Contents

4

Hans Turck GmbH & Co. KG | T +49 208 4952-0 | F +49 208 4952-264 | [email protected] | www.turck.com6 Connection.........................................................................................................................................21

6.1 Connecting the device in Zone 2 and Zone 22 ........................................................21

6.2 Connecting the modules to Ethernet ........................................................................21

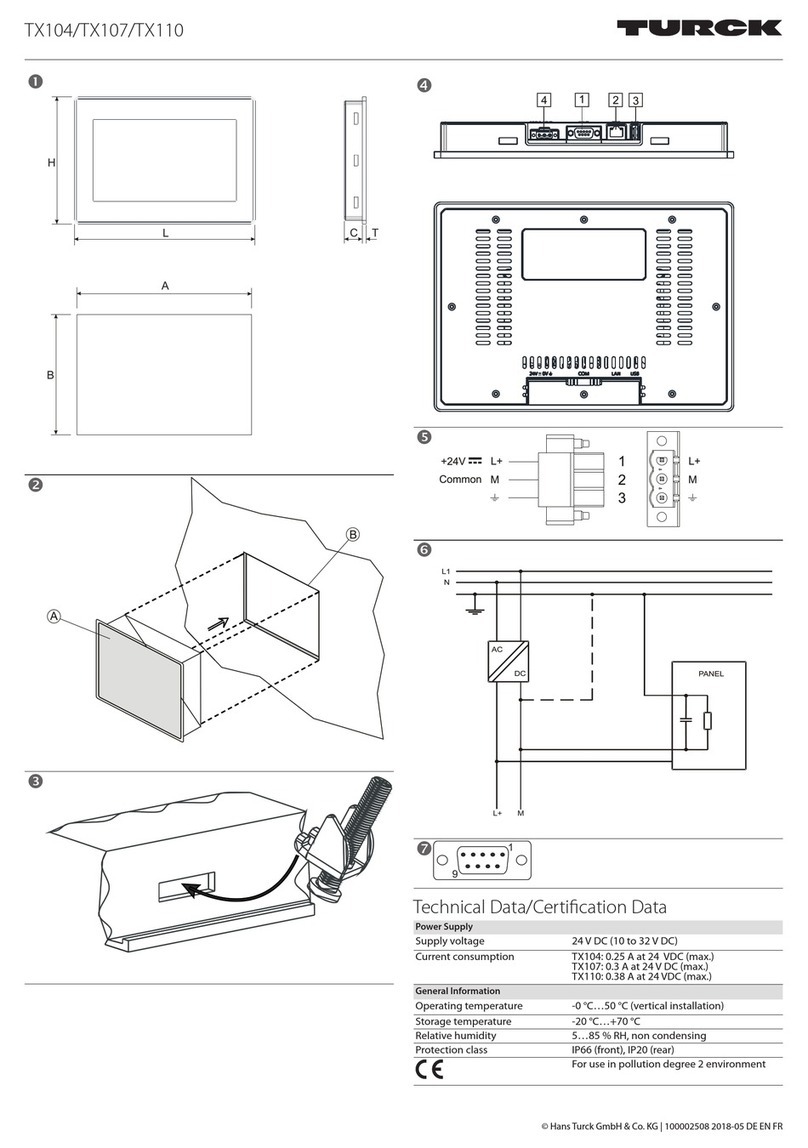

6.3 Connecting the power supply ....................................................................................22

6.4 Connecting RFID read/write devices .........................................................................23

6.4.1 Connecting read/write heads for the HF bus mode..........................................................23

6.5 Connecting digital sensors and actuators................................................................27

7 Commissioning .................................................................................................................................28

7.1 Adjusting network settings.........................................................................................28

7.1.1 Adjusting network settings using switches on the device .............................................28

7.1.2 Adjusting the network settings via the Turck Service Tool ............................................30

7.1.3 Adjusting network settings via the web server ..................................................................32

7.2 Preparing the device for commissioning via the web server ...............................33

7.2.1 Opening the web server and editing the settings.............................................................33

7.2.2 Establishing the connection between the OPC UA server and OPC UA client........37

7.2.3 Validating security certificates ..................................................................................................40

7.2.4 Adapting settings for OPC UA communication – set endpoints..................................42

7.2.5 Setting the OPC UA password...................................................................................................47

7.2.6 Setting up an OPC UA client via an SDK ................................................................................49

8 Setting ................................................................................................................................................50

8.1 Information model – mapping....................................................................................50

8.1.1 RFID channels – mapping in the information model........................................................52

8.1.2 Variable Presence – tag present at read/write head.........................................................58

8.1.3 Setting HF bus mode for OPC UA.............................................................................................58

8.1.4 Digital channels (DXP) – mapping in the information model .......................................63

8.2 Setting RFID interface parameters via the web server...........................................64

8.2.1 Setting RFID channel parameters via the web server.......................................................64

8.2.2 HF applications – selecting the tag type...............................................................................66

8.2.3 HF applications – setting the bridging time (bypass time) ............................................68

8.2.4 Setting digital channels (DXP) parameters via the web server.....................................69

8.2.5 Digital channels – setting switchable VAUX power supply............................................70

8.3 Setting RFID interface parameters via the DTM......................................................72

8.3.1 Connecting the device with the PC.........................................................................................72

8.3.2 Editing parameter data with the DTM – online parameterization...............................75

8.3.3 Evaluating diagnostics with the DTM.....................................................................................76

8.3.4 Reading process input data with the DTM – measured value.......................................77

8.4 Testing the device with demo programs..................................................................78

8.4.1 Testing RFID methods..................................................................................................................79

8.4.2 Testing the reading of UID or EPC ...........................................................................................80

8.5 Setting UHF readers......................................................................................................81

8.5.1 Setting UHF readers via the DTM.............................................................................................81

8.5.2 Setting UHF readers via the web server.................................................................................81

8.5.3 Testing UHF readers via the web server ................................................................................83

9 Operation ...........................................................................................................................................85

9.1 Executing a method and calling data........................................................................85

9.1.1 Example: Reading or writing tags with a specific UID ......................................................86

9.2 HF applications – using the ScanStart method .......................................................92

9.2.1 Executing the ScanStart method by setting the ScanActive variables ......................92

9.3 HF applications – using the ScanStart method in HF bus mode ..........................93