Harris 9250-05 User manual

© 2000 HARRIS INSTRUMENT CORPORATION.

ALL RIGHTS RESERVED

Model 9250-05 High-Speed Resistance Tester

Operators Manual

High-Speed Resistance Tester – Model 9250-05

Operators Manual

Section Table of Contents

Introduction 3

Product Overview 3

Computer Interface 4

Operational Considerations 5

Manual Conventions 5

Pow er Sw itch 5

Product Specifications 6

Pow er 6

Accuracy 6

Resolution 7

Connections 7

Terminal INPUT Connector 7

Serial Communications Connector 8

Logic Input Connector 8

Physical Dimensions 8

Optional Configurations 9

Accessories 9

Model 9250-05 Commands 10

Data Entry Conventions 10

Invalid Command Response 11

Averaging Setting 11

Baud Rate Setting 12

Resistance Calibration 12

Line SYNC Commands 13

Line SYNC ON 13

Line SYNC OFF 13

Limits Settings 13

Set UPPER Limit 13

Set LOWER Limit 13

Start Readings 13

HELP Screen 14

Set Resistance Range 14

Stop Readings 15

Auto-Range Selection 15

Set Auto-Range ON 15

Set Auto-Range OFF 15

Diagnostic Output 15

Restore Factory Defaults 15

System Operation 16

Serial Communications 16

RX/TX Lamps 16

Configuring Window s® TERMINAL 17

Verify Communications 18

Model 9250-05 Calibration 19

Calibration Example 19

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

2

Introduction

The Harris Instrument Corporation High-Speed Resistance Tester – Model 9250-05 is designed

for high-volume testing of the resistance of the parts and components manufactured in industrial

environments. It is a high-resolution ohmmeter that couples laboratory precision with the durability

and speed required by industry.

Utilizing a powerful digital signal processor (DSP) micro-controller, the Model 9250-05 is capable

of 250 readings per second over a serial communications link (RS-232) or via a remote LED

Display/Keypad Customer interface (DK Option). The Model 9250-05 responds to a variety of

ASCII commands and includes a help screen for operator assistance. The resistance tester

requires connection to a host computer or any device capable of transmitting commands via RS-

232. Calibration is software controlled.

Product Overview

The Model 9250-05 performs a 4½-digit, 4-wire Kelvin-based resistance measurement. The use

of a four-terminal resistance measurement system eliminates the inaccuracies introduced by test

lead resistance. All functions of the Model 9250-05 are selected and data is returned by

commands across the serial communications link.

The measurement ranges are selectable via instructions from the host computer (or optional LED

Display/Keypad Customer Interface). Resistance ranges of 0.20000, 2.0000, 20.000,

200.00, and 2,000.0 are available and can be operator selectable or can be set up for auto-

range selection. Auto-ranging selects the range when the resistance falls below 10% of the

current range and automatically switches to the lower range. A lighted ON/OFF push-button

switch is mounted on the front panel of the unit, along with two red LED lamps that indicate when

the serial communications link is functioning.

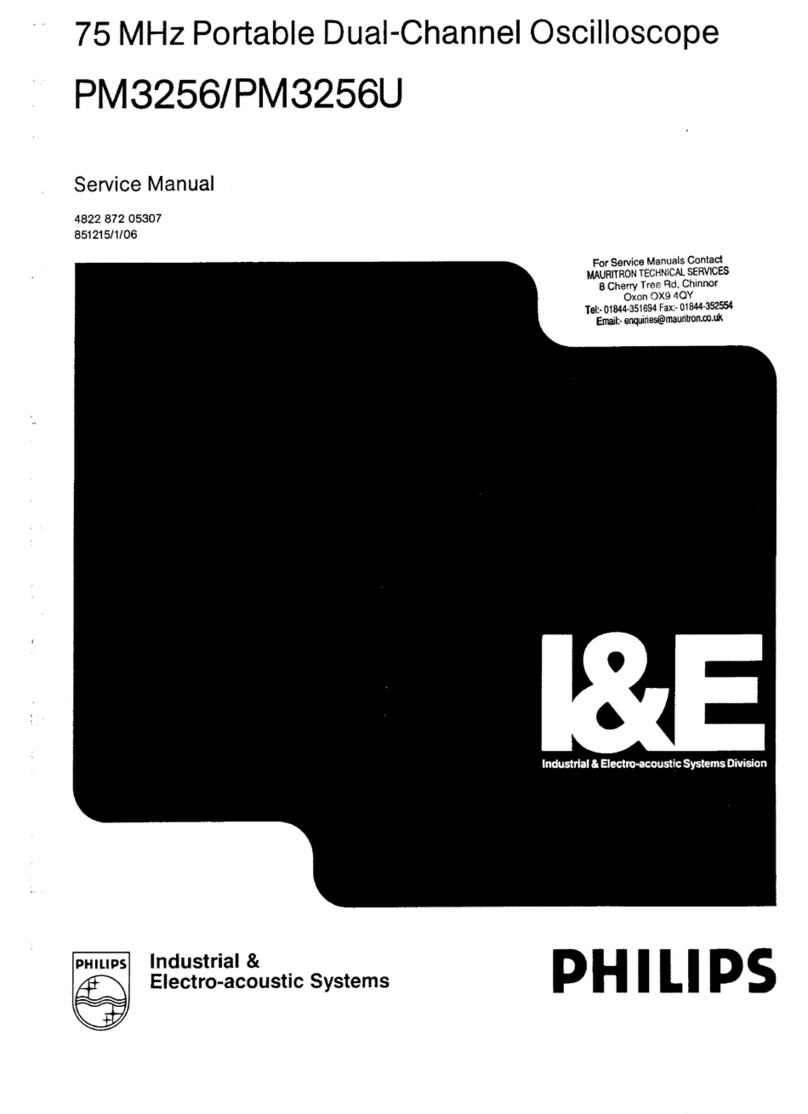

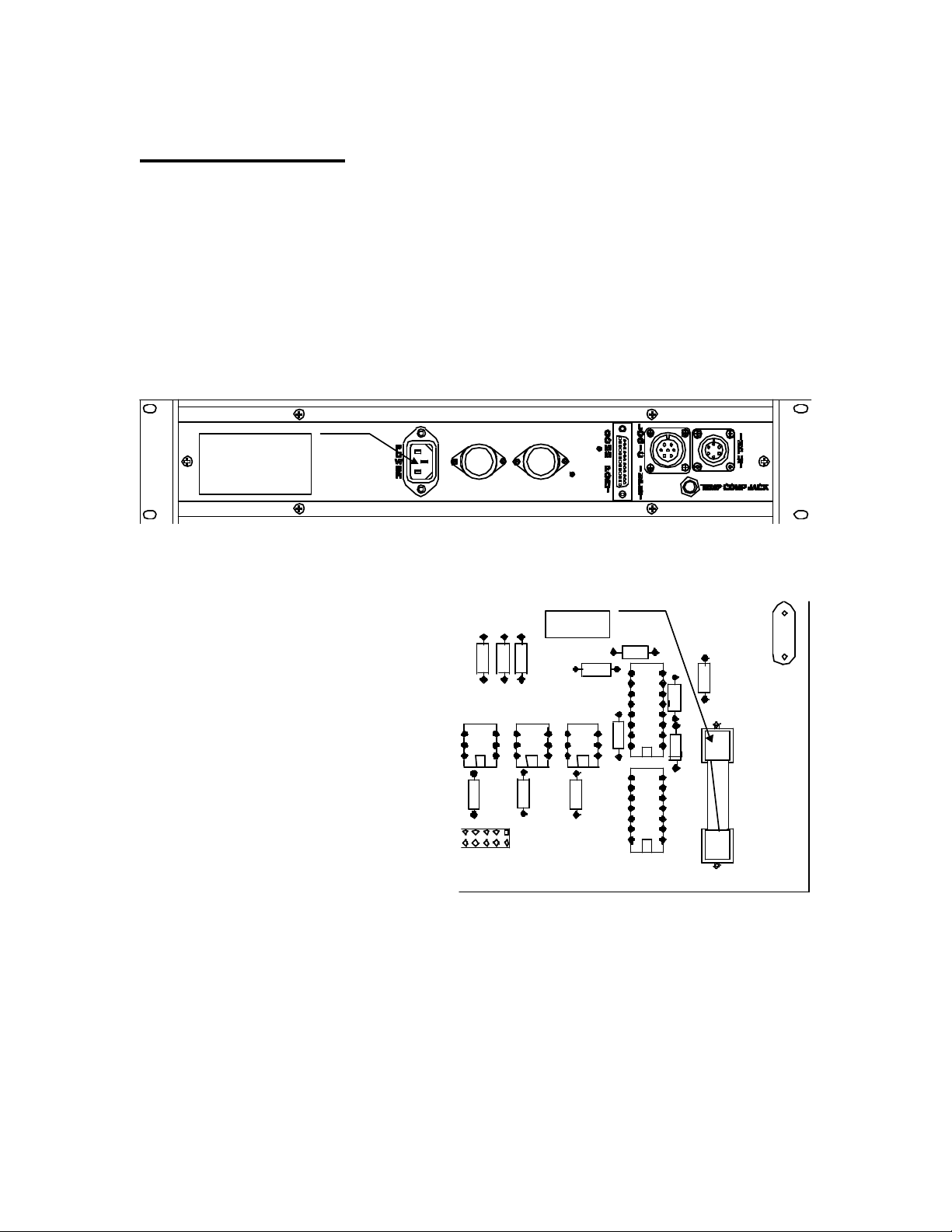

Figure 1: Typical Model 9250-05 Front Panel

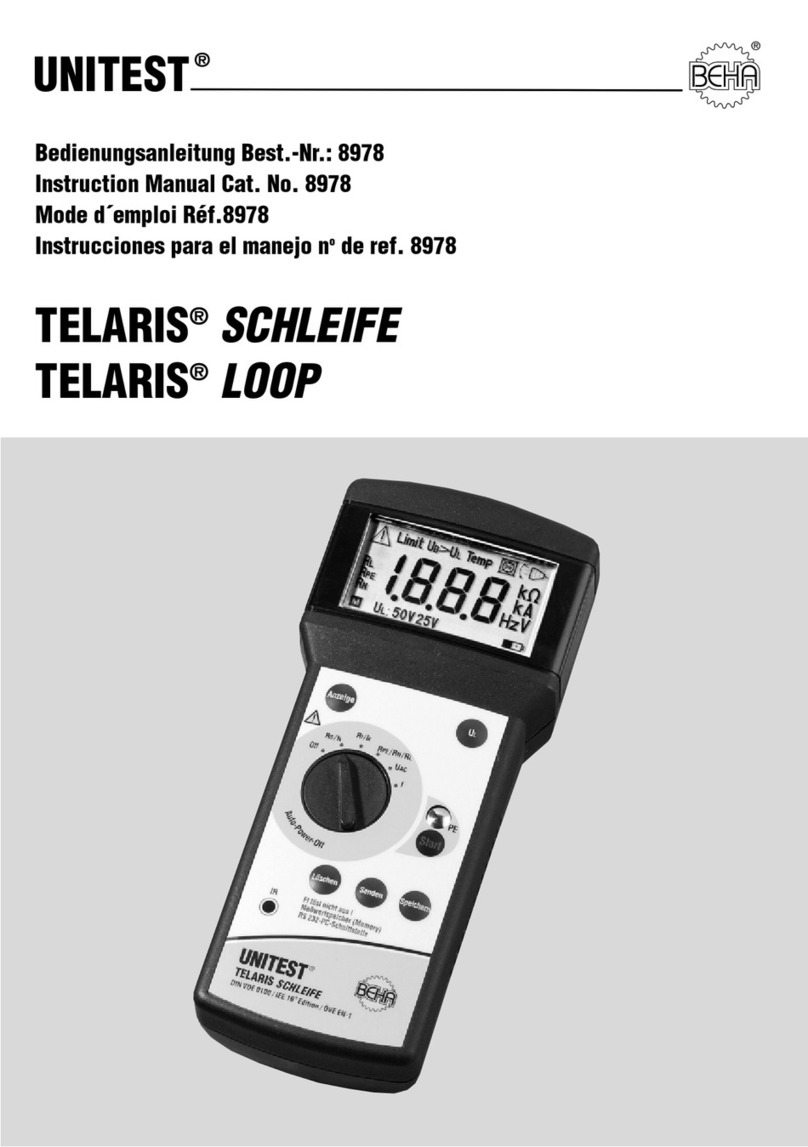

Figure 2: Typical Model 9250-05 Back Panel

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

3

The Model 9250-05 also includes a relay output which may be triggered via high/low limits (set via

the computer interface) permitting the automated rejection (GO/NO-GO) of unacceptable

components. To protect the instrument from high voltage damage, there is a safety relay that locks

out the resistance tester during high-pot or surge tests.

A Temperature Compensation probe input is available for measuring the ambient temperature. An

infrared Temperature Compensation Probe is available for measuring the temperature of the part

under test by the Model 9250-05. The temperature range is 0 - 120ºC with an accuracy of ±2ºC.

The temperature is available over the serial communications link.

Computer Interface

The resistance ranges are selected and data returned by ASCII commands via the serial

communications link to either a host computer or the LED Option Customer Interface. The unit

requires a RS-232 command to begin sending, and to stop, resistance readings. The Model 9250-

05 returns the measured data within 10msec over the RS-232 communications link (format

X.XXXX followed by a carriage return/line feed) with a floating decimal point matching the

selected range. Resistance range changes and temperature readings may be polled from the link.

Calibration is performed by placing a calibration standard for each range across the resistance

tester inputs and transmitting a calibration command for each range.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

4

Operational Considerations

The Model 9250-05 is highly resistant to most of the industrial environments that can cause

problems with resistance test equipment. The operating temperature of the Model 9250-05 is 32ºF

to 122ºF [0ºC to 50ºC]. Operations outside this range should be avoided. Temperature

compensation for resistance readings is detailed in the TC Option section (if applicable).

NOTE:

If any welding is to be performed near the Model 9250-05, or

anywhere on the process line where the Model 9250-05 is installed,

disconnect ALL cables from the Model 9250-05. This prevents system

overload by the current generated from welding.

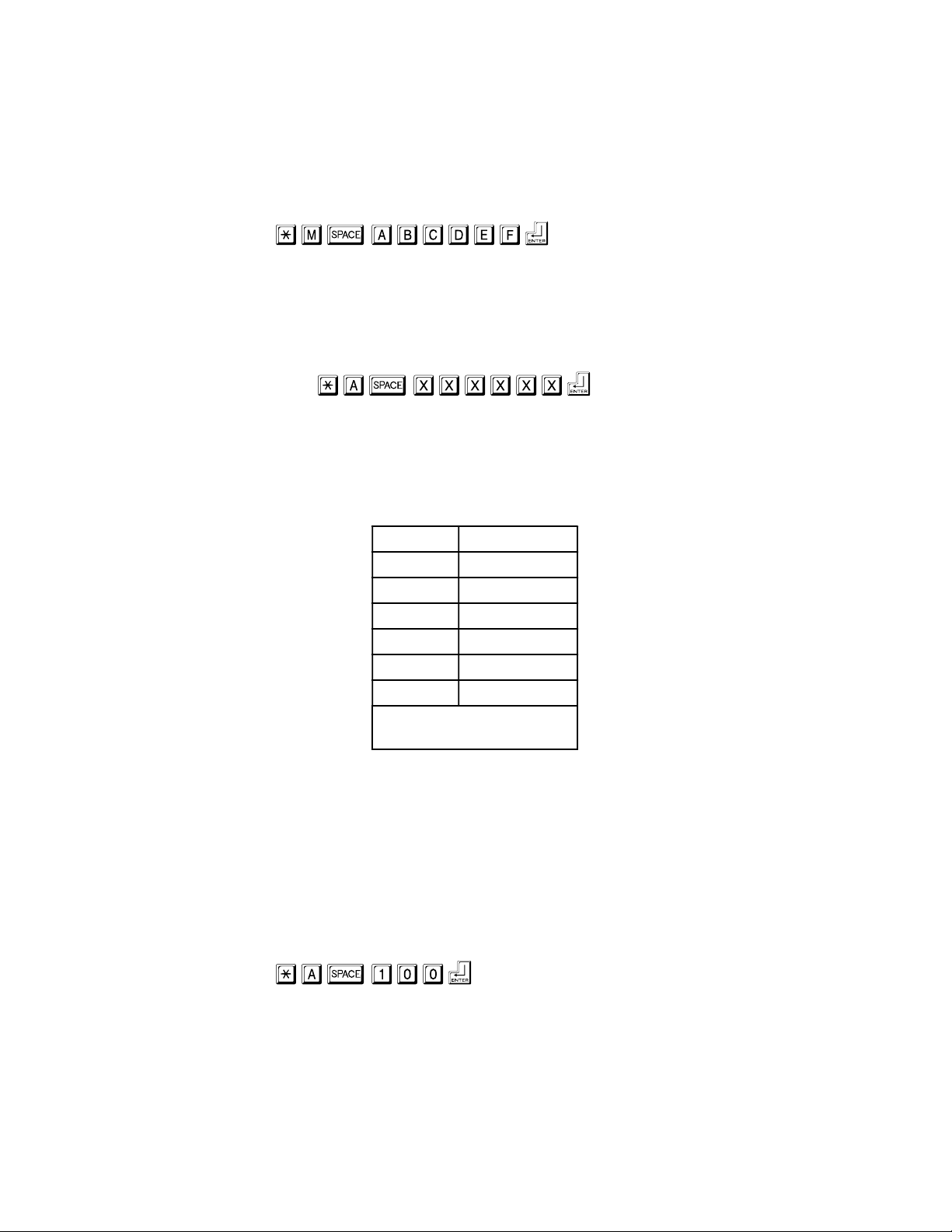

Manual Conventions

Throughout this manual section, there are many keyboard commands that will be used to signify

command sequences. Different fonts will be used for the keyboard commands. The following

table describes these commands and keystrokes.

Key Description

Space Bar

Enter Key

Command Sequence Start

Backspace

Caps Lock

Keystroke

*S Communications Software Response

Mouse Action on Host Computer

Table 1: Manual Conventions

Power Switch

A lighted push-button power switch is located on the front panel of the Model 9250-05. This

switch is the master power switch for the unit. If this switch is pushed in, the green LED lamp

should light. If the lamp does not illuminate, check the power line cord connections to ensure that

the unit has power. If the unit does have power and the lamp will still not illuminate, contact Harris

Instrument Corporation IRT Service for more information.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

5

Product Specifications

The Model 9250-05 is available with a variety of standard and optional features which allow the

unit to meet a wide range of industrial resistance testing requirements.

Power

Power Supply (rated at 122ºF [50ºC]):

105VAC - 125VAC @ 50Hz - 60Hz, 2.0Amp Maximum, 250Watts Maximum;

208VAC - 248VAC @ 50Hz - 60Hz, 1.0Amp Maximum, 250Watts Maximum.

Power connection is via a three-prong HP-

style enclosed connector on the back panel

of the unit.

The power line is filtered to suppress power

line transient noise and power line induced

RF interference. Quick disconnect power

line connections are made directly to the

internal power line filter inside the enclosure.

The input power is fused with a 2Amp Slo-

Blo type 3AG fuse. See Figure 4 for fuse

location.

Accuracy

±0.02% of Full Scale

±1 digit at 25ºC

±0.02% per ºC for 0ºC - 50ºC.

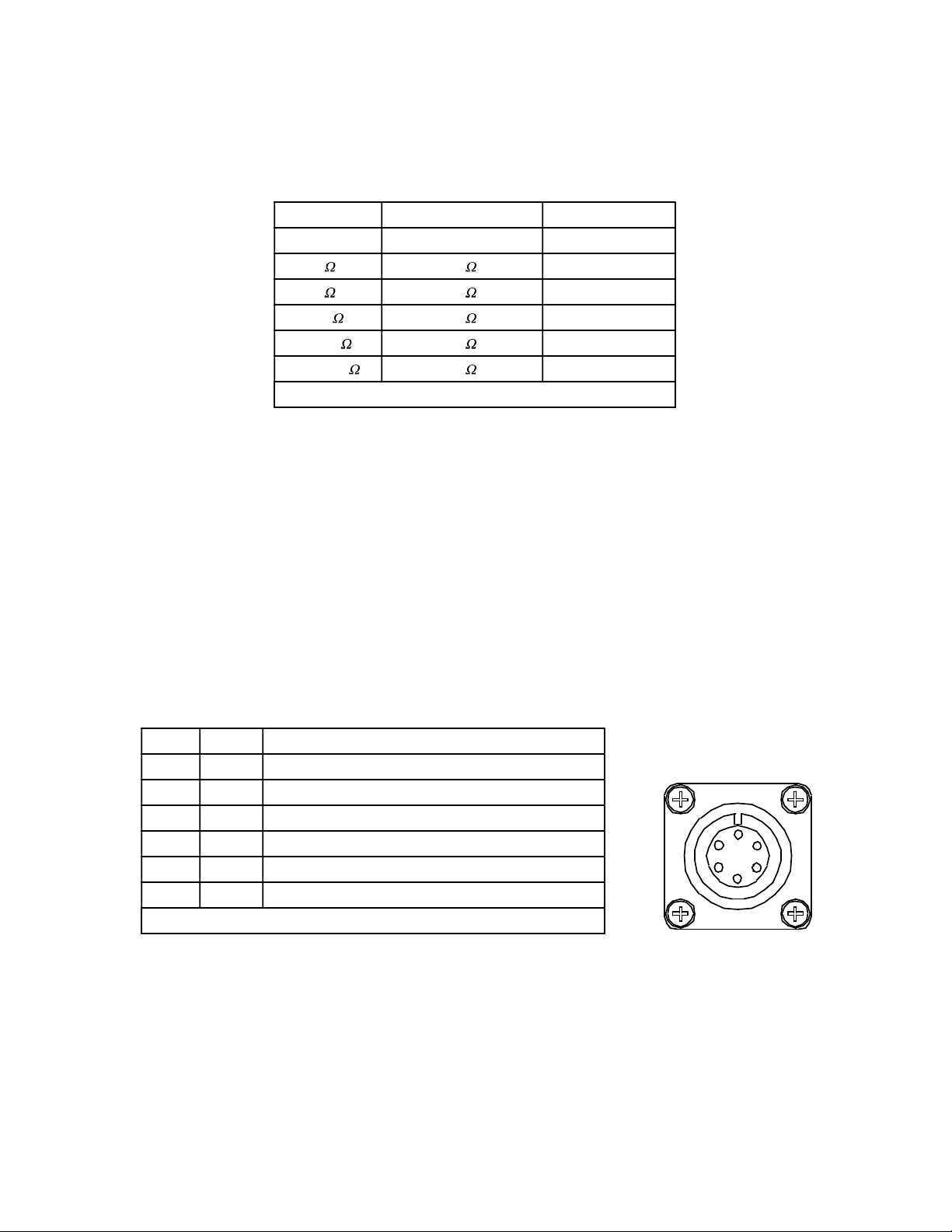

Figure 3: Power Connection for Model 9250-05

Figure 4: Fuse Location on 3696032 Board

Fuse

HP-Style

Power Cord

Connector

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

6

Resolution

The resolution of the Model 9250-05 is based upon the range of resistance tests being performed.

Range Resolution (4½-digit) Range Number

0 None 0

0 - 0.2 0.00001 1

0 - 2.0 0.00010 2

0 - 20.0 0.00100 3

0 - 200.0 0.01000 4

0 - 2000.0 0.10000 5

Table 2: Resolution Specifications and Range Numbers

The Range Number in Table 2 is the value (X) entered with the Set Range command.

Connections

There are several connectors on the back panel of the Model 9250-05 for attachment of terminals,

RS-232, resistance inputs, and logic inputs.

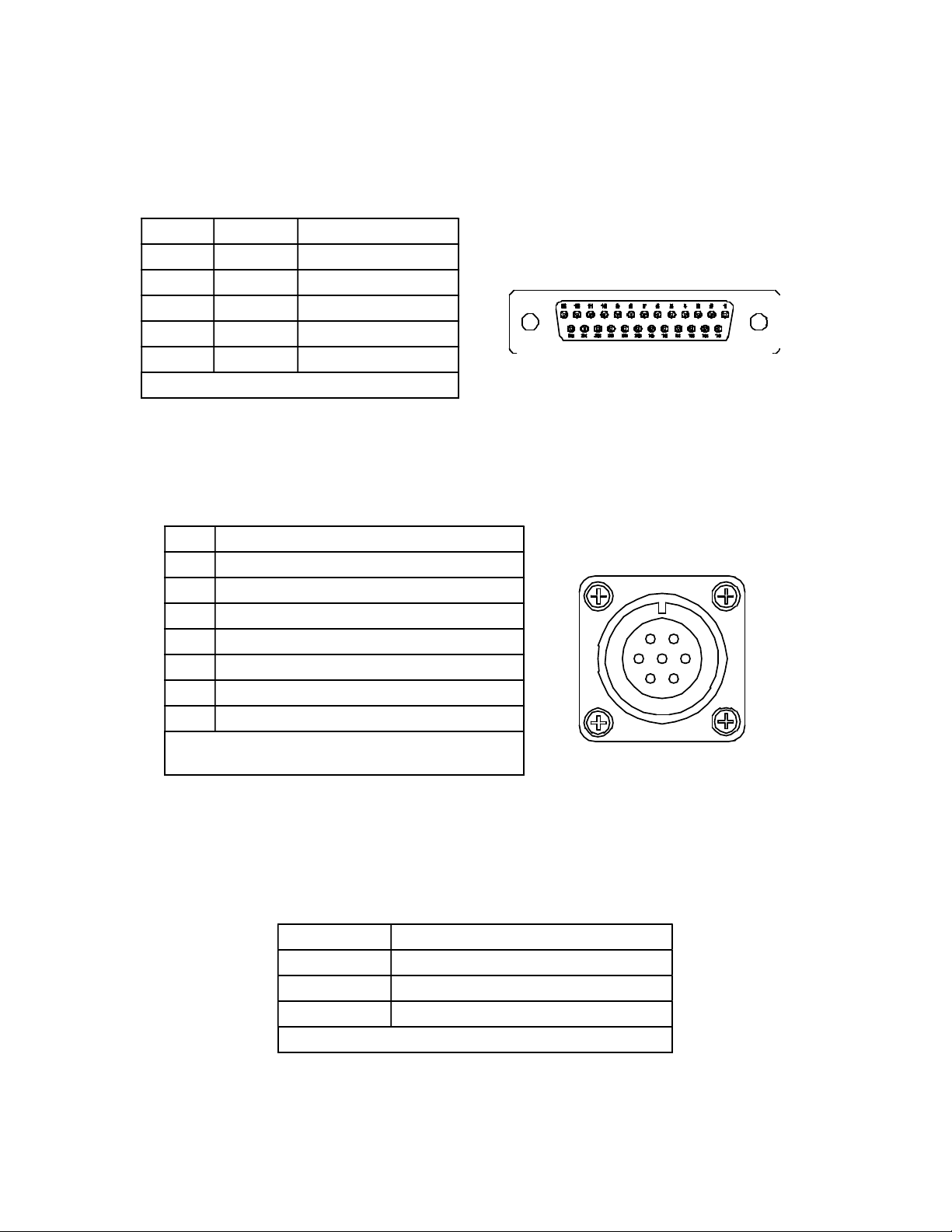

Terminal INPUT Connector

The six-pin MS-Style female circular connector on the back panel of the unit is for the current and

voltage terminals, and the GO/NO-GO relay (dry contact closure) output. A 4-wire Kelvin

connection is required. No internal snubbing is provided for the relays. All voltages are compliance

voltages.

Pin # Term Function

AI - Current Minus – 5VDC @ 1Amp Full Scale

BI + Current Plus – 5VDC @ 1Amp Full Scale

C - - - GO/NO-GO Relay – 2A @ 30VDC, 1/2A @ 120VAC

D - - - GO/NO-GO Relay – 2A @ 30VDC, 1/2A @ 120VAC

EV - Voltage Minus – 5VDC @ 1Amp Full Scale

FV + Voltage Plus – 5VDC @ 1Amp Full Scale

Table 3: 6-pin Terminal INPUT Circular Connector Pinouts

Figure 5: INPUT

Connector

A

B

C

DE

F

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

7

Serial Communications Connector

The Serial Communications Connector is a female D-Shell Sub-Miniature 25-pin connector (DB-

25) for the Serial Communication Link. This connector uses the RS-232C protocol.

Pin # Term Function

2 TX Transmit Data

3 RX Receiver Data

5 CTS Clear-to-Send

7 GND Signal Ground

20 DTR Data-Terminal Ready

Table 4: DB-25 Connector Pinouts

LOGIC INPUT Connector

Several logic inputs to the Model 9250-05 are available via the 7-pin MS-style female circular

connector on the back panel {Figure 7}.These inputs are not currently defined and will be

available by custom order in the first quarter of 1998.

Pin # Function

A Input 1

B +5VDC

C Input 4

D Input 3

E Input 2

F LOGIC COMMON

G GROUND

Table 5: 7-pin Logic INPUT Circular Connector

Pinouts

Physical Dimensions

The standard Model 9250-05 is provided in a 19 inch [483mm] rack mount case.

View Dimension

Front Panel 19.00" [483mm] wide x 3.50" [89mm] tall

Side Panel 14.00" [356 mm]

Back Panel 17.00" [432mm]

Table 6: Rack Mount Case Dimensions

Figure 6: DB-25 Connector Pinouts

Figure 7: Logic Input

Circular Connector

2

3

5

7

20

A

B

CD

E

F

G

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

8

A bench top model is also available (optional).

View Dimension

Front Panel 11.25" [286mm] wide x 3.75" [95mm] tall

Side Panel 14.00" [356mm]

Back Panel 11.00" [279mm]

Table 7: Bench-top Case Dimensions

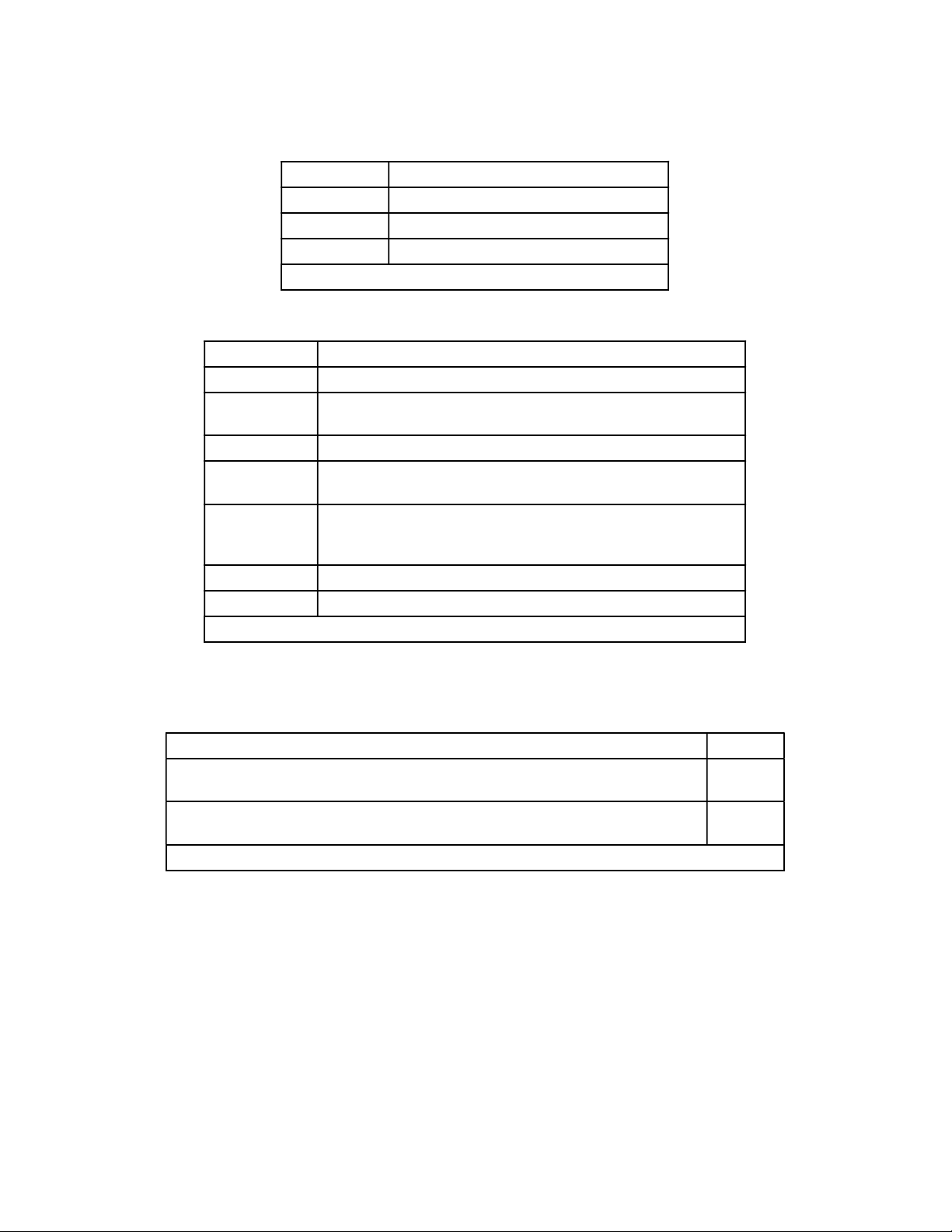

Optional Configurations

Option Description

TC Option Temperature Compensation – Measures ambient temperature.

IRTC Option Infrared Temperature Compensation – Measures temperature of

part under testing by Model 9250-05.

MPI Option Multiplexing Input – Multiple test input.

LED Option LED Display/Keypad Customer Interface – Remote display and

keypad for entry of commands and control of the Model 9250-05.

LCD Option

LCD Touchscreen Customer Interface – Remote touch screen

for entry of commands and control of the Model 9250-05

(availab le first quarter 1998).

HR Option High Resistance Testing (available first quarter 1998).

LR Option Low Resistance Testing (availab le first quarter 1998).

Table 8: Options for Model 9250-05

Accessories

Several accessories for the Model 9250-05 are available from Harris Instrument Corporation.

Accessory Nam e

Circular Mating Connector for INPUT 6-pin MS-Style circular connector (supplied

with every Model 9250-05). -97

Circular Mating Connector for LOGIC INPUT 7-pin MS-Style circular connector

(supplied with every Model 9250-05 in first quarter 1998). -97/7

Table 9: Accessories for Model 9250-05

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

9

Model 9250-05 Commands

The Model 9250-05 is controlled by a host computer. A remote LED Display/Keypad is also

available and is detailed in the DK Option section of this manual (if applicable).

The following commands must be entered in FULL CAPITAL LETTERS, proceeded by an

asterisk symbol (*). The command sequencer is case sensitive, so setting the CAPS LOCK key to

ON with the host computer is recommended.

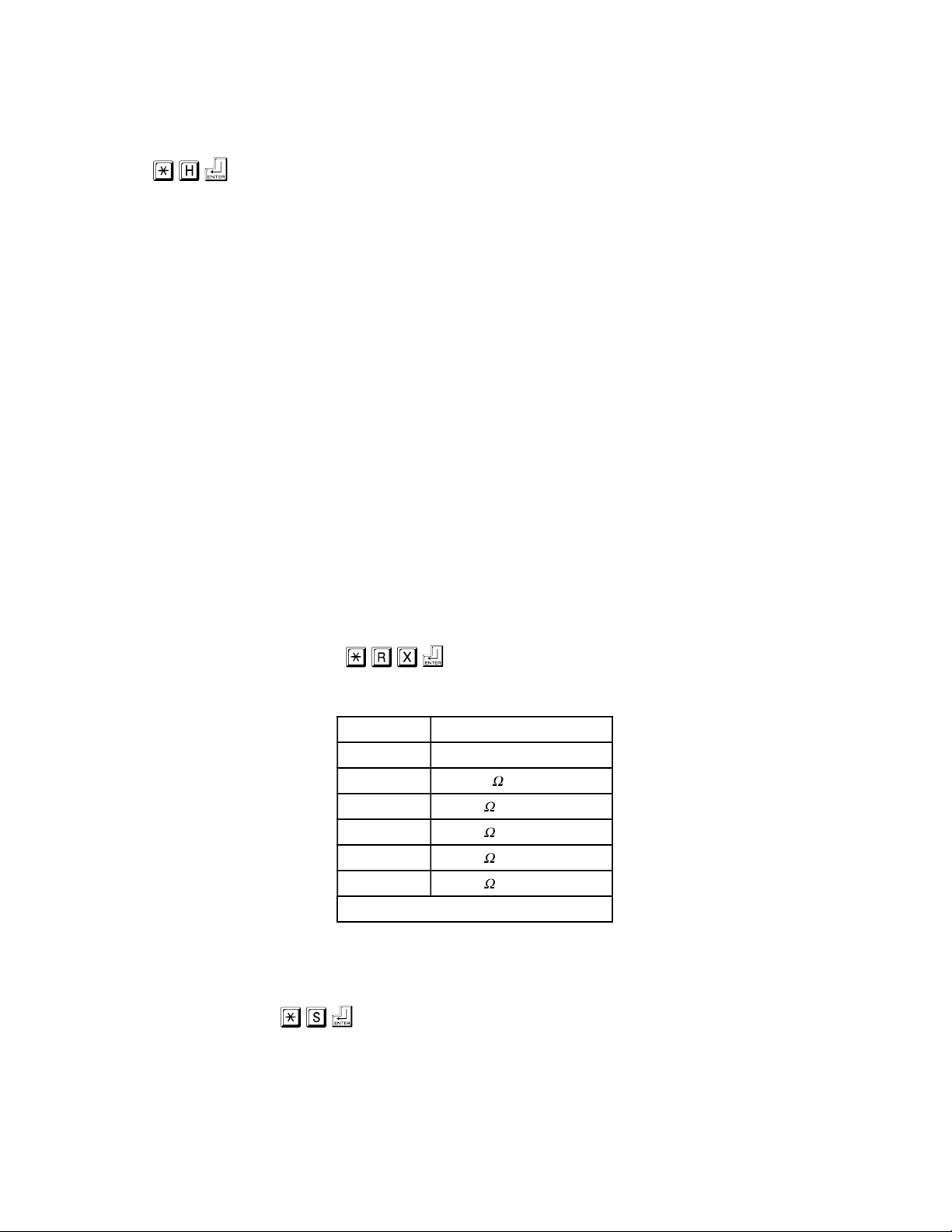

Comm and Sequence Description

Set Averaging: Numb er of averages (1 - 10000, 60).

Set Baud Rate: 9600, 19200, 38400, 57600.

Calibrate: Calibrate current range at XXXXXX .

Set Line SYNC: Power line SYNC set OFF.

Set UPPER Limit: Set high limit at XXXXXX .

Start Readings: Begin sending resistance readings.

or Display Help Screen.

Set Line SYNC: Power line SYNC set ON.

Set LOWER Limit: Set the low limit at XXXXXX .

Set Range: Change to x resistance range (0, 1, 2, 3, 4, 5).

Stop Readings: Stop sending resistance readings.

Set Auto-Range: Auto-range mode set ON.

Set Auto-Range: Auto-range mode set OFF.

Diagnostics – Displays the raw counts from the analog-to-digital

converter for calib ration and troubleshooting.

Reset: Sets all user selected variab les to factory default.

Table 10: Command Sequence Listing

Commands for Temperature Compensation – TC & IRTC Options, can be found in the TC

Option section. Commands for the Multiplex Input Option – MPI Option, can be found in the MP

Option section. Operation with the LED Display/Keypad – LED Option, is documented in the DK

Interface section, while operation with the LCD Touchscreen Display – LCD Option, is covered

in the LCD Section.

Data Entry Conventions

All data entered in XXXXXX entries (LOW Limit, HIGH Limit, etc.) may be entered as 1 to 10

digits with a decimal point if necessary. The decimal point position on all displayed variables

matches current customer selected decimal point position. Up to ten command sequences may be

sent in rapid succession by the terminal device EXCEPT the calibration command and the factory

default command.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

10

Invalid Command Response

Any time an invalid command is sent via the serial communications link to the Model 9250-05, the

system will respond with a “What?” statement. The following example shows the Set LOW Limit

command being used with an improper sequence.

Command> *M ABCDEF

What?

Any time a “What?” response is received in the communications terminal software, check the

command sequence that was previously entered and re-enter the command sequence properly.

Averaging Setting:

The Set Average command will change the number of averages that will be used to calculate the

resistance reading using the example formula (XXXXXX = number of readings, factory default

value is 60 readings) on the next page.

The averaging value will affect the update rate as shown in Table 11 (9600 baud):

Setting Update Rate

1 110Hz

100 83Hz

200 33Hz

500 15Hz

1000 8Hz

10000 0.8Hz

Table 11: Update Rates with

Averaging Settings

Higher baud rate settings will increase the update rate.

Example: 57600 baud with averages @ 1 = 250Hz update rate.

Averaging Formula:

Output reading = (SUM of readings) divided by setting value.

Example: A total of 100 readings is required for averaging. Enter the following command

sequence for setting the averaging:

Command> *A 100

The 100 readings are totaled and divided by 100 to give the average readings. With no averaging,

the actual readings will be displayed.

Typically, the averaging setting is 60 with Line SYNC set on. This gives the best overall output for

the system.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

11

Baud Rate Setting:

The Set Baud Rate command will change the serial communications baud rate (bps). The valid

baud rates are (underlined rate is the factory default):

9600, 19200, 38400, 57600.

Example: Setting the baud rate to 19200

Command> *B 19200

See System Operation – Serial Communications for more information on the serial

communications link.

Resistance Calibration:

NOTE:

Any units delivered from the factory with certified calibration

SHOULD NOT BE RE-CALIBRATED by the operator.

This WILL void the certified calibration.

Calibration of the Model 9250-05 is performed by placing a calibration standard, near the full scale

resistance for each range, across the meter inputs and transmitting a calibration command for the

current selected range over the serial communications link.

Command>*C XXXXXX

When the full scale reading is complete, the unit will prompt the operator to insert a lower (10% of

first standard) resistance standard across the meter inputs. This will assures an accurate zero

reference point for each range.

Example: Calibrating to a 1.9 resistance standard.

Command>*C 1.9000

Command> Please insert a low resistance

standard

Line SYNC Commands

There are two commands for setting line SYNC, ON or OFF.

Line SYNC ON:

This command turns the power line synchronization ON (maximum update rate is now 60Hz).

This allows the Model 9250-05 to give steady readings output.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

12

All Set Averaging values from 1 to 60 will output at 60Hz with Line SYNC set ON. Averaging

values higher than 60 will result in update rates lower than 60 Hz with Line SYNC set ON.

Line SYNC OFF:

This command will turn the power line synchronization off. Line SYNC ON is the factory default

for the Model 9250-05.

Limit Settings

High and low limit settings are available with the Model 9250-05. The Set UPPER Limit command

sets the high limit and the Set LOWER Limit command sets the low limit.

Set UPPER Limit:

Enter the UPPER Limit in OHMS, with the appropriate decimal point. When resistance =

1.5000 and the high limit = 1.4900 the “GO” relay will be open.

Example: Set UPPER Limit to 20.500.

Command> *E 20.500

Set LOWER Limit:

Enter the LOWER Limit in OHMS, with the appropriate decimal point. When resistance =

1.0999 and the low limit = 1.1000 the “GO” relay will be open.

Example: Set LOWER Limit to 10.500.

Command> *M 10.500

Start Readings:

The Start Readings command will initiate the sending of resistance readings for the current range.

The measured data will be in the following format (this reading is for Range One):

.XXXXX

Note that the decimal point will move, depending upon which range is being tested (i.e. Range

Two = X.XXXX, for Range Three = XX.XXX, etc.).

HELP Screen: or

This displays a screen with all of the command sequences listed with short descriptions and value

ranges. Also displayed is a short summary of many of the settings for the system under Current

Settings.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

13

Sample HELP Screen output:

Command> *H

*A_XXXXX - Number of averages (1-10000).

*B_XXXXX - Set baud rate (9600, 19200, 38400, 57600).

*C_XXXXXX - Calibrate current range at XXXXXXohms.

*E_XXXXXX - Set the UPPER Limit at XXXXXXohms.

*G - Output resistance readings, *S - Stop sending readings.

*H - (Help) Sends this output.

*K_XXXXXX - Set temperature coefficient.

*I - Temperature Compensation ON, *J - Temperature Compensation OFF.

*L - Line SYNC ON, *D - Line SYNC OFF.

*M_XXXXXX - Set the LOWER Limit at XXXXXXohms.

*Q_XX.X - Set reference temperature for compensation.

*RX - Change to X resistance range (0, 1, 2, 3, 4, 5).

*T - Output the current temperature.

*U - Auto-range mode ON, *V - Auto-range mode OFF.

*X - Multiplexer command string, *X 1-2R4,4-9R1,3-7R2.

*Y_XX.X - Temperature calibration point.

Current Settings - Range: 2 ohm

Averages: 00060 Baud rate is now: 9600

High Limit: 1999.99 Low Limit: .000

The line synchronization is: ON

Temp. Compensation: OFF

Temperature Coefficient: .00393

Reference Temperature: 25.0

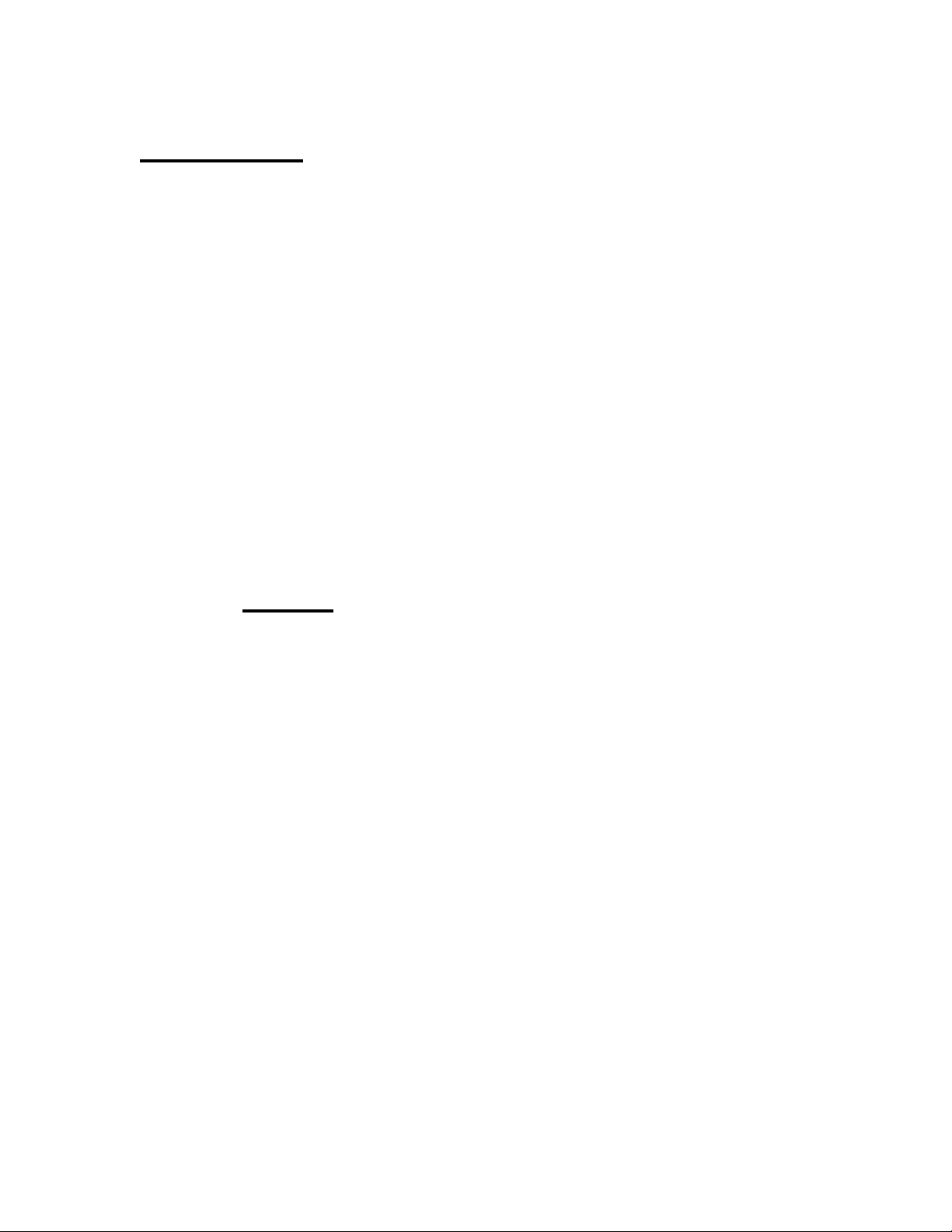

Set Resistance Range:

The resistance range may be changed by the Set Resistance Range command. Valid settings are:

Setting Range

0 Turns off Safety Relay

1 0.20000

2 2.0000

3 20.000

4 200.00

5 2000.0

Table 12: Resistance Range Settings

If an invalid range for the test is selected, the unit will default to Range 2 (2). The unit will

default to no relays on (Range 0) at power up.

Stop Readings:

When the Model 9250-05 is powered on, the unit is in IDLE Mode. It is taking no readings in this

mode. After the Start Readings command or the Send Temperature command are given, the unit

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

14

can be returned to IDLE Mode with the Stop Readings command. Also, any command entered

(except Start Readings or Send Temperature) will return the unit to the IDLE Mode.

Auto-Range Selection

One of the premiere features of the Model 9250-05 is the Auto-Range Selection. The Auto-Range

command begins the automatic selection of the resistance range. When the measured resistance

falls below 10% of the current range, the meter will automatically switch to the next lower range.

Set Auto-Range ON:

Turn on the automatic ranging feature.

Set Auto-Range OFF:

Disables the automatic range selection. The meter will remain on the last selected range until a

new range command is issued. Auto-Range OFF is the factory default.

Diagnostic Output:

Displays the raw counts from the analog-to-digital converter. Used in calibrating the system.

Restore Factory Defaults:

This command will reset the stored system settings to the factory defaults. Calibration values are

not affected by this command.

Factory Default System Settings are:

Serial Communications: 9600 Baud Rate

Resistance Range: Range 0

Auto-Range: OFF

Averages: 60

Power Line SYNC: ON

Temperature Compensation: OFF

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

15

System Operation

Before applying power to the Model 9250-05, set up the communications software that will be

used to interface with the Model 9250-05. Also be sure that the communications lines are installed

and attached to the Model 9250-05 and the host computer.

Serial Communications

The host computer serial communications interface for the Model 9250-05 is based upon the DEC

VT-100 (ANSI) terminal emulation for the IBM PC®for RS-232 communications. The RS-232

output communications port operates as the DCE, with the host computer as the DTE. Any ANSI

terminal emulator will probably function with the Model 9250-05 as a terminal emulator, as well as

many commercial communications software packages (such as PROCOMM®).

Communications protocol for the serial output are RS-232C ASCII, six-characters with a decimal

point, space padded with a carriage-return and line feed in a 10-bit frame running:

No Parity, Eight Data Bits and One Stop Bit (N,8,1)

with One Start Bit.

The communications can be set for a baud rates of (underlined is factory default):

9600bps, 19200bps, 38400bps, 57600bps.

When setting up for operation with a personal computer (PC), be sure that no other serial devices

are sharing the communications port on the PC. The Model 9250-05 requires a standard

communications port for operation.

For this manual, the Windows® TERMINAL program will be used as an example communications

program for interfacing with the Model 9250-05. The Windows® TERMINAL communications

program must be configured to operate with the Model 9250-05.

RX/TX Lamps

In the middle of the front panel of the Model 9250-05 are two red lamps labeled RX and TX.

These lamps will illuminate when RS-232 communications are in operation. Whenever commands

are being received by the Model 9250-05, the RX lamp will illuminate and whenever the unit is

transmitting data to the host computer (or LED Display/Keypad Customer Interface – DK Option

section), the TX lamp will illuminate.

If these lamps do not light when power is on to the unit AND the host computer is sending

commands to the Model 9250-05, verify that the serial communications cable is properly attached

at both ends. If the lamps still will not illuminate, contact Harris Instrument Corporation IRT

Service for more information.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

16

Configuring Windows® TERMINAL

The following example on the next page is based upon the Microsoft® Windows® for Workgroups

TERMINAL software program. This program is used because of the commonplace occurrence

of it on most DOS-based computer systems today. Any DEC VT-100 (ANSI) compatible terminal

emulation program can be used to communicate with the Model 9250-05 RS-232 customer

interface.

Terminal Start TERMINAL.EXE (located in the Accessories or Main

Program Group).

Settings Open the Settings Menu and select Terminal Emulation...

Terminal Emulation...

Verify that the DEC VT-100 (ANSI) Terminal Emulation is

selected. If it is not selected, click on the DEC VT-100

(ANSI) choice.

OK

Click on OK to close the Terminal Emulation dialog box.

Open the Settings menu again and select

Communications...

Settings

Communications

Select under the CONNECTOR Scroll Box the proper

communications port on the host computer that is connected

to the Model 9250-05. Typically, this w ill be COM2 as the

mouse for Window s®is typically on COM1 .

COM2 Select the 9600 Radio Button in the BAUD RATE area.

9600 Select the 8 Radio Button in the DATA BITS area.

8Select the 1 Radio Button in the STOP BITS area.

1Select the None Radio Button in the PARITY area.

None Select the None radio button in the FLOW CONTROL area.

None Click on OK to Close the COMMUNICATIONS Dialog Box.

SETTINGS Open the Settings menu.

Modem Commands Select Modem Commands...

None Select the None radio button in the Modem Defaults area.

OK Close the Modem Commands dialog box.

File Save the settings for operating the Model 9250-05 by

choosing the Save As function under the File menu.

Save As... Save file as 9250.TRM

OK Click on OK to close the File dialog box.

Now, whenever starting Terminal to operate the Model 9250-05, load the file 9250.TRM and the

settings for the Model 9250 factory defaults will be available.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

17

Verify Communications

If the Model 9250-05 is connected correctly to the host computer and the TERMINAL or other

communications software is configured properly, when power is applied to the Model 9250-05 the

communications software should respond within ten seconds with:

Warm up!

After approximately four to five seconds, the output will read:

Power up!

Once the power up message is displayed, the unit is in IDLE Mode. It is not taking readings from

the terminal probes. To start taking readings, issue the Start Readings command; or configure the

unit with one of the other commands.

NOTE:

The Model 9250-05 is a precision resistance measurement instrument

and requires a warm-up period of approximately five minutes

BEFORE readings should be taken.

Also, verify that the RX and TX lamps on the front of the Model 9250-05 are illuminating when

the unit is receiving commands (RX) or transmitting data (TX).

If the unit will not issue the power up messages within ten to twenty seconds, check the serial

communications cable to ensure that it is connected properly. Also check that power is applied to

the unit (green LED indicator on ON/OFF push-button switch is illuminated). If both of these

checks are valid, contact Harris Instrument Corporation IRT Service for more information.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

18

Model 9250-05 Calibration

Calibration of the Model 9250-05 is relatively simple as the adjustments to the system are all

software-controlled. The following example details the calibration of the unit.

NOTE:

Any units delivered from the factory with certified calibration

SHOULD NOT BE RE-CALIBRATED by the operator.

This WILL void the certified calibration.

To perform the following Calibration Procedure later in this manual, it is suggested that you obtain

six resistors or resistance standards. The values of these standards for this example are:

1.9K ±10%, 190 ±10%, 19 ±10%, 1.9 ±10%, 0.19 ±10%, and 0.019 ±10%.

Almost any standard or resistor can be used for the Calibration Procedure, as long as they match

the ranges of the meter and are 10% of the higher standard.

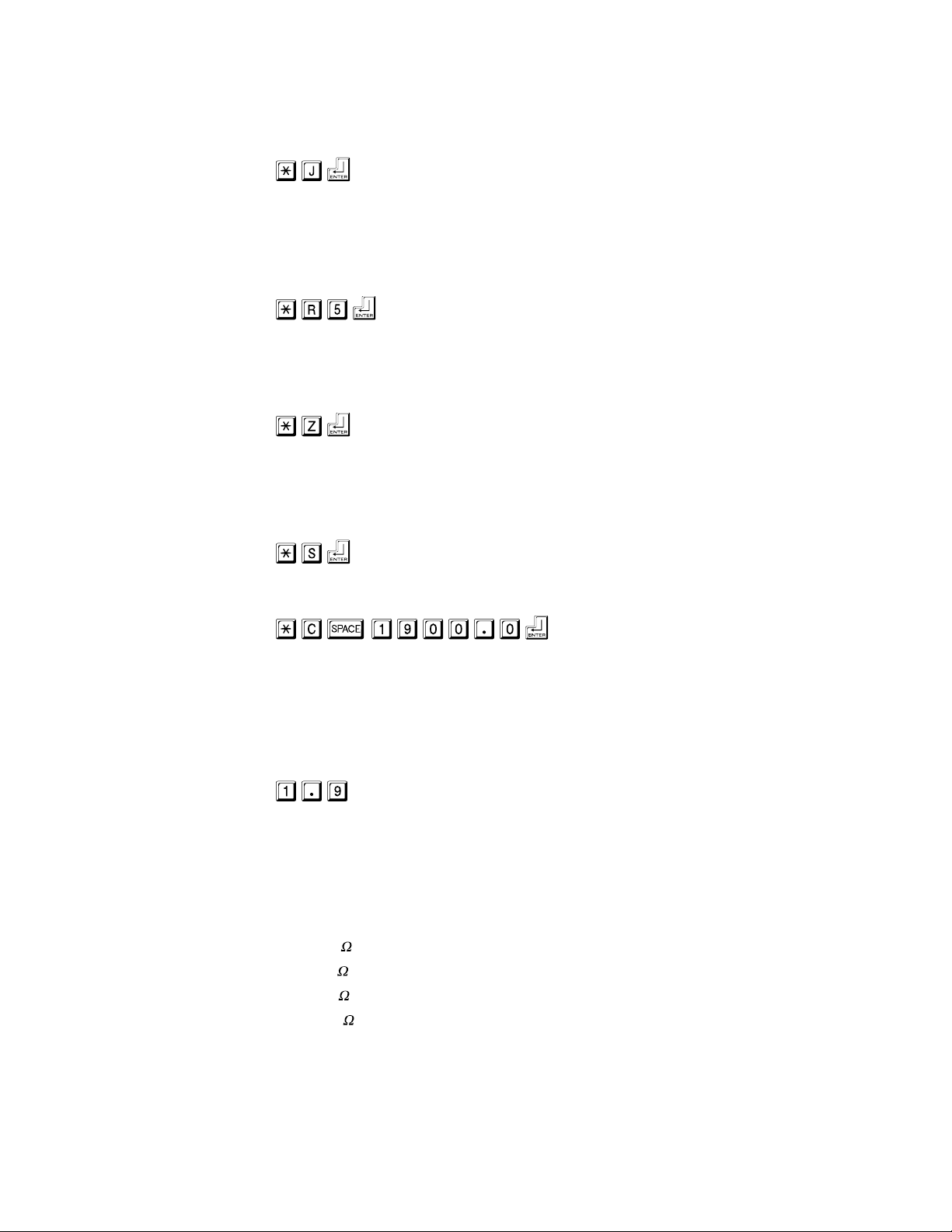

Calibration Example

1) Apply power to the Model 9250-05.

WARM UP!

POWER UP!

The unit will respond with “WARM UP!” within ten seconds and “POWER UP!” in another four

to five seconds.

2) Perform the Set Averaging command and set the number of readings to average to 60.

Command> *A 60

The Averaging value is now set to 60.

3) Set Line SYNC ON.

Command> *L

The Line Sync is now enabled.

4) Disable the Auto-Range function.

Command> *V

The Auto-Range command has been disabled.

9250-05-Manual.DOC

07/19/00

High-Speed Resistance Tester – Model 9250-05

Operators Manual

19

5) Disable Temperature Compensation, if applicable.

Command> *J

Temperature Compensation is now disabled.

6) Place a 1.9K ±10% resistance standard on the resistance test inputs to the Model 9250-05.

7) Perform the Set Resistance Range command for the 2K range – Range 5.

Command> *R5

The unit is now set for testing in the 2K range.

8) Display the Diagnostic Output for verification of resistance reading.

Command> *Z 61,234

Verify that the reading output is 60,000 ± 3,000. If out of range, then verify connections to the

resistance tester and that the range is set correctly.

9) Stop diagnostic readings.

Command> *S

10) Begin the Resistance Calibration command.

Command> *C 1900.0

The unit will now prompt you to connect a lower resistance standard (199 ±10%) to the unit and

then enter the value of the low resistance standard.

Command> Please insert a low resistance

standard

11) Enter the value of the 1.9 standard.

Command> 1.9

The 2K range is now calibrated.

12) Repeat steps 6 through 11 to calibrate the remaining ranges substituting the following values

for step 6 and step 7.

Step 6 Step 7 Step 11

199 ±10% *R4 199.00

19 ±10% *R3 19.000

1.9 ±10% *R2 1.9000

0.19 ±10% *R1 0.1900

Re-enable any applicable functions and options.

Table of contents

Other Harris Test Equipment manuals

Popular Test Equipment manuals by other brands

iqualitrol

iqualitrol iRock-439T instruction manual

Dräger

Dräger 8103530 Instructions for use

Keysight Technologies

Keysight Technologies InfiniiVision M9241A SCPI Programmer's Guide

The Diagnostic Box

The Diagnostic Box TDB760 operating manual

TESTO

TESTO 175-H2 manual

Dräger

Dräger Alcotest 7410 GLC Operator's manual