Contents

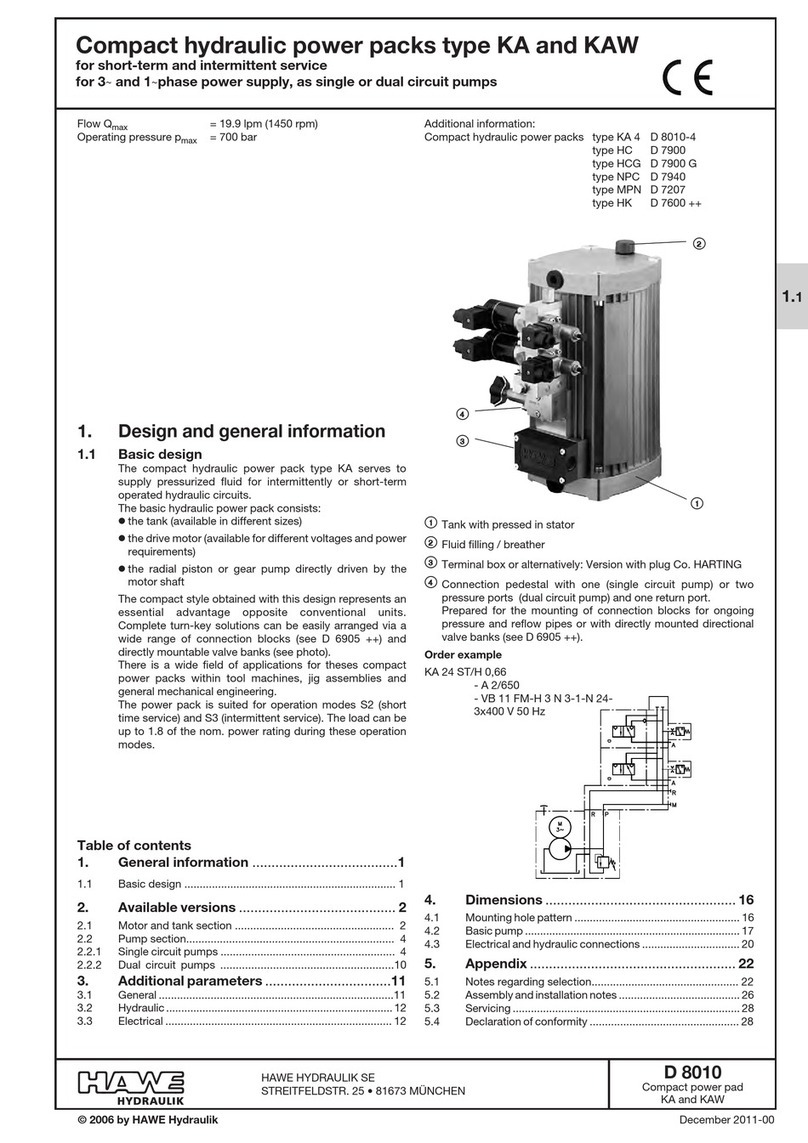

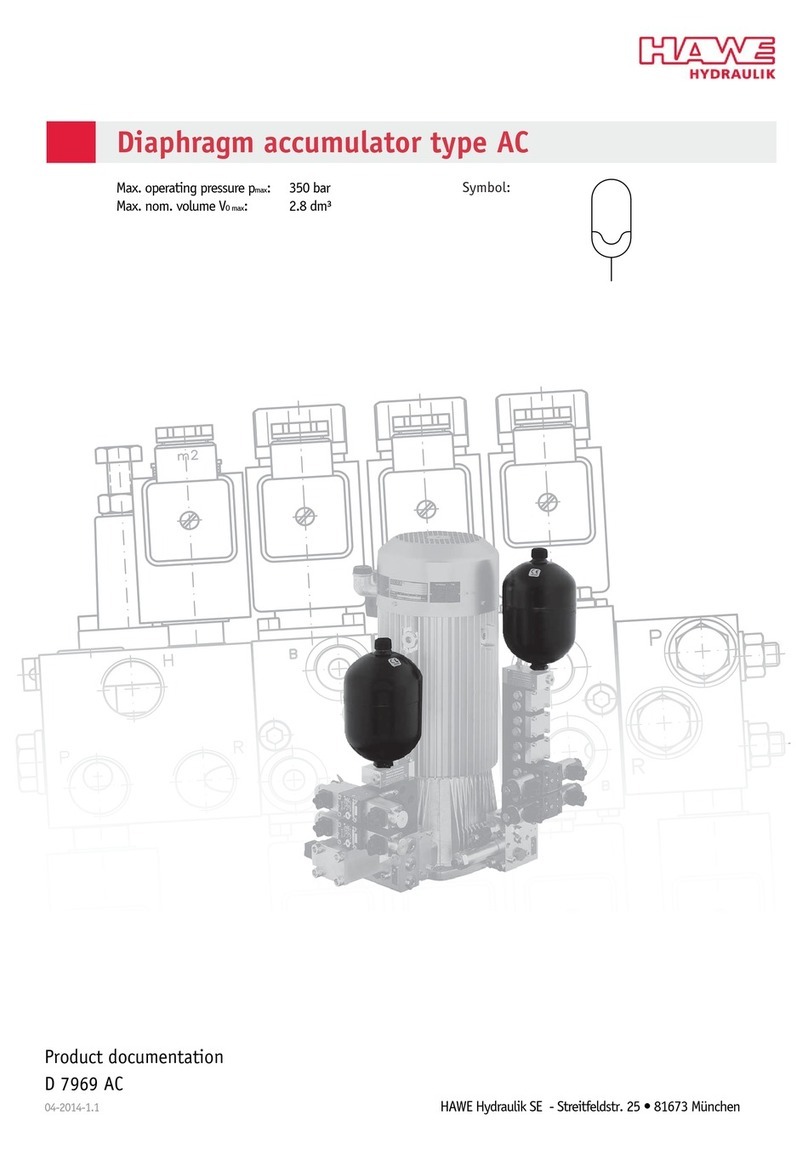

1 Overview diaphragm accumulator type AC............................................................................................................ 4

2 Available versions, main data............................................................................................................................. 5

3 arameters......................................................................................................................................................... 8

3.1 General............................................................................................................................................................... 8

4 Dimensions...................................................................................................................................................... 10

4.1 Diaphragm accumulator....................................................................................................................................... 10

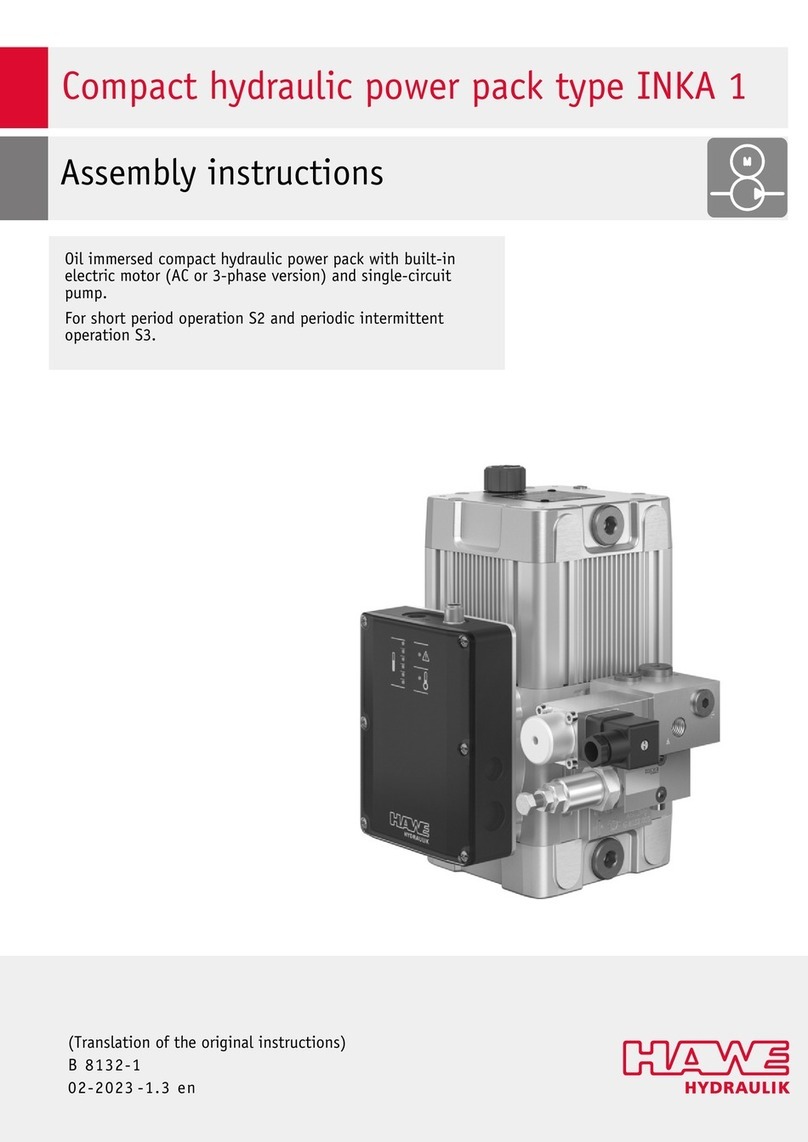

5 Assembly, operation and maintenance recommendations.....................................................................................19

5.1 General note .....................................................................................................................................................19

5.1.1 Safety in truction ............................................................................................................................................. 19

5.1.2 Legal provi ion ................................................................................................................................................. 19

5.1.3 Tran port and torage......................................................................................................................................... 20

5.2 Intended u e..................................................................................................................................................... 20

5.3 A embly information......................................................................................................................................... 21

5.3.1 In tallation and commi ioning............................................................................................................................21

5.4 Operating in truction .........................................................................................................................................24

5.5 Maintenance information..................................................................................................................................... 24

5.5.1 Replacing USIT ring (20).....................................................................................................................................24

5.5.2 Checking ga lling pre ure................................................................................................................................25

6 Other information.............................................................................................................................................26

6.1 Note regarding the lay-out.................................................................................................................................26

6.2 Acce orie , pare part and eparate component ..................................................................................................27

6.2.1 Te ting device DFM.............................................................................................................................................27

6.2.2 Mounting bracket .............................................................................................................................................. 27

6.2.3 Fitting ............................................................................................................................................................. 28

© HAWE Hydraulik SE D 7969 - 11-2020-1.8 3/29