Unidrive M/HS Frame 5 to 6 Power Installation Guide

Issue Number: 8

Contents

1 Safety information .....................................................................................12

1.1 Warnings, Cautions and Notes ..............................................................................12

1.2 Important safety information. Hazards. Competence of designers and installers ..12

1.3 Responsibility .........................................................................................................12

1.4 Compliance with regulations ..................................................................................12

1.5 Electrical hazards ...................................................................................................13

1.6 Stored electrical charge .........................................................................................13

1.7 Mechanical hazards ...............................................................................................13

1.8 Access to equipment ..............................................................................................13

1.9 Environmental limits ...............................................................................................13

1.10 Hazardous environments .......................................................................................13

1.11 Motor ......................................................................................................................14

1.12 Mechanical brake control .......................................................................................14

1.13 Adjusting parameters .............................................................................................14

1.14 Electromagnetic compatibility (EMC) .....................................................................14

2 Product information ..................................................................................15

2.1 Introduction ............................................................................................................15

2.2 Model number ........................................................................................................15

2.3 Nameplate description ...........................................................................................16

2.4 Ratings ...................................................................................................................17

2.5 Drive features .........................................................................................................19

3 Mechanical installation .............................................................................21

3.1 Safety information ..................................................................................................21

3.2 Planning the installation .........................................................................................22

3.3 Terminal cover removal ..........................................................................................24

3.4 Dimensions and mounting methods .......................................................................27

3.5 Enclosure for standard drives ...............................................................................31

3.6 Enclosure design and drive ambient temperature ..................................................36

3.7 Heatsink fan operation ...........................................................................................36

3.8 Enclosing standard drive for high environmental protection ..................................37

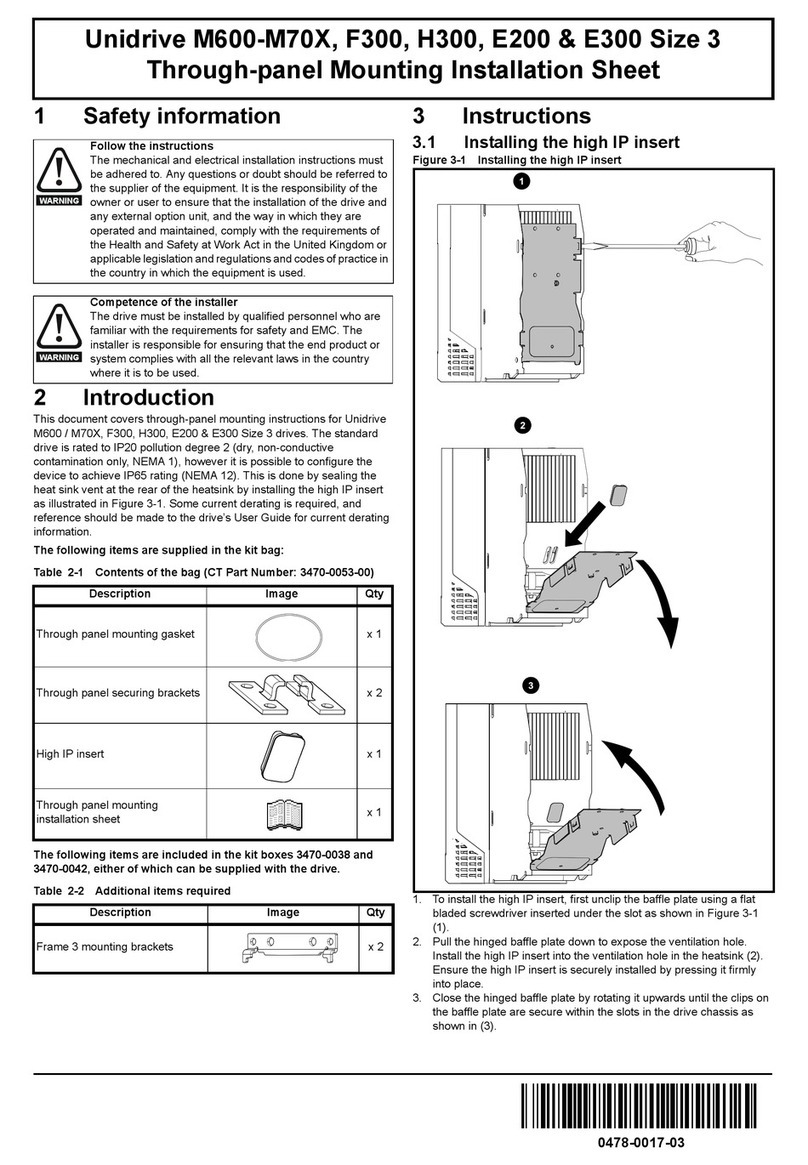

3.9 Installa ion of high IP insert for size 5 ....................................................................39

3.10 Internal braking resistor ..........................................................................................41

3.11 External EMC filter .................................................................................................43

3.12 Terminal size and torque set ings ..........................................................................45

3.13 Routine maintenance .............................................................................................45

4 Electrical installation .................................................................................48

4.1 Power and ground connections ..............................................................................49

4.2 AC supply requirements .........................................................................................51

4.3 Supplying the drive with DC ...................................................................................53

4.4 DC bus paralleling ..................................................................................................53

4.5 24 Vdc supply .........................................................................................................54

4.6 Low voltage opera ion ............................................................................................56

4.7 Fan power supply ...................................................................................................56

4.8 Ratings ...................................................................................................................57

4.9 Output circuit and motor protection ........................................................................57

4.10 Braking ...................................................................................................................60

4.11 Ground leakage ......................................................................................................66

4.12 EMC (Electromagnetic compatibility) .....................................................................67

5 Technical data ............................................................................................82

5.1 Drive technical data ................................................................................................82

5.2 Optional external EMC filters ...............................................................................105