Harsen GU611A User manual

Other Harsen Controllers manuals

Popular Controllers manuals by other brands

Bartlett

Bartlett 3K Operation manual

Regin

Regin OPTIGO OP5 Instruction

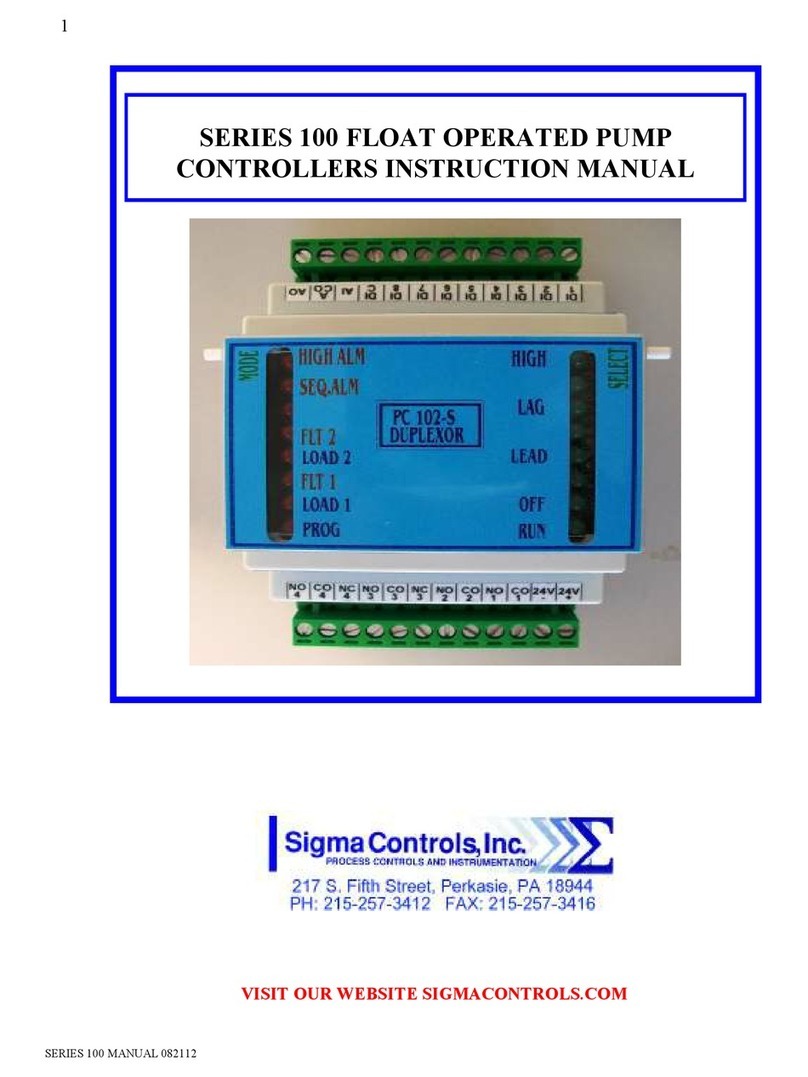

Sigma Controls

Sigma Controls 100 Series instruction manual

Mitsubishi Electric

Mitsubishi Electric RJ71PB91V-U-IN-E user manual

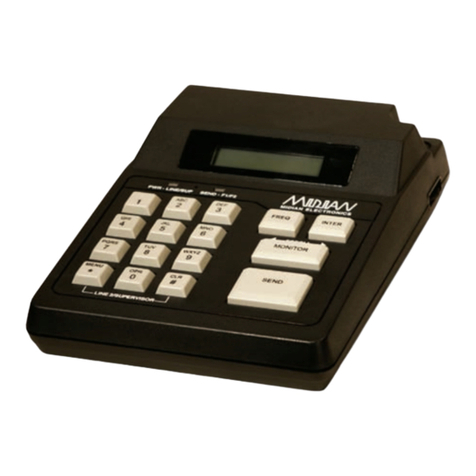

Midian Electronics

Midian Electronics TRC-1 manual

Hycontrol

Hycontrol MINIFLEX LR Installation and operation manual

NuAire

NuAire Ecosmart ES-ISC Series Installation and Maintenance

Mitsubishi Electric

Mitsubishi Electric MELSEC Q Series Reference manual

Avonic

Avonic CD500 user manual

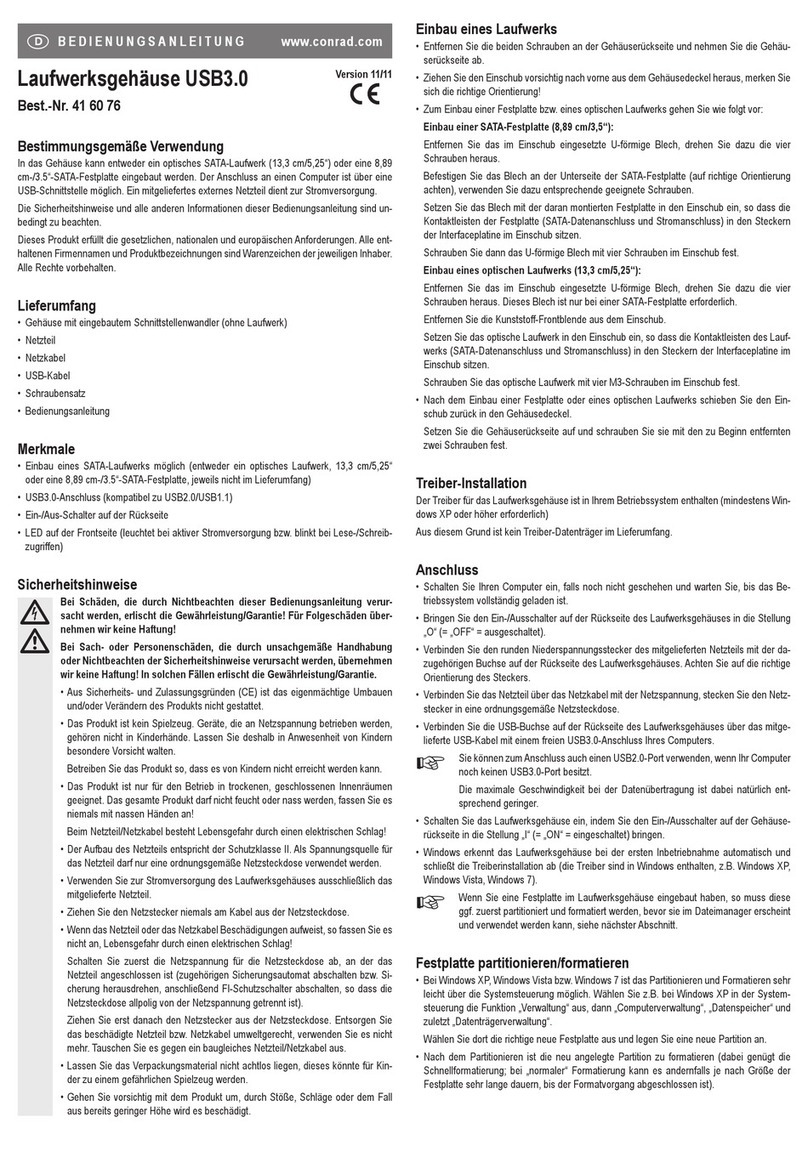

Conrad

Conrad 41 60 76 operating instructions

cherry creek systems

cherry creek systems 310-0176 CHEAT SHEET

Sygonix

Sygonix 2443708 operating instructions

Belimo

Belimo CQB24-3 instruction manual

Sentera Controls

Sentera Controls DRPUM Mounting and operating instructions

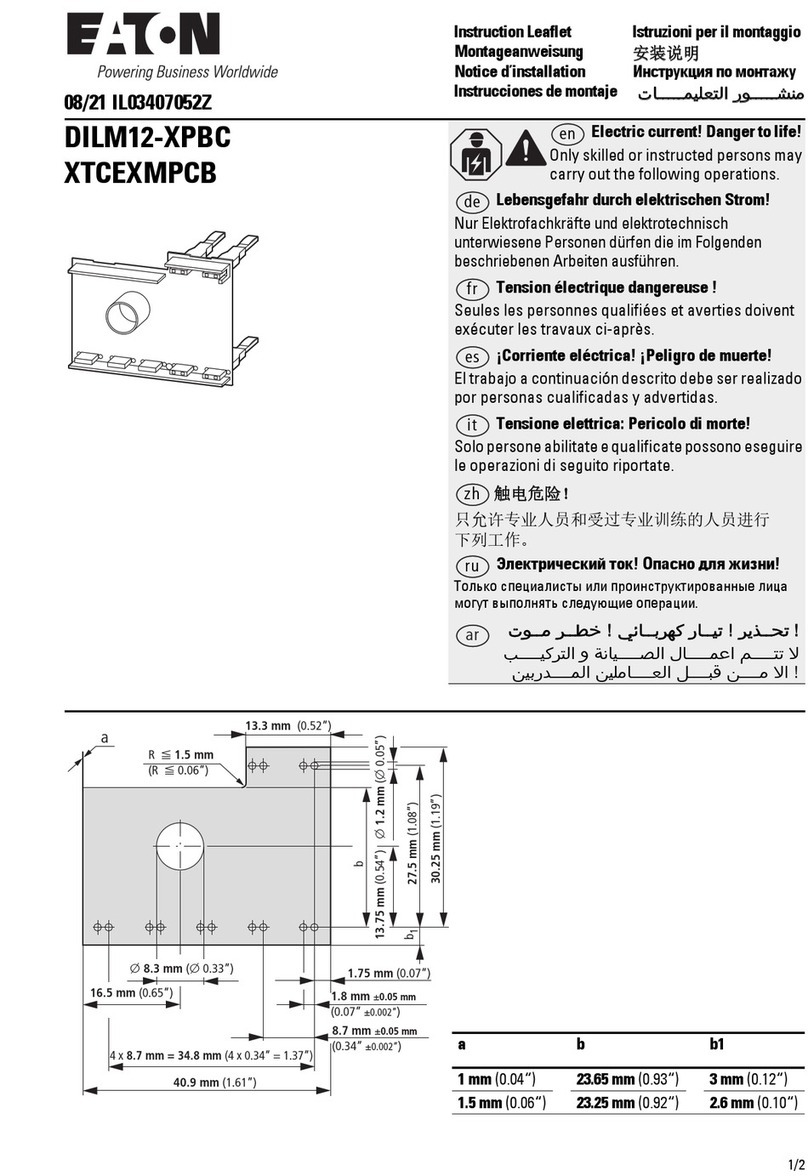

Eaton

Eaton DILM12-XPBC Instruction leaflet

Ruckus Wireless

Ruckus Wireless SmartZone 300 Quick setup guide

Toshiba

Toshiba TS3000 Series instruction manual

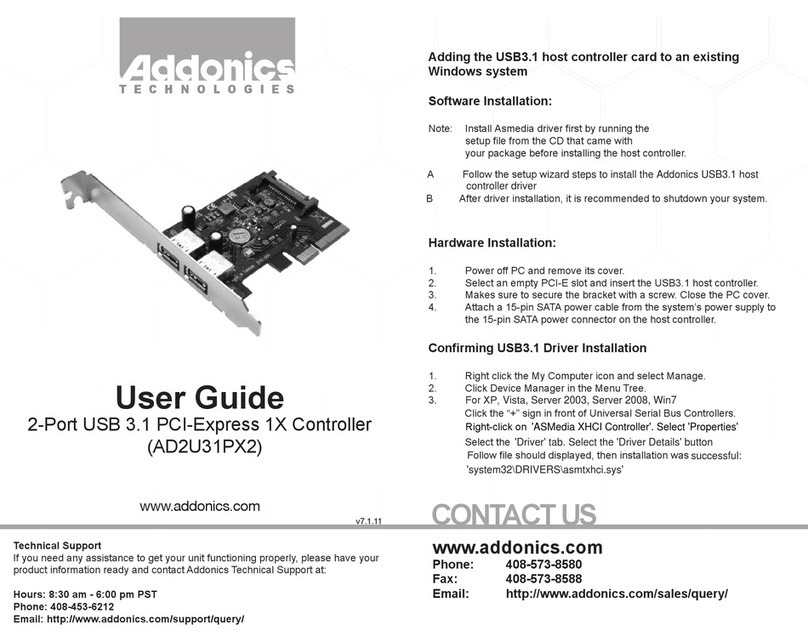

Addonics Technologies

Addonics Technologies AD2U31PX2 user guide