HARWI 625-H User manual

1

MANUAL

625-H/U

Harwi Holland BV

Lage Dijk 28

5705 BZ Helmond

the Netherlands

Tel. 31 (0) 543355

Fax 31 (0) 522305

2

CONTENTS

APPLIANCE....................................................................................................................................................................................3

GENERAL INDICATIONS/SAFETY REGULATIONS .....................................................................................................................4

GENERAL INFORMATION............................................................................................................................................................. 5

MANUFACTURER ..................................................................................................................................................................... 5

MACHINE...................................................................................................................................................................................5

EU DECLARATION OF CONFORMITY FOR MACHINERY: ..................................................................................................... 5

TECHNICAL DETAILS.................................................................................................................................................................... 6

NOISE INFORMATION ..............................................................................................................................................................6

SECURING MACHINE TO THE GROUND..................................................................................................................................... 7

SECURING ................................................................................................................................................................................ 7

DIRECTION OF SPINDLE ROTATION ..........................................................................................................................................8

PROPER DIRECTION IS CLOCKWISE.....................................................................................................................................8

OPERATING THE MACHINE ......................................................................................................................................................... 9

OPERATING THE MACHINE ....................................................................................................................................................... 10

OPERATING THE MACHINE ....................................................................................................................................................... 11

OPERATING THE MACHINE ....................................................................................................................................................... 12

MAINTENANCE............................................................................................................................................................................ 15

MAINTENANCE............................................................................................................................................................................ 18

CLEANING, LUBRICATING AND GREASING......................................................................................................................... 18

40 PRODUCTIVE HOURS................................................................................................................................................... 18

160 PRODUCTIVE HOURS................................................................................................................................................. 18

1000 PRODUCTIVE HOURS............................................................................................................................................... 18

MAINTENANCE............................................................................................................................................................................ 19

MAINTENANCE............................................................................................................................................................................ 20

MAINTENANCE............................................................................................................................................................................ 21

WIRING DIAGRAM....................................................................................................................................................................... 22

3

APPLIANCE

The radial arm saw type 625-H, 625-U en 625-

2-K are to be used for cutting wood and wood-

like panels, and with the proper saw-blade

plastics and non-ferrous materials.

Maximum material sizes are:

Height: 135 mm

Cutting length standard 625 mm

Cutting of other materials with the standard saw-

blade is prohibited. Cutting of other materials

with the proper saw-blade only with permission

of manufacturer.

All other appliances except for the above are

improper use of the machine and therefore

prohibited. The manufacturer cannot be held

responsible for damage as a result of improper

use. Damage will be recovered from the user.

The machine may not be used, operated or

maintained by persons not acquainted with the

risks of the machine.

Permission for operating, using and maintaining

the machine have to be clearly described by a

person or persons responsible with the

organisation.

Maintenance has to be performed by the

manufacturer or customer service.

One has to be acquainted and comply with the

country’s applicable safety regulations.

Only original Harwi parts are to be used. We

cannot give warranty or be held responsible for

damage caused by using non-original Harwi

parts.

The manufacturer cannot be held responsible

for damage caused by using non-original Harwi

parts.

REMAINING RISKS

If the machine is completely used according to

all safety regulations there still will remain some

risks:

Touching of the saw-blade within the sawing

area.

Touching of the saw-blade when the lid is

opened.

Breaking of the saw-blade or parts of the

saw-blade hurtling out of the guard.

Touching of parts under voltage while

junction box is opened.

Damage to the hearing caused by constant

use of the machine without ear protection.

Throw out of harmful dusts or vapours by using

a dust extractor with bad performance or no

dust extractor at all

4

GENERAL INDICATIONS/SAFETY REGULATIONS

Harwi Holland B.V. has bestowed great care on

compiling this manual. Before operating the

machine read the complete manual carefully.

Person under the age of 18 are not allowed to

work on or with circular machines, except for a

training program on a legal basis. The machine

may only be operated by educated personnel or

under supervision of educated personnel.

To avoid touching with rotating saw-blades

make sure that:

clothing fits tightly to the body

work with closed fingers

no rings or other jewellery are worn

a hairnet is used by long hair

Be careful when changing the saw-blades.

They are sharp and can cause injuries.

Do not remove woodchips when the saw-blade

is running. Stop the machine first. Broken saw-

blades or deformed blades are not to be used.

Neither are HSS blades.

The applied saw-blade is to be used and

sharpened according to the directions of the

manufacturer. Sharpening only by competent

craftsmen.

Stick to max. admissible r.p.m. mentioned on

the blade. Preferably use noise-reduced saw-

blades.

Take care of proper support when cutting long

are large material.

Flexible hoses of the dust extractor have to be

of a highly inflammable quality (according to

DIN 4102).

The safety guard and other safety equipment

may not be removed or put out or order.

Assembling or repairs are only to be performed

if the machine cannot be switched on. The

switch or the main switch are to be turned off

and locked with for instance a padlock.

Repairs to the electricity supply are only to be

executed by skilled craftsmen.

When leaving the working area make sure that

the machine cannot be switched on by

incompetent persons. It is obligatory to wear a

dust-mask, ear protection and safety glasses.

Take care of a clean working area.

The machine has to be lighted. When using

strip lighting take into account the stroboscopic

effect. A rotating saw-blade seems to be

standing still.

5

GENERAL INFORMATION

MANUFACTURER

HARWI Holland B.V.

Lage Dijk 28

5705 BZ Helmond, The Netherlands

Tel: 0492-54 33 55

Fax: 0492-52 23 05

MACHINE

Radial arm saw:

Type:.625-H, 625-U, 625-H 2K

Machine number:.................................

Manufactured:............................................

EU DECLARATION OF CONFORMITY FOR MACHINERY:

(according to Annex II A of the Machine Directive)

We, HARWI Holland B.V. Lage Dijk 28, 5705 BZ Helmond, the Netherlands herewith declare, on our

own responsibility that the product:

HARWI RADIAL ARM SAW TYPE................................................. ,

MACHINENUMBER..........................,

which this declaration refers to, is in conformity with the following stand:

2006/42/EG meets requirements EMV 2004/108/EG NEN-EN 1870-17:2007

Nederland, Helmond Quality controller. (name)..................................................

dated.................................................(Signature)

6

TECHNICAL DETAILS

MEASURES AND WEIGHTS

Technical data:

625-H

625-U

625-2K

Height of cut (standard) mm

135

135

135

Height of cut (max.) mm

160

160

160

Height of cut angle 45º mm

-

70

-

Length of cut mm

625

625

1250

Length of cut angle 45º mm

-

625

-

Length of cut arm at 45º mm

-

400

-

Height adjustment mm

95

50

95

Saw-blade diameter standard mm

Ø 400

Ø 400

Ø 400

Saw-blade diameter max. mm

Ø 450

Ø 450

Ø 450

Saw-blade bore mm

Ø 30

Ø 30

Ø 30

Adjustable arm mm

-

0-45º

-

Measures table top mm

800*940

800*1470

1645*940

Table height mm

840

840

840

Motor power kW

3

3

3

Voltage V

400V 3~

400V 3~

400V 3~

Spindle speed rpm

2800

2800

2800

Weight kgs

211

218

348

Used saw-blades must be conform prEN 847-1.

Maximum thickness of saw-blade is 3.6 mm.

NOISE INFORMATION

Used saw-blade: :Leuco proline 101420/10005 ∅400, Z=48 d=30.

A-weighed Equivalent Continuous noise Pressure

Idle dB(A) :81.0 dB(A)

Loaded dB(A) :84.4 dB(A)

Measuring performed according to DIN 45635 part 1659. Measured when cutting chipboard, thickness

18 mm, length 2 meters.

Safe deviation can be approx. 3 dB(A).

The above-mentioned values are radiated noise pressures and not necessarily noise pressures to work

safely with this machine. Supplementary measures for ear protection can be necessary. The following

can be of influence.

duration of operations

working area

other noises

Maximum value may vary per country. Above information can be used for better valuation of dangers

and risks subsequent to using this machine.

7

SECURING MACHINE TO THE GROUND

SECURING

1 Mark the holes for the adjusting bolts on

the floor.

2 Remove plastic caps if necessary.

3 Move the machine.

4 Secure adjusting bolts.

5 Place the machine over the bolts.

6 Check if the machine is level. If

necessary fill up.

7 Fasten with proper tool.

8

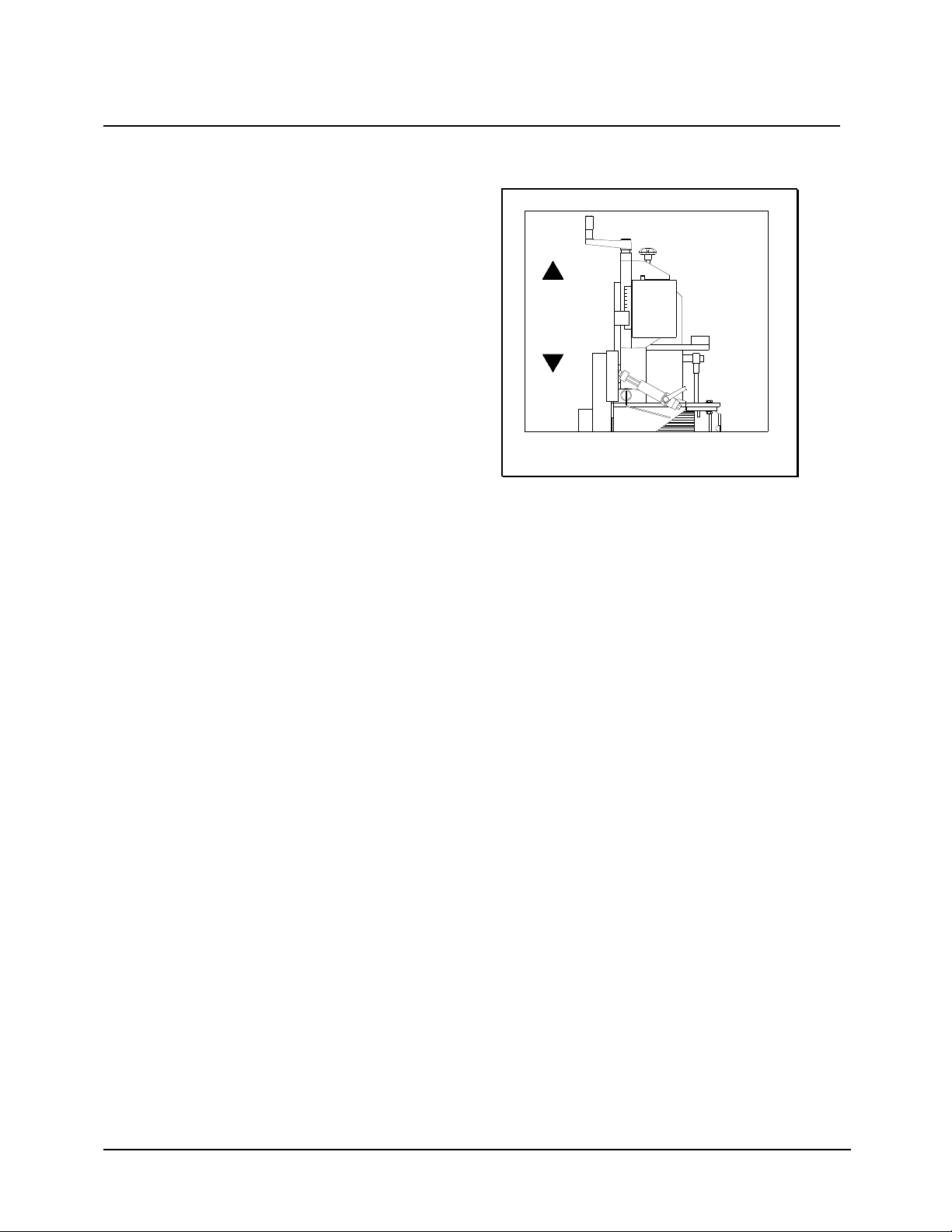

DIRECTION OF SPINDLE ROTATION

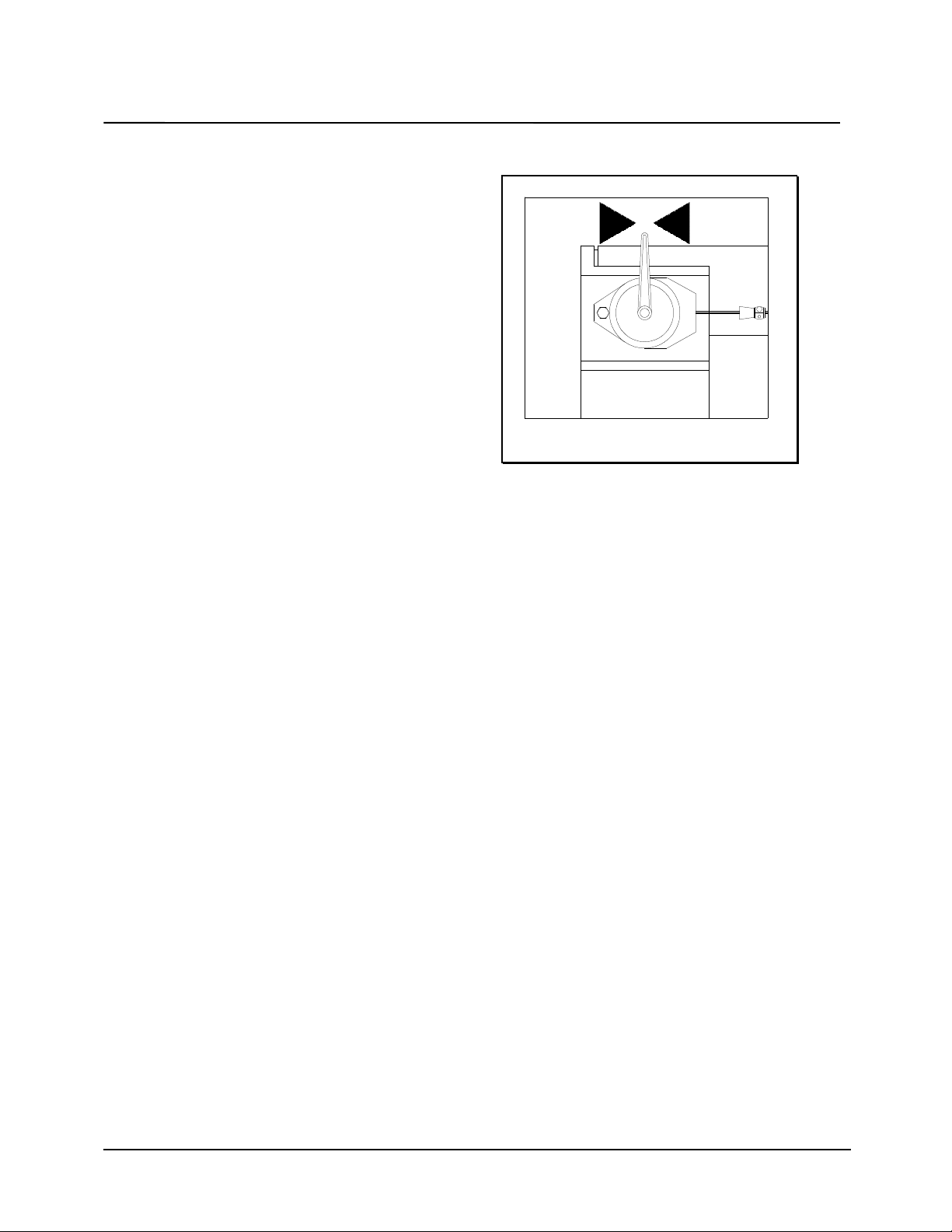

First remove the saw-blade

PROPER DIRECTION IS CLOCKWISE

1 The right direction is marked on the red

guard with an arrow (Fig. 1).

2 Turn off the main switch.

3 Move the carriage to the front.

4 Block the carriage with the knob on top of

the unit.

5 Loosen the safety guard with the black

knob at the front side.

6 Move the guard backwards. The saw-

blade is free now.

7 Block the saw-blade.

8 Loosen the spindle nut clockwise with the

flat key.

9 Remove the saw-blade and the front

flange.

10 Turn on main switch.

11 Push the green button.

12 Push the red button.

13 Check if the spindle is running clockwise

while running out.

14 Turn off main switch.

15 Assemble saw-blade, front flange and nut.

16 Assemble safety guard and fasten with

black knob.

Figure 1

9

OPERATING THE MACHINE

SQUARE MITRING TO THE FENCE

1 Move the carriage to the front.

2 Fasten the carriage with the blocking

knob, on top of the unit.

3 Turn the saw unit downwards with the

handle on top of the carriage (Fig. 2).

4 The bottom side of the measure pointer

has to be approx. 2 mm under 0 mm.

5 Loosen the blocking knob on top of the

carriage.

6 Let the carriage run backwards behind the

stop.

7 The machine is ready for cutting.

Figure 2

0

1

2

3

4

5

6

7

8

9

10

10

OPERATING THE MACHINE

CUTTING AT AN ANGLE UNDER 45º (625-U)

B.M.O. TILTING THE MOTOR

1 Move the carriage to the front (Fig. 3).

2 Fasten the carriage with the blocking

knob, on top of the unit.

3 Turn the saw unit completely upwards

with the handle on top of the carriage.

4 Keep your right hand at the bottom side

of the motor en loosen the handle with

your left hand. Push the motor with your

right hand, against the 45º stop.

5 Fasten the handle with you left hand.

6 Turn the saw unit downwards with the

handle.

7 The top side of the yellow measure pointer

has to be approx. 2 mm under 0 mm.

8 Loosen the blocking knob on top of the

carriage.

9 Let the carriage run backwards behind the

stop.

10 The machine is ready for cutting.

11 Motor from 45º to 0º; put your right hand

at the bottom side of the motor, loosen the

handle with your left hand. Support the

motor with you right hand till 0º.

Figure 3

11

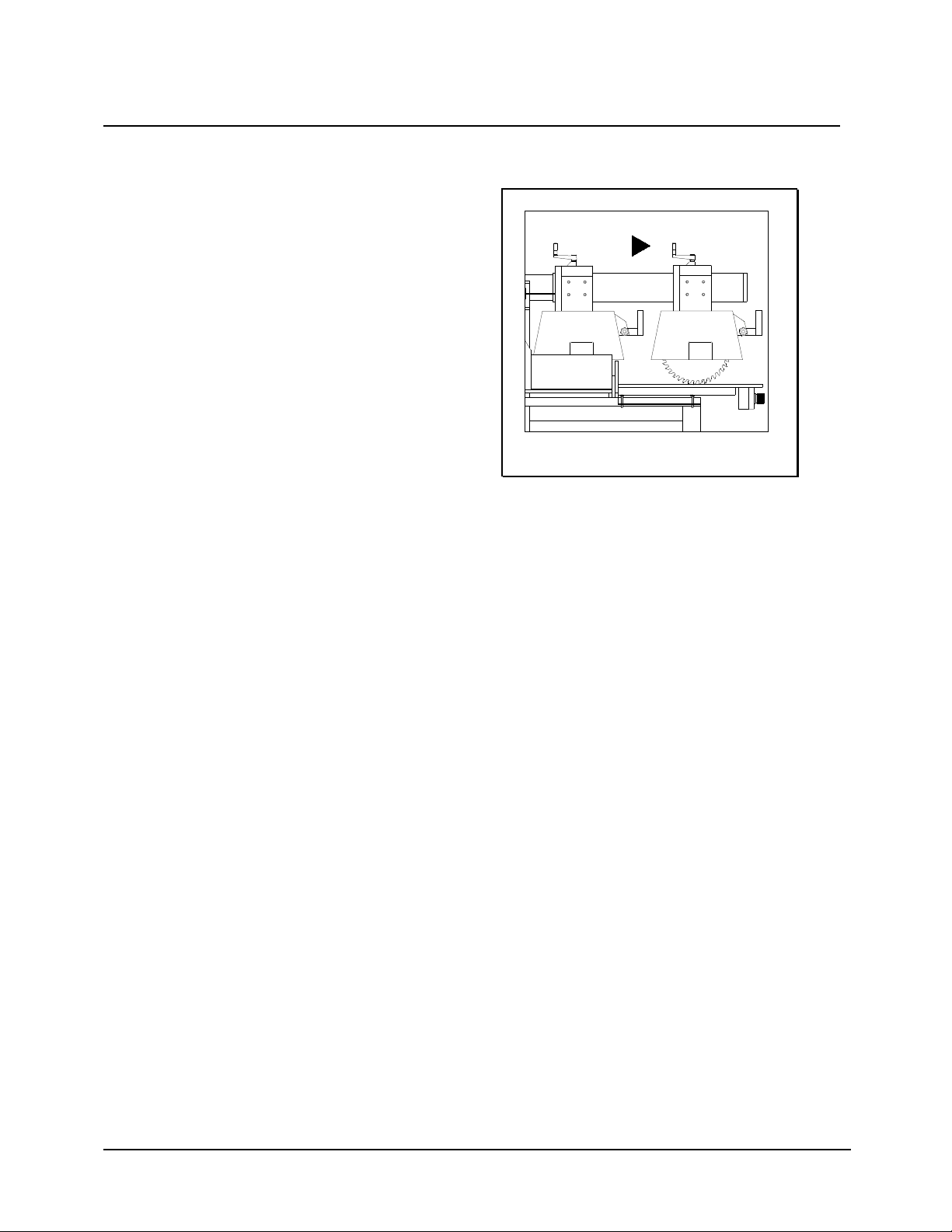

OPERATING THE MACHINE

CUTTING AT AN ANGLE UNDER 45º (625-U)

B.M.O. SWINGING THE ARM

1 Turn the handle at the right backside of

the vertical support backwards (= loosen).

2 Push the arm against the stop of 45º (Fig.

4).

3 Turn the handle on the vertical support

forwards (= fasten).

4 Check the proper adjustment of the

height (has to be 2 mm under 0 mm).

Figure 4

12

OPERATING THE MACHINE

CUTTING AT AN ANGLE BETWEEN 0 AND

45º (625-U)

B.M.O. SWINGING THE ARM (Fig. 5)

1 Move the carriage to the front.

2 Fasten the carriage with the blocking

knob, on top of the unit.

3 Turn the saw-blade slightly upwards.

4 Turn the handle at the backside of the

vertical support a quarter stroke

backwards (= loosen).

5 Set the right angle b.m.o. the measure

scale in the table top.

6 Turn the handle forwards (=tighten).

7 Let the saw-blade touch the topside of the

tabletop.

8 Switch on the machine.

9 Cut a groove.

B.M.O. TILTING THE MOTOR (Fig. 6)

1 Move the carriage to the front.

2 Fasten the carriage with the blocking knob

on top of the unit. Turn up the saw-blade

with the handle on top of the carriage.

3 Set the right angle b.m.o. the measure

scale on the saw unit.

4 Keep your right hand at the bottom side of

the motor. Loosen the handle with your left

hand.

5 Check if the saw-blade is adjusted at the

proper angle.

6 Tighten the handle with your left hand.

7 Let the saw-blade touch the topside of the

tabletop.

8 Switch on the machine.

9 Cut a groove.

Figure 5

Figure 6

13

OPERATING THE MACHINE

COMPOUND ANGLES

1 B.m.o. swinging the arm and tilting of the

motor. Repeat cutting at an angle under

45º or cutting between 0 en 45º.

14

MAINTENANCE

COUNTER BALANCER

Takes the saw-blade automatically back behind

the stop in the 0-position (Fig. 7).

TIGHTEN THE SPRING

1 Put the carriage in the 0-position.

2 Put the delivered plastic key in the hole at

the front side of the counter balancers.

3 Turn the key clockwise (+).

LOOSEN THE SPRING

1 Put the carriage in the 0-position.

2 Push the control spring between the

counter balancer and the support

downwards.

3 The counter balancer can be adjusted at

the proper tension.

Figure 7

15

MAINTENANCE

HANDLE FOR BLOCKING

For blocking of the arm, at the right back side

of the vertical support. Adjust with 10 mm and 5

mm allen key (Fig. 8).

CLAMP TOO LOOSE

1 Handle too much to the front.

2 Loosen the handle backwards.

3 Loosen the block of the handle with a 5

mm allen key.

4 Hold the handle.

5 Turn the adjusting bolt a quarter of a

stroke clockwise with a 10 mm allen key.

6 Tighten the block of the handle with a 5

mm allen key.

CLAMP TOO TIGHT

1 Handle too much to the back.

2 See above. Turn the adjusting bolt a

quarter of a stroke anti-clockwise.

Figure 8

16

MAINTENANCE

ADJUSTMENT ARM TOWARDS THE FENCE

(625-U)

ADJUSTING SQUARNESS

With the adjusting bolts at the back of the

vertical support by using two 13 mm flat keys.

ADJUSTING SWINGING

With the adjusting bolts at the back of the

vertical support by using two 13 mm flat keys.

17

MAINTENANCE

ADJUSTING OF THE SAW-BLADE TO THE

TABLE TOP

ADJUSTING SQUARNESS (Fig. 9)

1 Loosen the adjusting ring at the bottom

slide of the sliding bush. The sliding bush

is positioned at the front side of the

motor.

2 Turn in the bolt between the height

adjusting support and the motor support

at the backside of the carriage.

3 Adjust the saw-blade with a square,

square to the tabletop.

4 Secure the handle on the sliding bush

tightly.

5 Push the lower adjusting ring against the

sliding bush.

6 Re-adjust the bolt at the backside of the

carriage.

ADJUSTING 45º

1 Loosen the adjusting ring at the topside of

the sliding bush.

2 Adjust the saw-blade under 45º with a

bevel.

3 Fasten the handle on the sliding bush

tightly.

4 Push the upper adjusting ring against the

sliding bush.

Figuur 9

18

MAINTENANCE

CLEANING, LUBRICATING AND

GREASING

40 PRODUCTIVE HOURS

Perform following maintenance every 40

productive hours.

1 Clean tracks of the horizontal slideway.

Lubricate slightly.

2 Clean the spindle of the height

adjustment. Grease slightly.

3 Clean the rotating unit at the backside of

the machine (625-U). Grease slightly.

4 Clean the bearings of the carriage.

160 PRODUCTIVE HOURS

Perform following maintenance every 160

productive hours.

5 Wear and tear of cables.

6 Broken or torn parts of the electric circuit.

7 Brake time of saw-blade (= less than 10

seconds).

8 Operations and state of maintenance of

the guard and its fixation.

9 Check dust outlet for free passage.

1000 PRODUCTIVE HOURS

Perform following maintenance every 1000

productive hours.

10 Check tolerance of saw spindle.

11 Check bolt and nut connections of motor.

19

MAINTENANCE

PARTS 625-H

1 Counter balancer

2 Handle height adjustment

3 Safety guard

4 Switch

5 Motor carriage

6 Blocking knob motor carriage

7 Motor

8 Plastic key counter balancer

9 Flat key

10 Main switch

PARTS 625-U

1 Counter balancer

2 Handle height adjustment

3 Safety guard

4 Switch

5 Motor carriage

6 Blocking knob motor carriage

7 Motor

8 Plastic key counter balancer

9 Flat key

10 Main switch

11 Handle

12 Handle sliding bush

20

MAINTENANCE

RADIAL ARM SAW TYPE 625-H

45 732 6 101

9

8

This manual suits for next models

3

Table of contents