Hatz 1B30V User manual

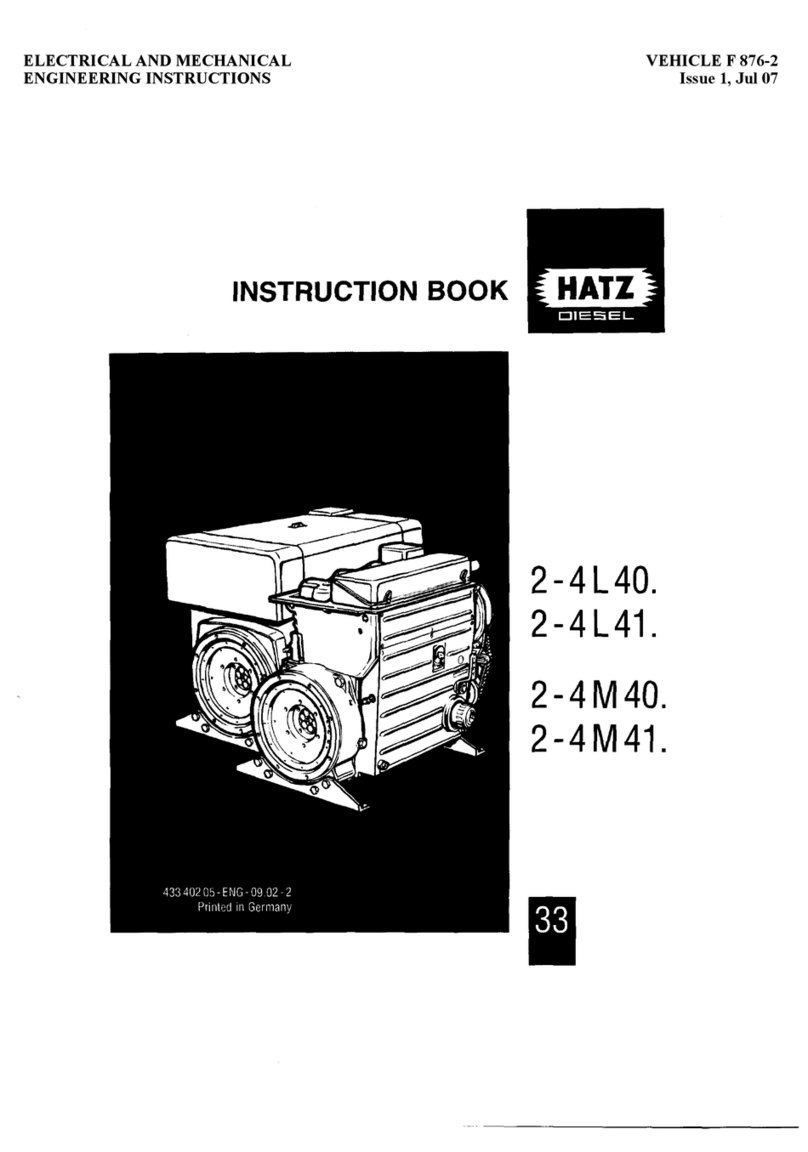

INSTRUCTION BOOK

33

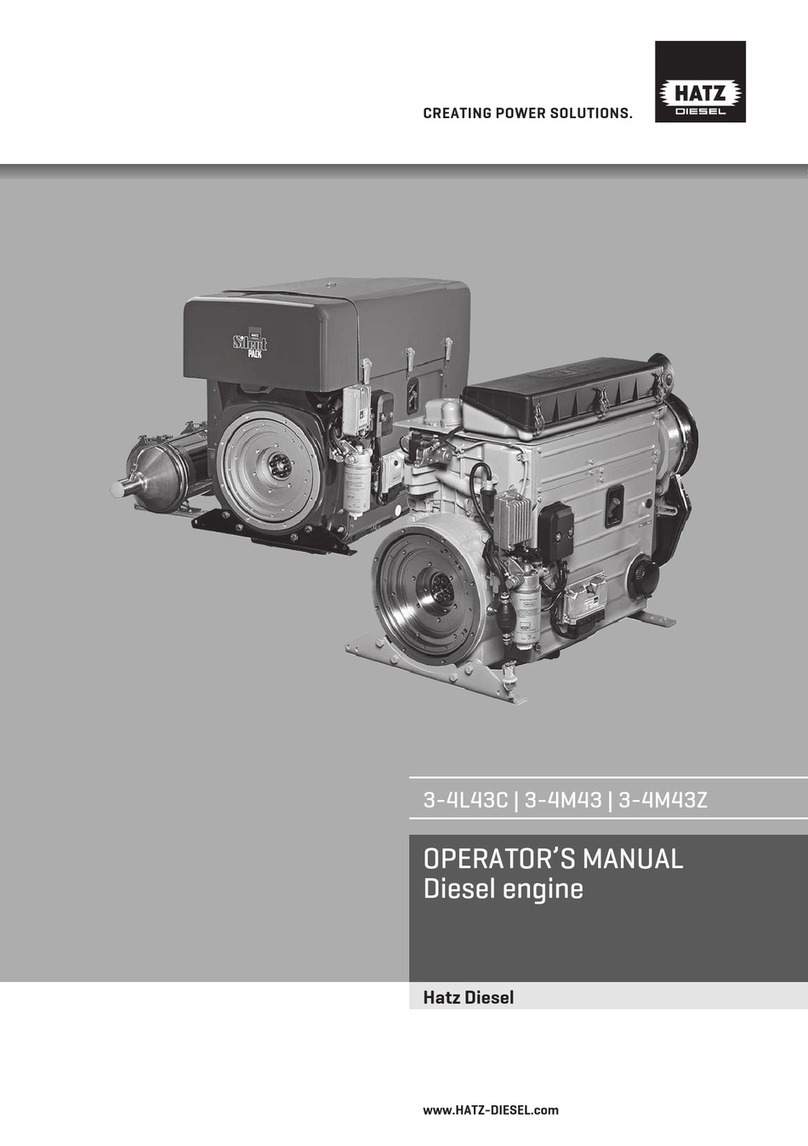

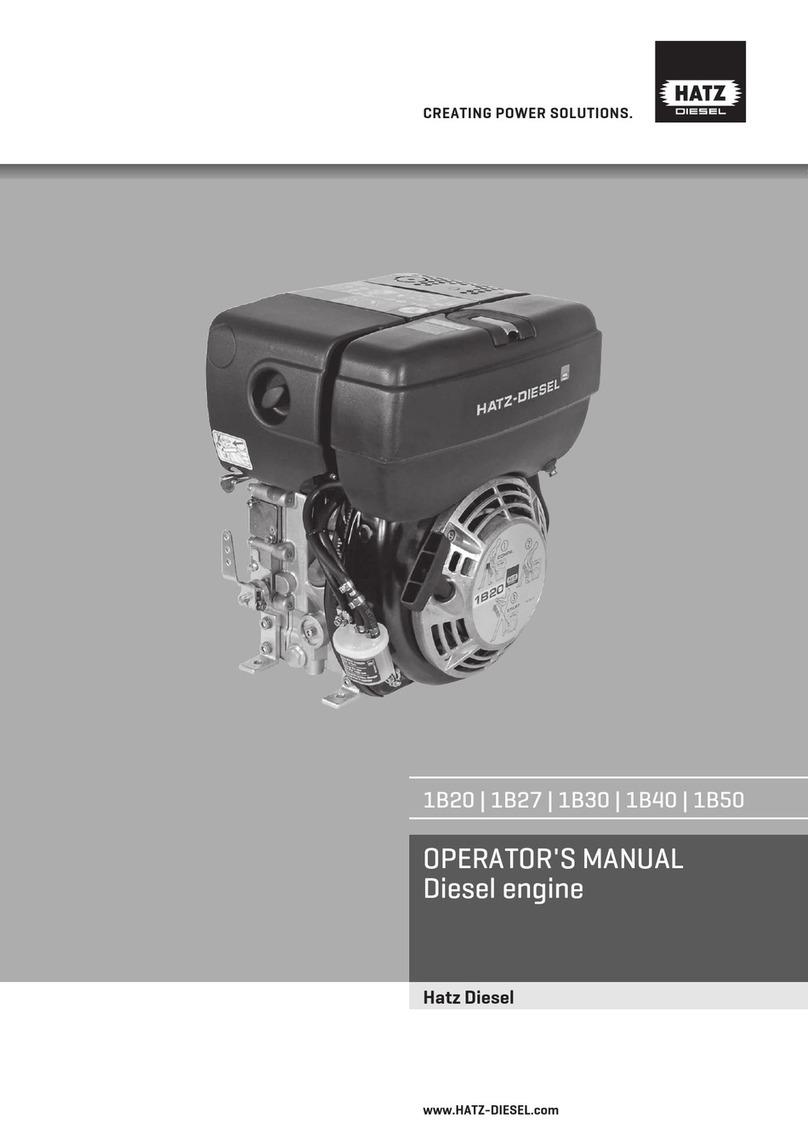

1B 30V

1B 40V

1B 40W

1B 50V

1B 50W

433 816 76-USA-EPA IV-CARB

12.07-0.05

Printed in Germany

INCLUDES SUPPLEMENTAL INFORMATION TO THE

OWNER’S MANUAL FOR 2008 AND LATER EPA CERTIFIED

NONROAD COMPRESSION-IGNITION ENGINES

INCLUDES SUPPLEMENTAL INFORMATION TO THE

OWNER’S MANUAL FOR 2008 AND LATER CALIFORNIA

REGULATIONS FOR HEAVY-DUTY OFF-ROAD ENGINES

A new HATZ Diesel engine - working for you

This engine is intended only for the purpose determined and tested by the manufacturer of the

equipment in which it is installed. Using it in any other manner contravenes the intended purpose.

For danger and damage due to this, Motorenfabrik HATZ assumes no liability. The risk is with the

user only.

Use of this engine in the intended manner presupposes compliance with the maintenance and repair

instructions laid down for it. Noncompliance leads to engine breakdown.

Please do not fail to read this operating manual before starting the engine. This will help you to avoid

accidents, ensure that you operate the engine correctly and assist you in complying with the mainte-

nance intervals in order to ensure long-lasting, reliable performance.

Please follow all maintenance references carefully including the schedule for 2008 and later

EPA certified nonroad compression-ignition engines and for 2008 and later CARB certified

off-road engines to prevent our environment.

Please pass this Instruction Manual on to the next user or to the following engine owner.

The worldwide HATZ Service Network is at your disposal to advise you, supply with spare parts and

undertake servicing work.

You will find the address of your nearest HATZ service station in the enclosed list.

Use only original spare parts from HATZ. Only these parts guarantee a perfect dimensional stability

and quality. The order numbers can be found in the enclosed spare parts list. Please note the spare

part kits shown in Table M00.

We reserve the right to make modifications in the course of technical progress.

MOTORENFABRIK HATZ GMBH & CO KG

1

Page

1. Important safety notes

when operating the engine 3

2. Description of the engine 5

3. General notes 6

3.1. Technical data 6

3.2. Transport 7

3.3. Notes on installation 7

3.4. Load on engine 7

3.5. EPA / CARB - type plates 7

3.6. Emission-related installation

instructions 9

3.7. Closed crankcase ventilation system 9

4. Operation 9

4.1. Prior to first-time start-up 9

4.1.1. Engine oil 9

4.1.2. Fuel 10

4.2. Starting 11

4.2.1. Preparations for starting 11

4.2.2. Recoil start for versions without

electric starter 11

4.2.3. Recoil start for versions with

electric starter 12

4.2.4. Electric starter 13

4.3. Stopping the engine 15

5. Maintenance 17

5.1. Maintenance chart 17

5.2. Maintenance every 8 – 15

operating hours 19

5.2.1. Checking engine oil level 19

5.2.2. Check air intake area for

combustion and cooling 19

5.2.3. Check air cleaner maintenance

indicator 19

Page

5.3. Maintenance every 250

operating hours 20

5.3.1. Changing engine oil 20

5.3.2. Checking and adjusting

valve clearances 20

5.3.3. Cleaning the air cleaner zone 22

5.3.4. Checking screw connections 22

5.3.5. Cleaning the exhaust mesh inlet 22

5.4. Maintenance every 500

operating hours 23

5.4.1. Renewing fuel filter 23

5.4.2. Air cleaner maintenance 24

5.5. Maintenance every 1000

operating hours 26

5.5.1. Cleaning the oil filter 26

5.6. Servicing: once a year 27

5.6.1. Draining the fuel tank 27

6. Malfunctions – causes – remedies 29

7. Work on the electrical system 33

8. Storage out of use 33

SUPPLEMENTAL INFORMATION TO

THE OWNER’S MANUAL FOR 2008

AND LATER EPA CERTIFIED NONROAD

COMPRESSION IGNITION ENGINES 35

SUPPLEMENTAL INFORMATION

TO THE OWNER’S MANUAL FOR

2008 AND LATER CALIFORNIA

REGULATIONS FOR HEAVY-DUTY

OFF-ROAD ENGINES 45

2

Contents

This symbol identifies important safety precautions.

Please comply with these most carefully in order to avoid any risk of injury to persons or

damage to materials.

General legal requirements and safety regulations issued by the competent authorities or

industrial accident insurers must also be complied with.

1. Important safety notes when operating the engine

HATZ diesel engines are efficient, strong and durable. For this reason they are frequently installed on

equipment used for commercial purposes.

The manufacturers of such equipment must observe any relevant equipment safety regulations when

the engine forms part of an overall system.

A few general points concerning operating safety should none the less be noted.

Depending on the engine’s operating and installation conditions, equipment manufacturers and their

users may have to fit safety or protective devices in order to prevent improper use. Examples:

– Exhaust system components as well as the surface of the engine will naturally be hot and must not

be touched while the engine is running or until it has cooled down after being stopped.

– Incorrect wiring or improper operation of the electrical system may cause sparking and must there-

fore be avoided.

– Provide protection against contact with rotating parts once the engine is connected to the driven

equipment or machine.

HATZ protective guards are available for the belt drive of the cooling fan and alternator drive

systems.

– Always observe the start-up information in the operating instructions before starting the engine:

this is particularly important when starting an engine with the recoil starter !

– Mechanical starting devices should not be operated by children or persons deficient in physical

strength.

– Check that all safety devices are in place before starting the engine.

– Ensure that operation, maintenance and repair of the engine are undertaken by suitably trained

personnel only.

– Protect the starter key against unauthorised use.

– Do not run the engine in closed or badly ventilated rooms.

Do not breath in emissions – danger of poisoning!

– Also fuel and lubricants could contain poisonous components. Please follow the instructions of the

mineral oil producer.

3

Important safety notes when operating the engine

– The engine must be stopped before performing any maintenance, cleaning- or repair work.

– Stop the engine before refilling the fuel tank.

Never refuel near a naked flame or sparks which could start a fire. Don’t smoke. Don’t spill fuel.

– Keep explosive materials as well as flammable materials away from the engine because the exhaust

gets very hot during operation.

– Wear close-fitting clothing when working on the engine while it is running.

Please don’t wear necklaces, bracelets or any other things which you could get caught with.

– Please pay attention to all advice- and warning stickers placed on the engine and keep them in

legible condition. Contact your next HATZ service station, if a sticker comes off or is illegible and

ask for a new one.

– We accept no liability for damage resulting from improper modifications to the engine.

Regular servicing in accordance with the details provided in this Instruction Book is essential to keep

the operating reliably and to ensure the exhaust quality of the engine.

When in doubt, consult your local HATZ service station before starting the engine.

4

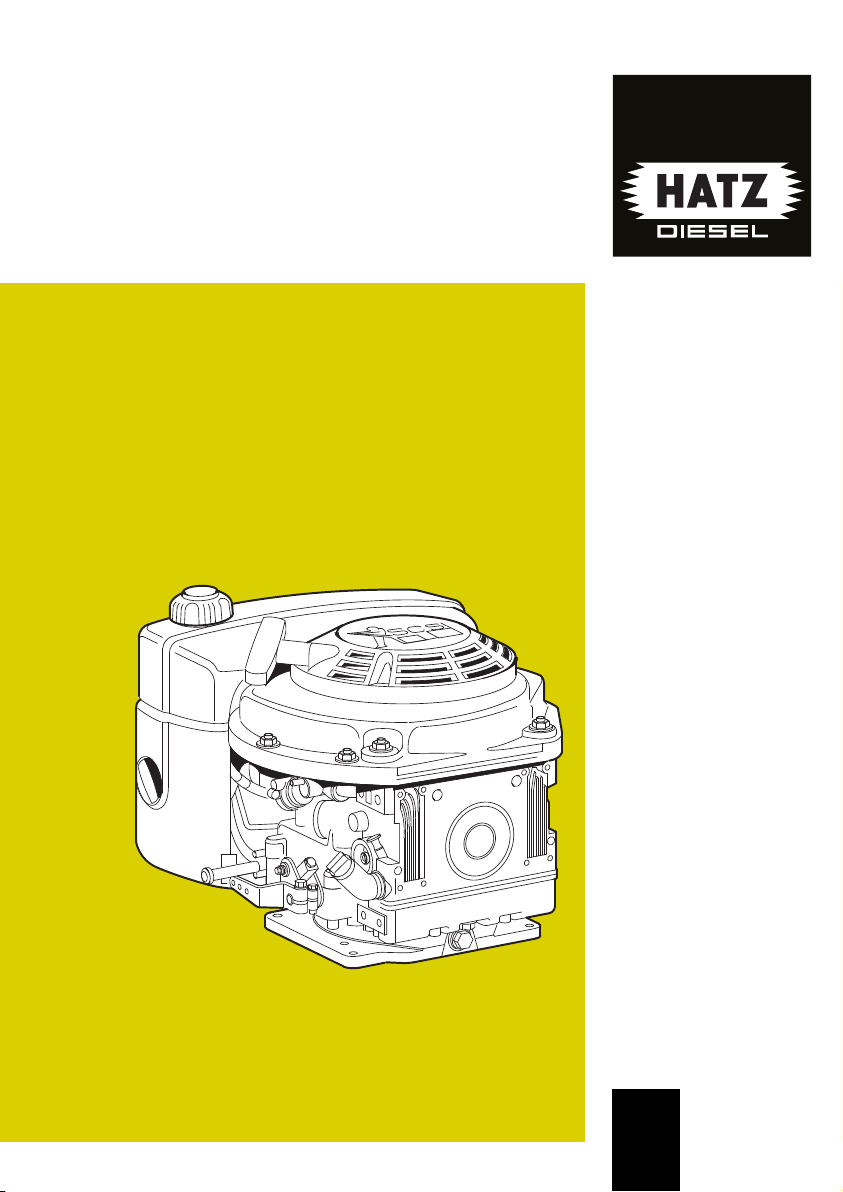

2. Description of the engine

5

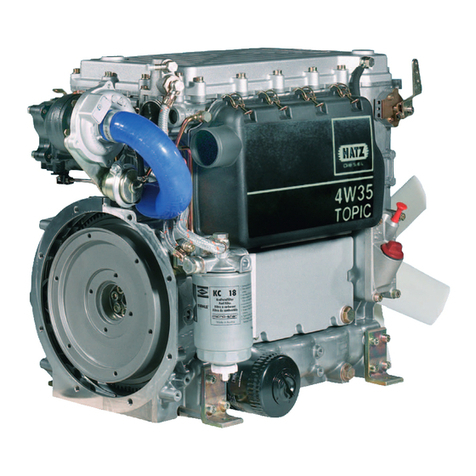

Fig 1

1 Fuel tank cap

2 Recoil starter

3 Dry-type air cleaner

4 Intake opening for cooling and

combustion air

5 Voltage regulator

6 Starter motor

7 Noise insulating hood

8 Lifting lug

9 Engine shutdown pin

10 Speed control lever

11 Oil filler pipe

12 Oil filter

13 Oil drain plug

14 Dipstick

15 Exhaust mesh insert

16 Exhaust silencer

17 Type plate

3. General notes

3.1. Technical data

1) These values are intended as an approximate guide. The max. marking on the dipstick is the

determining factor, Fig. 7.

2) Depending on model (see maintenance charts, chapter 5.1)

3) Exceeding these limits causes engine breakdown.

Tightening torques

Item Nm

Oil drain plug 50

Type 1B30 V 1B40 V/ W 1B50 V/ W

Design Air-cooled four-stroke diesel engine

Combustion system Direct injection

Number of cylinders 1 1 1

Bore / stroke mm 80 / 69 88 / 76 93 / 76

Displacement cm3347 462 517

Lubricating oil capacity l, approx. 1.1 1) 1.5 1) 1.5 1)

Difference between

„max.“ and „min“ levels l, approx. 0.5 1) 0.8 1) 0.8 1)

Lubricating oil consumption

after a running-in period max. 1 % of fuel consumption at full load

Lubricating oil pressure

(oil temperature 100 °C) approx. 2.5 bar at 3000 r.p.m.

Direction of rotation,

power take-off end counterclockwise

Valve clearance 10 - 30 °C

Inlet and exhaust valve mm 0.10 0.10 0.10

or automatically 2)

Max. angle from vertical in any

direction (continuous operation) 25° 3)

Weight (incl. fuel tank, air-cleaner,

exhaust silencer, recoil starter and

electric starter)

kg

approx. 42

1B40 V : 55

1B40 W: 57

1B50 V : 56

1B50 W: 58

Battery capacity max. 12 V / 60 Amp/h

6

3.2. Transport

Standard lifting lug „8“ is to allow the

engine and its auxiliaries to be trans-

ported safely, chap. 2. It is not suitable or ap-

proved for lifting the complete equipment to

which the engine is attached.

3.3. Notes on installation

The „Guide to selecting and installing an engine“

contains all the necessary information on engine

applications if you have an engine which has not

yet been installed in equipment and still has to

be fitted or set up.

This guide is available from your local

HATZ service station.

2

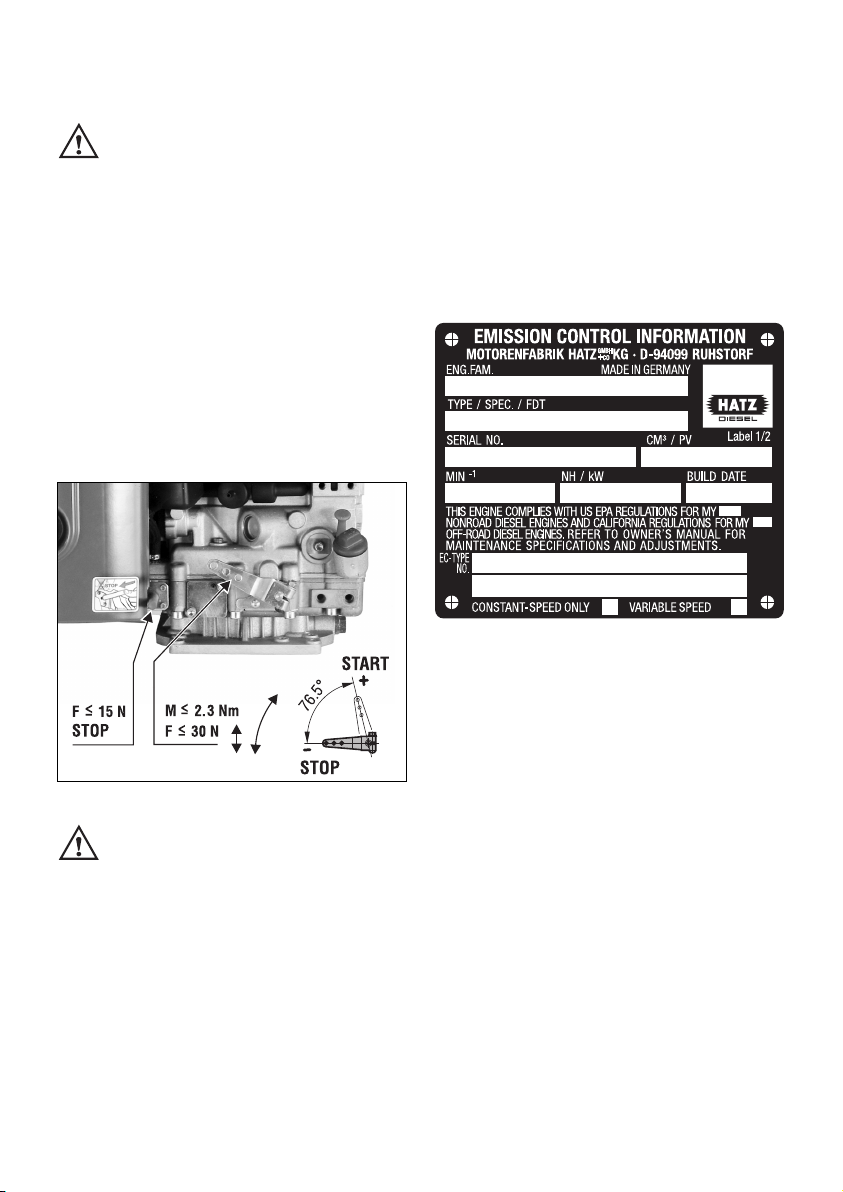

The permitted loads and elements

on the speed adjusting lever and the

engine shutdown pin should be observed as an

excess can lead to damage to the contacts and

inner governor parts.

3.4. Load on engine

See supplemental information for EPA certified

engines, Page 35; resp. supplemental informa-

tion for California regulations for off road

engines, Page 45.

3.5. EPA/CARB-type plates and

fuel label

There are two EPA/CARB- type plates applied

for the identification of the engine. The type

plates are placed on the noise insulating hood

(chapt. 2).

They include the following emission control in-

formation (Figure 3a):

Label 1/2

3a

➀EPA / CARB - Engine Family Number

➁engine type / spec. (only for special

equipment) /Fuel Delivery Timing

➂engine number

(also stamped on crankcase, Fig.4)

➃max. engine rated speed

➄build date

➅displacement

➆rated power

➇“constant speed only” (if requested)

➈“variable speed” (if requested)

Every engine is equipped with an additional

loose engine type plate. If the original type

plate on the engine is not readily visible after

the engine is installed in the equipment then

the second loose type plate must be attached

on the equipment in such a manner that it is

readily visible to an average person.

The layout is identical for constant-speed and

variable speed application.

➀

➁

➂

➃➄

➅

➆

➇➈

7

For any offer as well as spare parts orders it is

necessary to mention the following data (also

see spare parts list, page 1):

➁engine type / spec.

(only for special equipment)

➂engine number

➃max. engine rated speed

Attention:

If the engine was certified for constant-speed

application and shall be used so, the field “con-

stant-speed only” is marked with “X”.

If the engine was certified for variable speed ap-

plication and shall be used so, the field “variable

speed” is marked with “X”.

Always install the engine for its intended applica-

tion in order to comply with EPA and CARB

emission regulation requirements.

Label 2/2

3b

The engine must be operated with “LOW SUL-

FUR FUEL OR ULTRA LOW SULFUR FUEL

ONLY”.

The label also states the applicable emission-

related power category of the engine.

EMISSION CONTROL INFORMATION

LOW SULFUR FUEL OR

ULTRA LOW SULFUR FUEL ONLY

Power category:

❏< 8 kW / ❏ 8-19kW / ❏ 19-37kW /

❏37-56 kW PM Standard: 0.3 g/kWh

Label 2/2

Fuel label

3c

The fuel label is placed nearby the fuel inlet.

If there was no fuel tank mounted to the engine,

the label has to be permanently attached to the

equipment near the fuel inlet.

4

Engine serial number on crankcase.

LOW SULFUR FUEL OR ULTRA

LOW SULFUR FUEL ONLY

8

3.6. EMISSION-RELATED

INSTALLATION INSTRUCTIONS

See supplemental information for EPA certified

engines, Page 35; resp. supplemental informa-

tion for California regulations for off road

engines, Page 45.

3.7. Closed crankcase ventilation

system

Please note that the engine has a closed

crankcase ventilation system.

Exceeding the maximum admissible tilt angle

(see chapter 3.1. Technical data) can cause

damage to the engine.

In cases where the maximum angle is exceeded,

the engine must be stopped immediately.

Before restarting, the engine must be in a hori-

zontal position and the air filter and inlet mani-

fold must be checked for any oil contamination.

If there are any oil contamination, please consult

your nearest HATZ service station.

4. Operation

4.1. Before starting up for the

first time

Engines are normally supplied dry, i.e. not con-

taining fuel or oil.

4.1.1. Engine oil

Oil quality

Qualified are all trademark oils which fulfil at

least one of the following specifications:

ACEA – B2 / E2 or more significant

API – CD / CE / CF / CF-4 / CG-4 or more

significant.

If engine oil of a poorer quality is used, reduce

oil change intervals to 150 hours of operation.

Oil viscosity

5

Select the viscosity class according to the ambi-

ent temperature for cold starts.

-40

-30

-20

-10

0

10

20

30

40

50

10 4

86

68

50

32

14

-4

-22

-40

OIL: SAE...

°C°F

5W/30

5W/40

10W/40

10W/30

15W/40

30

40

122

10 W

9

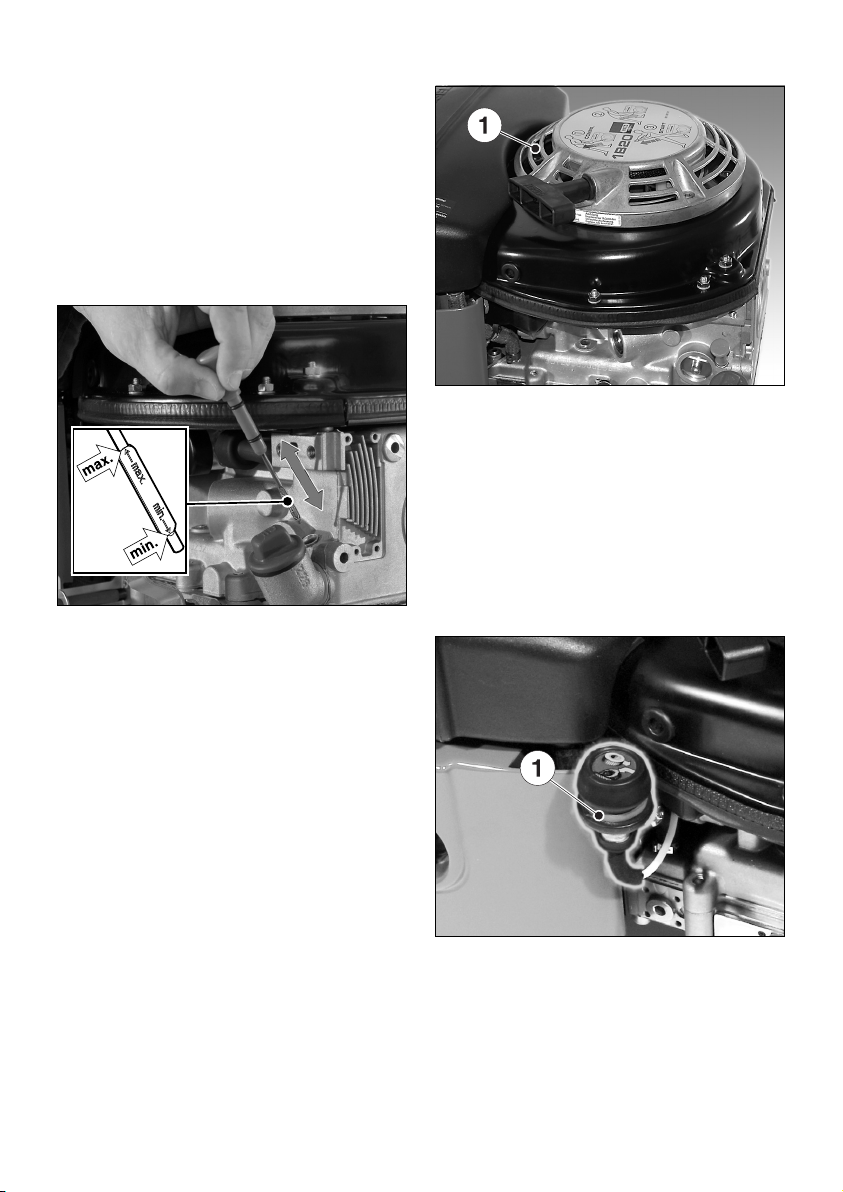

When adding oil or checking the oil level, the

engine must be horizontal.

6

– Remove oil filler screw „1“ and dipstick „2“.

7

– Add engine oil up to the MAX mark on dip-

stick.

Lubricating oil capacity: see Chapter 3.1.

– Insert the oil filler screw and tighten it (hand-

tight only).

4.1.2. Fuel

Stop the engine before refilling the fuel

tank. Never refuel near a naked flame

or sparks which could start a fire.

Don’t smoke. Use only pure fuel and clean

filling equipment. Take care not to spill fuel.

All diesel oils which satisfy the following specifi-

cations are suitable:

EN 590 or

BS 2869 A1 / A2 or

ASTM D 975 -1D / 2D

8

– Before the first start or if the fuel tank has

been run dry, completely fill the fuel tank with

diesel. The bleeding of the fuel system is auto-

matically.

At temperatures below 0 °C, winter-grade fuel

should be used or paraffin added to the fuel well

in advance.

Lowest ambient

temperature when

starting, in °C

Paraffin content for:

Summer Winter

fuel fuel

0 up to –10 20 % –

–10 up to –15 30 % –

–15 up to –20 50 % 20 %

–20 up to –30 – 50 %

10

4.2. Starting

Do not run the engine in closed or

badly ventilated rooms – danger of poi-

soning! Before starting the engine, ensure that

no-one is in the danger area close to the en-

gine or equipment, and that all protective

guards are fitted.

4.2.1. Preparations for starting

If possible, disengage the engine from any

driven equipment.

The auxiliary equipment should always be placed

in neutral.

9

– Set speed control lever „1“; First of all put the

lever in STOP-position and then either to

1/2 START or max. START position, as desired

or necessary.

Starting at a lower speed will help to prevent

exhaust smoke.

– Now, the engine is ready for starting.

Important !

After long-time standstill (approx. 6 months or

even longer) or first operation, operate engine

with low adjusted speed and without load for

approx. 20 sec. after start. This measure assures

a lubrication of all bearings before increasing

speed and load.

It also prevents an insufficient lubrication.

10

Never use starting sprays !

4.2.2. Recoil start for versions without

electric starter (till -6 °C)

– For starting preparations, see Chapter 4.2.1.

Starting procedure

11

– Pull the starting cable out by the handle until

you feel a slight resistance.

11

– Let the cable run back; in this way the entire

length of the starting cable can be used to

start the engine.

– Devices which are not securely fastened

should be restrained with the foot.

12

– Grip the handle with both hands.

13

– Commence pulling the starting cable vigorous-

ly and at an increasing speed (do not jerk it

violently) until the engine starts.

Note:

If after several attempts of starting the exhaust

begins to emit white smoke, move the speed

control lever to the STOP position and pull the

starting cable out slowly 5 times. Repeat the

starting procedure, Chapter 4.2.1.

4.2.3. Recoil start for versions with

electric starter (till -6°C)

The recoil starter at engines with electric start is

an emergency starting device without decom-

pression automatic.

Therefore, attention has to be paid to the exact

starting procedure as mentioned below.

– Prepare the engine for starting;

see Chapter 4.2.1.

– Pull out the handle with the cord slowly until

compression resistance is clearly felt; Fig. 11.

– Continue to pull slowly but with greater force

until the resistance becomes noticeably less

(compression overcome).

– Now let the cord run back - the engine is in

the correct starting position.

In this way the engine can be accelerated

through about one and a half revolutions with

the starting cord, to overcome compression re-

sistance and achieved the required momentum

for starting.

– Support equipment with the foot if it is too

light in weight or liable to tip over.

– Take hold of the handle with both hands;

Fig. 12.

– Pull the starting cord up forcefully and at an

increasing speed (but do not jerk it) - the en-

gine should then start; Fig. 13.

12

Note:

In the case of engines with automatic electrical

shutdown system (see next chapter), first

actuate the starter switch from position 0 to

position I, then perform a recoil start within the

following 12 seconds. If the engine does not run

after 12 seconds, this means that the electrical

system blocks the fuel supply to the injection

pump.

In this case, the engine cannot be started.

As a solution, turn the starter key back to posi-

tion 0, then turn it to position I again. Now, start

the engine within the following 12 seconds.

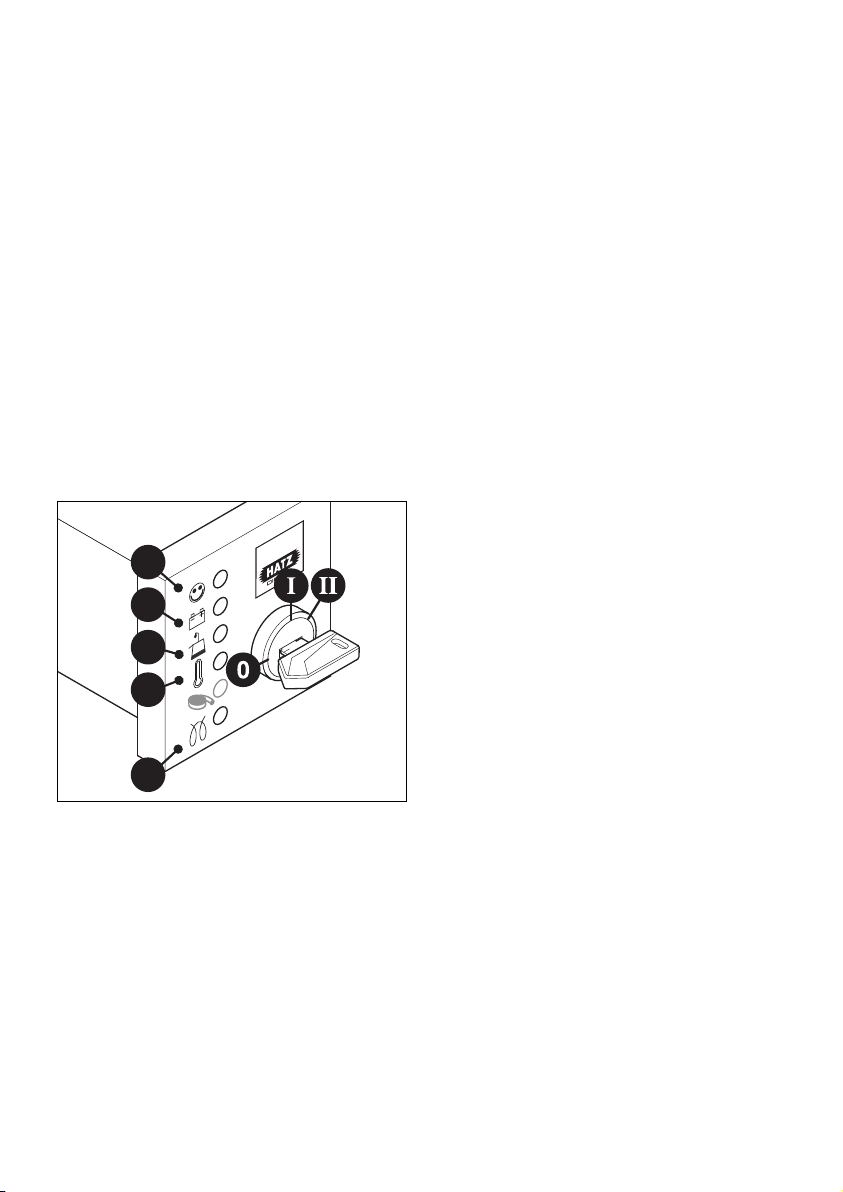

4.2.4. Electric starter

– For starting preparations, see Chapter 4.2.1.

14

– Insert the key to its stop and turn it to

position I.

– Battery charge telltale „2“ and oil pressure

warning „3“ must light up.

– Turn start key to position II.

1

2

3

4

5

– As soon as the engine runs, release the start

key. It must return to position I by itself and

remain in this position during operation.

The battery charge telltale and oil pressure

warning must go out immediately after start-

ing. Indicator light „1“ is on when the engine

is in operation.

– The engine temperature display „4“ (additional

equipment) lights up if the temperature at the

cylinder head becomes too high.

Switch off the engine and trace and elimi-

nate the cause of the problem, chap. 6.

– Always turn the start key back to position 0

before re-starting the engine. The repeat lock

in the ignition lock prevents the starter motor

from engaging and possibly being damaged

while the engine is still running.

Preheating device with automatic heating

timer (additional equipment)

The preheating light „5“ lights up additionally at

temperatures below 0° Celsius (Fig. 14).

– After the light has gone out, start the engine

without delay.

13

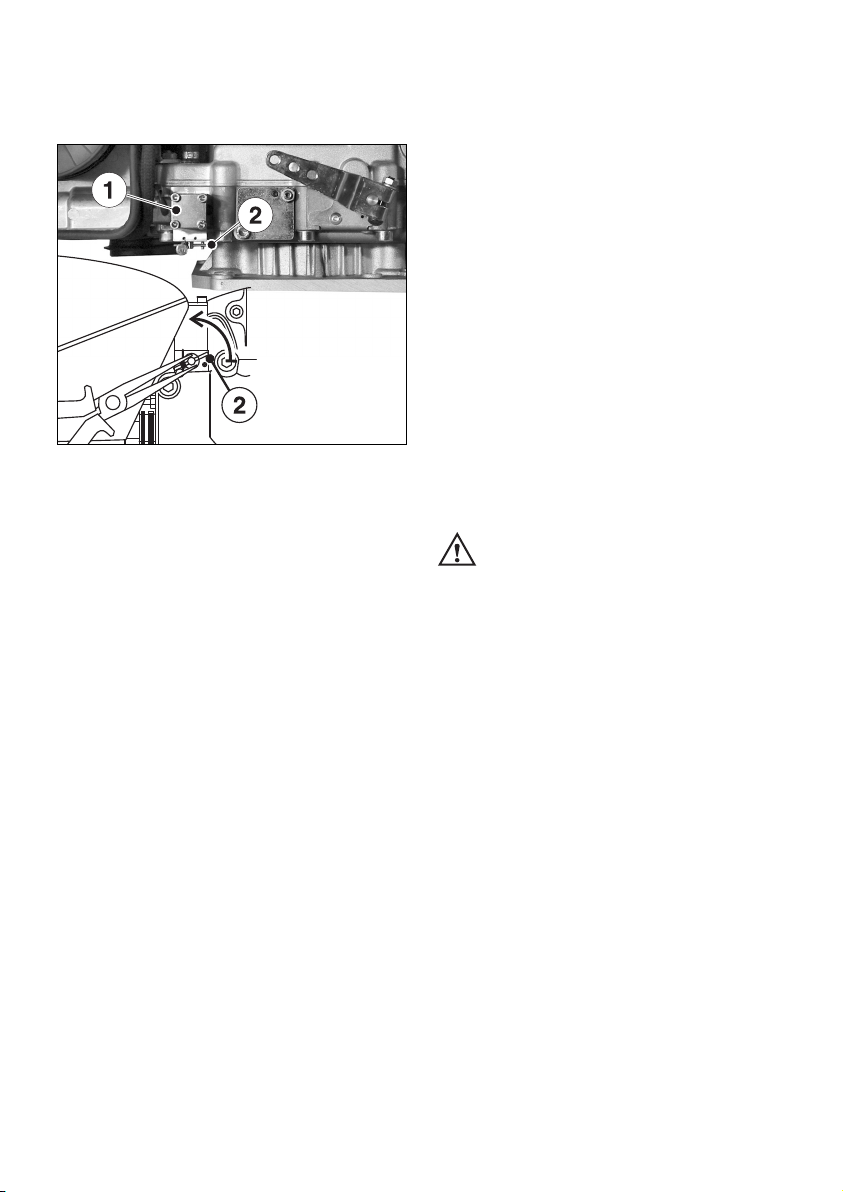

Fuel shut-off valve, stop solenoid

(additional equipment)

15

As soon as the starting key is at Position I,

fuel shut-off valve „1“ is electrically released.

The fuel feed to the injection pump is then open

and the engine is ready to start.

When the engine is running, turning the starting

key to position 0 closes the shut-off valve and

interrupts the fuel supply to the injection pump,

so that the engine stops; Chapter 4.3.

This shut-off valve is also used for the automatic

electrical shutdown system.

Emergency start

If the shut-off valve is blocking the fuel supply

as a result of an electrical fault and the engine

therefore cannot be started, an emergency start

can be attempted.

Proceed as follows for this:

– For emergency starting, turn the lever at fuel

shut-off solenoid „2“ anti-clockwise by at least

90° using suitable pliers. The lead seal wire

will break off.; Fig. 15.

– As soon as the emergency start lever is in the

starting position, the electric starter or recoil

starter can be used; Chapter 4.2.2 and 4.2.3.

The oil level must always be checked before an

emergency start, as insufficient oil pressure

can lead to complete damage of the engine

within a very short time.

After this, the engine can only be

stopped with the starting key in the

emergency operating mode if the emergency

starting lever is first turned back clockwise to

the stop position.

Immediately after a period of emergency

running, ascertain the cause of the fault and

have it rectified; Chapter 6.

Have the emergency-starting lever sealed once

again by a HATZ service point.

When the automatic electrical shutdown system

is used, the emergency start described above

means that liability for risks must be accepted

by the operator (Motorenfabrik HATZ assumes

no liability) !

In case of difficulty contact the nearest HATZ

service point.

14

Automatic electrical shutdown system

(additional equipment)

This is characterized by a brief flashing of all

pilot lamps once the starter key has been turned

to position I (Fig. 14).

Important !

If the engine cuts out immediately after starting

or switches off by itself during operation, a

monitoring element in the automatic shutdown

system has tripped. The corresponding indicator

light (Fig. 14, positions 2 - 4) will come on.

After the engine has stopped, the display contin-

ues to glow for about 2 minutes.

The electrical device then switches itself off au-

tomatically.

The display lights up again after the start key

has been turned back to position 0 and then to

position I again.

Trace and eliminate the cause of the operating

fault before trying to restart the engine

(see chapter 6.2.).

The display light goes out when the engine is

next started.

Even with automatic shutdown monitoring

the oil level must be checked every 8 – 15

operating hours (Chapter 5.2.1.).

4.3. Stopping the engine

16

– Move the speed adjustment lever „1“ back

to the STOP position. The engine cuts out.

Note:

Engines with a fixed lower idling speed cannot

be switched off using the speed adjustment

lever. See the paragraph entitled „Other ways of

switching off the engine“.

Other ways of switching off the engine

1. Fuel shut-off valve, stop solenoid

(optional extra)

– Turn ignition key to the 0 position. The engine

cuts out, Fig. 18.

15

2. Stop pin (optional extra)

17

– Press the stop pin „2“ until the engine cuts out

(see also Fig. 16, pos. 2).

– Once the engine has cut out, release the

pin „2“ and ensure that it returns to its initial

position, Fig. 16.

18

Depending upon the model, the battery charge

indicator „2“ and oil pressure warning indicator

„3“ will come on again after the engine comes to

a stop.

1

2

3

4

5

05221301

– Turn the key to position 0 and remove it.

All the indicator lights must go out.

Note:

Failure to return the starter key to position 0

may result in the battery being totally

discharged.

If operation of the engine is inter-

rupted for any reason, or at the end of

the working day, the starter key should be kept

out of reach of unauthorised persons.

16

5. Maintenance

Only carry out maintenance work with the engine switched off.

Observe all relevant laws and regulations governing the handling and disposal of used oil,

filters and cleaning agents.

Protect the starting key against unauthorised use.

On engines with an electric starter, disconnect the battery’s negative terminal.

When maintenance work has been completed, check that all tools have been removed from the

engine and all protective guards fitted again.

Before starting the engine, ensure that there are no persons in the danger area close to the en-

gine or equipment.

5.1. Maintenance chart

Maintenance interval Maintenance work required Chap.

17

Every 8 – 15

operating hours,

or before each daily

start-up

Check oil level.

Check combustion and cooling air intake zone.

Check air-cleaner maintenance indicator.

5.2.1.

5.2.2.

5.2.3.

Every 250

operating hours

Change engine oil.

Check and adjust valve clearances. (Not applica-

ble with automatic self adjusting valve clearance

models, see next page)

Clean cooling air area.

Check screw connections.

Clean mesh insert for exhaust.

5.3.1.

5.3.2.

5.3.3.

5.3.4.

5.3.5.

Every 500

operating hours

Change fuel filter element.

Dry-type air cleaner maintenance.

5.4.1.

5.4.2.

Every 1000

operating hours Clean the oil filter. 5.5.1.

Once a year Siphon water out of fuel tank. 5.6.1.

8-

15

250

500

1000

Depending whether the engine is equipped with

or without automatic valve clearance adjustment

one of the illustrated maintenance plans is in-

cluded. This label should be affixed to the engine

or equipment in an easily visible position. The

maintenance chart governs the maintenance in-

tervals.

On new or reconditioned engines, after the

first 25 operating hours, always

– Change engine oil, Chapter 5.3.1.

– Check valve clearances and adjust if

necessary, Chapter 5.3.2.

– Examine screw connections, chapter 5.3.4.

Do not tighten the cylinder head fastening.

If the engine is not used frequently, change the

engine oil after 12 months at the latest, regard-

less of the actual number of hours it has been in

operation.

18

Model without automatic valve clearance adjustment.

Model with automatic valve clearance adjustment.

5.2. Maintenance every 8 – 15

operating hours

5.2.1. Checking engine oil level

To check the oil level, the engine must be

standing level and be switched off.

– Remove any dirt from the oil dipstick area.

19

– Check the dipstick oil level and, if necessary,

add oil to the max. mark, Chapter 4.1.1.

5.2.2. Check air intake area for

combustion and cooling

Heavy contamination is an indication that in-

creased dust accumulation necessitates a

correspondingly shorter maintenance interval,

Chapter 5.3.3. and 5.4.2.

20

– Check air intake points „1“ for severe blockage

due to leaves, heavy dust accumulation etc.,

and if necessary clean them.

5.2.3. Check air cleaner maintenance

indicator (optional extra)

Mechanical service indicator

21

– Increase the speed of the engine briefly to the

maximum. If the rubber bellows shrinks and

covers the green area „1“, the air cleaner sys-

tem should be serviced, Chapter 5.4.2.

Under dusty conditions, check the rubber

bellows several times per day.

19

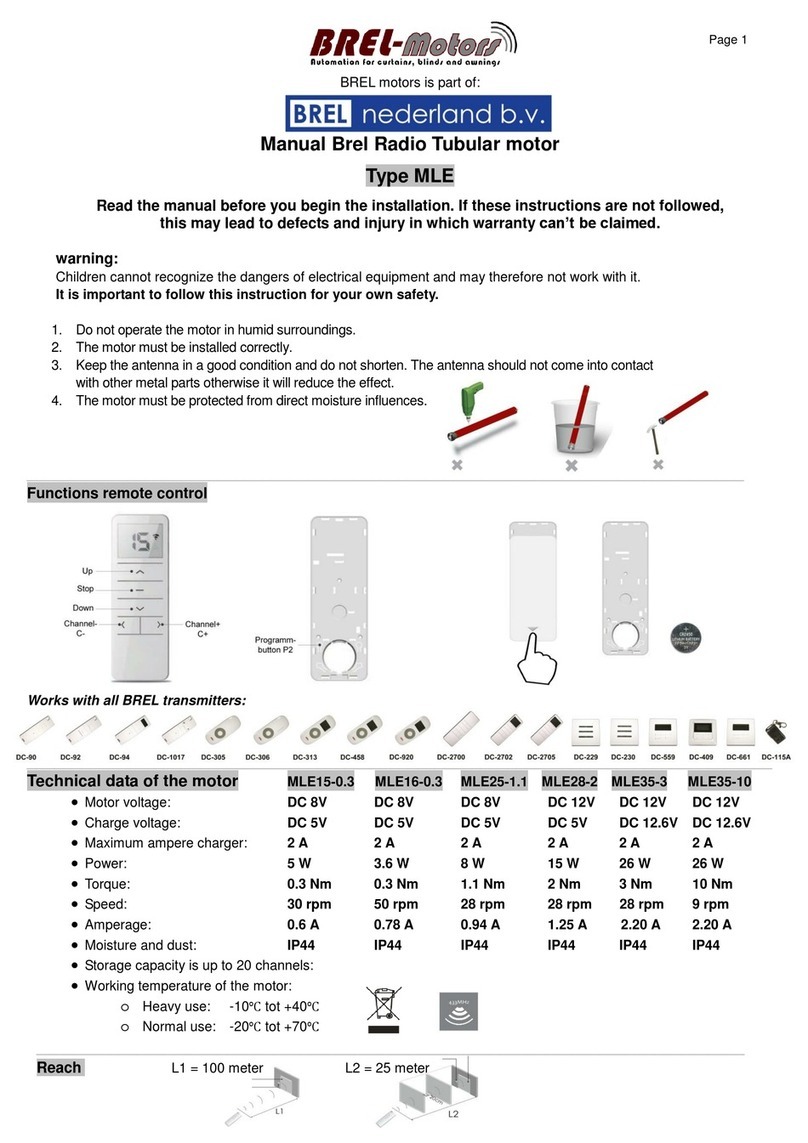

Other manuals for 1B30V

1

This manual suits for next models

4

Table of contents

Other Hatz Engine manuals

Popular Engine manuals by other brands

Hyundai Seasall

Hyundai Seasall S250S Workshop manual

Archive

Archive CG13 Booklet

Robin America

Robin America EX17 parts manual

Continental Refrigerator

Continental Refrigerator IO-240-A Installation and operation manual

MTU

MTU 20 V 4000 M73 x operating instructions

Ingersoll-Rand

Ingersoll-Rand MVA017B/VSM-5842 Operation and Maintenance Information