GB

7

CONTENTS

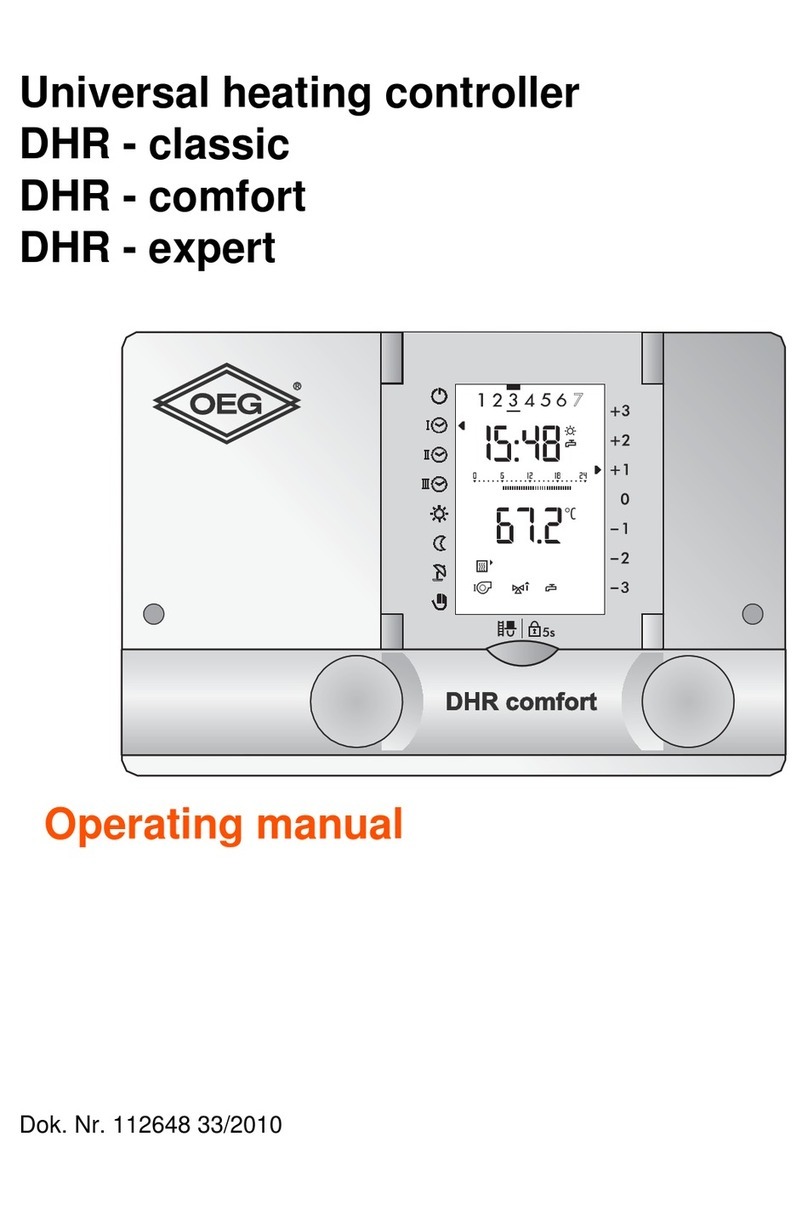

USER MANUAL

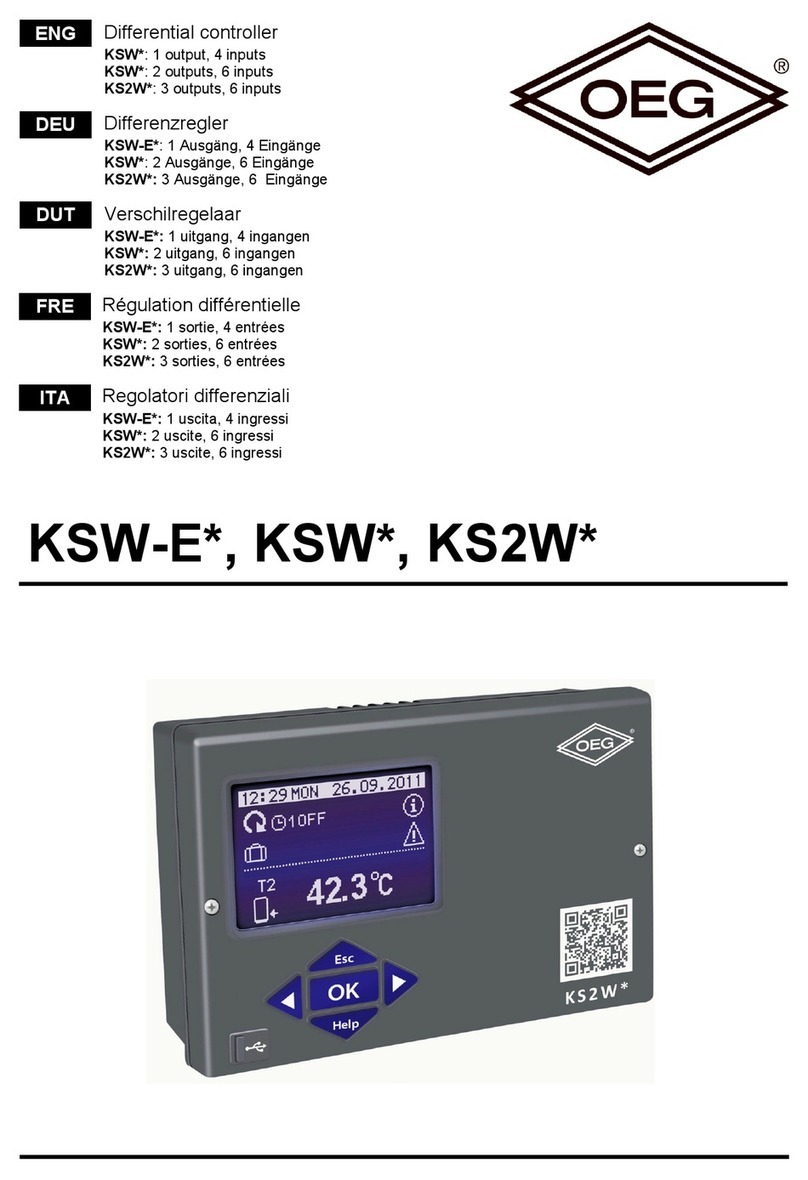

Description........................................................................................................................8

Graphic LCD display .........................................................................................................9

Operation mode and temperature setting........................................................................16

SETTINGS MANUAL

Three step setup .............................................................................................................20

Menu...............................................................................................................................23

Program timer..................................................................................................................25

Controller parameters settings........................................................................................26

Basic parameters .........................................................................................................29

Mixing heating circuit....................................................................................................30

Direct heating circuit.....................................................................................................30

Domestic hot water.......................................................................................................31

Heat sources................................................................................................................32

Basic controller settings ..................................................................................................33

Default settings................................................................................................................34

Controller data.................................................................................................................34

SERVICE SETTING MANUAL

Service settings...............................................................................................................35

Description of operation and additional possibilities........................................................45

Automatic temperature sensor detection.........................................................................54

INSTALLATION MANUAL

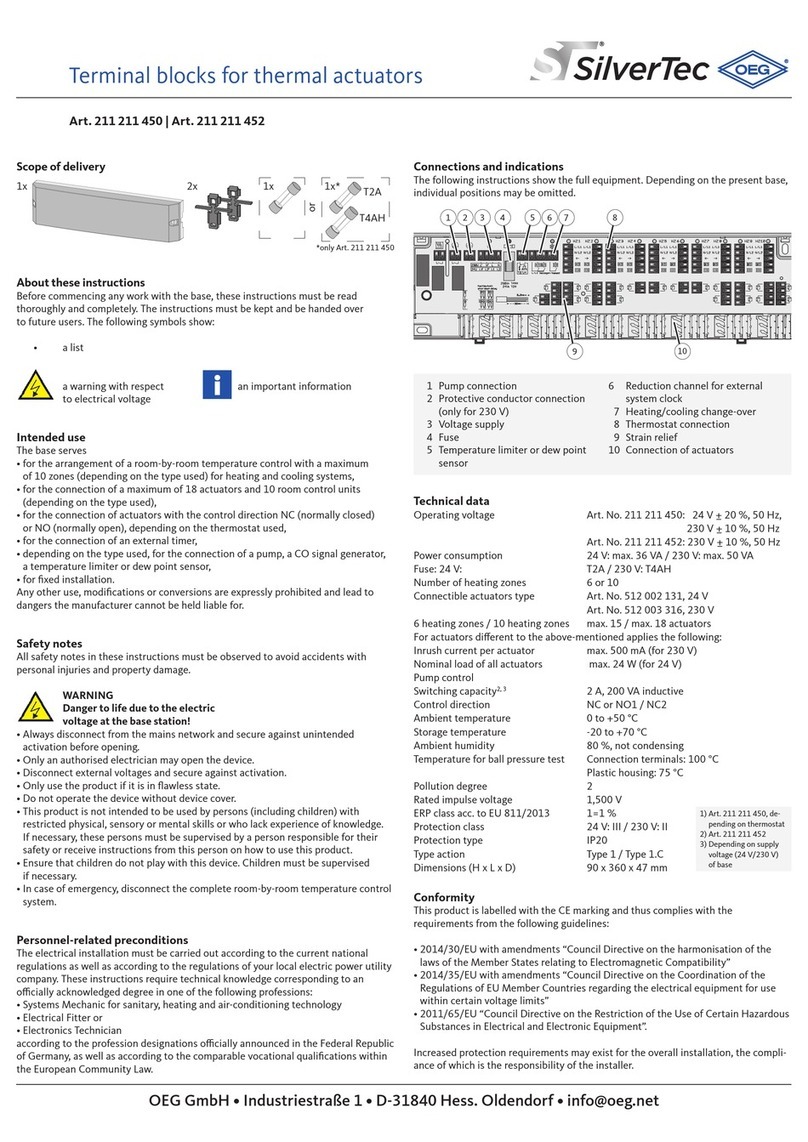

Safety precautions...........................................................................................................55

Controller installation.......................................................................................................55

Technical data.................................................................................................................66

Declarations and statements...........................................................................................67

Hydraulic and electric schemes.....................................................................................133

Notes.............................................................................................................................167

Heruntergeladen von manualslib.de Handbücher-Suchmachiene