HAWE Hydraulik KA2 User manual

Type KA2 and KAW2 compact hydraulic

power pack

Assembly instructions

with operating and maintenance information

B 8010

04-2021-1.0en

Hydraulic power pack with radial piston or gear pump

and integrated electric drive

© by HAWE Hydraulik SE.

The reproduction and distribution of this document as well as the use and communication of its contents to others without explicit

authorization is prohibited.

Offenders will be held liable for the payment of damages.

All rights reserved in the event of patent or utility model applications.

Brand names, product names and trademarks are not specifically indicated. In particular with regard to registered and protected names

and trademarks, usage is subject to legal provisions.

HAWE Hydraulik respects these legal provisions in all cases.

Printing date / document generated on: 19.04.2021

2/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

Table of Contents

1 About these instructions.................................................................................................................................. 5

1.1 Target audience................................................................................................................................................. 5

1.2 Applicable documents......................................................................................................................................... 5

1.3 Safety instructions and symbols...........................................................................................................................6

2 For your safety................................................................................................................................................ 8

2.1 Intended use..................................................................................................................................................... 8

2.2 Misuse.............................................................................................................................................................. 8

2.3 Residual risks.................................................................................................................................................... 9

2.4 Duties of the operator...................................................................................................................................... 10

2.5 Qualification of the personnel............................................................................................................................10

2.6 Personal protective equipment........................................................................................................................... 11

3 About this product......................................................................................................................................... 12

3.1 Identification...................................................................................................................................................12

3.2 Product description...........................................................................................................................................14

3.3 Assembly.........................................................................................................................................................15

4 Transport and storage..................................................................................................................................... 16

4.1 Safety instructions........................................................................................................................................... 16

4.2 Transport.........................................................................................................................................................16

4.3 Scope of delivery............................................................................................................................................. 18

4.4 Checking the delivery........................................................................................................................................18

4.5 Storage........................................................................................................................................................... 19

5 Assembly and installation...............................................................................................................................20

5.1 Mechanical connection......................................................................................................................................20

5.1.1 Pump dimensions............................................................................................................................................. 21

5.1.2 Additional components’ dimensions.................................................................................................................... 23

5.2 Hydraulic connection........................................................................................................................................ 26

5.3 Electrical connection........................................................................................................................................ 29

5.3.1 Safety instructions........................................................................................................................................... 29

5.3.2 Electrical connection markings........................................................................................................................... 30

5.3.3 Connecting the electric drive.............................................................................................................................30

5.3.3.1 Connections on terminal box............................................................................................................................. 32

5.3.3.2 Connections with Harting plug...........................................................................................................................32

5.3.3.3 Motor data...................................................................................................................................................... 33

5.3.3.4 Current consumption characteristic lines............................................................................................................. 35

5.3.4 Connecting level switch and temperature switch.................................................................................................. 37

5.3.4.1 Connections on terminal box............................................................................................................................. 39

5.3.4.2 Connections with Harting plug...........................................................................................................................40

5.3.4.3 Terminal box with additional connection............................................................................................................. 41

5.3.4.4 Harting plug with additional connection............................................................................................................. 41

5.3.5 Connecting the fan...........................................................................................................................................42

6 Start-up......................................................................................................................................................... 43

6.1 Safety instructions........................................................................................................................................... 43

6.2 Checks before commissioning.............................................................................................................................44

6.3 Set motor protection circuit.............................................................................................................................. 44

6.4 Filling hydraulic uid........................................................................................................................................44

6.5 Setting pump’s rotation direction....................................................................................................................... 45

6.6 Starting and bleeding....................................................................................................................................... 45

HAWE Hydraulik SE B 8010 - 04-2021 - 1.0 3/61

7 Maintenance...................................................................................................................................................47

7.1 Safety instructions........................................................................................................................................... 47

7.2 Cleaning..........................................................................................................................................................48

7.3 Maintenance plan............................................................................................................................................. 48

7.4 Service............................................................................................................................................................49

7.4.1 Visual check: Hydraulic lines (pipes and hoses)....................................................................................................49

7.4.2 Visual check: Electrics (cables, connections, plugs)...............................................................................................49

7.4.3 Checking electrical equipment............................................................................................................................49

7.4.4 Checking and replacing hydraulic hoses...............................................................................................................49

7.4.5 Changing hydraulic uid....................................................................................................................................50

7.4.6 Checking the uid level.................................................................................................................................... 51

7.4.7 Checking and replacing the silica gel lter.......................................................................................................... 51

7.5 Repairs............................................................................................................................................................52

8 Troubleshooting..............................................................................................................................................53

9 Disassembly and disposal................................................................................................................................54

9.1 Safety instructions........................................................................................................................................... 54

9.2 Disassembly and disposal.................................................................................................................................. 54

10 Appendix........................................................................................................................................................56

10.1 Technical data..................................................................................................................................................56

10.2 Declaration of incorporation (Machinery Directive)............................................................................................... 58

10.3 Declaration of conformity (Low Voltage Directive)................................................................................................ 59

11 Contact details............................................................................................................................................... 60

4/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

1About these instructions

This manual is part of the product and describes the safe and proper use in all operating phases.

All photos and drawings in this manual show an available product variant. For precise details concerning

the variant you have purchased, please refer to the type plate attached to the product.

Read instructions before use.

Make the manual accessible to operating and maintenance personnel at all times.

Keep this manual for the lifetime of the product.

Only pass on the product to third parties together with this manual.

1.1 Target audience

The target audience of this manual is trained and qualied personnel who are familiar with the installa-

tion, operation and maintenance of machines.

The manual provides relevant information for the machine manufacturer and machine operator as well as

for training courses.

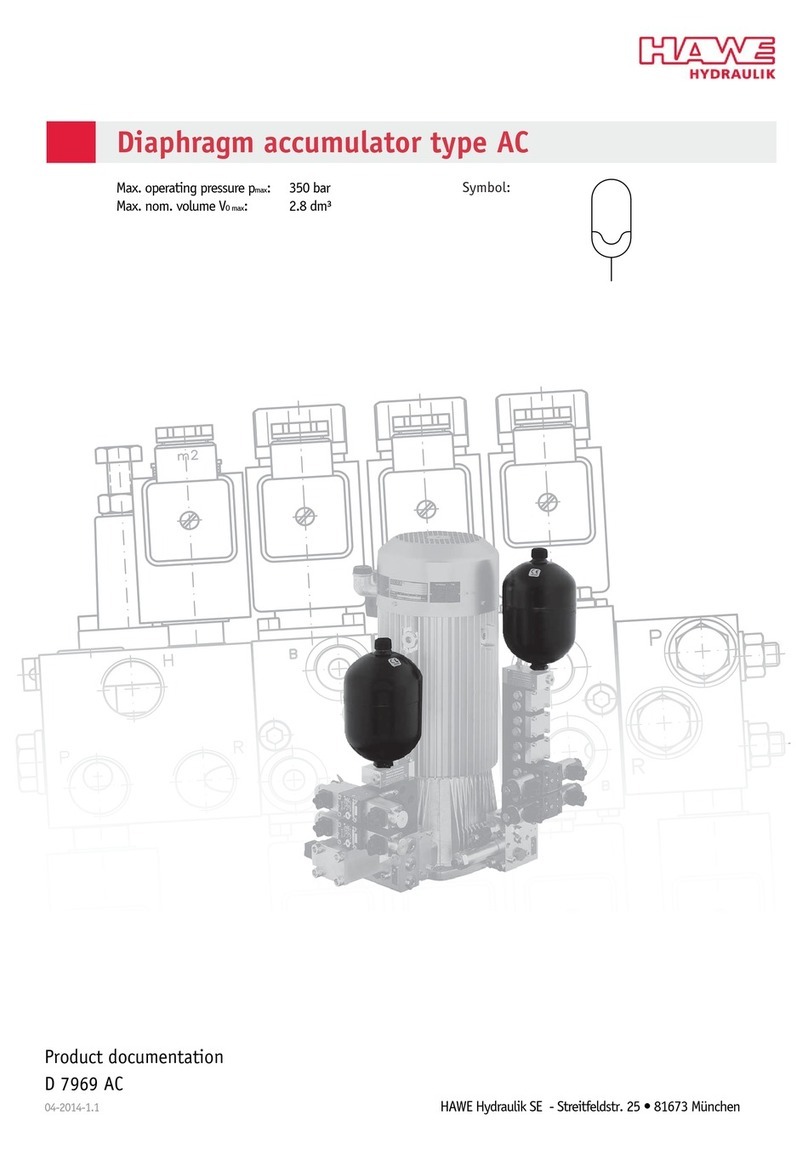

1.2 Applicable documents

Title/purpose Document

Machine manufacturer’s hydraulic and electrical connection schematic

Document required to install hydraulic power pack correctly in entire

machine

Manufacturer’s

operating instructions

Data sheet

Characteristics and application ranges for this product

D 8010

Oil recommendations D 5488/1

Optional add-ons to hydraulic power pack from other manufacturers

e.g. hydraulic accumulator, lter etc.

Manufacturer’s

operating instructions

Explanations "Declaration of incorporation

acc. to Machinery Directive",

page 58

"CE declaration acc. to Low

Voltage Directive", page 59

HAWE Hydraulik SE B 8010 - 04-2021 - 1.0 5/61

1.3 Safety instructions and symbols

Safety indication In these instructions, the following warning and safety notes are used:

Symbol Meaning

Draws your attention to a hazardous situation that can lead directly to serious injury

or death if not avoided.

Draws your attention to a hazardous situation that can indirectly lead to serious

injury or death if not avoided.

Draws your attention to a hazardous situation that can indirectly lead to light to

moderate injury if not avoided.

Notice to prevent environmental and material damage.

Information to ensure the correct use of the product.

Safety symbols General safety symbol

Draws your attention to additional safety information.

Slipping hazard Dragging hazard from moving parts

Harmful substances Tripping and falling hazard

Fire accelerants Falling loads

Burn hazard Crushing hazard

Electrical voltage Suspended loads

No access to persons with pacemakers

and defibrillators

Mandatory signs Protective equipment

Safety boots

Wear appropriate safety boots to protect your feet against mechanical hazards

Work gloves

Wear suitable work gloves to protect your hands against chemical and mechanical

hazards.

Safety goggles

Wear safety goggles to protect your eyes against chemical and mechanical hazards.

6/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

Protective equipment

Protective clothing

►Wear tted clothing without protruding parts.

►Follow the safety data sheet of the hydraulic uid.

HAWE Hydraulik SE B 8010 - 04-2021 - 1.0 7/61

2For your safety

The product is built according to the state of the art and recognized safety regulations.

Nevertheless, there is a risk of personal injury and damage to property if this chapter and the safety

instructions in this manual are not observed.

2.1 Intended use

The compact hydraulic power pack is designed as a hydraulic uid supply in hydraulic systems.

The compact hydraulic power pack is designed for the following operating modes

■S2: Short period operation

■S3: Periodic intermittent operation

■The product is a technical work tool and intended for commercial and industrial use only.

■The product may only be operated in accordance with the technical data, operating conditions and

performance limits specied in this manual.

■Only use original accessories and original spare parts approved by the manufacturer.

Partly completed machinery

The product is a partly completed machine according to the EC Machinery Directive 2006/42/EC and

is intended exclusively for installation in a machine or system. The product is controlled via the

manufacturer's machine / plant control.

►Follow the manufacturer's operating instructions.

2.2 Misuse

■use in other operating modes than specied in the intended use

■Using the product beyond the specied performance limits

■Use of hydraulic uids other than those specied in these instructions

■Connecting consumers other than those specied

■Improperly installed, outdated, non-secured or damaged pipes and hose lines

■Use in atmospheres at risk of explosion

■Structural changes, especially if function and safety are compromised

8/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

2.3 Residual risks

DANGER

Danger from hydraulically operated parts when installing the compact hydraulic power pack in a

complete system

Risk of serious or fatal injury

The compact hydraulic power pack produces, directs or regulates ow rates. These ows usually power

hydraulic consumers in machines or systems.

►Observe the compact hydraulic power pack’s project documentation when incorporating it into a

machine or system.

►Note that new potential dangers may arise when the compact hydraulic power pack is incorporated

into a complete system.

►Assess and document the new dangers in the complete system’s manual.

WARNING

Fire hazard due to ammable and oxidising hydraulic uid.

Risk of serious injury or death.

►Avoid re and open light and do not smoke anywhere near the hydraulic power pack.

►Ensure that no hydraulic uid can escape.

►Do not use any ammable or corrosive cleaning agents.

►Observe the safety data sheet from the hydraulic uid manufacturer.

►Shield ignition sources with a surface temperature of > 200°C.

CAUTION

Danger of burning due to hot metal surfaces on the hydraulic power pack, particularly on the tank,

motor, valve blocks and valves.

Risk of minor burns

►Do not touch the hydraulic power pack or directional valve solenoids during operation.

►Allow the hydraulic power pack and directional valve solenoids to cool down before any work.

►Wear protective gloves.

►If surface temperatures >60°C occur during operation, set up safety barriers.

►Ensure that fresh air can be drawn in and that warm air can escape.

►No changes of any kind (mechanical, welding or soldering work) may be made.

CAUTION

Exposure to hydraulic uid.

Health risk.

►Wear protective gloves and goggles.

►Avoid prolonged skin contact with hydraulic uids.

►Thoroughly wash any body parts exposed to hydraulic uid.

►Observe safety instructions on the safety data sheet of the hydraulic uid manufacturer.

HAWE Hydraulik SE B 8010 - 04-2021 - 1.0 9/61

CAUTION

Risk of falling from leaking hydraulic uid

Spilled or leaked hydraulic uid can form a slippery lm on the oor.

►Use suitable aids when lling or bleeding.

►Check all connecting elements that convey oil for leaks before switching on the motor in the parent

system.

►Wipe up leaked hydraulic uid with suitable aids.

2.4 Duties of the operator

Observe and comply with regulations:

►Do not put the product into operation until the complete machine or system complies with the

country-specic regulations, safety regulations and standards of the application.

►Observe and apply regulations for accident prevention and environmental protection.

Operate product safely:

►Despite safety devices, the product still poses residual risks. Observe the safety instructions in this

manual to reduce health hazards and avoid dangerous situations.

►The operator must ensure that the operating conditions (see general, hydraulic and electrical data)

are within the operating limits of the product.

►Keep all instructions / signs on the product in legible condition and observe them.

Instruct personnel:

►Regularly train the personnel in all points of these instructions and ensure that they are observed.

►Ensure the terms of the industrial safety and operating instructions are observed.

►Only use qualied personnel. Due to their training and experience, the qualied personnel must be

able to recognize risks and avoid possible hazards.

2.5 Qualification of the personnel

The activities described in these instructions require basic knowledge of mechanics, hydraulics and

electrics.

For the transport and handling of heavy loads, additional knowledge in handling hoists and slings is

required.

►The activities may only be carried out by an appropriate specialist or an instructed person under the

supervision of a specialist.

►Activities other than those described in these instructions may only be performed by HAWE or

authorized specialist companies.

►The personnel must have read and understood these instructions.

Trained personnel Personnel instructed comprehensively, by skilled staff on behalf of the owner, in how to perform its

appointed tasks and in how to use the product safely.

Specialist personnel Due to their technical training, knowledge and experience, specialists are able to assess and carry out the

assigned work and can independently recognize possible dangers.

Qualied electrician A person with appropriate professional training, knowledge and experience, so that he/she can recognize

and avoid dangers that can be caused by electricity.

Auditor Persons of a technical inspection body who are authorized to perform testing and monitoring tasks for

pressure equipment and electrical systems.

10/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

2.6 Personal protective equipment

Personal protective equipment is designed to prevent and reduce hazards.

In the instructions, safety instructions with mandatory symbols indicate the wearing of special

protective equipment for special activities.

Instruction and supply is carried out by the operator.

HAWE Hydraulik SE B 8010 - 04-2021 - 1.0 11/61

3About this product

3.1 Identification

Order coding and type plate shown are only an example.

KA 24

KA 28

1

22

S

L1

KS

KTF

E/

P/

H 1.81

HZ 0.59/8.8

- A1/280

- ...

- FSR-24V - 3x400 V 50 Hz

- 3x400 V 50 Hz /24 V DC - G 1/2 x 300

Oil drain hose

Motor voltage

Fan

Motor voltage

Fan (on side)

Valve combination acc. to commission number

Pump version

Electrical connection

Additional options

Mounting position

Tank size

Basic type and motor power

Motor type code

■Coding KA = 3-phase motor

■Coding KAW = AC motor

12/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

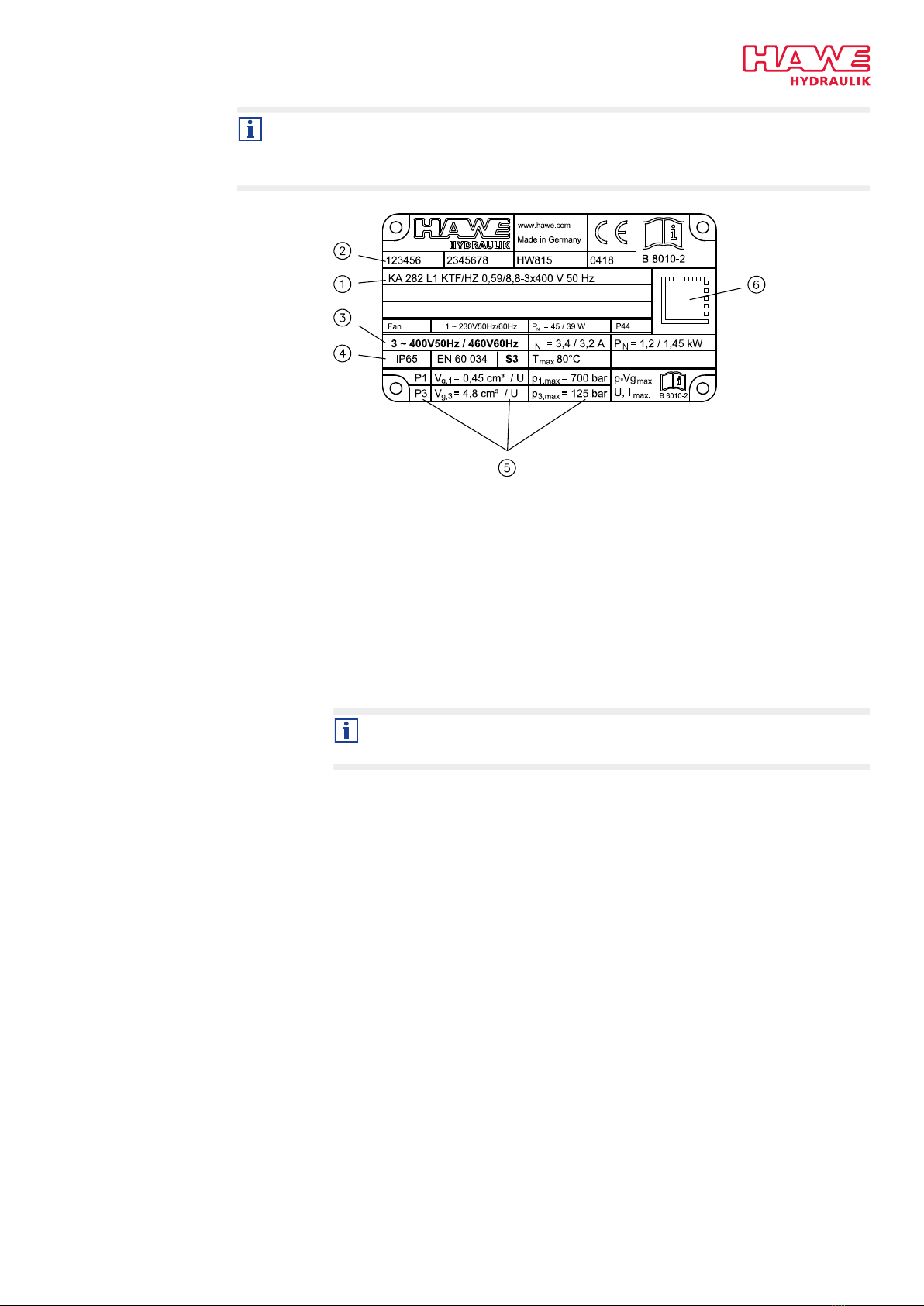

Type plate The commission number on the type plate identies the product uniquely and completely, including

all tted components.

The data are stored with the manufacturer and encoded in the DataMatrix on the type plate.

1Order coding, type coding

2– Customer order, commission number

– Production order

– Customer material number

– Date of manufacture (week XX in Year XX)

3– Motor voltage/power frequency

– Nominal current IN (50 Hz/60 Hz)

– Nominal power PN (50 Hz/60 Hz)

The actual power consumption depends on the load and can be up to 1.8 x nominal

power.

4– Protection class

– EN standard

– Operating mode

– max. temperature

– Operating capacitor only with AC motor (not included)

5– Pump port (P1 = single circuit, P3 = dual circuit)

– Geometric output volume VG (cm3/rev)

– Pump’s max. permissible operating pressure

6DataMatrix code

HAWE Hydraulik SE B 8010 - 04-2021 - 1.0 13/61

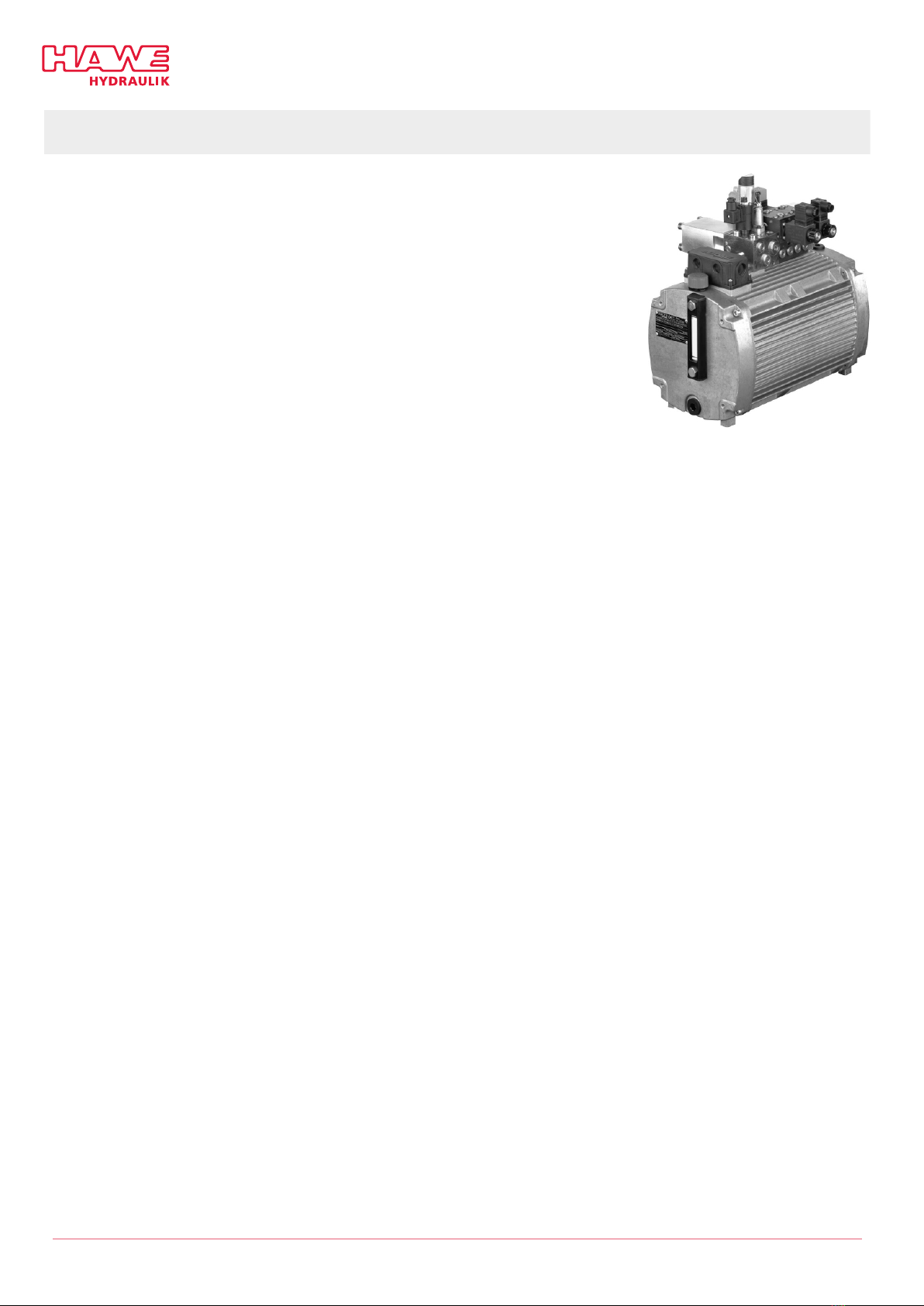

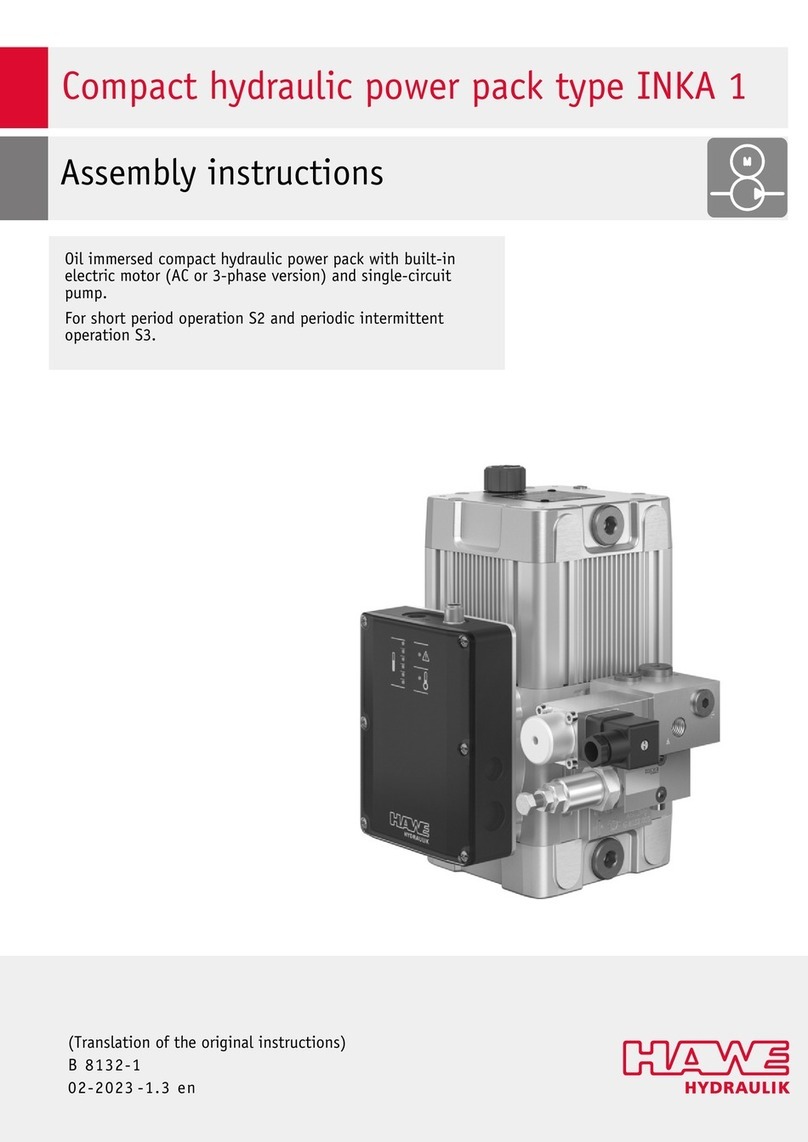

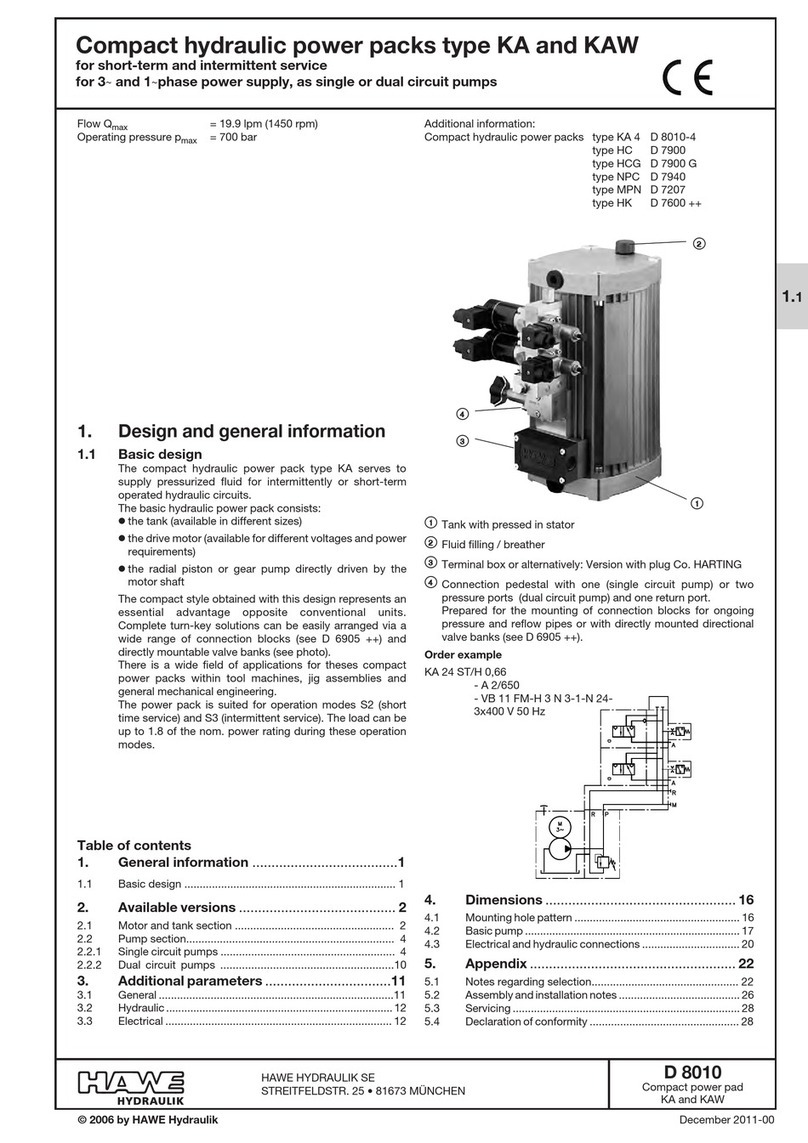

3.2 Product description

Compact hydraulic power packs are a type of hydraulic power

pack. They are characterised by a highly compact design, since

the motor shaft of the electric drive also acts as the pump shaft.

Compact hydraulic power packs are designed to supply hydraulic

circuits with hydraulic uid.

The compact hydraulic power pack type KA consists of the

tank, the integrated motor and the radial piston or gear pump

directly attached to the motor shaft. The compact design that

this achieves is a crucial advantage compared to conventional

hydraulic power packs.

The compact hydraulic power pack’s uncompromisingly module

design will enable you to quickly and easily set up a variety of

usage volumes and sizes. Compatible, ready-for-connection,

complete solutions can be assembled easily using a wide range

of connection blocks and the valve banks that can be combined

with them.

For systems with high loads, a fan that enables additional heat

dissipation can be optionally mounted on the housing. The fan is

powered by a separate motor independently of the pump motor.

KA2 and KAW2-type compact hydraulic

power pack

14/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

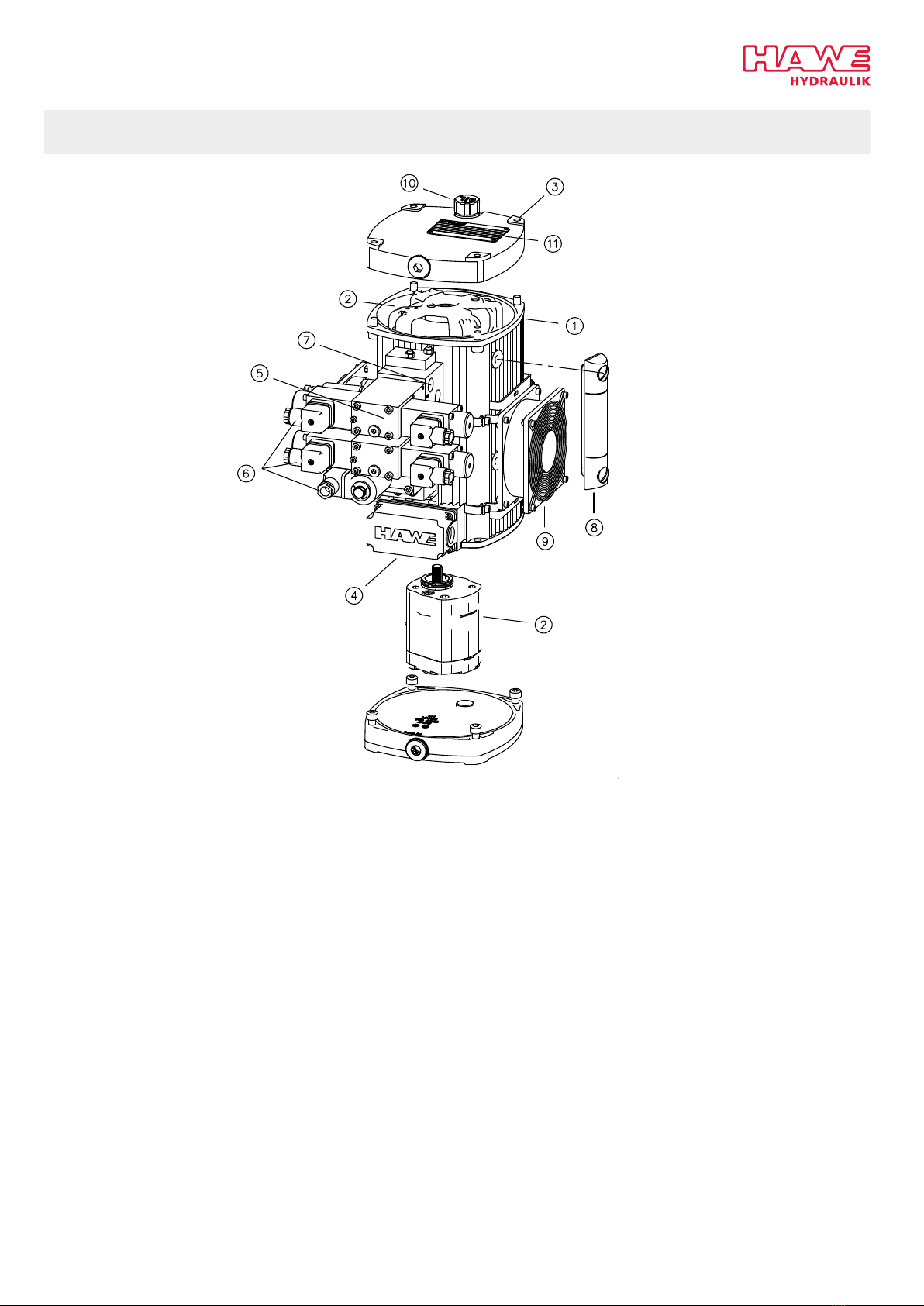

3.3 Assembly

1Hydraulic uid tank with motor

2Pump

3Fastening, e.g. for transport eyelets

Here: 2 x eye-bolts

4Terminal box for electrically connecting motor and monitoring components, e.g. temperature and level switches

5Connection block and valve bank

6Electrical connection of valves and monitoring components, e.g. pressure switches

7Hydraulic connection to consumers

8Level gauge

9External fan (optional)

10 Hydraulic uid ller neck and breather lter

11 Type plate

HAWE Hydraulik SE B 8010 - 04-2021 - 1.0 15/61

4Transport and storage

4.1 Safety instructions

WARNING

Falling, tipping and toppling heavy loads

Risk of serious injury

►Make sure that the danger zone, the area beneath suspended loads and the transport path is clear

of people.

►Wear safety shoes and protective gloves.

DAMAGE

Risk of damage from improper transport

►Only use the intended eyelets for transport.

►Make sure that belts or chains do not tear or knock components off the hydraulic power pack during

transport.

DAMAGE

Damage to the silica gel lter

►The tapped journal of the silica gel lter can shear off due to lateral forces. For transport and

assembly the silica gel lter is therefore replaced by a tapped plug in the opening.

►Transport and assemble the hydraulic power pack only with the tapped plug screwed in.

DAMAGE

Pollution from transport while lled with hydraulic uid

Hydraulic uid must be prevented from escaping into the environment.

►When transporting after prior use, drain the hydraulic uid from the tank.

►Collect cleaning, operating and lubrication uids and consumable materials in suitable containers

and dispose of them according to local regulations.

4.2 Transport

Transporting the product

Make sure that the eye-bolts are rmly attached, that there are enough of them and that they are in

the correct positions on the hydraulic power pack.

►Use the specied eye-bolts when moving the unit using belts, chains or carry handles.

►Transport methods depend on the hydraulic power pack’s weight, see "Technical data", page 56.

►Use suitable lifting gear and industrial trucks or have two people lift and carry the unit by its carry

handles.

Attachment points for

transport eye-bolts The eye-bolts are included with the product.

16/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

Vertical version Pump with fan

1Eye-bolt screw-in points 1Eye-bolt screw-in points

Horizontal version

1Eye-bolt screw-in points

HAWE Hydraulik SE B 8010 - 04-2021 - 1.0 17/61

4.3 Scope of delivery

Included in scope of

delivery

■Hydraulic power pack (motor and pump in tank) with power connection (terminal box or Harting plug)

and, if applicable, suppressor

■2 transport eye-bolts on container

■Temperature switch coding T on type KAW (hydraulic power pack with alternating current)

■Breather lter, with oil dipstick on some versions

■Oil drain screw or oil drain hose

■Cap for oil ller or ller reduction with screen

Additional accessories depending on the variant chosen.

Type-specic parameters are listed on the product’s type plate, e.g.: Data on motor and pump

power.

For further technical data, refer to HAWE publication D 8010.

"Applicable documents", page 5

Not included in scope of

delivery

Electrical connection

■Line connector M12x1, 4-pin for option PM.

■Line connector M12x1, 5-pin for option KD, KS (vertical version):

(Coding KD, KS is level gauge with N/C or N/O contact switch)

Motor

■Operating capacitor for AC variant type KAW

■Motor protection circuit

Accessories for commissioning

■Damping elements for fastening

■Hydraulic uid

■Electronic controller elements for the hydraulic system

4.4 Checking the delivery

Unpacking and inspecting

1. Take out the product. Use the eye-bolts to help when doing so.

2. Check that the product is complete and check for transport damage.

■If there is any damage, refuse shipment or sign for damage when accepting it.

■Note all transport damage on the transport documents or the carrier's delivery note.

■Take photos of any product damage and submit a claim to the manufacturer immediately.

3. Dispose of the packaging in accordance with local regulations.

18/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

Submit claims to:

HAWE Hydraulik SE

Einsteinring 17

85605 Aschheim

Germany

Email: inf[email protected]e

www.hawe.com

Phone: +49 (0) 89 / 37 91 00 - 1000

Claims for damage can only be accepted if submitted within the applicable claim periods. HAWE

cannot accept liability for later claims.

4.5 Storage

DAMAGE

Damage from incorrect storage

Protect the product from soiling and damage.

►Keep the product wrapped in a plastic bag when storing it to protect it from dust and constant air

circulation.

►Seal all hydraulic uid ports with caps or dummy plugs.

►Store the product in a position matching its intended mounting position, with the hydraulic uid

ller port at the top and the uid drain at the bottom.

Storage conditions Storage space ■dark

■keep away from direct sunlight and other light sources with heavy UV share

■constant temperature and humidity

■do not store close to facilities that product ozone (electric drives, high-

voltage equipment or similar)

Storage temperature +15°C to +20°C

Relative humidity 65% +/- 10%

HAWE Hydraulik SE B 8010 - 04-2021 - 1.0 19/61

5Assembly and installation

5.1 Mechanical connection

Assembly Setting up and attaching

1. Check the order coding to identify the intended mounting position.

■Vertical (type: KA...S...) or

■Horizontal (type: KA...L...)

2. Check that the support/frame possesses sufcient load capacity. This depends on the hydraulic power

pack’s weight.

3. Drill fastening holes as instructed by the mounting hole pattern.

4. Bolt into the M8 threaded holes using the recommended damping elements.

■The horizontal version can also be incorporated vertically.

■If you are installing a horizontal version vertically:

– Position with bleeder at top.

– Position the integrated pump at the bottom.

– Turn only the top housing covers, keep the extensions in their original positions.

Mounting hole pattern Horizontal version coding LVertical version coding S

Coding tank size a

-- 284

01, 1 336

02, 2 484

22, 3 684

Recommended fastening

with damping element

1Damping element #40x30/M8 (65 Shore)

20/61 B 8010 - 04-2021 - 1.0 HAWE Hydraulik SE

This manual suits for next models

8

Table of contents

Other HAWE Hydraulik Power Pack manuals

HAWE Hydraulik

HAWE Hydraulik INKA 1 User manual

HAWE Hydraulik

HAWE Hydraulik D 7969 AC Operator's manual

HAWE Hydraulik

HAWE Hydraulik A 100 User manual

HAWE Hydraulik

HAWE Hydraulik AC Series Operator's manual

HAWE Hydraulik

HAWE Hydraulik KA User manual

HAWE Hydraulik

HAWE Hydraulik HLU LE-X User manual

HAWE Hydraulik

HAWE Hydraulik HICON User manual

HAWE Hydraulik

HAWE Hydraulik HR 050 User manual