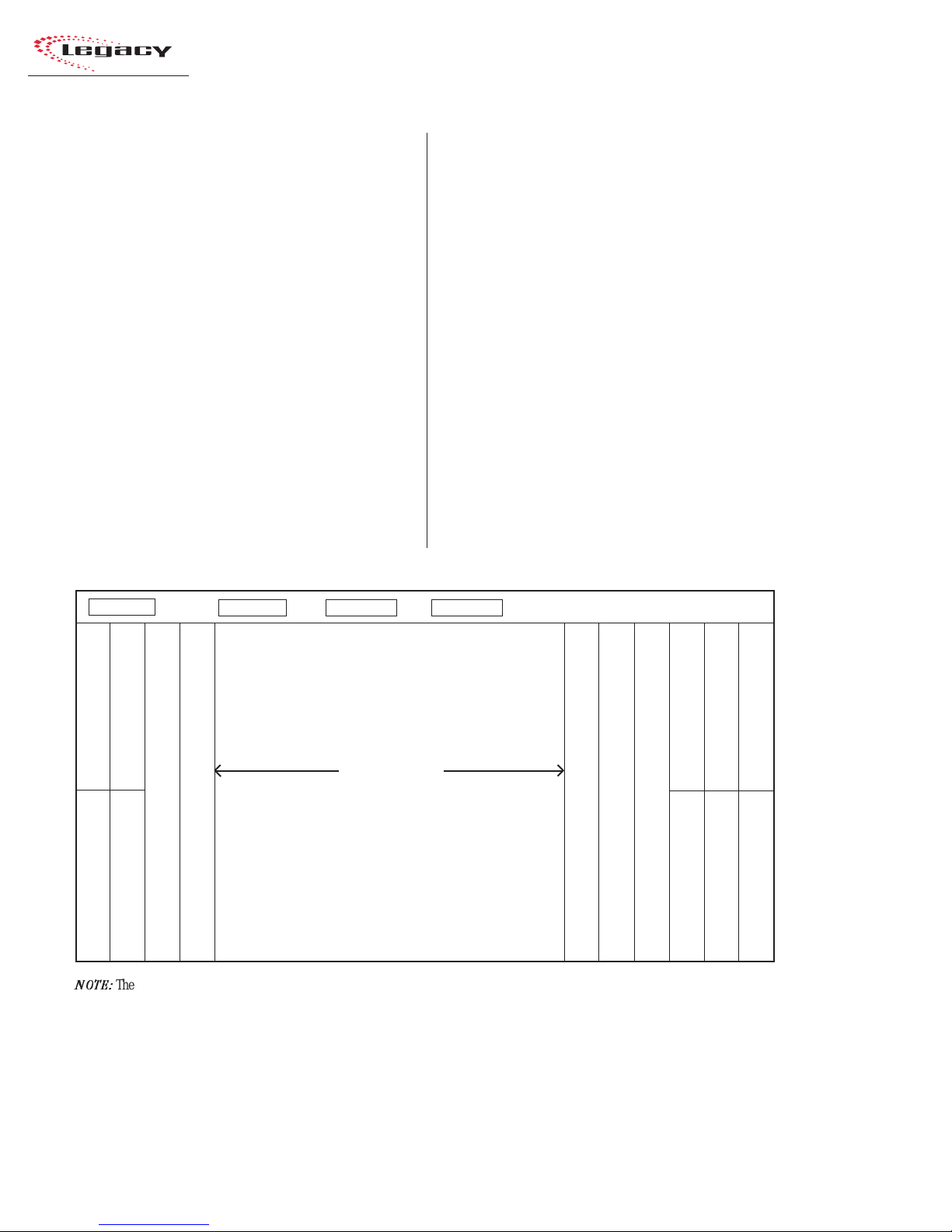

DimensionTable

Mainframe A B C

Legacy-14 41.13"[1044.7] 38.94" [989.1] 39.20" [995.7]

Legacy-22 54.44"[1383.2] 51.70"[1313.5] 52.00"[1321.2]

Legacy-30 67.24"[1708.4] 64.50"[1638.8] 64.75"[1645.1]

Millimeter dimensions in brackets. All dimensional tolerances are

+¼" [6.35], -0" [0.0]. Typical front setback is 12" [304.8]. Allow

14" [355.7] clearance above the countertop.

Revision B • 1/03

HARRIS CORPORATION

2-2

2 Installation

MAINFRAME CONFIGURATION

The Legacy design positions the input modules

inthe physical center of the mainframe.This gives

the operator equal reach to peripheral equipment

located to the either side of the console.

ModulePlacement

The 14, 22, or 30 input module positions can

have any combination or order of the following

modules installed: Universal Input,Telco/Codec

(fourmaximum),andRemoteLineSelector(RLS).

The remaining console positionsarefixed.TheMic

Preamplifier module(s), Meter Switcher module,

Control Room module, optional Studio module,

and the two Output modules must be positioned

as shown in the illustration below.

Console Installation

To simplify console installation,logic cable wir-

ingdiagramsfor specific peripheralequipmentare

available from the Harris Technical Services de-

partment. See page 4-1 for contact information.

INSTALLATION NOTE: Do not locate the con-

solenear intense electromagnetic hum fields,such

as those produced by large power transformers

and by audio amplifiers that use inexpensive

power transformers operating in or near satura-

tion.Strongelectromagneticfields mayimpair the

performanceoftheLegacyandneighboring equip-

ment.Audio cables mustalso berouted to achieve

maximum practical distance from all AC power

mains wiring.

Reserved position (covered by a 25" Blank panel)

Reserved position (covered by a 25" Blank panel)

Meter Switcher (standard)

Control Room (standard)

Studio (optional) 25”blank panel (standard)

Legacy Mainframe,Module Configuration

Mic Preamp (standard)

Output 1 (standard)

Output 2 (standard)

NOTE:

The number of input module positions matches the console model number (e.g., Legacy-22 has 22 input positions). There are

two DSP cards in the Legacy-14, three in the Legacy-22, and four in the Legacy-30.

The areas covered by the five 12.25" Blank Panels can be used for mounting Harris BMXdigital Accessory Panels or custom remote

control panels. Since the Harris BMXdigital Accessory Panels are 6" long, a PRE99-1100 Divider Kit (for mounting up to four

Accessory Panels in place of two 12.25" Blank Panels), or a PRE99-1101 Divider Kit (for mounting up to six Accessory Panels in place

of three 12.25" Blank Panels) is required. Typically, the PRE99-1100 Divider Kit is installed in place of the Blank Panels on the left

end of the console and the PRE99-1101 is installed in place of the Blank Panels on the right end of the console. 6" Blank Panels

(PRE99-1714-3) cover unused Accessory Panel positions.

Input modules

The input module positions are

filled with any combination or

number of Universal Input and

Remote Line Selector modules,and

up to fourTelco/Codec modules.

Unused positions are covered with

25" Blank Panels.

12.25" Blank Panel (standard)

12.25" Blank Panel (standard)

12.25" Blank Panel (standard)

12.25" Blank Panel (standard)

12.25" Blank Panel (standard)

DSP Card 1 (Master) DSP Card 2 DSP Card 3* DSP Card 4* * (number of DSPs present

set by the frame size)

Mic Preamp 2 (optional)

12.5”blank panel (standard)

12.5”blankpanel

(standard)

2 Installation

Revision B • 1/03

HARRIS CORPORATION

2-3

MeterPanel

The meter panel contains three horizontal bar-

graphmeters.Twoofthemetersprovideindividual

level monitoring for the Program 1 and 2 out-

puts.The third meter is used to monitor the level

of Cue, Program 3 or 4, any external input, the

Send output, or the Telco Record output, as se-

lected on the Meter Switcher module.The level at

which the peak indicator (PK) comes on, as well

asthe meter displaymode (peakhold or non-peak

hold),may be set for each meter via DIP switches

on each meter display board.

The meter panel also contains a slaveable 12/

24-hour digital clock (HH:MM:SS) and an event

timer (MM:SS:T) that can be controlled manu-

ally, through buttons on the Meter Switcher mod-

ule, or automatically through module On com-

mands.

For additional information on the meter panel,

see pages 3-15 and 3-16.

CONNECTOR ACCESS

All module connectors are hidden below the

meterpanel in normal operation.Themeter panel

connects to the rear of the console by hinges.To

access the connectors, open the meter panel by

lifting it up and rotating it toward the rear of the

console until it stops.

Caution: Make sure that the panel is open all

the way so that it does not accidentally fall shut.

To facilitate initial wiring, the meter panel can

be removed from the mainframe chassis.

To removethe meterpanel from themainframe:

1Open the meter panel fully and unplug the

meterpowercable(attached to the rearpanel)

and the two cables (meter signals and talk-

back mic) from the Meter Switcher module.

2With another person holdingthemeter panel,

remove the screws and bushings that attach

each gas spring to the meter panel. Lay the

gas springs on the mainframe while working.

3Unlatchthehinges bymovingtherelease pins

to their unlocked positions and lift the meter

panel up and off the mainframe.

Toreinstall the meterpanel,alignthe two halves

of the hinges, then release the pins out of their

unlockedpositions.

Reattach each gas spring to the meter panel by

inserting a screw through the gas spring and the

bushing.

Main Meters

(Program 1 and 2)

Clock Event

Timer

Aux Meter

(Meter Switcher:Displays

Cue,Program 3 or 4,Send,

or Telco Record)

Legacy Meter Panel

Revision B • 1/03

HARRIS CORPORATION

2-4

2 Installation

GROUNDING ANDSHIELDING

The broadcast facility’s technical ground can

be connected to the mainframe chassis using the

threaded insert on the rear of the console (shown

in the Power Connections drawing on this page).

Use a 10-32 screw and crimp lug to terminate the

facility’s technical ground wire.

Connect the cable shields at both the console

and the peripheral end when all system compo-

nents share a common ground potential and are

usingisolated groundAC outlets tied individually

back to the main technical ground.

If isolated ground AC outlets are not available,

connect the cable shields at the console end only.

The shields should be floated (left unconnected)

at the peripheral device end. Ensure the periph-

eral devices connect to a clean ground through

their power cords, or through separate ground

wires to the facility’s technical ground.

POWER SUPPLY GROUNDING

NOTE: The Power Supply chassis

connects to the AC mains safety or

“U”ground wire.

AUDIOGROUNDNOISES: Buzz pickup is gener-

ally electrostatic—such as capacitive coupling

between an audio line and a power line.To avoid

audio ground noises, do not route audio lines in

the same wireway as an AC power line.

INSTALLINGBACKUPBATTERIES

ThreeAA rechargeable NiCad batteriesare sup-

pliedinthe 76-2001Tool Kit.They supplya“Keep

Alive” voltage to hold each module’s logic state

duringmomentary power outages.They mount in

a battery clip located below the three 12" blank

panels on the right end of the console.

To install the backup batteries:

1Removethethreeblankpanelslocatedinfront

of the Output modules.

Threaded

Insert for

10-32

screw

Power

Supply

Status

48VDC

Power

Meter

Panel

Power

Power Connections —

Console Mainframe, Rear Panel

POWERSUPPLY

The power supply assembly is rack mounted (it

requires 2 RU or 3.5" [88.9 mm] of rack space)

within the console cabinetry, below and to the left

or right of the supporting countertop.The Legacy

Power Supply must be installed so that the 30

foot power supply cable supplied with the Power

Supply is not under any tension when routed

through the cabinet and connected to the

mainframe’s rear panel connectors.

ConnectingthePowerSupply

The power supply cable has two connectors:

• A 5-pin connector to supply 48 volt DC

power to the console.

• A 4-pin connector to supply power supply

statusinformation (Imminent Power Loss)

to the console.

Both connectors must be attached to the back

of the Legacy and to the power supply.

DC GROUNDING NOTE:

Do not

connect

the audio or logic supply

ground wiring to the chassis of the

power supply.

AC GROUNDING NOTE: Do not

defeat the safety ground in any way.

Doing so may provide a potentially

dangerous condition to the operator.

2 Installation

Revision B • 1/03

HARRIS CORPORATION

2-5

Master clocks are available from:

ESE

142 Sierra St.

El Segundo,CA 90245.

Telephone: 310.322.2136

www.ese-web.com

-+-

+- +

Output 1

Output 2

Blank

Middle 12.25" Blank Panel

removed to show the

battery clip

12.25" Blank panel

12.25" Blank panel

Backup Battery Installation

12345678901234567890123

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

1

234567890123456789012

3

12345678901234567890123

Clock Option Switches (DS1)

Clock circuit board DIP switch.

Factory default settings are DOWN.

12 3 45

SWITCH DOWN

12-hour

TC89

ESE Disabled

(Autonomous)

Unused

Unused

Clock PCA

SWITCH UP

24-hour

TC90

ESE Enabled

(Slaved)

Unused

Unused

2Install the batteries into the battery clip,

observing the correct polarity marked on the

battery clip, as shown below.

Note: Replace batteries yearly to ensure con-

tinuous backup protection. Because this device is

optimized for continuous slow charge operation,

usePanasonicP-50AAHbatteries(ortheirequiva-

lent).To prolong battery life,remove the batteries

when the console will be powered down for an

extended period.

SETTINGTHE CLOCK

The digital time-of-day clock can operate in au-

tonomous or slave modes. When used autono-

mously (the factory preset), a temperature-con-

trolled quartz crystal oscillator controls the clock

timing.In slave mode,clock timing comes from a

TC89-orTC90-compatible ESE master clock ref-

erence signal.

The operating mode (autonomous or ESE slave),

the type of ESE signal (TC89 orTC90), and the

type of clock time desired (12-hour or 24-hour

format)are set using DIP switchDS1on the clock

PCA. DS1 is on the right rear edge of the circuit

board.

To access the clock PCA,open the meter panel.

The clock PCA is mounted behind the clock dis-

play on the meter panel.

Withthe clock set toautonomous mode,it must

be set after power-up. There are three clock set

buttons on the bottom left front of the clock PCA.

• Usethe right button (Fast) toscroll bymin-

utes at a time.

• Use the middle button (Slow) to scroll by

seconds at a time.

• Use the left button (Hold) to synchronize

the console clock to an external time refer-

ence by setting the clock ahead of the

Clock Circuit Board,left front edge

Setting the Clock

Hold Slow Fast

Revision B • 1/03

HARRIS CORPORATION

2-6

2 Installation

METERSETUP

The level at which theblue peakindicators turn

on, as well as the meter display mode (peak hold

ornon-peak hold), is set separately for eachmeter

usingDIPswitchesontheedgeofeach meter PCA.

Toaccess the meter DIP switches,openthemeter

panel by lifting it up and rotating it toward the

rearof the console until itstops.Each meter’s DIP

switchesare locatedon theunderside of the meter

panel, directly below the right end of each meter.

externaltimereference,then press and hold

the HOLD button to freeze the time.When

theexternaltime reference reachesthe time

ontheLegacy clock,release the HOLDbut-

ton to start the clock.

When an ESE time-code signal is connected to

theBNC connector onthe clock circuitboard, and

slave mode is selected (DS1-3 is set UP),the clock

does not require setting. If the ESE time-code sig-

nal fails, the clock automatically defaults to its

internal crystal reference oscillator, flashing the

display colons to indicate the loss of time-code.

EVENTTIMER

The event timer displays time in minutes, sec-

onds and tenths of seconds.The only timer option

setting is whether to display the tenths of seconds

digit as the timer runs. DS1-1 (a DIP switch on

the timer circuit board, located behind the timer

display),setswhether the tenths are shownor not.

In the UP position, the tenths of seconds are dis-

played.Inthe DOWNposition,the factory default,

the tenths do not display while the timer runs.

Note that the tenths of seconds are always shown

when the timer is in the Stop or Hold mode.

EventTimer Option Switches (DS1)

12345678901234567890123456

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

1

234567890123456789012345

6

12345678901234567890123456

Timer circuit board DIP switch.

Factory default settings are DOWN.

12345

Timer PCA

SWITCH UP

Unused

Unused

Unused

Unused

.1 sec display ON

SWITCH DOWN

Unused

Unused

Unused

Unused

.1 sec display OFF

MeterDIP SwitchDefinitions

# Switch Name UP Function (switch set up) DOWN Function (switch set down)

1 Peak Indicator Level See Switch 1 and 2Table,below

2 Peak Indicator Level See Switch 1 and 2Table,below

3 Meter Display Mode Non-peak hold Peak hold

4 Spare Switch

5 Termination Switch Set UP for Meter 1 (PGM 1) Set DOWN for Meters 2 & 3

Switch 1 and 2Table

Use these switches to set the level

wheretheBluepeakindicatorslight.

#1 # 2 Peak Level

DOWN DOWN 0dB

UP DOWN -2dB

DOWN UP -4dB

UP UP -6dB

Meter Option Switches (DSW2)

Meter PCA

123 45

1234567890123456789012345678901212345678901234567

1234567890123456789012345678901212345678901234567

Switches1,2,3 shown down,

switches4 and 5shown up.

2 Installation

Revision B • 1/03

HARRIS CORPORATION

2-7

WIRE PREPARATION

All Legacy audio and logic wiring terminates

in AMP MOD IV receptacle contacts at the con-

sole.Strandedwire of 22 to 26AWG,with insula-

tion diameters of .040 to .060 inch, can be used

with the AMP MOD IV receptacle contacts.

Follow these steps for audio wire preparation:

1Stripthecableinsulationjacketandfoil shield

back 1½" [38.10 mm].

2Remove the foil shield and sleeve the drain

wire with 20 AWG Teflon sleeving. Leave

9/64" [3.57 mm] of the drain wire exposed.

3Cover the cut end of the jacket with 3/4"

[19.05mm] of heat-shrinktubing.Shrinkthis

tubing,centeredonthe jacket cut end,to hold

the drain wire sleeving in place.

4Strip the signal wire insulation back 9/64"

[3.57 mm].

5Crimp the receptacle contact onto the wire

and insulation.

Audio Cable Shield Note: To ensure your in-

stallation follows recommended grounding pro-

cedures, you must sleeve all drain wires with Te-

flon sleeving and put heat shrink tubing over all

cable jacket cut ends to insulate the shield wire.

Cabling andWiring

Before installing the console,draw up a facility

wiringplan thatlists theconsole interconnections

withallperipheraldevices.Identify and createtags

for all audio and logic cabling.List each connec-

tion in a master facility wiring logbook to facili-

tate wiring installation, future system wiring

changes,equipment updates,and system trouble-

shooting.

Refer to the module Quick Connection Guides,

on pages 2-16 to 2-49, for information on each

audio and logic connection (including block dia-

grams for each logic interface connector) and on

each module’s setup DIP switches.

REQUIREDCABLES ANDWIRE

The Legacy uses the following types of cables

and wires:

• Analog audio connections require two-

conductor, stranded, insulated, foil-shield

cable using a separate shield drain wire

(equivalentto Belden 8451,9451or8761).

• AES/EBU connections require 110 ohm

two-conductor, stranded, insulated, foil-

shield cable containing a separate shield

drain wire (equivalent to Belden 1800A).

• Logic control cables require stranded, 22

AWG, multiple-conductor, non-shielded,

jacketed cable (equivalent to Belden 9423,

8457 or 9421).The number of conductors

usedis determined bythe application.Typi-

cally cables with five and eight wires are

most often used for constructing logic

cables.Even though there are eighteen dis-

tinctsignals onthe LogicInterface connec-

tor, only a handful are typically used for

any given application.

AMP MOD IV Receptacle Contacts

9/64”[3.57mm]

Insulation Barrel

Properly

Crimped Contact

Wire Barrel

Revision B • 1/03

HARRIS CORPORATION

2-8

2 Installation

Logic control cables are fabricated in a similar

manner to the audio wiring.Strip the jacket insu-

lation back 1½" [38.10 mm], sleeve the cut end

with 3/4" [19.05 mm] of shrink tubing and strip

the insulation from each wire 9/64" [3.57 mm].

CRIMPTOOL OPERATION

A ratcheting AMP MOD IV crimp tool is

included in the tool kit.The tool crimps both the

insulation and wire barrels on the AMP MOD IV

receptacle contacts in one crimping action.

To use the ratcheting crimp tool:

1Hold the crimp tool with the printed side up.

Insertthecontact from theoppositeside, with

the barrel openings up, until the insulation

barrel end is flush to the opening of the die.

Close the tool only until the anvil holds the

contact in place (Refer to the cutaway view

on this page).

2Insert the stripped wire into the contact until

it hits the tool’s wire stop. Hold the wire in

place while squeezing the tool handles to

crimp the contact onto the wire. The tool

handlesautomaticallyreleaseandspringopen

after the crimp cycle is complete.

Once the contact has been crimped, insert and

lock the contact receptacle into the appropriate

connectorhousing following thepin-out diagrams

found in the Quick Guides on pages 2-16 to 2-49.

A receptacle contact is inserted into the hous-

ing with its locking tab side toward the locking

tab slots on the side of the connector housing. A

slight click can be heard when the contact’s lock-

ing tab springs up into the locking tab slot.

To removeacontactfromahousing,thePRE70-

129 Contact RemovalTool (included in the PRE

76-2001 tool kit) is required. Insert the tool’s tip

into the locking tab slot and press the locking tab

down while lightly pulling on the wire to remove

the contact from the housing.

CrimpTool — CutawayView

Anvils

Printed

Side

Wire Stop

AMP MOD IV

Receptacle

Contact

Die

LockingTab

LockingTab Slots

Contact RemovalTool

ReceptacleContact

Insertion & Removal Detail

AMP MOD IV

Contact

CrimpTool

Audio Wire,ready for insertion into an

AMP MOD IV connector housing

AMP MOD IV

Receptacle Contacts

Cable ID

Tag

3/4”[19.05mm]

Shrink Tubing

Teflon Sleeving

over drain wire

This manual suits for next models

2

Table of contents

Other Harris Recording Equipment manuals