7. Do not use the shaper as a toy. Do not use near

or around children.

8. Keep hands a ay from cutting tool.

9. Never run stock bet een the fence and the

cutter.

10. Al ays use a miter gauge and clamp

attachment hen shaping small pieces. The fence

should be removed during this operation.

11. Al ays feed against the rotation of the cutter.

12. Work-piece to be adequately supported during

machining/feeding using, here necessary,

additional support, e.g. for long ork-pieces.

13. Keep cutters sharp and free from rust and pitch,

follo ing tool manufacturers’ instructions for use,

adjustment and repair of tools.

14. Only use flat orkpieces in the shaper, never

use arped or t isted lumber.

15. Never take off too much material in one pass.

Make several lighter passes.

16. Set up operations henever possible to have

the cutters under the orkpiece, al ays use proper

speed setting for the cutter being used.

17. Not removing any splinters or other part of the

ork-piece from the cutting area hile the machine

is running.

18. Ensure the maximum rotational speed marked

on the tools is not exceeded.

19. Make sure cutters are properly secured before

starting shaper.

20. Use guards, guides, and hold-do n herever

possible, not using the machine unless the guards

and other safety devices necessary for machining

are in position, in good orking order and properly

maintained.

21. Do not perform any operation freehand. Use the

fence for straight shaping.

22. Push blocks or push sticks shall be used in

circumstances here it is necessary to push the

orkpiece against the fence.

23. Avoid a k ard operations and hand positions

here a sudden slip could cause your hand to move

into the spinning blade.

24. The machine shall be connected to an external

chip and dust extraction system; the dust extraction

equipment is to be s itched on before commencing

machining.

25. Period check the brake function to make sure

the stop time of the sa blade is less than 10s.

26. Only tools suitable for hand feed machines,

conforming to EN 847-1 and EN 847-2:2013 and

marked MAN shall be used in order to reduce

severity of injuries and kickback speed.

27. When using milling tools ith diameter ≥16 mm

and circular sa -blades, they shall conform to EN

847-1:2013 and EN 847-2:2013; tool holders shall

conform to EN 847-3:2013; Shank milling tools ith

cutting circle diameter lo er than 16 mm can be

used ithout restriction.

28. Use table rings or table insert to close the gap

bet een the table and the spindle to a minimum.

29. Fit the tooling to the machine to operate in the

correct direction of rotation. Avoid injury hen on

use of tool carriers and handling tools.

30. Don't misuse, foreseeable misuse includes, e.g.

feeding small ork-pieces ithout safety appliance,

mounting of a sa blade on the arbor instead of

milling tools and feeding ork-pieces in the same

direction as of the running tool (climb cutting).

4.3 Residua Risks

1. Take precautions to reduce the hazard of

inhalation of harmful dusts (e.g. earing a dust

mask);

2. Wear ear protection to prevent hearing loss;

3. Al ays ear safety glasses. also use a face or

dust mask if cutting operation is dusty;

4. Against the hazard of cutting hen handling

cutters into the machine or doing maintenance;

5. Not to try removing chips hilst the cutter (s) is

(are) running and the shaper unit(s) is (are) not in

the rest position;

6. Not to try using the machine unless all of the

guards and other safety devices necessary for

machining are in good orking order;

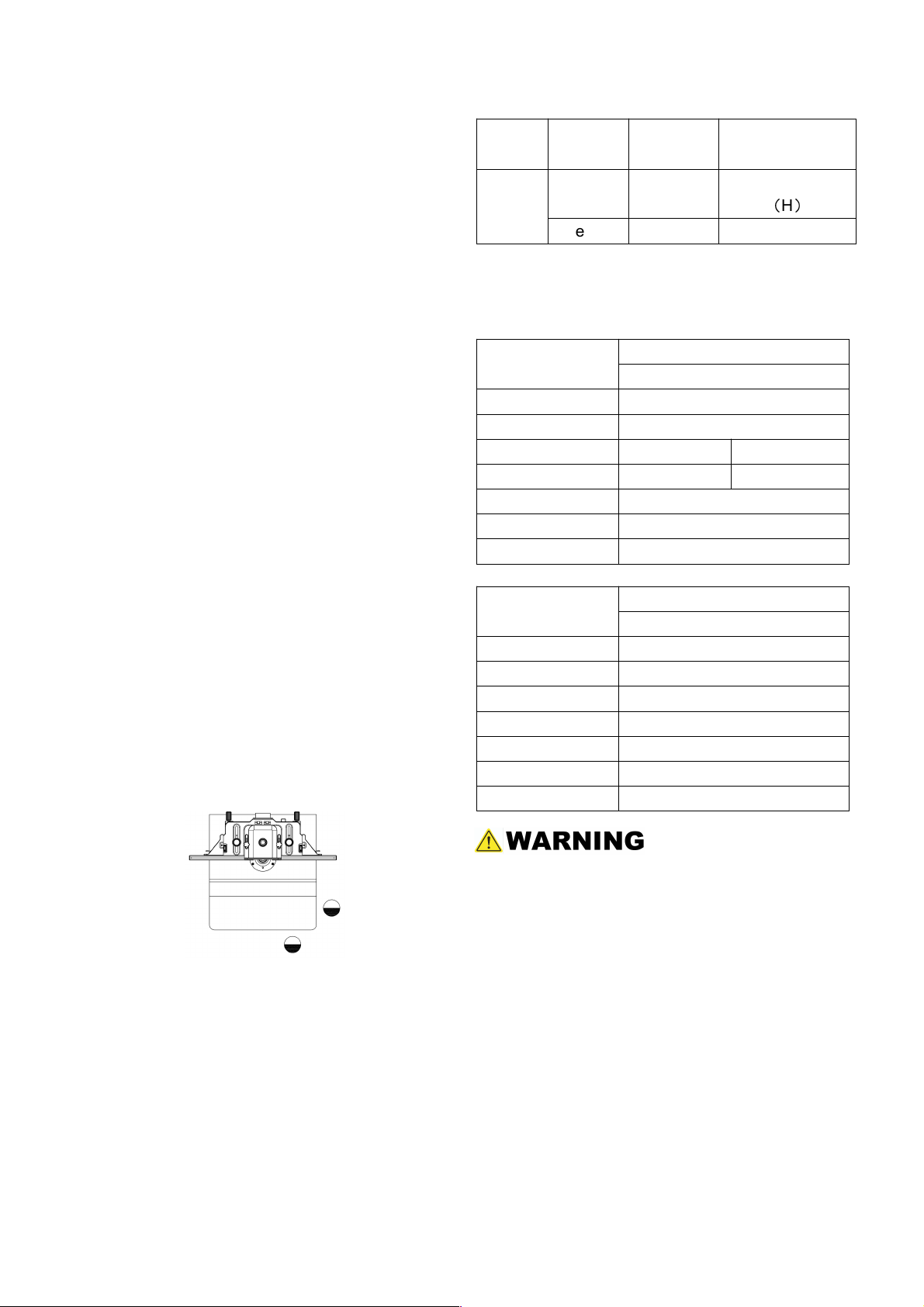

4.4 Safety Equipment

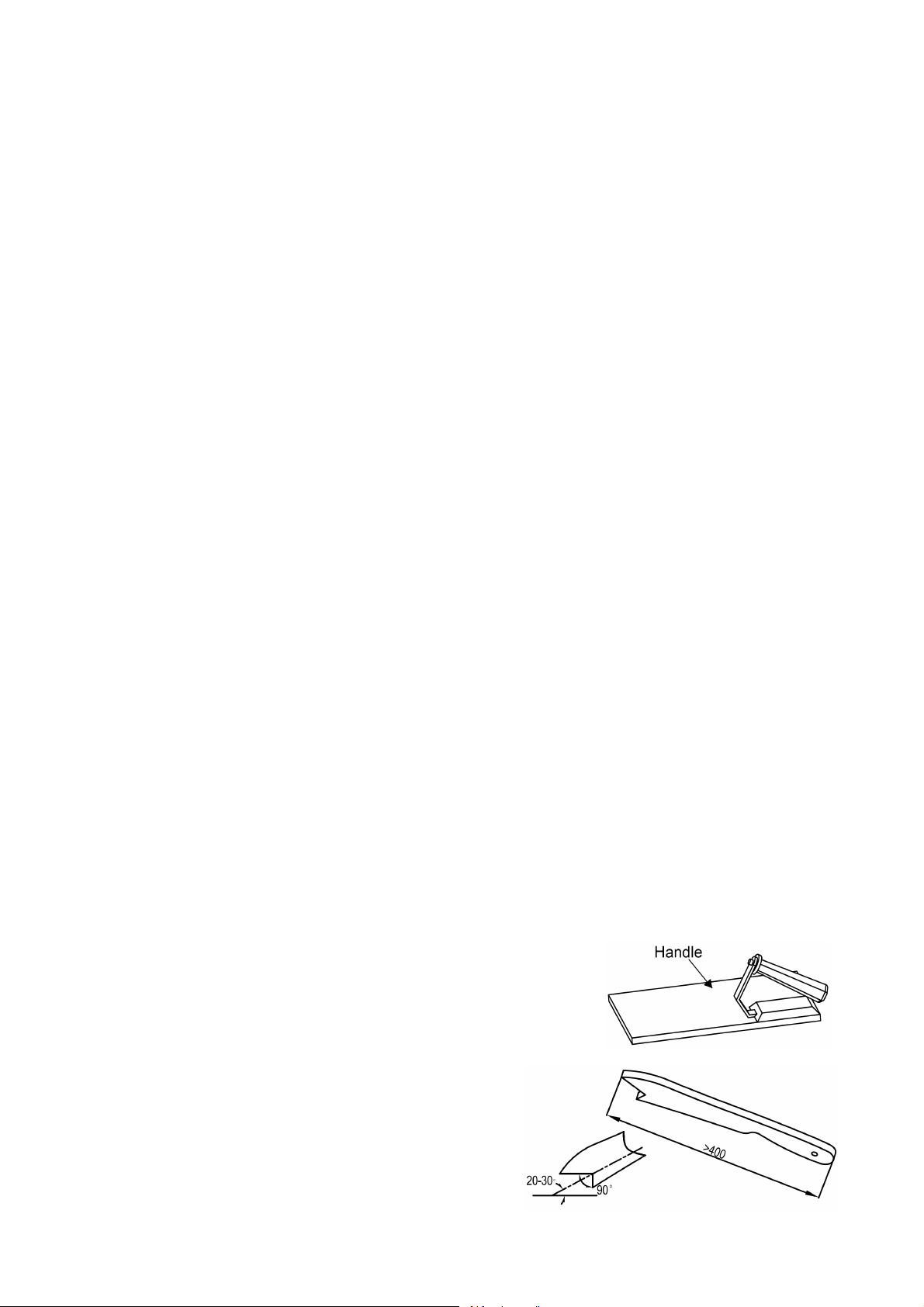

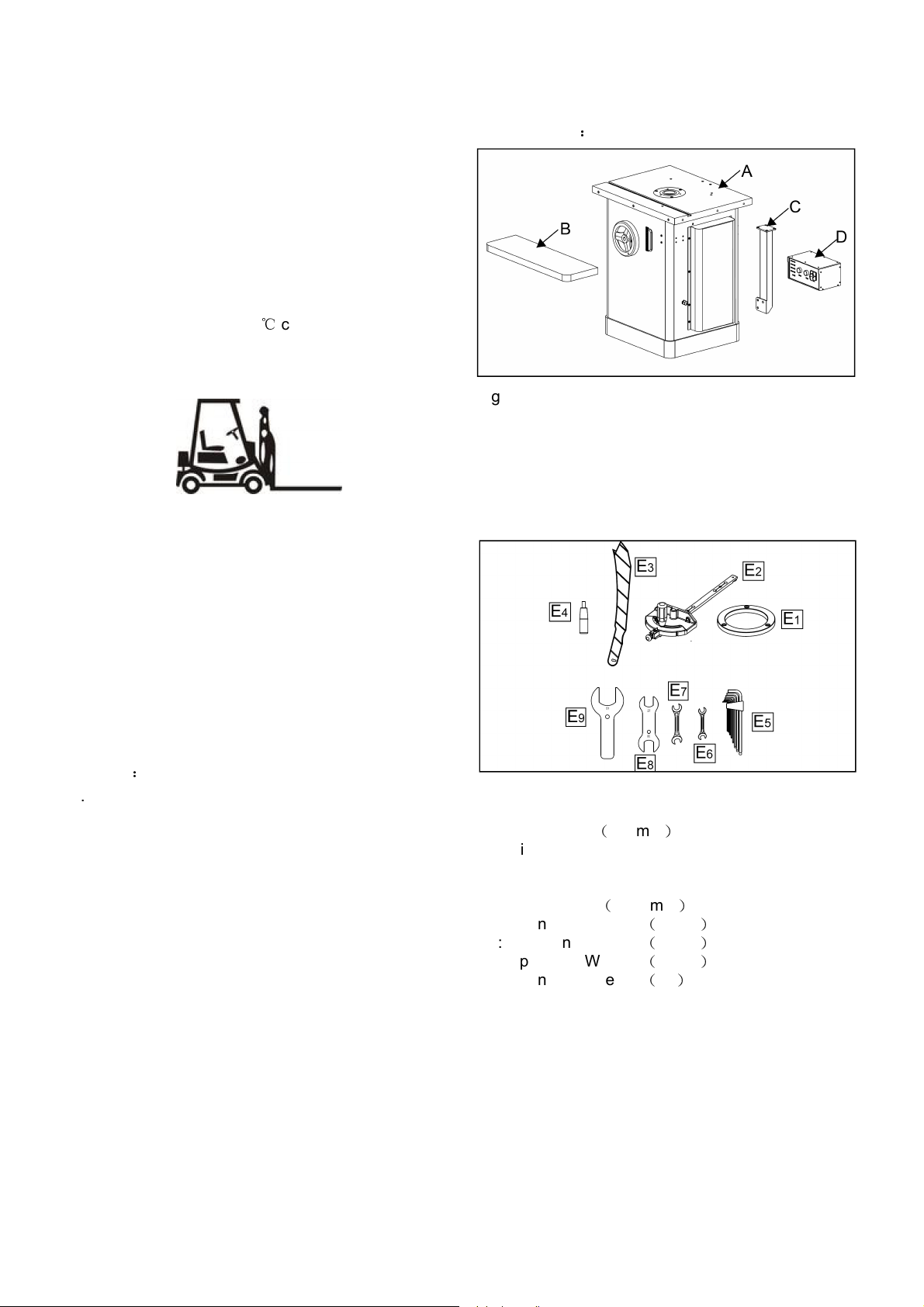

To prevent your hands being close to the cutter, a

push block (Fig.3) or push stick (Fig.4) must be

used hen cutting small or narro stock.

Fig. 3

Fig. 4