HAWE Hydraulik HICON User manual

Compact hydraulic power pack type HICON

Original assembly instructions

B 8543

10-2021-1.0en

Operating pressure pmax:

Geometric displacement volume:

Usable volume (tank) Vuse max:

170 bar

0.5 cm3/rev

0.6 l

© by HAWE Hydraulik SE.

The reproduction and distribution of this document as well as the use and communication of its contents to others without explicit

authorization is prohibited.

Offenders will be held liable for the payment of damages.

All rights reserved in the event of patent or utility model applications.

Brand names, product names and trademarks are not specifically indicated. In particular with regard to registered and protected names

and trademarks, usage is subject to legal provisions.

HAWE Hydraulik respects these legal provisions in all cases.

HAWE Hydraulik cannot provide individual guarantees that the stated circuits or procedures (including in part) are not subject to the

intellectual property rights of third parties.

Printing date / document generated on: 20.10.2021

2/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

Table of Contents

1 About these instructions.................................................................................................................................. 4

1.1 Target audience................................................................................................................................................. 4

1.2 Safety instructions and symbols...........................................................................................................................4

1.3 Applicable documents......................................................................................................................................... 5

2 For your safety................................................................................................................................................ 7

2.1 Intended use.....................................................................................................................................................7

2.2 Misuse.............................................................................................................................................................. 7

2.3 Residual risks.................................................................................................................................................... 7

2.4 Duties of the operator........................................................................................................................................8

2.5 Qualification of the personnel............................................................................................................................. 8

2.6 Personal protective equipment.............................................................................................................................9

3 About this product......................................................................................................................................... 10

3.1 Structure......................................................................................................................................................... 10

3.2 Functions........................................................................................................................................................ 10

3.3 Control............................................................................................................................................................11

4 Transport and storage..................................................................................................................................... 12

4.1 Scope of delivery............................................................................................................................................. 12

4.2 Checking the delivery........................................................................................................................................12

4.3 Storage........................................................................................................................................................... 13

5 Assembly and installation...............................................................................................................................14

5.1 Mechanical connection......................................................................................................................................14

5.2 Hydraulic connection........................................................................................................................................ 14

5.3 Electrical connection........................................................................................................................................ 15

6 Start-up......................................................................................................................................................... 18

6.1 Switching the hydraulic system on/off................................................................................................................ 18

7 Maintenance...................................................................................................................................................19

7.1 Maintenance plan............................................................................................................................................. 19

7.2 Service............................................................................................................................................................19

7.2.1 Vent the hydraulic system................................................................................................................................. 19

7.2.2 Checking the hydraulic uid level.......................................................................................................................20

7.2.3 Replacing the hydraulic uid............................................................................................................................. 20

8 Disassembly and disposal................................................................................................................................22

9 Troubleshooting..............................................................................................................................................23

10 Appendix........................................................................................................................................................24

10.1 Technical data..................................................................................................................................................24

10.1.1 Weight............................................................................................................................................................ 24

10.1.2 General data....................................................................................................................................................24

10.1.2.1 Tank size.........................................................................................................................................................25

10.1.3 Electrical data..................................................................................................................................................25

10.2 Circuit diagram................................................................................................................................................ 26

HAWE Hydraulik SE B 8543 - 10-2021 - 1.0 3/27

1About these instructions

This manual is part of the product and describes the safe and proper use in all operating phases.

All photos and drawings in this manual show an available product variant. For precise details concerning

the variant you have purchased, please refer to the type plate attached to the product.

Read instructions before use.

Make the manual accessible to operating and maintenance personnel at all times.

Keep this manual for the lifetime of the product.

Only pass on the product to third parties together with this manual.

1.1 Target audience

The target audience of this manual is trained and qualied personnel who are familiar with the installa-

tion, operation and maintenance of machines.

The manual provides relevant information for the machine manufacturer and machine operator as well as

for training courses.

1.2 Safety instructions and symbols

Safety indication In these instructions, the following warning and safety notes are used:

Symbol Meaning

DANGER

Draws your attention to a hazardous situation that can lead directly to serious injury

or death if not avoided.

WARNING

Draws your attention to a hazardous situation that can indirectly lead to serious

injury or death if not avoided.

CAUTION

Draws your attention to a hazardous situation that can indirectly lead to light to

moderate injury if not avoided.

Notice to prevent environmental and material damage.

Information to ensure the correct use of the product.

Safety symbols General safety symbol

Draws your attention to additional safety information.

Slipping hazard Dragging hazard from moving parts

Harmful substances Tripping and falling hazard

Fire accelerants Falling loads

4/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

Burn hazard Crushing hazard

Electrical voltage Suspended loads

No access to persons with pacemakers

and defibrillators

Mandatory signs Protective equipment

Safety boots

Wear appropriate safety boots to protect your feet against mechanical hazards

Work gloves

Wear suitable work gloves to protect your hands against chemical and mechanical

hazards.

Safety goggles

Wear safety goggles to protect your eyes against chemical and mechanical hazards.

Protective clothing

►Wear tted clothing without protruding parts.

►Follow the safety data sheet of the hydraulic uid.

1.3 Applicable documents

Standard Designation

2006/42/EC Directive 2006/42/EC of the European Parliament and of the Council of

17 May 2006 on machinery, and amending Directive 95/16/EC

2014/30/EU Directive 2014/30/EU of the European Parliament and of the Council

of 26 February 2014 on the harmonisation of the laws of the Member

States relating to electromagnetic compatibility

2011/65/EU, RoHS Directive 2011/65/EU of the European Parliament and of the Council

of 8 June 2011 on the restriction of the use of certain hazardous

substances in electrical and electronic equipment

Regulation (EC) No 1907/2006 Regulation (EC) No 1907/2006 of the European Parliament and of the

Council of 18 December 2006 concerning the Registration, Evaluation,

Authorisation and Restriction of Chemicals (REACH), establish-

ing a European Chemicals Agency, amending Directive 1999/45/EC

and repealing Council Regulation (EEC) No 793/93 and Commission

Regulation (EC) No 1488/94 as well as Council Directive 76/769/EEC

and Commission Directives 91/155/EEC, 93/67/EEC, 93/105/EEC and

2000/21/EC

ISO 4406 Hydraulic uid power. Fluids. Method for coding the level of contamina-

tion by solid particles

IEC 60529 Protection classes provided by housings (IP code) (IEC 60529:1989 +

A1:1999 + A2:2013)

DIN EN ISO 12100 Safety of machinery - General principles for design - Risk assessment

and risk reduction

EN 626-1:1994+A1:2008 Safety of machinery — Reduction of risks to health from hazardous

substances emitted by machinery — Part 1: Principles and specifica-

tions for machinery manufacturers

DIN EN 894-3 Safety of machinery - Ergonomics requirements for the design of

displays and control actuators - Part 3: Control actuators

HAWE Hydraulik SE B 8543 - 10-2021 - 1.0 5/27

Standard Designation

DIN EN 894-4 Safety of machinery - Ergonomics requirements for the design of

displays and control actuators - Part 4: Location and arrangement of

displays and control actuators

EN 953:1997+A1:2009 Safety of machinery — Guards — General requirements for the design

and construction of xed and movable guards

DIN EN 1005-2 Safety of machinery - Human physical performance - Part 2: Manual

handling of machinery and component parts of machinery

DIN EN 1005-4 Safety of machinery - Human physical performance - Part 4: Evaluation

of working postures and movements in relation to machinery

EN 1037:1995+A1:2008 Safety of machinery — Prevention of unexpected start-up

DIN EN ISO 4413 Hydraulic uid power - General rules and safety requirements for

systems and their components

EN 13478:2001+A1:2008 Safety of machinery — Fire prevention and protection

DIN EN ISO 13732-1 Ergonomics of the thermal environment - Methods for the assessment

of human responses to contact with surfaces - Part 1: Hot surfaces

DIN EN ISO 13849-1 Safety of machinery - Safety-related parts of control systems - Part 1:

General principles for design

DIN EN ISO 13849-2 Safety of machinery - Safety-related parts of control systems - Part 2:

Validation

DIN EN ISO 19353 Safety of machinery - Fire prevention and re protection

6/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

2For your safety

The product is built according to the state of the art and recognized safety regulations.

Nevertheless, there is a risk of personal injury and damage to property if this chapter and the safety

instructions in this manual are not observed.

2.1 Intended use

■The product is a technical work tool and intended for commercial and industrial use only.

■The product may only be operated in accordance with the technical data, operating conditions and

performance limits specied in this manual.

■Only use original accessories and original spare parts approved by the manufacturer.

■The product may be used to control single and double-acting consumers. The size of the consumers is

limited by the minimum and maximum ll volume of the tank.

Partly completed machinery

The product is a partly completed machine according to the EC Machinery Directive 2006/42/EC and

is intended exclusively for installation in a machine or system. The product is controlled via the

manufacturer's machine / plant control.

►Comply with the manufacturer’s operating instructions.

2.2 Misuse

■Use in other operating modes than specied in the intended use

■Using the product beyond the specied performance limits

■Do not use the product in potentially explosive areas.

■Do not paint over seals and hose lines.

2.3 Residual risks

When handling hydraulic uid, comply with the safety data sheet of the manufacturer of the

hydraulic uid.

DANGER

Risk to life due to explosive combustion

Hydraulic uid and its associated mists and vapours are oxidizing. Contact with ignition sources will

lead to explosive combustion. Risk of serious injury or death.

►Avoid re and open light and do not smoke anywhere near the product.

►Immediately dispose of any ammable materials moistened with hydraulic uid as hazardous waste.

►Do not use any ammable or corrosive cleaning agents.

HAWE Hydraulik SE B 8543 - 10-2021 - 1.0 7/27

WARNING

Electrical and magnetic elds

Electrical and magnetic elds impair the functionality of cardiac pacemakers and implanted

defibrillators.

►People with pacemakers or implanted defibrillators must maintain a sufcient distance from

magnets.

►Advise people with pacemakers or implanted defibrillators against approaching magnets.

►Cordon off the area around the drive system and afx suitable warning signs to the barriers.

WARNING

Risk of injury through crushing or cutting

Body parts might get trapped or cut off between the machine frame and hydraulic system in the event of

careless transport, installation and de-installation.

►Never reach between the hydraulic system and the machine frame.

►Ensure that other people cannot enter the danger area.

►Wear gloves and work shoes.

2.4 Duties of the operator

Observe and comply with regulations:

►Do not put the product into operation until the complete machine or system complies with the

country-specic regulations, safety regulations and standards of the application.

►Observe and apply regulations for accident prevention and environmental protection.

Operate product safely:

►Despite safety devices, the product still poses residual risks. Observe the safety instructions in this

manual to reduce health hazards and avoid dangerous situations.

►The operator must ensure that the operating conditions (see general, hydraulic and electrical data)

are within the operating limits of the product.

►Keep all instructions / signs on the product in legible condition and observe them.

Instruct personnel:

►Regularly train the personnel in all points of these instructions and ensure that they are observed.

►Ensure the terms of the industrial safety and operating instructions are observed.

►Only use qualied personnel. Due to their training and experience, the qualied personnel must be

able to recognize risks and avoid possible hazards.

2.5 Qualification of the personnel

The activities described in these instructions require basic knowledge of mechanics, hydraulics and

electrics.

For the transport and handling of heavy loads, additional knowledge in handling hoists and slings is

required.

►The activities may only be carried out by an appropriate specialist or an instructed person under the

supervision of a specialist.

►Activities other than those described in these instructions may only be performed by HAWE or

authorized specialist companies.

►The personnel must have read and understood these instructions.

8/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

Trained personnel Personnel instructed comprehensively, by skilled staff on behalf of the owner, in how to perform its

appointed tasks and in how to use the product safely.

Specialist personnel Due to their technical training, knowledge and experience, specialists are able to assess and carry out the

assigned work and can independently recognize possible dangers.

Qualied electrician A person with appropriate professional training, knowledge and experience, so that he/she can recognize

and avoid dangers that can be caused by electricity.

Auditor Persons of a technical inspection body who are authorized to perform testing and monitoring tasks for

pressure equipment and electrical systems.

2.6 Personal protective equipment

Personal protective equipment is designed to prevent and reduce hazards.

In the instructions, safety instructions with mandatory symbols indicate the wearing of special

protective equipment for special activities.

Instruction and supply is carried out by the operator.

HAWE Hydraulik SE B 8543 - 10-2021 - 1.0 9/27

3About this product

3.1 Structure

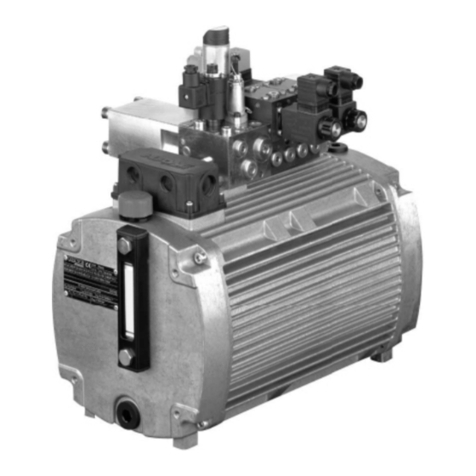

The hydraulic power pack consists of a fully enclosed metal housing containing a tank, a brushless

electric drive, and a gear pump.

The bell housing contains the following:

■hydraulically actuated shuttle valve

■two congurable pressure-limiting valves for safeguarding the system pressure

■two check valves for stop function that can be activated hydraulically

■two overpressure valves for safeguarding maximum pressure in the event of heating

■emergency manual valve

3.2 Functions

Further information see "Circuit diagram".

Motor Check valve 1 Check valve 2

Pressure at connection A ON

(anti-clockwise

rotation direction)

OPEN OPEN

Consumer hydraulically held in

place OFF CLOSED CLOSED

Pressure at connection B ON

(clockwise

rotation direction)

OPEN OPEN

Pressure at connection A Energize the electric drive so there is pressure at connecting line A. The motor and pump deliver a ow

rate. The ow rate ows via the open check valves to consumer port A.

Stop function The electric drive is not energized. The closed check valves ensure the consumer remains hydraulically

held in place.

Pressure at connection B Energize the electric drive so there is pressure at connecting line B. The pump and motor deliver a ow

rate. The ow rate ows via the open check valves to consumer port B.

Manual override The system can be switched to a pressureless state using the emergency manual valve.

CAUTION

Injuries due to cylinders dropping down in the event of a strong pressure drop

In the event of a strong pressure drop, connected cylinders may drop down very quickly, causing damage

or injuries.

►Secure connected cylinders before opening the emergency manual valve.

Opening the emergency manual valve:

1. Unscrew the screw attached to the side of the connection block anti-clockwise by 3 to a maximum of

5 revolutions.

✓Port A is connected to the tank.

✓A line to Port B is opened if turned by a further revolution.

10/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

DAMAGE

Damage to the environment or property due to leaking hydraulic uid

If the screw is unscrewed too far, it may jump out due to the system pressure and hydraulic uid

may leak.

2. Closing the emergency manual valve: Tighten the screw with a torque of 3.0+0.5Nm.

Protection against

overpressure

The congurable pressure-limiting valves are installed upstream of the check valves. Two additional

pressure-limiting valves with a higher opening pressure located downstream of the check valves protect

the system against excessive pressure. Hydraulic uid ows back to the tank.

3.3 Control

All of the necessary safety equipment, safety functions and the safety controller should be provided

by the machine manufacturer.

■The motor’s duty cycle should be monitored by the device control. An increase in the duty cycle is an

indicator of abnormal internal leakage.

HAWE Hydraulik SE B 8543 - 10-2021 - 1.0 11/27

4Transport and storage

Observe the following safety instructions additionally to the safety instructions in chapter For your

safety.

CAUTION

Personal injury through tipping or falling load

The product might tip over or fall during transport. This could lead to hands and feet becoming trapped.

►Adhere to the symbols on the packaging.

►Use permitted transport aids to carefully transport the product as close to the installation location

as possible.

►Select transport aids that will allow the maximum load to be transported safely.

►Wear safety shoes, work gloves and safety glasses.

4.1 Scope of delivery

Delivery of the completely assembled units includes:

■Hydraulic power pack

°Current-carrying lines with eyelets

°Connecting lines for CAN bus and signal control with free cable ends

°Hydraulic connections with protective covers

Hydraulic uid is not included in the scope of delivery.

4.2 Checking the delivery

Unpacking 1. Remove product.

2. Check product for transport damage and completeness.

Note transport damage on the transport documents or on the carrier's delivery bill.

Document transport damage with photos and report to the manufacturer.

3. Properly dispose of the product packaging in accordance with local regulations.

DAMAGE

For any defect found, le a complaint immediately with:

HAWE Hydraulik SE

Einsteinring 17

85609 Aschheim near Munich, Germany

Tel.: +49 89 379100-1491

service@hawe.de

Claims for damages can only be addressed within the applicable complaint periods. HAWE does not

accept any liability for subsequent complaints.

12/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

4.3 Storage

DAMAGE

Property damage from incorrect storage

Incorrect storage can lead to damage. Refer to the technical data.

Store the product and its individual components as follows:

■Store in accordance with IP67.

■Protect against sunlight (UV radiation).

■Storage temperature between -40 °C and +80 °C

■Do not store near sources of ignition or heat, aggressive media (e.g. acids, fuels or lubricants) or

ozone-producing sources of light (e.g. fluorescent light sources, mercury-vapour lamps).

■If stored for more than 2 years, protect the valves and valve controls against resinification of the

hydraulic uid. Please contact the hydraulic uid manufacturer in this regard.

■Avoid electric drives and electronic components being subjected to mechanical shocks.

HAWE Hydraulik SE B 8543 - 10-2021 - 1.0 13/27

5Assembly and installation

Observe the following safety instructions additionally to the safety instructions in chapter For your

safety.

DAMAGE

Material damage due to mechanical damage

Protect the product from mechanical damage during assembly and installation, e.g. by padding.

5.1 Mechanical connection

DAMAGE

Property damage from incorrectly installed hydraulic system

►Assembly by trained specialists only.

►Ensure all labels and markings of the hydraulic system are easily visible and legible after assembly.

►Check installation space/connection points for damage.

Add components which were not included in the scope of delivery (e.g. hydraulic uid). Use ltered

hydraulic uid (10 µm).

1. Place the hydraulic power pack in position in the higher-level machine.

2. Ensure all the fastening bores and hydraulic connections align correctly.

3. Attach the hydraulic power pack using the two M8 threads with a maximum torque of 18Nm.

4. After a week of operating time at the latest, check the ttings.

5.2 Hydraulic connection

DAMAGE

Damage from connecting soiled components

Connecting soiled components may cause system failure and irreparable damage.

►Clean the workspace before connecting the hydraulic system.

►Clean hydraulic components before connecting the hydraulic system.

►Only use hydraulic uid of sufcient grade.

DAMAGE

Damage to valves caused by air bubbles

The system to be connected must already be lled with hydraulic uid free of air bubbles before the

hydraulic power pack is connected. Air bubbles in the hydraulic uid cause damage to valves.

Connecting hydraulic hoses Protective transport caps have been removed.

1. Connect the hose via thread H1/8".

✓max. screw-in depth: 9.3 mm

✓max. tightening torque: depending on connection material, max. 7 Nm

14/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

Filling with hydraulic uid The system to be connected is already lled with hydraulic uid free of air bubbles.

1. Open the tank lling screw.

2. Filter fresh hydraulic uid (Titan CHF 11S or Titan CHF 202). Recommended lter: 10µm.

3. Turn the hydraulic power pack so that the tank points upwards.

4. Pour the ltered hydraulic uid into the tank.

Maximum permissible quantity (see Chapter 10.1, "Technical data") can be read from the oil

level gauge if the installation position is horizontal. Use a dipstick if the installation position is

vertical.

5. Gently shake the hydraulic power pack so that the air bubbles pass into the tank.

✓Wait a few hours until all the air bubbles are in the tank.

6. Operate the system with the hydraulic power pack 2-3x with low pressure until there is no more air in

the system.

7. Close the tank lling screw with a tightening torque of 6+2Nm.

8. Assemble the hydraulic power pack in the intended installation position.

9. Vent the hydraulic system using the venting provisions on the consumer.

10. Correctly dispose of the hydraulic uid, hydraulic uid container and any cloths contaminated with

hydraulic uid.

5.3 Electrical connection

DANGER

Risk of fatal injury from electric shock

Touching live components directly or indirectly causes injury or death.

►Electrical and electronic components must only be replaced and connected by trained specialist

personnel.

►Obey all applicable electrical safety rules.

►Only connect electric lines to the hydraulic system while the system is de-energized.

WARNING

Electrical and magnetic elds

Electrical and magnetic elds impair the functionality of cardiac pacemakers and implanted defibrilla-

tors.

►People with pacemakers or implanted defibrillators must maintain a sufcient distance from

magnets.

►Advise people with pacemakers or implanted defibrillators against approaching magnets.

►Cordon off the area around the drive system and afx suitable warning signs to the barriers.

HAWE Hydraulik SE B 8543 - 10-2021 - 1.0 15/27

DAMAGE

Hazard for electronic components – property damage

Electromagnetic waves lead to malfunctions of electrical or electronic equipment.

►To prevent electrostatic discharge, do not touch electronic components and contacts.

►After switching off the electrical power supply, wait at least 15 minutes for the energy stored in

the capacitors to dissipate.

►Do not expose components to moisture and an aggressive environment.

►To avoid overheating, always keep ventilation openings (if any) open and allow sufcient air

circulation.

1. Secure the unit against being switched on unintentionally.

2. Wire the motor with the machine controls in accordance with the circuit diagram.

1WH - signal 12 V/24 V port A ow, port B

2GN - signal 12 V/24 V port B ow, port A

3GY - signal GND

Flow at A and reux at B

1WH - signal 12 V/24 V

2GN - signal 0 V

3GY - signal GND

16/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

Flow at B and reux at A

1WH - signal 0 V

2GN - signal 12 V/24 V

3GY - signal GND

3. Connect the hydraulic power pack to the electrical power supply.

4. Check the electrical connections after a week’s operating time.

HAWE Hydraulik SE B 8543 - 10-2021 - 1.0 17/27

6Start-up

WARNING

Danger of crushing/malfunction from unexpected startup

Body parts may be crushed or severed if the system starts up unexpectedly.

►Keep the danger zone clear of people.

►Wear protective clothing.

CAUTION

Burn hazard from hot surfaces and hydraulic uid

A burn hazard results from directly or indirectly coming into contact with hot hydraulic uid and hot

components of the hydraulic system.

►Wear work gloves.

►Arrange the access to the hydraulic system in such a way that hot surfaces are not accessible to the

user.

►Wait until the hydraulic system has cooled down before servicing or disassembling it.

Only trained specialist personnel may perform commissioning.

The unit is secured against being switched on unintentionally.

1. Check the hydraulic power pack has been connected correctly:

✓mechanically: ange

✓hydraulically: hose lines, hydraulic uid

✓electrically: wiring, power supply, control

✓xed installation: attachment to the machine, in/on the base

2. Check the hydraulic uid level.

3. Vent the connected hydraulic lines to the hydraulic power pack.

During the venting process, it is not permitted for anyone to be in the hazardous area. Please refer

to the operating instructions of the machine manufacturer/system operator for the measures and

regulations for a safe venting process.

4. Check the hydraulic uid level again after several strokes or after the hydraulic system has been

vented.

5. Check valve switching and functional sequence as per the Functions .

6.1 Switching the hydraulic system on/off

The hydraulic system is switched on and off via the system controller. Initial start-up of the system must

have been performed properly.

18/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

7Maintenance

Maintenance measures consist of inspection, service and repair. Maintenance measures are described here.

►Maintenance work must only be carried out by qualied personnel.

►Tasks not described in this chapter may only be carried out by HAWE Service.

►If faults or damage occur, switch off the hydraulic system immediately.

►Observe the information in the supplier documentation.

►Document all activities in a maintenance log.

WARNING

Danger of accident and fatal injury due to lack of maintenance or careless maintenance

Omitted or negligently performed maintenance can cause the hydraulic system to malfunction.

Improperly performed maintenance or improperly conducted troubleshooting can pose a danger to

personnel.

►Read and abide by all instructions provided in this section.

Observe the following safety instructions additionally to the safety instructions in chapter For your

safety.

7.1 Maintenance plan

Failure of hydraulic systems

Hydraulic system failures are often caused by an incorrect choice of hydraulic uid or excessive

solid contamination in the hydraulic uid. High solid contamination is due to lack of maintenance

of the hydraulic system.

►Select hydraulic uid according to specifications.

►Carry out the activities described in this section carefully and in due time.

Interval

Activities to be performed

Once a week following

commissioning As required Once a year

Check safety markings ✓

Checking the electrical contacts ✓ ✓

Visual check for external leakage ✓✓

Check the cable for damage ✓

Vent the hydraulic system ✓

Checking the hydraulic uid level ✓

Replacing the hydraulic uid ✓

7.2 Service

7.2.1 Vent the hydraulic system

The machine manufacturer must set up provisions for venting on the consumer for the hydraulic system.

HAWE Hydraulik SE B 8543 - 10-2021 - 1.0 19/27

7.2.2 Checking the hydraulic uid level

DAMAGE

Material damage due to operation without hydraulic uid

If the hydraulic uid level falls below the minimum level, the operating temperature may rise, the

hydraulic pumps may suck in air and the hydraulic pump may fail due to cavitation.

►During initial commissioning and after each opening of the hydraulic system

►Fluid level too low: top up hydraulic uid.

1. Check the uid level in the tank.

If the installation position is horizontal, read off the maximum permissible level of the hydraulic

uid from the oil level gauge.

If the installation position is vertical, determine the maximum permissible level of the hydraulic

uid using a dipstick.

2. Fluid level too low: top up hydraulic uid.

CAUTION

Overpressure in the tank due to an excessive lling quantity

If too much hydraulic uid is lled into the tank, overpressure occurs. The tank container can burst and

the escaping hydraulic uid may cause serious injuries.

►Do not exceed the maximum usable tank volume.

►Wear protective clothing.

Fill volume

of hydraulic uid

Coding Fill volume (l) Usable volume (l)

10.370 0.300

20.560 0.450

30.750 0.600

7.2.3 Replacing the hydraulic uid

The hydraulic system is switched off and secured against unintentional restart.

The system is pressureless.

The work environment is clean.

1. Wait until the system has cooled down.

2. Place a suitable receptacle under the hydraulic power pack.

3. Open the tank lling screw.

4. Tilt the hydraulic power pack so that the hydraulic uid can completely ow out of the tank into the

receptacle.

5. Filter fresh hydraulic uid (Titan CHF 11S or Titan CHF 202). Recommended lter: 10µm.

6. Turn the hydraulic power pack so that the tank points upwards.

7. Pour the ltered hydraulic uid into the tank.

Maximum permissible quantity (see Chapter 10.1, "Technical data") can be read from the oil

level gauge if the installation position is horizontal. Use a dipstick if the installation position is

vertical.

8. Gently shake the hydraulic power pack so that the air bubbles pass into the tank.

✓Wait a few hours until all the air bubbles are in the tank.

20/27 B 8543 - 10-2021 - 1.0 HAWE Hydraulik SE

Table of contents

Other HAWE Hydraulik Power Pack manuals

HAWE Hydraulik

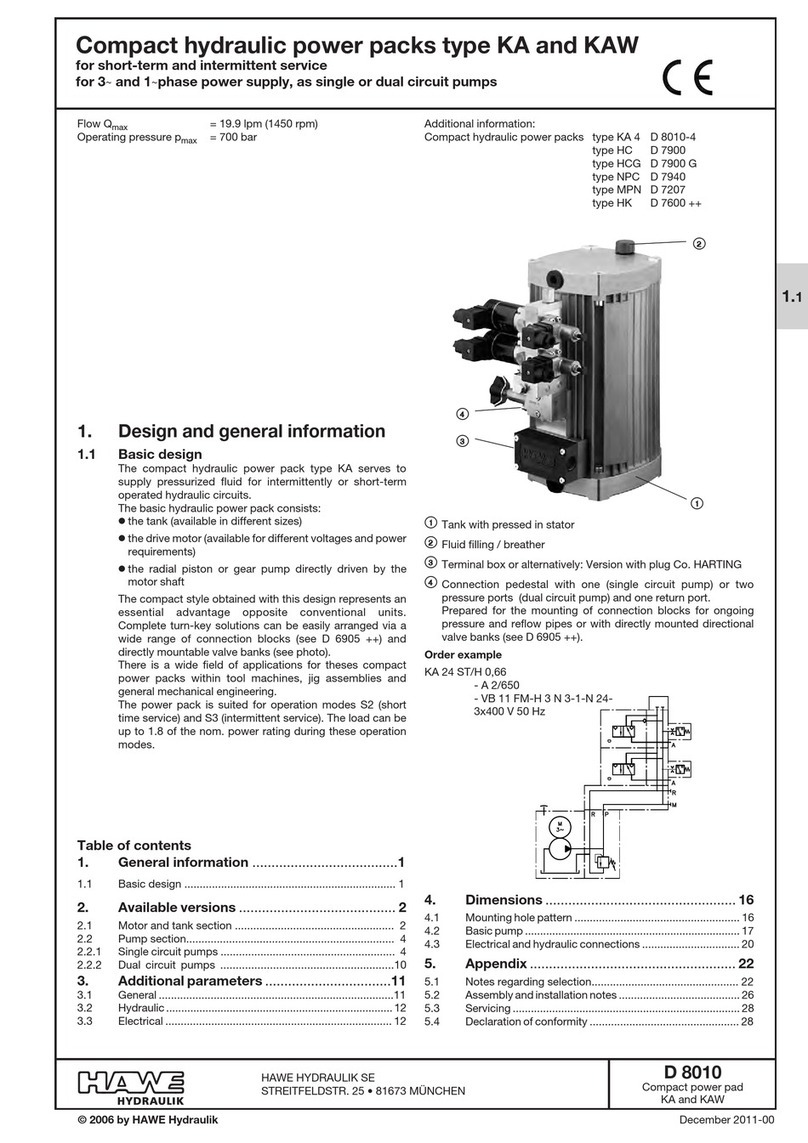

HAWE Hydraulik KA2 User manual

HAWE Hydraulik

HAWE Hydraulik INKA 1 User manual

HAWE Hydraulik

HAWE Hydraulik HR 050 User manual

HAWE Hydraulik

HAWE Hydraulik D 7969 AC Operator's manual

HAWE Hydraulik

HAWE Hydraulik KA User manual

HAWE Hydraulik

HAWE Hydraulik A 100 User manual

HAWE Hydraulik

HAWE Hydraulik HLU LE-X User manual

HAWE Hydraulik

HAWE Hydraulik AC Series Operator's manual

Popular Power Pack manuals by other brands

GOAL ZERO

GOAL ZERO Extreme 350 user guide

wattstopper

wattstopper FS-PP v2 installation instructions

Centech

Centech CHICAGO ELECTRIC 38391 owner's manual

POWER START

POWER START PS-775LI Operating and safety instructions

FJDynamics

FJDynamics FJD PONY 500 Combo user manual

Flashfish

Flashfish A1001 user manual