Hathorn H2 User manual

1

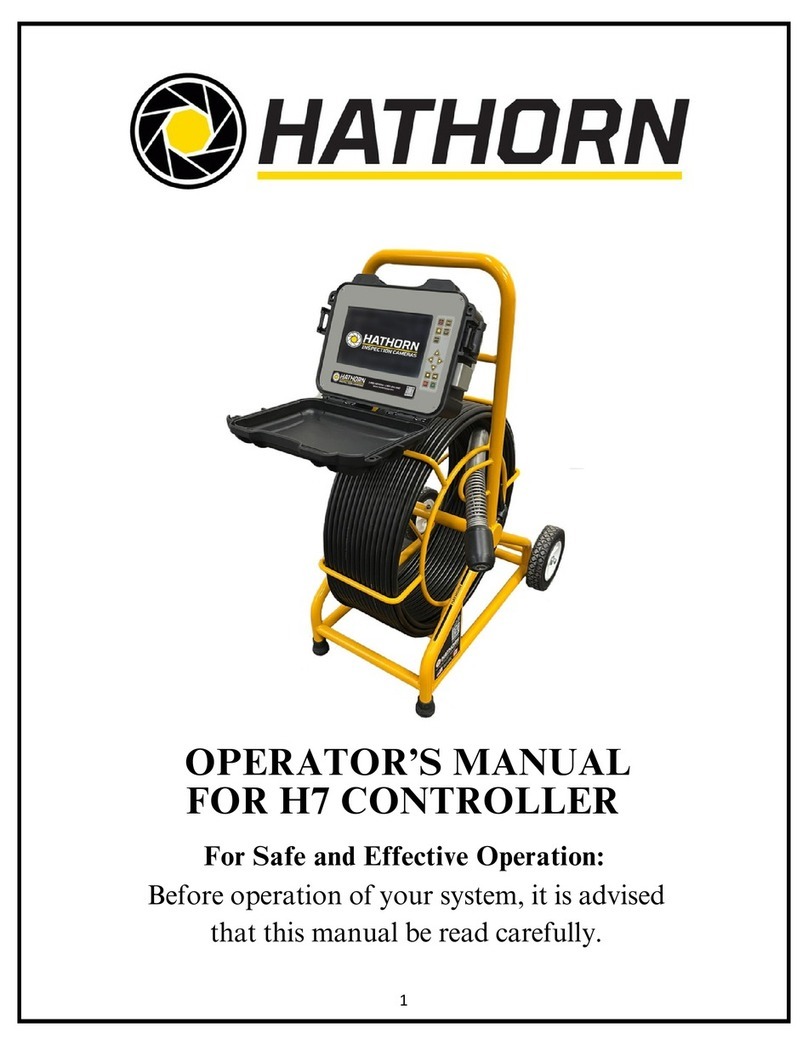

OPERATOR’S MANUAL

FOR H2 CONTROLLER

For Safe and Effective Operation:

Before operation of your system, it is advised

that this manual be read carefully.

2

3

CONTENTS

PAGE 4

PAGE 5

PAGE 6

PAGE 7-8

PAGE 9

PAGE 10

PAGE 11

PAGE 12

PAGE 13-14

LIMITED WARRANTY

LIMITATION OF WARRANTY/ SERVICE/

FREIGHT PRODUCT SPECIFICATIONS

FEATURE IDENTIFICATION

USER INSTRUCTIONS

INSPECTION PROCEDURE

LOCATING THE SONDE

MAINTENANCE

REPAIR FACILITIES IN USA & CANADA

4

LIMITED WARRANTY

This Limited Warranty provides one full year of coverage under our manufacturer’s standard

new product warranty. Hathorn® Corporation warrants to the original purchaser of our

products that the product shall function as designed for a period of one year from the original

date of purchase under normal and proper usage. This one year Limited Warranty covers

malfunctions resulting from defects in materials or workmanship only. If the product fails to

function as designed under normal and proper usage due to defects in materials or

workmanship during the period of this Limited Warranty, we will repair, adjust or replace

defective parts as Hathorn® Corporation deems appropriate.

This Limited Warranty applies only to Hathorn® Corporation sewer and gas camera

systems that are distributed in the United States, Canada and Australia that are purchased

from Hathorn® Corporation or a Hathorn® Corporation authorized dealer as identified on

our website. The Limited Warranty is not transferable under any circumstances. This

Limited Warranty does not apply to Hathorn® Corporation brand products imported

and/or sold by unauthorized dealers, distributors or other sellers.

NOT COVERED BY WARRANTY

This one year Limited Warranty does not cover damage or malfunctions stemming from

other than normal and proper usage or from products not meeting the requirements of end

users. This Limited Warranty also does not cover the following: (a) intentional or

accidental misuse or abuse (including, but not limited to, damage to push rod from

excessive force), (b) failure to follow operating or maintenance instructions, (c) repairs by

any individual or entity other than an authorized Hathorn® Corporation repair center, (d)

use of product components, accessories or consumables not manufactured by Hathorn®

Corporation (e) product tampering, (f) droppage, (g) battery leakage if equipped, (h) media

cards, (i) excessive light damage to the camera element or (j) damage resulting from being

used in extreme environments or due to weather events. Wear and tear are not covered.

Hathorn®'s responsibility under this Limited Warranty is limited to the repair, adjustment

or replacement of defective parts as determined by Hathorn® Corporation in its sole

discretion. Hathorn® Corporation shall not be held liable for any damages, including, but

not limited to direct, indirect, special, or consequential damages arising out of, resulting

from, or in any way connected to the use of Hathorn® products. Hathorn® assumes no

responsibility for other’s use or misuse of its products. Hathorn® Corporation assumes no

responsibility for warranties either expressed or implied.

By purchasing a Hathorn® Corporation product, you accept the terms of this limited

warranty. You also agree that Hathorn® Corporation shall have no liability to you or any

end user for any damages resulting from delay or loss of use of the product due to failure

of the product within the warranty period, or otherwise, or in service or repair. Hathorn®

shall have no liability for general, special, incidental or consequential damages arising out

of the use or misuse of Hathorn® products.

You also agree that the application and use of a Hathorn® Corporation product is beyond

our control and is the sole responsibility of the user. By receiving and using one of

Hathorn®’s products, you hereby acknowledge and agree that: you have selected the

correct product for your intended use and will examine the product you are purchasing

when it arrives to ensure that it meets your needs, you will properly test the product prior

to its actual use, you and/or your organization have proper practices in place for the safe

use of this equipment and that end users have been trained on its safe operation.

Hathorn® products are not intrinsically safe, not explosion proof and misuse of the

product may cause physical or psychological injury, pain, suffering, illness, disfigurement,

temporary or permanent disability, economic or emotional loss or death; and Hathorn®

Corporation shall not be held liable for any damages, including but not limited to direct,

indirect, special, or consequential damages arising out of, resulting from, or in any way

connected to the improper or incorrect use of the product and assumes no responsibility

for other’s use of the product.

5

SERVICE

RETURN FREIGHT

LIMITATION OF LIABILITY

NON-WARRANTY CHARGES

Repairs centers will charge direct for non-warranty repairs and may require payment prior

to repair.

If the product requires service, please contact the Hathorn® service centre or one of our

authorized repair centers. Some service locations are listed in this document (Pages 18 &

19). The remainder can be found on our website.

After requesting a Return Merchandise Authorization (RMA), ship the item PREPAID

and INSURED to the appropriate service center. Hathorn® is not responsible for damages

or loss incurred in connection with mailing and/or transportation of products.

Warranty: Pre-Paid by customer as above, returned by Hathorn® on our account.

Non-Warranty: Freight paid by customer both directions.

Weight

45lbs

Length x Width x Depth

33" X 19" X 16"

Power

AC/DC Adapter

12V - 4.1A

Battery

Only Milwaukee® M18 18V or equivalent

Battery Life

~5hrs using 3.0Ah (not recording & sonde off)

Battery Extender

Yes with on-screen battery display

Display

Type

Impact-resistant LCD

Size

7"

Resolution

1024 x 600 pixels

Brightness

500 cd/m2

Footage Counter

Feet or Meters with reset function

Sonde Frequencies

High power 512Hz

Environmental

Operating Temperature

-10°C to 50°C [14°F to 122°F]

Storage Temperature

-20°C to 60°C [-4°F to 140°F]

6

PRODUCT SPECIFICATIONS

18V Battery

Cradle and

AC/ DC

Adapter

Power Input

7

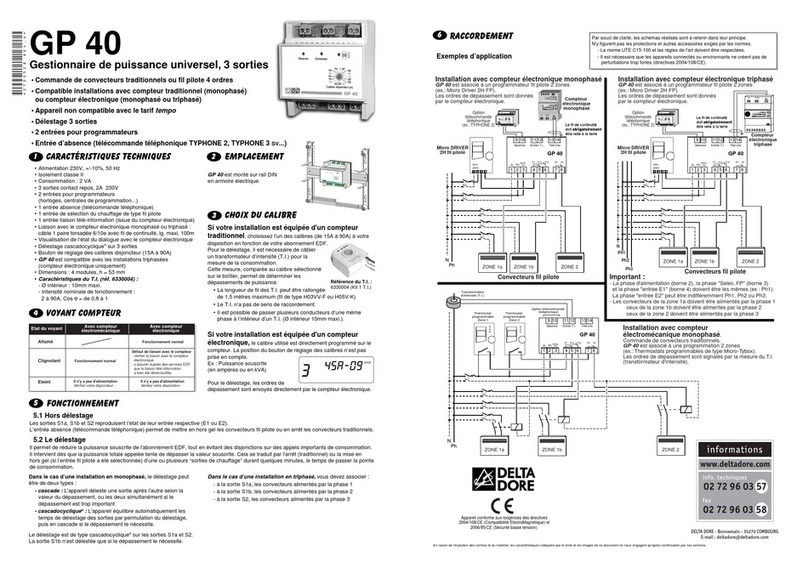

FEATURE IDENTIFICATION

Battery Mount

on Back

resets footage

counter

turns Sonde on/off

Multi-Function button

on the side:

8

7” LCD

Screen

LED Lights

Plastic Skid/Sleeve

Sapphire Camera Window

FEATURE IDENTIFICATION

11

Turning Your Monitor On

Press and hold the Multi-Function button until the counter starts flashing.

Once the counter is flashing, release the button to reset the counter to zero.

Insert the battery to turn on the controller and initiate the display. System will

turn on automatically.

Note: It is good practice to remove batteries from electronic

equipment after use. Failure to do so may result in the batteries

being drained over extended periods.

USER INSTRUCTIONS

On the main screen push and hold the Multi-Function button until the footage

counter stops flashing to turn the sonde on or off. Sondes are locatable up to

~15ft depth, dependent upon the type of pipe (concrete/steel/cast iron) and the

presence of thick concrete, sand or other utilities.

Turning the Sonde On /Off

Footage Counter Reset

14

Skids or sleeves should ALWAYS be used to protect the camera head.

Depending on the size of the pipe you are inspecting, you may need to use a

skid, so the camera is centered or off the floor of the line. Care should be

taken so the skids do not snag in the line.

Under normal operating situations, the camera is used with a smaller

protective sleeve in lines under 4” in diameter or a larger grooved skid in 4”

lines or larger.

INSPECTION PROCEDURE

Slowly push the camera into the pipe and maneuver the camera into

position to feed down the pipe, making sure the flex neck does not kink

or double back on itself.

Push the camera slowly and carefully during the inspection, taking

note of the conditions of the pipe for possible hazards that may

entangle or damage the camera on entry or retrieval.

When negotiating a corner, care should be taken not to butt the nose

of the camera against the sidewall with any force. It would be better to

let the camera “work” its way around the corner. If resistance is

encountered when turning the corner and there are no visible signs of

blockage, turning the push rod or pulling the camera back and forth

sometimes helps.

Should resistance become extreme, or the camera get entangled or

stuck, slowly push it back and forth to free it. Sometimes, turning the

push rod may also help. If the camera is visible, you may be able to

free it with your hand or by some other means.

Upon completion of the inspection and retrieval of the camera, it may

be necessary to ‘manipulate’ the camera around the initial bend (clean

out) in the pipe with a pole or other device if required.

NEVER use the camera to unclog a drain or clear debris in the pipe.

Doing so can cause damage to the camera head or lens.

NEVER force the camera down a pipe as this may cause a kinked cable

which will require expensive repairs.

NEVER use a pressure washer to clean any part of the system. High

pressure water can cause degradation of the electronic parts, causing

damage.

NEVER unspool all of the rod from a reel. Always leave a few turns of

rod on the reel to aid with respooling.

1.

2.

3.

4.

5.

6.

7.

8.

9.

15

Insert the sonde into the drain and locate it while it is still just in view at the

drain or duct entrance. Hold the locator vertically - directly over the sonde

with the antenna in line with the sonde. Adjust the locator sensitivity so the

bar graph reads between 60% and 80%. Push the sonde along the pipe to the

desired area.

LOCATING THE SONDE SIGNAL (512HZ)

Approach the peak of the signal, working perpendicular to the pipe.

Move the locator backwards and forwards and stop when the bar graph

indicates a Peak.

Push the camera 4-6 ft. further, pinpoint, and mark the position. Repeat

this pinpointing procedure at similar intervals along the line of the drain

or duct until the survey is completed.

Most locators will automatically display the depth of a located sonde,

provided the locator is correctly oriented and positioned above the

sonde.

1.

2.

3.

16

WARNING

NEVER USE A POWER WASHER TO CLEAN YOUR

INSPECTION EQUIPMENT. PRESSURIZED WATER

MAY GET INTO UNSEALED AREAS SUCH AS THE USB

BLOCK, KEYBOARD, REEL HUB ASSEMBLY AND SLIP

RING HOUSING CAUSING DAMAGE.

WATER DAMAGE TO ELECTRONIC EQUIPMENT IS

NOT COVERED BY YOUR WARRANTY.

Inspection Camera - After every use, the camera should be cleaned and

checked for possible damage. External scuffing of the camera case is

normal and should be of no concern. The camera view port is made of

sapphire and should be cleaned with a soft, damp cloth. Grease, dirt or

scratches will affect the quality of the video and if the lens is badly

scratched it should be replaced.

LED Light Replacement - The camera heads use LED lighting and cannot

be replaced by the operator. These lights use very little power and unless

physically damaged or extreme voltage is applied to them, should last

indefinitely. If replacement is necessary, the camera should be returned to

the factory.

Reel and Cable Assembly Maintenance - The reel and cable assembly

should be kept clean from dirt, slime, grit, etc. When winding the cable

back onto the reel after an inspection, it is good practice to use a cloth to

wipe off any debris.

MAINTENANCE

17

Repairs, warranty or otherwise, returned to must be submitted with a

“Return Maintenance Authorization.” For “RMAs” please contact:

Note: For other repair center locations please

visit www.hathorncorp.com/find-a-repair-center.

REPAIR FACILITIES - USA

Hathorn USA

Address: 739 North Wilson Road, Columbus, OH, 43204

Phone: 1-855-863-9226 FAX: 1-905-604-3400

Email: [email protected]

Website: www.hathorncorp.com

Kaiser Premier USA – Mobile Repairs South West

Address: 6108 Wild Fox Court, Elk Grove, CA 95757

Phone: 1-916-995-2743

Email: [email protected]

Website: www.kaiserpremier.com

Utility Equipment Technology Ltd

Address: 382 Stevens Rd., Rockwall, TX 75032

Phone: 1-972-771-8958 FAX: 1-972-772-8195

Email: [email protected]

Website: utilityequipmenttechnology.com

Minicam

Address: 12600 Newburgh Rd, Livonia, MI 48150

Phone: 1-855-863-9226 FAX: 1-905-604-3400

Email: [email protected]

Website: www.minicaminc.com

18

REPAIR FACILITIES - CANADA

Repairs, warranty or otherwise, returned to must be submitted with a

“Return Maintenance Authorization.” For “RMAs” please contact:

Hathorn Canada - Ontario, Manitoba & Eastern Canada

Address: 255 Shields Court, Unit C, Markham, ON L3R 8V2

Phone: 1-905-604-7040 FAX: 1-905-604-3400

Email: [email protected]

Website: www.hathorncorp.com

Pipescope Solutions

Address: 1439 Youville Drive, Ottawa, ON K1C 4M8

Phone: 1-647-991-6735

Email: [email protected]

Note: For other repair center locations please

visit www.hathorncorp.com/find-a-repair-center.

Access Spec Telecommunications - Quebec

Address: 328 Rue St Paul, Repentigny, QC J5Z 4H9

Phone: 1-450-581-7009

Email: [email protected]

Website: www.accessspec.com

The Drain Camera Shop – British Columbia

Address: Unit 148 11782 River Road, Richmond, BC V6X 1Z7

Phone: 1-250-514-5976

Email: [email protected]

Website: www.thedraincamerashop.com

FixedRight – Alberta and Saskatchewan

Address: 8812-185 St. NW, Edmonton, ALB T5T 1W5

Phone: 1-780-690-9080

Email: [email protected]

Website: www.fixedright.ca

19

20

Hathorn USA

Hathorn Canada

255 Shields Court, Unit C

Markham, Ontario, Canada

L3R 8V2

+1 (866) HATHORN

739 North Wilson Road

Columbus, Ohio, USA

Table of contents

Other Hathorn Controllers manuals

Popular Controllers manuals by other brands

Gruppo Ferroli

Gruppo Ferroli FZ4B Use and Installation Instructions

Control Microsystems

Control Microsystems SCADAPack 350 Hardware manual

nxt

nxt BIA-nXt-DPC 3-40 Installation and operation manual

Salus

Salus PC15V3 quick start guide

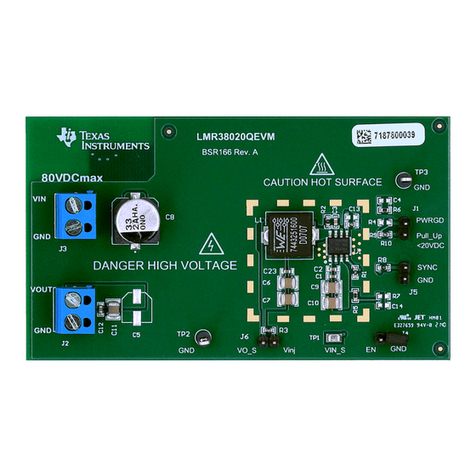

Texas Instruments

Texas Instruments LMR38020QEVM user guide

SSS Siedle

SSS Siedle EC 602 Series Product information