CONTENTS

1. Safety------------------------------------------------------------------------------------------------------ 1

1.1 General Machine Safety.----------------------------------------------------------------------------- 1

1.2 Band Saw Safety.-------------------------------------------------------------------------------------- 1

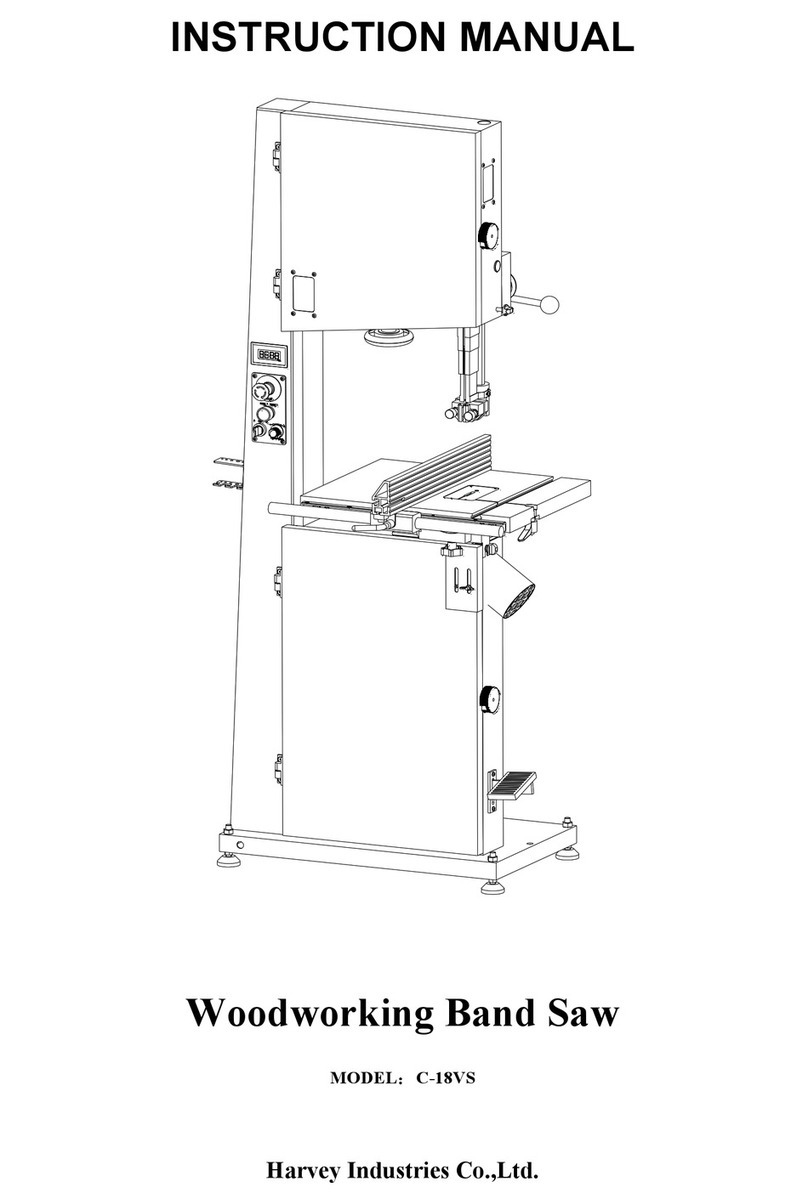

2. Feature Identification-------------------------------------------------------------------------------- 2

3. Specifications------------------------------------------------------------------------------------------ 3

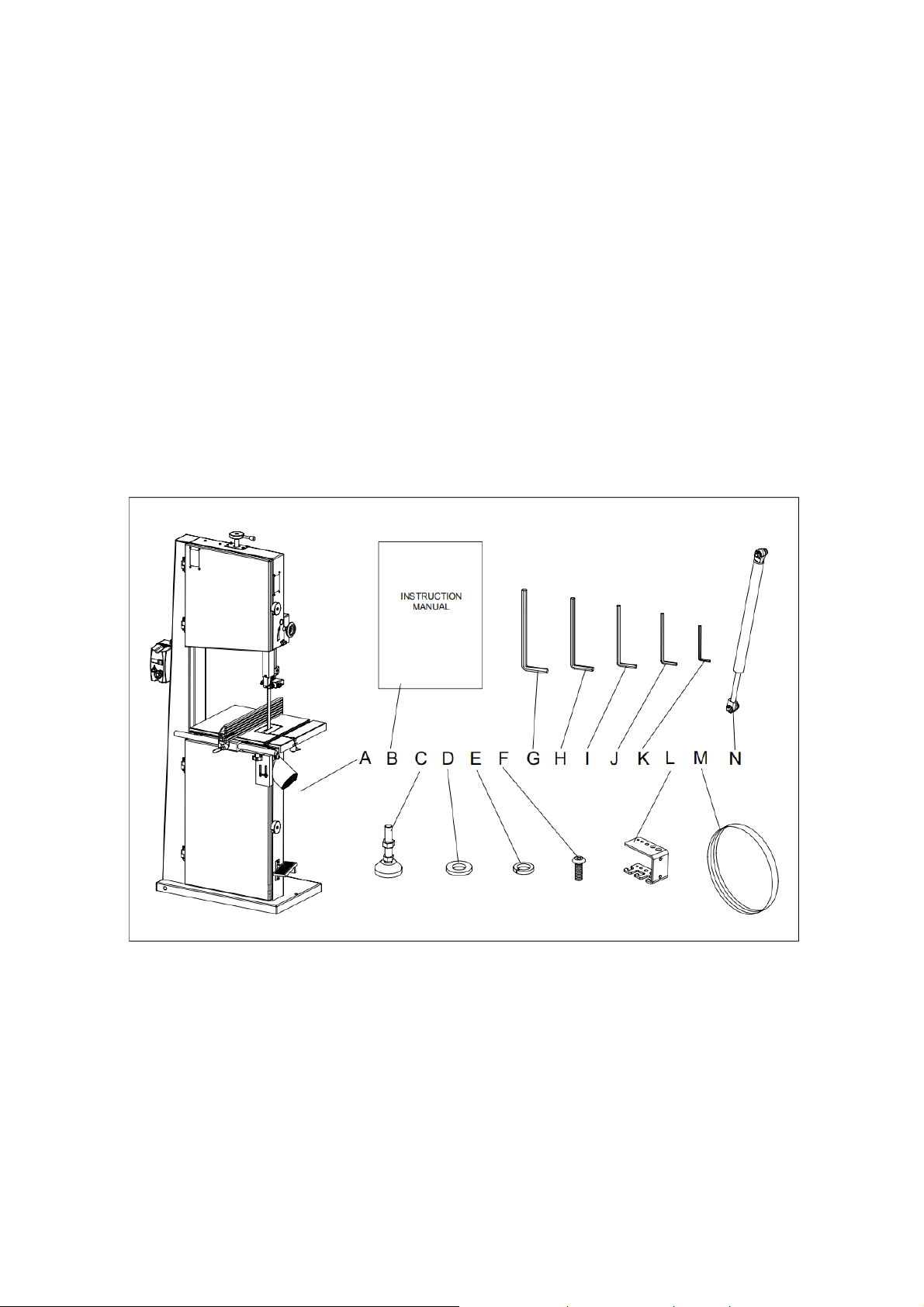

4. Unpacking and Setup-------------------------------------------------------------------------------- 4

4.1 Unpacking--------------------------------------------------------------------------------------------- -- 4

4.2 Checking Contents ----------------------------------------------------------------------------------- 4

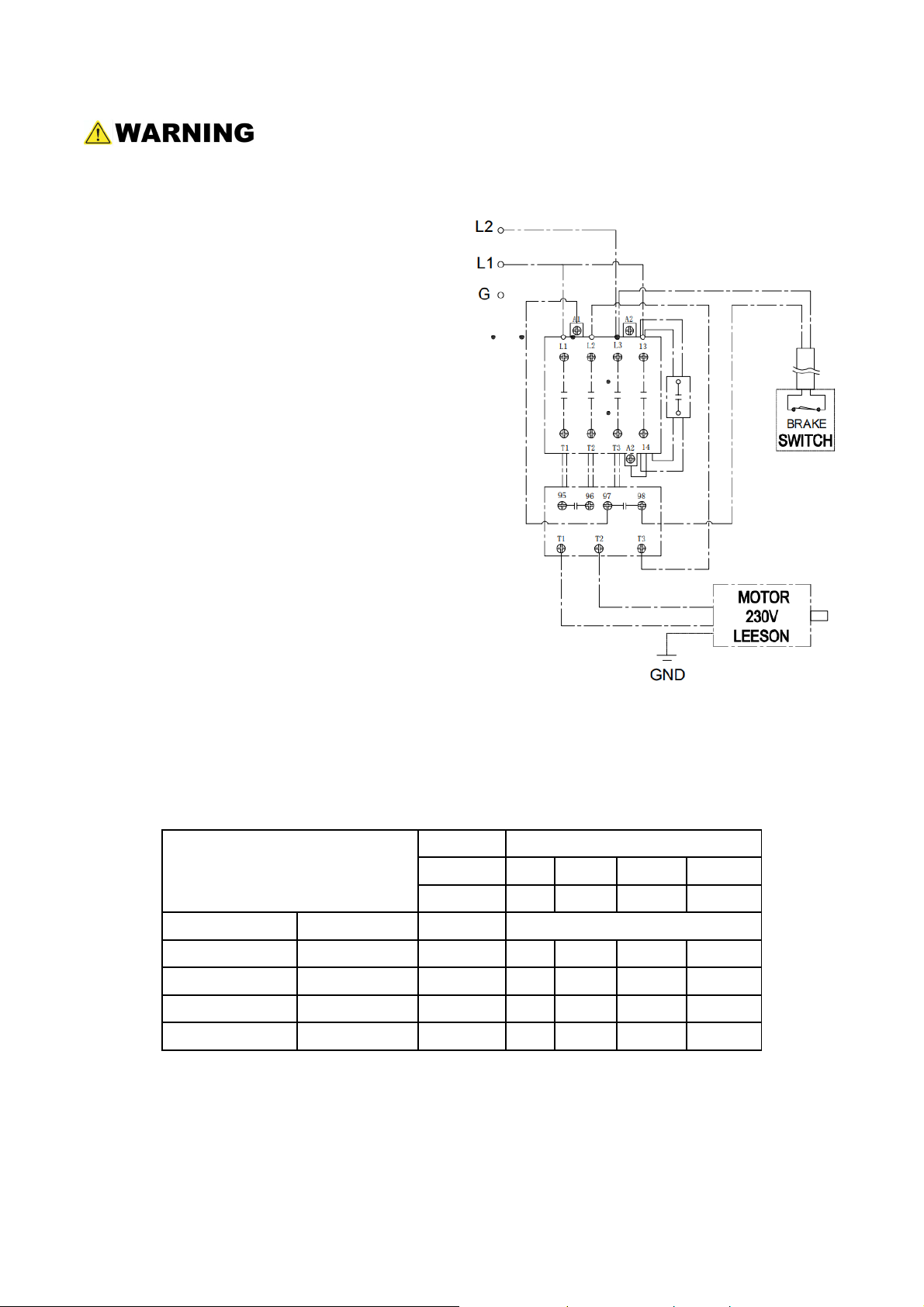

4.3 Power Supply------------------------------------------------------------------------------------------- 5

4.4 Grounding----------------------------------------------------------------------------------------------- 5

4.5 Extension Cords--------------------------------------------------------------------------------------- 5

4.6 Dust Collection----------------------------------------------------------------------------------------- 5

5. Assembly------------------------------------------------------------------------------------------------ 6

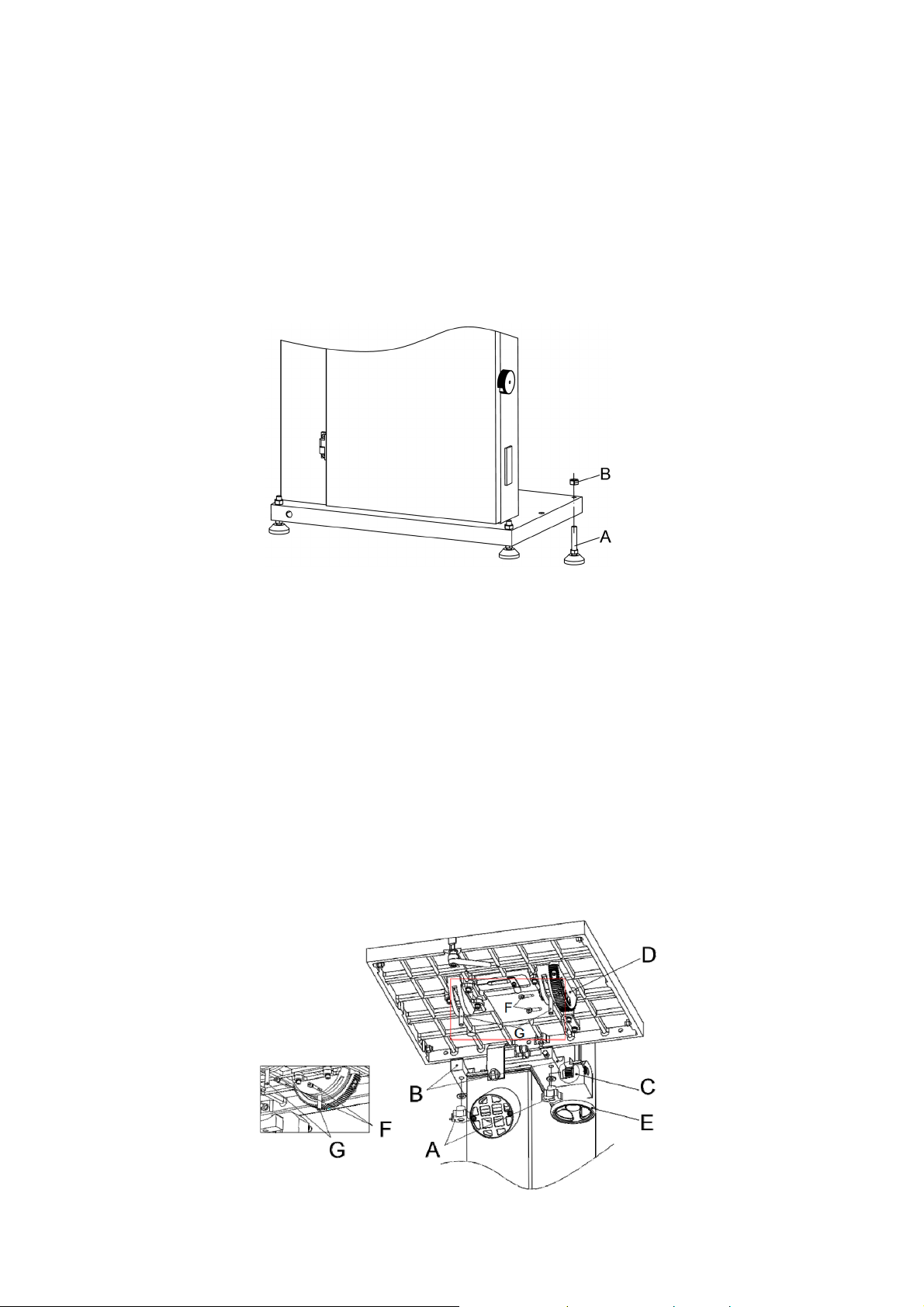

5.1 Stand Pad----------------------------------------------------------------------------------------------- 6

5.2 Work Table---------------------------------------------------------------------------------------------- 6

5.3 Spring Assembly--------------------------------------------------------------------------------------- 7

5.4 Rip Fence----------------------------------------------------------------------------------------------- 7

5.5 Tool Storage Hook------------------------------------------------------------------------------------- 7

5.6 Blade------------------------------------------------------------------------------------------------------ 8

6. Adjustment---------------------------------------------------------------------------------------------- 9

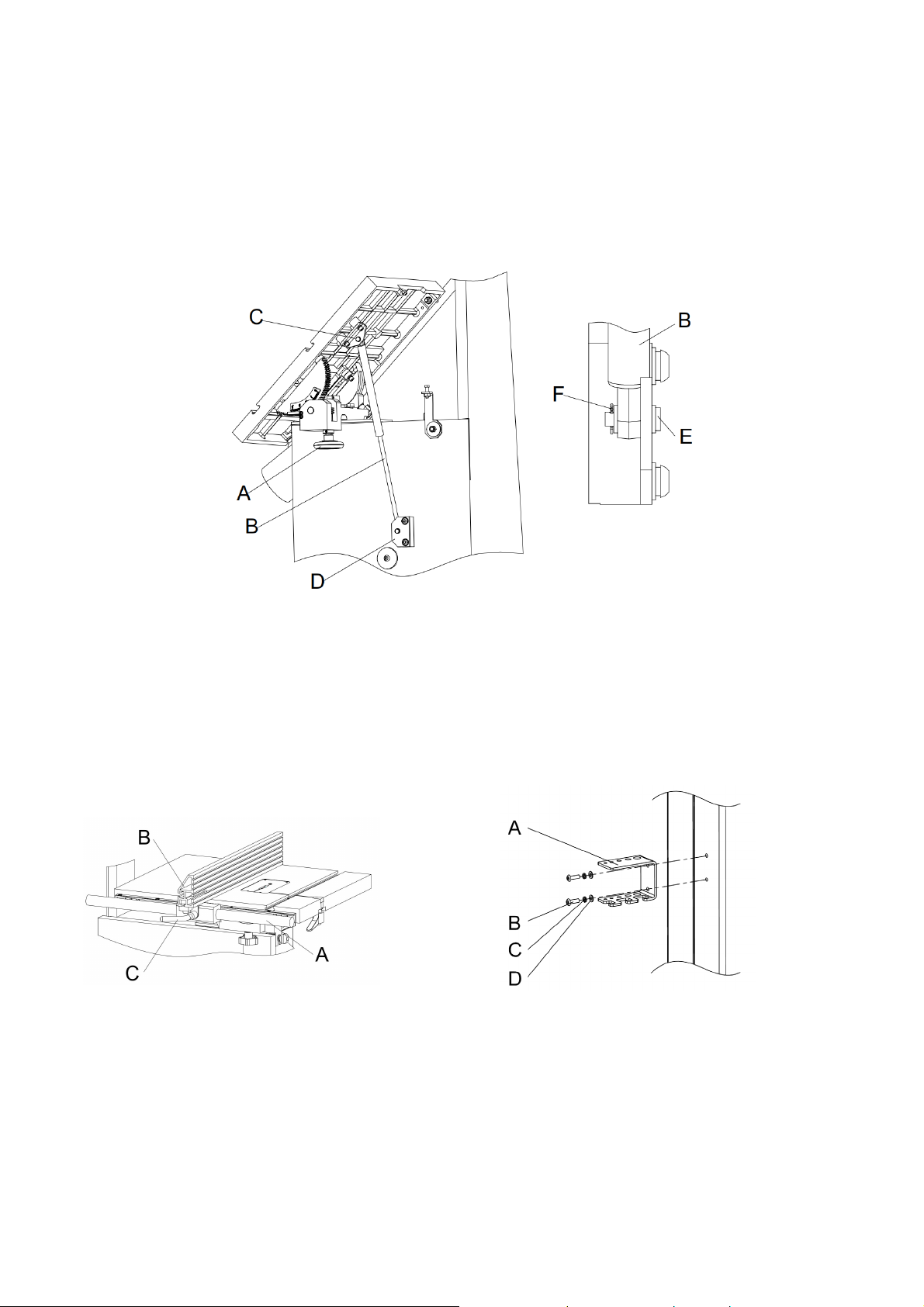

6.1 Blade------------------------------------------------------------------------------------------------------ 9

6.2 Blade Guide--------------------------------------------------------------------------------------------- 11

6.3 Work Table---------------------------------------------------------------------------------------------- 14

6.4 Fence----------------------------------------------------------------------------------------------------- 16

6.5 Belt Tension and Replacement--------------------------------------------------------------------- 18

7. Operation------------------------------------------------------------------------------------------------ 19

7.1 Switch----------------------------------------------------------------------------------------------------- 19

7.2 Brake Pedal--------------------------------------------------------------------------------------------- 19

8. Application---------------------------------------------------------------------------------------------- 20

8.1 Ripping --------------------------------------------------------------------------------------------------- 20

8.2 Crosscutting--------------------------------------------------------------------------------------------- 20

8.3 Resawing------------------------------------------------------------------------------------------------ 20

8.4 Curve Cutting------------------------------------------------------------------------------------------- 21

8.5 Blade Lead ---------------------------------------------------------------------------------------------- 21

9. Maintenance ----------------------------------------------------------------------------------------- 22

9.1 Lubrication----------------------------------------------------------------------------------------------- 22

9.2 Cleaning-------------------------------------------------------------------------------------------------- 22

9.3 Replacement-------------------------------------------------------------------------------------------- 22

9.4 Wheel Brush-------------------------------------------------------------------------------------------- 22

10. Trouble Shooting------------------------------------------------------------------------------------ 23

11. Exploded View and Parts List------------------------------------------------------------------ 25