Transmille 2100 Use and care manual

VERIFICATION AND CALIBRATION GUIDE

2100 / 3200

COMPLETE TESTING

ELECTRICAL TEST EQUIPMENT CALIBRATOR

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 1

Table Of Contents

SAFETY WARNINGS ................................................................................................................................................3

GENERAL..................................................................................................................................................................4

INSTALLING THE 3200 / 2100 CALIBRATION CONTROL PANEL .......................................................................4

CALIBRATING 3200 / 2100 CALIBRATOR - INTRODUCTION...............................................................................5

INSULATION RESISTANCE FUNCTION..................................................................................................................6

CONNECTIONS ..........................................................................................................................................................6

VERIFICATION METHOD..............................................................................................................................................6

VERIFICATION TEST POINTS.......................................................................................................................................6

CONTINUITY RESISTANCE FUNCTION..................................................................................................................7

CONNECTIONS ..........................................................................................................................................................7

VERIFICATION METHOD..............................................................................................................................................7

VERIFICATION TEST POINTS.......................................................................................................................................7

CONTINUITY CURRENT FUNCTION.......................................................................................................................8

CONNECTIONS ..........................................................................................................................................................8

CALIBRATION METHOD...............................................................................................................................................9

VERIFICATION TEST POINTS.......................................................................................................................................9

AC VOLTAGE SOURCE FUNCTION......................................................................................................................10

CONNECTIONS ........................................................................................................................................................10

CALIBRATION METHOD.............................................................................................................................................11

VERIFICATION TEST POINTS.....................................................................................................................................11

LOOP RESISTANCE FUNCTION............................................................................................................................12

CONNECTIONS ........................................................................................................................................................12

CALIBRATION METHOD.............................................................................................................................................14

VERIFICATION TEST POINTS.....................................................................................................................................14

RCD (RESIDUAL CURRENT DEVICE) CURRENT FUNCTION ............................................................................15

CONNECTIONS ........................................................................................................................................................15

CALIBRATION METHOD.............................................................................................................................................16

VERIFICATION TEST POINTS.....................................................................................................................................16

RCD (RESIDUAL CURRENT DEVICE) TRIP TIME FUNCTION............................................................................17

CONNECTIONS ........................................................................................................................................................17

VERIFICATION METHOD............................................................................................................................................18

VERIFICATION TEST POINTS.....................................................................................................................................18

PAT INSULATION RESISTANCE FUNCTION .......................................................................................................19

CONNECTIONS ........................................................................................................................................................19

VERIFICATION METHOD............................................................................................................................................19

VERIFICATION TEST POINTS.....................................................................................................................................19

PAT EARTH BOND RESISTANCE FUNCTION .....................................................................................................20

CONNECTIONS ........................................................................................................................................................20

CALIBRATION METHOD.............................................................................................................................................21

VERIFICATION TEST POINTS.....................................................................................................................................21

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 2

PAT EARTH BOND CURRENT FUNCTION...........................................................................................................22

CONNECTIONS ........................................................................................................................................................22

CALIBRATION METHOD.............................................................................................................................................23

VERIFICATION TEST POINTS.....................................................................................................................................23

PAT LOAD FUNCTION............................................................................................................................................24

CONNECTIONS ........................................................................................................................................................24

VERIFICATION METHOD............................................................................................................................................25

VERIFICATION TEST POINTS.....................................................................................................................................25

PAT LEAKAGE CURRENT FUNCTION .................................................................................................................26

CONNECTIONS ........................................................................................................................................................26

VERIFICATION METHOD............................................................................................................................................27

VERIFICATION TEST POINTS.....................................................................................................................................27

3200 / 2100 Verification Sheets Appendix A

3200 / 2100 Extended Specifications Appendix B

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 3

SAFETY WARNINGS

HIGH VOLTAGES

CONNECTIONS TO LINE

THIS VERIFICATION AND CALIBRATION GUIDE

INVOLVES CONNECTIONS TO LINE AND

MEASUREMENT OF HIGH VOLTAGES

FOR THIS REASON VERIFICATION AND

CALIBRATION SHOULD ONLY BE UNDERTAKEN

BY QUALIFIED PERSONNEL

THIS VERIFICATION AND CALIBRATION KIT IS

PROVIDED ‘AS-IS’ AND TRANSMILLE SHALL

NOT BE LIABLE FOR ANY INCIDENTAL, INDIRECT,

SPECIAL OR CONSEQUENTIAL DAMAGES

OR LOSS AS A RESULT OF USING THIS GUIDE OR

VERIFICATION AND CALIBRATION LEAD SET.

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 4

General

The steps detailed below will allow adjustment of a 3200 / 2100 Electrical Test Equipment Calibrator.

This requires the use of the 3200 / 2100/3200 Calibration control Panel program supplied and the 3200 / 2100

calibration lead set kit supplied by Transmille.

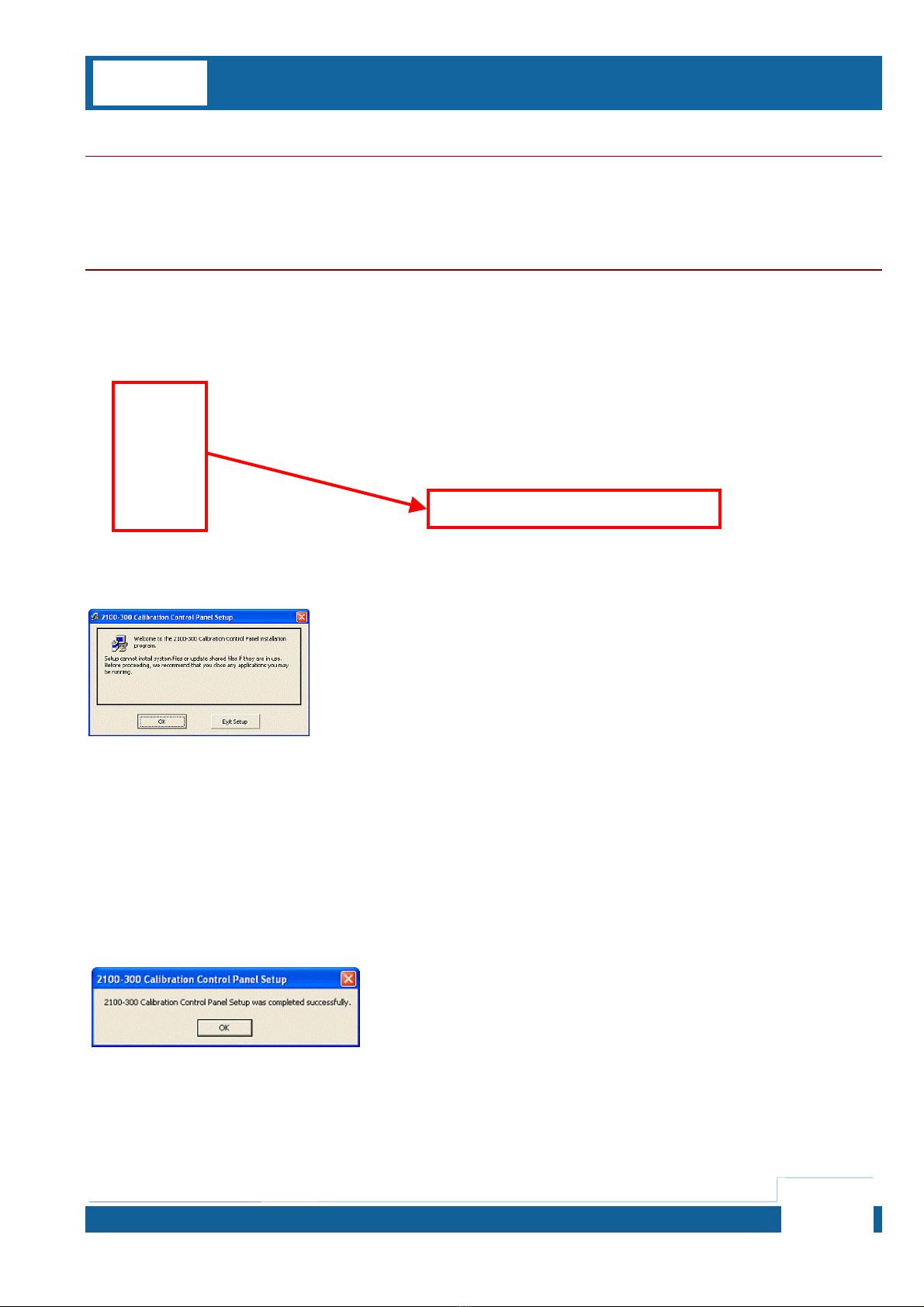

Installing the 3200 / 2100 calibration control panel

To install the 3200 / 2100 Calibration Control Panel, insert the supplied CD – this should autorun.

If the CD does not autorun, select START -> RUN -> AUTOCHECK.BAT

Click OK to proceed

Click button to begin install

Click OK to complete installation

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 5

Calibrating 3200 / 2100 calibrator - Introduction

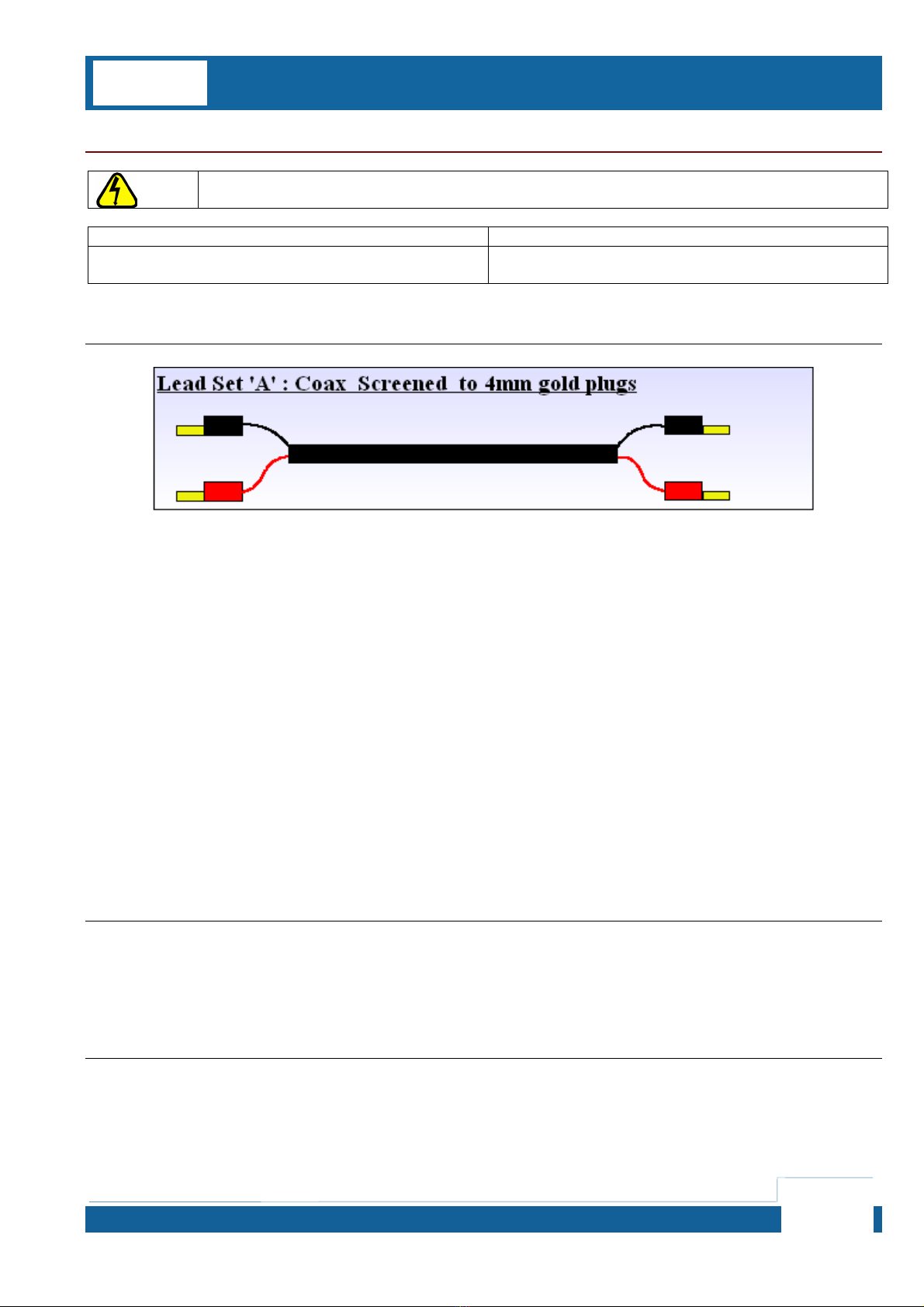

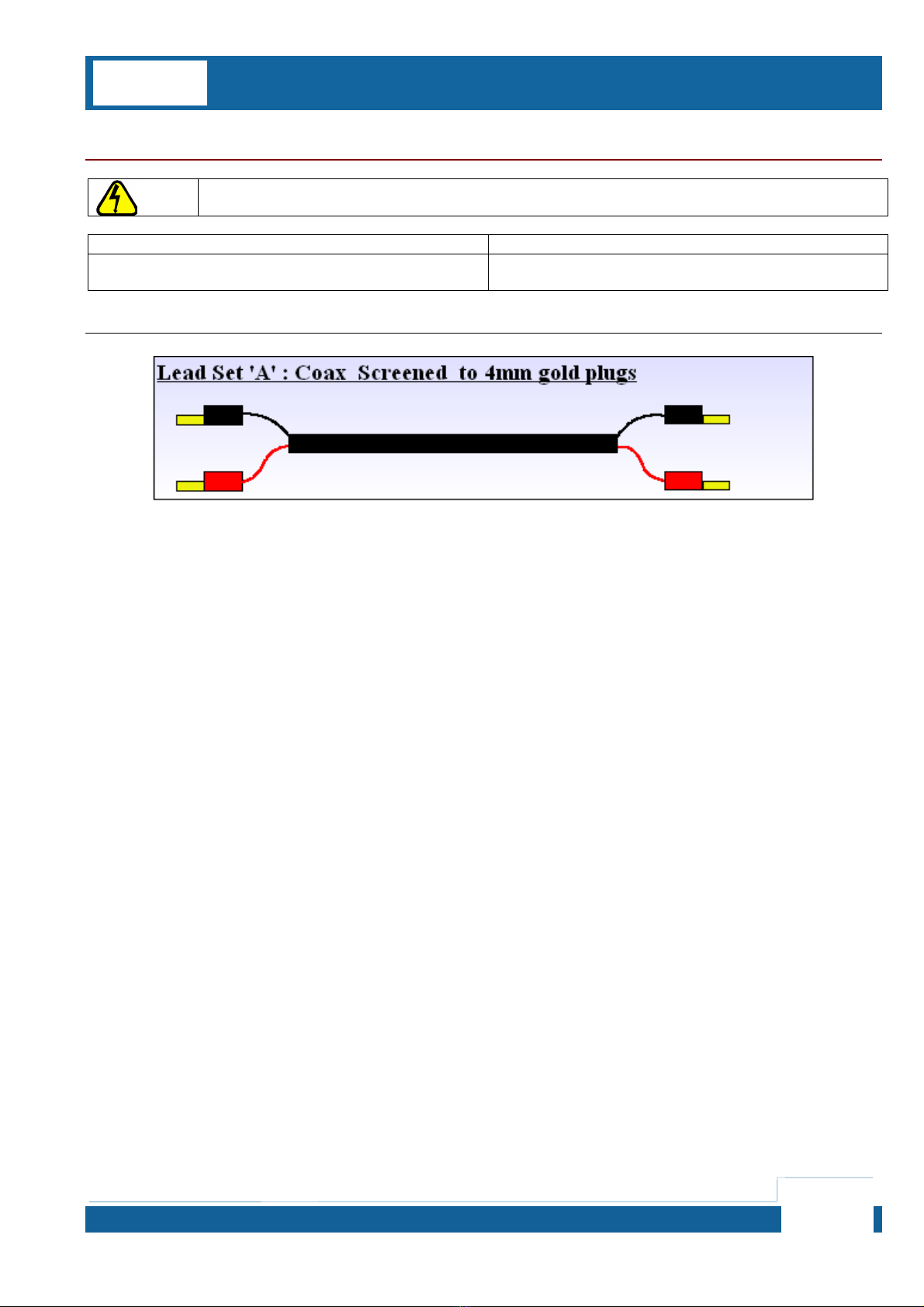

The 3200 / 2100 Calibration kit comprises of a set of test leads as follows :

In addition a performance verification sheet is provided –

this allows the 3200 / 2100 to be compared against manufacturers specifications.

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 6

Insulation Resistance Function

VERIFICATION AND CALIBRATION PROCEDURES ARE FOR USE BY QUALIFIED TECHNICIANS ONLY –

OBSERVE ALL PRECAUTIONS DURING CONNECTION AND MEASUREMENT OF LINE HIGH VOLTAGES

Equipment Required Comments

Resistance meter Capable of measuring 2GOhm

(10GOhm if 10G Option fitted)

Connections

Verification Method

1. Connect 3200 / 2100 to meter as per diagram using LEAD SET A

2. Select Insulation resistance mode and test points as per verification sheet using the 3200 / 2100 front panel and

record measurement obtained using 2-wire connection.

Verification Test Points

See Performance Verifications Sheet Page 1 & 2

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 7

Continuity Resistance Function

VERIFICATION AND CALIBRATION PROCEDURES ARE FOR USE BY QUALIFIED TECHNICIANS ONLY –

OBSERVE ALL PRECAUTIONS DURING CONNECTION AND MEASUREMENT OF LINE HIGH VOLTAGES

Equipment Required Comments

Resistance meter Capable of measuring 100mOhm to 1kOhm

4-Wire mode

Connections

Verification Method

1. Connect 3200 / 2100 to meter as per diagram using LEAD SET A and LEAD SET B

2. Select test point as per verification sheet using the 3200 / 2100 front panel and record measurement obtained

using 4-wire connection.

Verification Test Points

See Performance Verifications Sheet Page 2 & 3

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 8

Continuity Current Function

VERIFICATION AND CALIBRATION PROCEDURES ARE FOR USE BY QUALIFIED TECHNICIANS ONLY –

OBSERVE ALL PRECAUTIONS DURING CONNECTION AND MEASUREMENT OF LINE HIGH VOLTAGES

Equipment Required Comments

DC Current Source

eg. Multi Product Calibrator Capable of sourcing 100mA DC

Connections

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 9

Calibration Method

1. Connect 3200 / 2100 to meter as per diagram using LEAD SET A

2. Select continuity test current mode on 3200 / 2100 CCP

this will set the 3200 / 2100 to 1 Ohm output

3. Set 0mA DC output from current source

4. Adjust ZERO OFFSET using CCP software

5. Set 100mA DC output from current source

6. Adjust MULTIPLIER (FULL SCALE) using CCP software

Verification Test Points

See Performance Verifications Sheet Page 4

ZERO OFFSET ADJUST

A

djust cal factor using up/down buttons – note using the up/down button

automatically sends cal factor to calibrator, the send button is needed

only if a cal factor is manually typed into the cal factor value box.

MULTIPLIER ADJUST

A

djust cal factor using up/down buttons – note using the up/down button

automatically sends cal factor to calibrator, the send button is needed

only if a cal factor is manually typed into the cal factor value box.

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 10

AC Voltage Source Function

VERIFICATION AND CALIBRATION PROCEDURES ARE FOR USE BY QUALIFIED TECHNICIANS ONLY –

OBSERVE ALL PRECAUTIONS DURING CONNECTION AND MEASUREMENT OF LINE HIGH VOLTAGES

Equipment Required Comments

AC Voltage meter Capable of measuring up to 400V AC

Connections

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 11

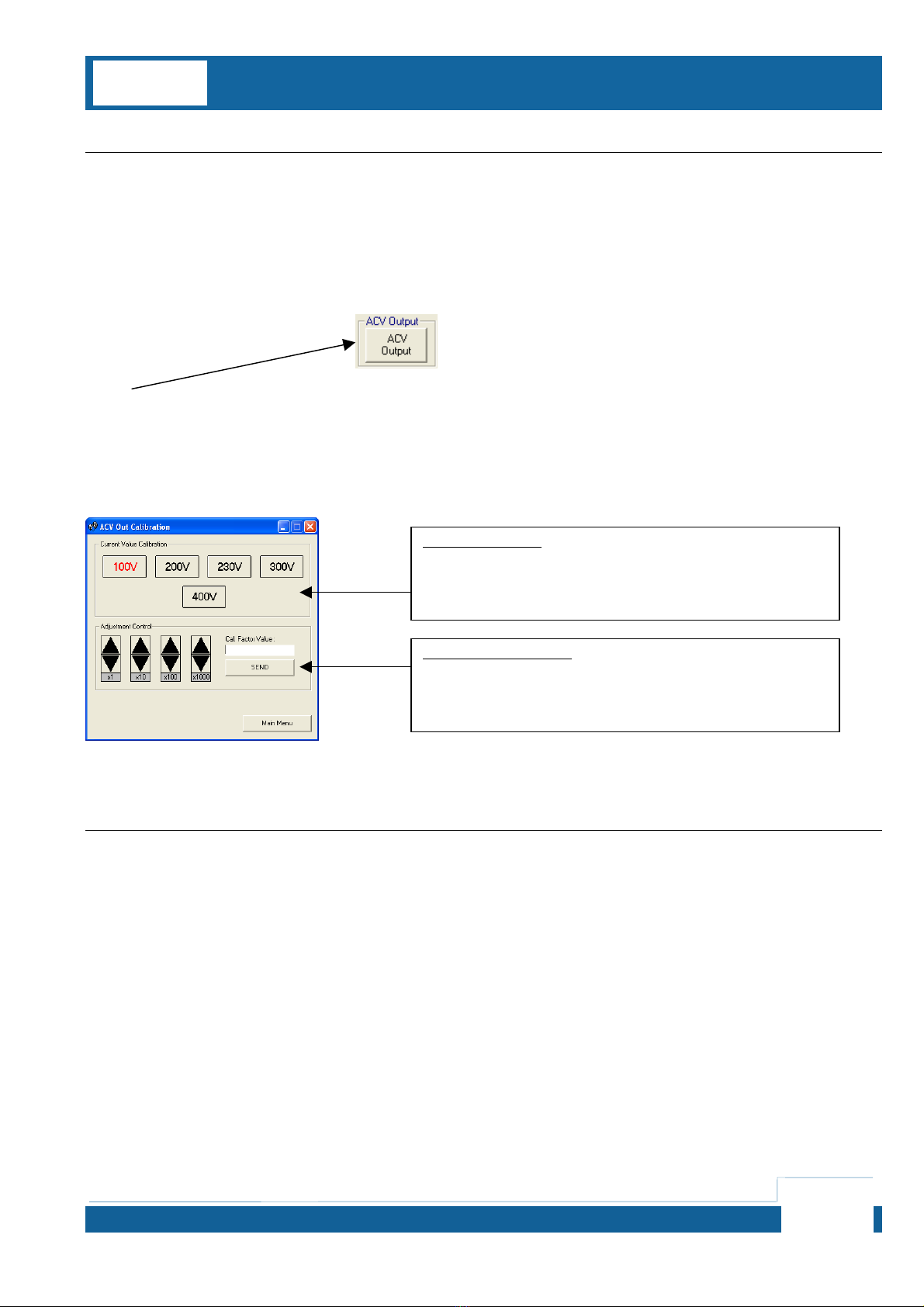

Calibration Method

1. Connect 3200 / 2100 to meter as per diagram using LEAD SET A

2. Select ACV Output mode on 3200 / 2100 CCP - this will set the 3200 / 2100 to 100V Output initially

3. Adjust cal factor using CCP software adjustment control

4. Select 200V, 230V, 300V and 400V ranges in turn and adjust each range in turn

Verification Test Points

See Performance Verifications Sheet Page 4

RANGE SELECTION

Select range to be calibrated here

ADJUSTMENT CONTROL

A

djust cal factor using up/down buttons – note using the up/down button

automatically sends cal factor to calibrator, the send button is needed

only if a cal factor is manually typed into the cal factor value box.

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 12

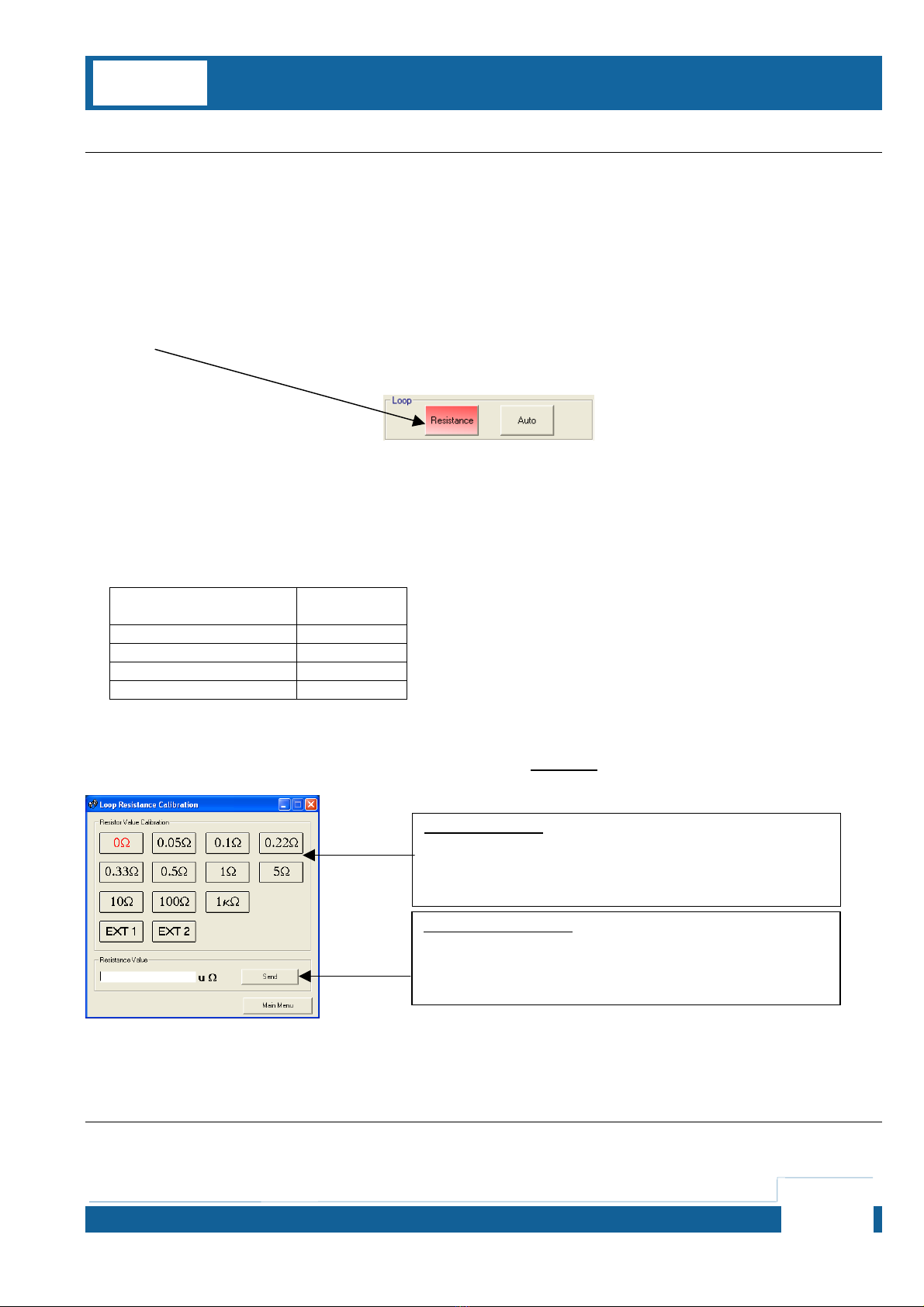

Loop Resistance Function

VERIFICATION AND CALIBRATION PROCEDURES ARE FOR USE BY QUALIFIED TECHNICIANS ONLY –

OBSERVE ALL PRECAUTIONS DURING CONNECTION AND MEASUREMENT OF LINE HIGH VOLTAGES

Equipment Required Comments

DC Voltage meter

DC Current Source Capable of sourcing up to1A DC

Connections

NOTES FOR USE WITH LEAD SET ‘C’

Set C1

COMMON SET OF TEST LEADS (RED & BLACK LEADS) IS A COMMON SET FOR USE WITH ANY TYPE OF

2100 / 3200 CALIBRATOR.

DEPENDING ON THE CONFIGURATION OF THE 2100 / 3200 CALIBRATOR THE SECOND LEAD SHOULD

BE EITHER :

Set C2

LEAD MARKED FOR ‘NORMAL’ CONFIGURATION EARTH-EARTH

OR

Set C3

LEAD MARKED FOR ‘EARTH-NEUTRAL’ (NO TRIP) CONFIGURATION –

NOTE THESE CALIBRATORS WILL BE MARKED AS EARTH-NEUTRAL ON THE REAR PANEL

OPTION LABEL IF CONFIGURED THIS WAY.

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 13

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 14

Calibration Method

1. Connect 3200 / 2100 to meter as per diagram using LEAD SET C

2. Select LOOP function on 3200 / 2100 and select MANUAL – type in 0.001 then press enter to reset the line

impedance compensation to ZERO before calibrating the loop resistance values.

3. Select Loop Resistance mode on 3200 / 2100 CCP

this will set the 3200 / 2100 to 0Ohms Output initially

4. Set the current source to the current as specified in the table below and measure voltage drop

Loop Resistance

Value Current

Setting

1 kOhm 1mA

100 Ohms 10mA

10 Ohms 100mA

< 5 Ohms 1A

5. Calculate resistance value using Ohms Law (V/I = R)

6. Enter calculated resistance into resistance value box on CCP in uOhms and click SEND

7. Repeat steps 4 to 6 for all resistance values.

Verification Test Points

See Performance Verifications Sheet Page 5

RANGE SELECTION

Select range to be calibrated here

ADJUSTMENT CONTROL

A

djust cal factor using up/down buttons – note using the up/down button

automatically sends cal factor to calibrator, the send button is needed

only if a cal factor is manually typed into the cal factor value box.

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 15

RCD (Residual Current Device) Current Function

VERIFICATION AND CALIBRATION PROCEDURES ARE FOR USE BY QUALIFIED TECHNICIANS ONLY –

OBSERVE ALL PRECAUTIONS DURING CONNECTION AND MEASUREMENT OF LINE HIGH VOLTAGES

Equipment Required Comments

AC Current Source Capable of sourcing up to 3A AC 50Hz

Connections

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 16

Calibration Method

1. Connect 3200 / 2100 to meter as per diagram using LEAD SET D

2. Select RCD Current mode on 3200 / 2100 CCP

this will set the 3200 / 2100 to 10mA Range in calibration mode (continuous reading)

3. Set the current source to the current range full scale

4. Adjust cal factor using CCP software adjustment control

5. Repeat process for each RCD current range

Verification Test Points

See Performance Verifications Sheet Page 6

RANGE SELECTION

Select range to be calibrated here

ADJUSTMENT CONTROL

A

djust cal factor using up/down buttons – note using the up/down button

automatically sends cal factor to calibrator, the send button is needed

only if a cal factor is manually typed into the cal factor value box.

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 17

RCD (Residual Current Device) Trip Time Function

VERIFICATION AND CALIBRATION PROCEDURES ARE FOR USE BY QUALIFIED TECHNICIANS ONLY –

OBSERVE ALL PRECAUTIONS DURING CONNECTION AND MEASUREMENT OF LINE HIGH VOLTAGES

Equipment Required Comments

Digital Storage Oscilloscope

RCD & oscilloscope Trigger Box Supplied with calibration kit

Connections

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 18

Verification Method

1. Connect 3200 / 2100 to meter as per diagram using RCD & OSCILLOSCOPE TRIGGER BOX

2. Select RCD Function on 3200 / 2100 – set 10mA / 40ms trip current / time

3. Adjust setting on oscilloscope for storage mode and to use external trigger input

Set 5V/Div Amplitude, 5ms Timebase.

Select external trigger and single shot storage mode as to view waveform as shown in screenshot below.

Adjust to trigger oscilloscope on a 5V rising edge.

4. Press the TEST soft key on the 3200 / 2100 to begin the test

If the button is pressed at the wrong part of the mains cycle an obviously incorrect time period will result.

Simply reset the oscilloscope / 3200 / 2100 and press button again to retest.

5. Read the timing from the oscilloscope – target value is 40ms ± 0.7ms

Verification Test Points

See Performance Verification Sheet Page 6

3200 / 2100 Verification & Calibration Guide

For Use With Calibration Control Panel & Calibration Lead Set

3200 Verification & Calibration Guide.doc

Page 19

PAT Insulation Resistance Function

VERIFICATION AND CALIBRATION PROCEDURES ARE FOR USE BY QUALIFIED TECHNICIANS ONLY –

OBSERVE ALL PRECAUTIONS DURING CONNECTION AND MEASUREMENT OF LINE HIGH VOLTAGES

Equipment Required Comments

Resistance Meter Capable of measuring up to 1kOhm

Connections

Verification Method

1. Connect 3200 / 2100 to meter as per diagram using LEAD SET G

2. Select PAT Insulation Resistance mode and test points as per verification sheet using the 3200 / 2100 front

panel and record measurement obtained using 2-wire connection.

Verification Test Points

See Performance Verifications Sheet Page 6

Other manuals for 2100

1

This manual suits for next models

1

Table of contents

Other Transmille Test Equipment manuals

Transmille

Transmille 5080 User manual

Transmille

Transmille 4610M Use and care manual

Transmille

Transmille 3000 Series Use and care manual

Transmille

Transmille 3000 Series User manual

Transmille

Transmille 1000 Series User manual

Transmille

Transmille 9000 Series User manual

Transmille

Transmille 1000 Series Use and care manual

Transmille

Transmille 4610M User manual

Transmille

Transmille 2100 User manual

Transmille

Transmille 3200B User manual