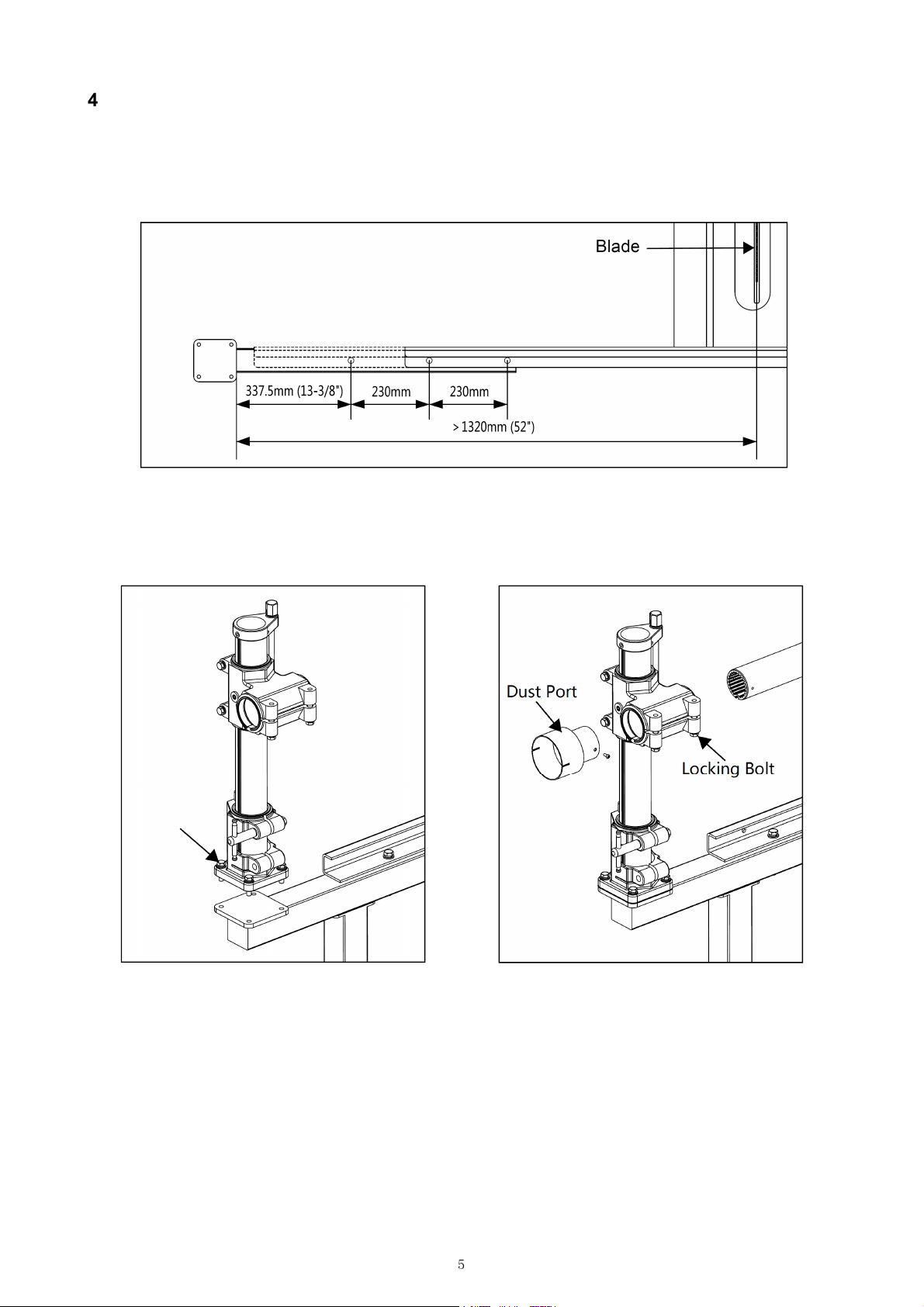

7

No e: You need o adjus he guard posi ion rela ive o he blade before using i .

You mus make sure ha he limi block shown in Fig. 10 is a he limi ing posi ion

when he overhead guard is in working s a e.

You mus make sure ha he guard will no in erfere wi h he riving knife and he

blade .

5.1 Adjus ing he Guard Posi ion Rela ive o he Blade (Lef and Righ & Up and

Down)

As shown in Fig.11 ①, loosen the olt (C), the arm unit can e e moved forward or

ackward to adjust the guard position relative to the lade (left and right) for ensuring the

gap etween the lade and guard is less than or equal to15mm, as Fig.11 ②shows.

As shown in Fig.11 ①, loosen the olt (D) and nut (E), rotate the hex nut (F) clockwise or

counterclockwise to ensure the gap etween the lade top teeth and guard is less than or

equal to 5mm when the guard is placed at the highest position,as Fig.11 ③shows. After

adjusting, tighten the olt (D) and nut (E).

Fig.11

5.2 Adjus ing he Parallelism of he Overhead Guard wi h he Blade and Table

As shown in Fig. 12, y releasing the kno (G) counterclockwise, you can swing the guard

to left or right to adjust the parallelism of the overhead guard with the lade; y releasing

the kno (H) counterclockwise, you can flip the guard to adjust the parallelism of the

overhead guard with the ta le.

Fig. 12