HAWE Hydraulik HLU LE-X User manual

Hydraulic Locking Unit (HLU) for Passenger

Restraint Systems

Translation of original assembly instruc-

tions

B 6052-21

11-2021 -1.7 en

Type:

ID no.:

System solution

HLU LE-X (M)

© by HAWE Hydraulik SE.

The reproduction and distribution of this document as well as the use and communication of its contents to others without explicit

authorization is prohibited.

Offenders will be held liable for the payment of damages.

All rights reserved in the event of patent or utility model applications.

Brand names, product names and trademarks are not specifically indicated. In particular with regard to registered and protected names

and trademarks, usage is subject to legal provisions.

HAWE Hydraulik respects these legal provisions in all cases.

HAWE Hydraulik cannot provide individual guarantees that the stated circuits or procedures (including in part) are not subject to the

intellectual property rights of third parties.

Printing date / document generated on: 15.11.2021

2/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

Table of Contents

1 About these instructions.................................................................................................................................. 5

1.1 About these instructions.....................................................................................................................................5

1.2 Target audience................................................................................................................................................. 5

1.3 Safety instructions and symbols...........................................................................................................................6

1.3.1 Safety instructions and symbols...........................................................................................................................6

1.4 Applicable documents......................................................................................................................................... 8

2 For your safety................................................................................................................................................ 9

2.1 Intended use.....................................................................................................................................................9

2.2 Misuse.............................................................................................................................................................. 9

2.3 Residual risks.................................................................................................................................................... 9

2.4 Duties of the operator...................................................................................................................................... 10

2.5 Qualification of the personnel............................................................................................................................11

2.6 Personal protective equipment........................................................................................................................... 11

3 About this product......................................................................................................................................... 12

3.1 Structure......................................................................................................................................................... 12

3.2 Functions........................................................................................................................................................ 13

3.2.1 Type EX: Blocking against extension................................................................................................................... 14

3.2.2 Type RE: Blocking against retraction...................................................................................................................14

3.2.3 Type DL (EX): Blocking against extension with comfort lock...................................................................................14

3.2.4 Type DL (RE): Blocking against retraction with comfort lock.................................................................................. 15

3.3 Instructions for the ride manufacturer................................................................................................................ 16

3.4 Markings..........................................................................................................................................................18

4 Transport and storage..................................................................................................................................... 19

4.1 Transport equipment......................................................................................................................................... 19

4.2 Checking the delivery........................................................................................................................................19

4.3 Storage........................................................................................................................................................... 20

5 Assembly and installation...............................................................................................................................21

5.1 Mechanical connection......................................................................................................................................22

5.2 Electrical connection........................................................................................................................................ 24

6 Start-up......................................................................................................................................................... 26

6.1 Starting up the hydraulic locking unit................................................................................................................ 26

7 Operation....................................................................................................................................................... 27

7.1 Switching on and off........................................................................................................................................27

7.2 Temporary shutdown......................................................................................................................................... 28

7.3 Response in emergency..................................................................................................................................... 28

7.3.1 Opening with power supply connected................................................................................................................ 28

7.3.2 Opening with power supply disconnected............................................................................................................ 29

7.3.3 Opening under high static load..........................................................................................................................29

HAWE Hydraulik SE B 6052-21 - 11-2021 - 1.7 3/63

8 Maintenance...................................................................................................................................................32

8.1 Maintenance plan............................................................................................................................................. 34

8.2 Cleaning and visual inspection for damage.......................................................................................................... 35

8.2.1 Locking unit.................................................................................................................................................... 35

8.2.2 Emergency override...........................................................................................................................................36

8.2.3 Piston rod....................................................................................................................................................... 36

8.2.4 Piston type accumulator....................................................................................................................................37

8.3 Mechanism.......................................................................................................................................................38

8.3.1 Check for leaks in the locking unit.....................................................................................................................38

8.3.2 Check function of emergency override button.......................................................................................................38

8.3.3 Check rod end bolt connection.......................................................................................................................... 39

8.3.4 Check pivot bearing clearance............................................................................................................................40

8.3.5 Replace pivot mounts....................................................................................................................................... 40

8.3.5.1 Rod-side rod end..............................................................................................................................................40

8.3.5.2 Base-side rod end............................................................................................................................................ 44

8.4 Electrics.......................................................................................................................................................... 47

8.4.1 Check and replace coil...................................................................................................................................... 47

8.5 Filling the hydraulic accumulator........................................................................................................................49

8.6 Functional check.............................................................................................................................................. 52

8.6.1 Locking function.............................................................................................................................................. 52

8.6.2 Opening function............................................................................................................................................. 53

8.6.3 Hold and drift function.....................................................................................................................................55

9 Disassembly and disposal................................................................................................................................56

10 Troubleshooting..............................................................................................................................................58

11 Appendix........................................................................................................................................................60

11.1 Technical data..................................................................................................................................................60

11.1.1 Operating conditions.........................................................................................................................................60

11.1.2 Weights and measures.......................................................................................................................................60

11.2 Shipping data.................................................................................................................................................. 61

11.3 System - parts list........................................................................................................................................... 62

4/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

1About these instructions

1.1 About these instructions

This manual is part of the product and describes the safe and proper use in all operating phases.

All photos and drawings in this manual show an available product variant. For precise details concerning

the variant you have purchased, please refer to the type plate attached to the product.

Read instructions before use.

Make the manual accessible to operating and maintenance personnel at all times.

Keep this manual for the lifetime of the product.

Only pass on the product to third parties together with this manual.

Device specially designed for use at fairs and/or amusement parks

The product may only be put into operation by the fairground ride manufacturer once the higher-

level system meets the requirements of DIN 13814, the Use of Work Equipment Directive 2009/104/

EC, the Directive 89/391/EEC and the national regulations of the country of use.

The information in these instructions must be supplemented by the plant manufacturer in

accordance with the results of his own risk assessment. The plant manufacturer must decide which

information contained in these installation instructions is relevant for the operator of the plant

and must pass on the information.

1.2 Target audience

The target audience of this manual is trained and qualied personnel who are familiar with the installa-

tion, operation and maintenance of machines.

The manual provides relevant information for the machine manufacturer and machine operator as well as

for training courses.

To request further information about the product, contact HAWE Micro Fluid GmbH.

HAWE Hydraulik SE B 6052-21 - 11-2021 - 1.7 5/63

1.3 Safety instructions and symbols

1.3.1 Safety instructions and symbols

Safety indication In these instructions, the following warning and safety notes are used:

Symbol Meaning

DANGER

Draws your attention to a hazardous situation that can lead directly to serious injury

or death if not avoided.

WARNING

Draws your attention to a hazardous situation that can indirectly lead to serious

injury or death if not avoided.

CAUTION

Draws your attention to a hazardous situation that can indirectly lead to light to

moderate injury if not avoided.

Notice to prevent environmental and material damage.

Information to ensure the correct use of the product.

Safety symbols General safety symbol

Draws your attention to additional safety information.

Slipping hazard Dragging hazard from moving parts

Harmful substances Tripping and falling hazard

Fire accelerants Falling loads

Burn hazard Crushing hazard

Electrical voltage Suspended loads

No access to persons with pacemakers

and defibrillators

Mandatory signs Protective equipment

Safety boots

Wear appropriate safety boots to protect your feet against mechanical hazards

Work gloves

Wear suitable work gloves to protect your hands against chemical and mechanical

hazards.

Safety goggles

Wear safety goggles to protect your eyes against chemical and mechanical hazards.

6/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

Protective equipment

Protective clothing

►Wear tted clothing without protruding parts.

►Follow the safety data sheet of the hydraulic uid.

HAWE Hydraulik SE B 6052-21 - 11-2021 - 1.7 7/63

1.4 Applicable documents

The locking unit has been designed and manufactured in compliance with engineering practice

according to the Pressure Equipment Directive (PED 2014/68/EU Article 4, paragraph 3), and is

safe to use. No EU Declaration of Conformity may be issued for pressure equipment and assemblies

classied in the Pressure Equipment Directive according to Article 4 (3). No CE mark may be afxed.

Standard Name

DIN EN 13814 Fairground and amusement park machinery and structure - Safety of

amusement rides and amusement devices

ASTM F2291 Standard Practice for Design of Amusement Rides and Devices

F 698-94 Standard Specification for Physical Information to be Provided for

Amusement Rides and Devices

F 846-92 Standard Guide for Testing Performance of Amusement Rides and

Devices

F 893-10 Standard Guide for Inspection of Amusement Rides and Devices

ISO 17842-01 Safety of amusement rides and amusement devices -- Part 1: Design

and manufacture

8/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

2For your safety

The product is built according to the state of the art and recognized safety regulations.

Nevertheless, there is a risk of personal injury and damage to property if this chapter and the safety

instructions in this manual are not observed.

2.1 Intended use

■The product is a technical work tool and intended for commercial and industrial use only.

■The product may only be operated in accordance with the technical data, operating conditions and

performance limits specied in this manual.

■Only use original accessories and original spare parts approved by the manufacturer.

■The product may be used outdoors and indoors.

■The product is used for the infinitely variable locking of passenger restraint systems on seats in

amusement rides and ying structures.

■Any rides that are operated as ying structures on the territory of the United States of America are

excluded from said use.

■Forces may only be transmitted to the locking unit by way of articulated lugs.

■Use the product only after undergoing training by the seat or ride operator.

Partly completed machinery

The product is a partly completed machine according to the EC Machinery Directive 2006/42/EC and

is intended exclusively for installation in a machine or system. The product is controlled via the

manufacturer's machine / plant control.

►Comply with the manufacturer’s operating instructions.

2.2 Misuse

■Use in other operating modes than specied in the intended use

■Using the product beyond the specied performance limits

■Do not convert the product or modify it in any way.

■Do not paint over elastic sealing parts, bearings of moving parts and hose lines.

■Do not use this product in potentially explosive atmospheres.

2.3 Residual risks

When handling hydraulic uid, comply with the safety data sheet of the manufacturer of the

hydraulic uid.

HAWE Hydraulik SE B 6052-21 - 11-2021 - 1.7 9/63

DANGER

Risk to life due to explosive combustion

Hydraulic uid and its associated mists and vapours are oxidizing. Contact with ignition sources will

lead to explosive combustion. Risk of serious injury or death.

►Avoid re and open light and do not smoke anywhere near the product.

►Immediately dispose of any ammable materials moistened with hydraulic uid as hazardous waste.

►Do not use any ammable or corrosive cleaning agents.

WARNING

Electrical and magnetic elds

Electrical and magnetic elds impair the functionality of cardiac pacemakers and implanted defibrilla-

tors.

►People with pacemakers or implanted defibrillators must maintain a sufcient distance from

magnets.

►Advise people with pacemakers or implanted defibrillators against approaching magnets.

►Cordon off the area around the drive system and afx suitable warning signs to the barriers.

WARNING

Risk of injury through crushing or cutting

Body parts might get trapped or cut off between the machine frame and hydraulic system in the event of

careless transport, installation and de-installation.

►Never reach between the hydraulic system and the machine frame.

►Ensure that other people cannot enter the danger area.

►Wear gloves and work shoes.

2.4 Duties of the operator

Observe and comply with regulations:

►Do not put the product into operation until the complete machine or system complies with the

country-specic regulations, safety regulations and standards of the application.

►Observe and apply regulations for accident prevention and environmental protection.

Operate product safely:

►Despite safety devices, the product still poses residual risks. Observe the safety instructions in this

manual to reduce health hazards and avoid dangerous situations.

►The operator must ensure that the operating conditions (see general, hydraulic and electrical data)

are within the operating limits of the product.

►Keep all instructions / signs on the product in legible condition and observe them.

Instruct personnel:

►Regularly train the personnel in all points of these instructions and ensure that they are observed.

►Ensure the terms of the industrial safety and operating instructions are observed.

►Only use qualied personnel. Due to their training and experience, the qualied personnel must be

able to recognize risks and avoid possible hazards.

10/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

2.5 Qualification of the personnel

The activities described in these instructions require basic knowledge of mechanics, hydraulics and

electrics.

For the transport and handling of heavy loads, additional knowledge in handling hoists and slings is

required.

►The activities may only be carried out by an appropriate specialist or an instructed person under the

supervision of a specialist.

►Activities other than those described in these instructions may only be performed by HAWE or

authorized specialist companies.

►The personnel must have read and understood these instructions.

Trained personnel Personnel instructed comprehensively, by skilled staff on behalf of the owner, in how to perform its

appointed tasks and in how to use the product safely.

Specialist personnel Due to their technical training, knowledge and experience, specialists are able to assess and carry out the

assigned work and can independently recognize possible dangers.

Qualied electrician A person with appropriate professional training, knowledge and experience, so that he/she can recognize

and avoid dangers that can be caused by electricity.

Auditor Persons of a technical inspection body who are authorized to perform testing and monitoring tasks for

pressure equipment and electrical systems.

2.6 Personal protective equipment

Personal protective equipment is designed to prevent and reduce hazards.

In the instructions, safety instructions with mandatory symbols indicate the wearing of special

protective equipment for special activities.

Instruction and supply is carried out by the operator.

HAWE Hydraulik SE B 6052-21 - 11-2021 - 1.7 11/63

3About this product

3.1 Structure

The hydraulic locking unit (HLU) (2) is a closed hydraulic system, including hydraulic uid, for the

infinitely variable locking of passenger restraint systems (1) on seats in amusement rides and ying

structures.

It is available in different sizes, which vary in cylinder stroke, direction of locking, extension forces,

operating loads and maximum loads, and supplies pressure according to the technical data specifications.

The operating principle of the four standard versions type EX, type RE, type DL (EX), and type DL (RE) is

described below.

To protect them from environmental effects, the emergency override buttons feature rubber caps.

12/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

Design of type EX and type

RE:

Design of type DL (EX) and

type DL (RE)

1 Rod end, base-side, with external thread 8 Wiper

2 V2 (only type DL): solenoid 2/2-way

directional seated valve

9 Piston rod

3 Emergency override button V2 with rubber

cap (only type DL)

10 Rod end lock nut

4 Emergency override button V1 with rubber

cap

11 Rod end, bar side, with internal thread

5 V1 2/2-way directional seated valve with

electromagnetically releasing check valve

12 Connection block

6 Piston type accumulator 13 Check valves with sealing caps

7 Double-acting cylinder

3.2 Functions

The inner tube of the clamped double-acting cylinder guides the piston rod with the piston. The

outer tube conveys the oil on the rod side to the anged connection block on the cylinder base. The

connection block holds the piston type accumulator, the electromechanically and manually releasing

HAWE Hydraulik SE B 6052-21 - 11-2021 - 1.7 13/63

check valve, and two pressure ports. The piston type accumulator preloads the unit to a dened pressure,

and captures the oil volume displaced by the piston rod when retracting. The piston type accumulator

allows the locking unit’s piston rod to extend at different speeds and forces depending on the pressure

ratios.

The seated valve allows oil ow in one direction only, blocking the other direction. Oil ow in both

directions is possible in normal operation by way of the electromechanical actuator (3) and/or (4). In

an emergency, the valve (4) must be actuated manually for the purpose. The pressure ports are used for

lling the unit with oil and configuring its pressure at the factory ("Structure", page 12).

WARNING

Danger to life if valves V1 and V2 are energized while running

If valves V1 and V2 are energized while the ride is running, the restraint system might release and riders

might suffer fatal injury.

■Keep valves V1 and V2 de-energized during operation.

■Observe the switching logic on page (18).

3.2.1 Type EX: Blocking against extension

Primary function:

Locking the restraint

system

The hydraulic locking unit is connected via the rod ends (1) and (11) to the ride’s restraint system (such

as the shoulder bar mechanism), and can be unlocked manually/electrically. When the restraint system is

closed, the piston rod (9) of the hydraulic cylinder (7) retracts, lling the hydraulic accumulator (6). This

builds up and maintains a hydraulic pressure. The restraint system is closed.

The piston rod (9) is prevented from extending by the check valve (5). The restraint system is thus

locked.

Secondary function:

Opening the restraint

system

The hydraulic locking unit acts as a bar drive. The piston rod (9) extends by extension force as soon

as the 2/2-way valve (5) is energized and thereby opened. The hydraulic pressure is relieved, and the

hydraulic locking unit’s restraint system (such as the bar) is actively opened.

3.2.2 Type RE: Blocking against retraction

Primary function:

Close and lock restraint

system

The hydraulic locking unit is connected via the rod ends (1) and (11) to the ride’s restraint system

(such as the shoulder bar mechanism), and can be unlocked manually/electrically. When the restraint

system is closed, the piston rod (9) of the hydraulic cylinder (7) is extended. The hydraulic pressure in

the accumulator (6) is relieved, ensuring correct internal ow of hydraulic uid. The restraint system is

closed.

The piston rod (9) is prevented from retracting by the check valve (5). The restraint system is thus

locked.

Secondary function:

None

The hydraulic locking unit type RE generates only low piston extension forces by design. When the 2/2-

way valve (5) is energized, and thereby opened, the piston rod (9) of the hydraulic cylinder (7) remains

extended. The piston rod can be moved in the retraction and extension directions.

It is not possible to drive the restraint system's opening motion by way of the hydraulic locking unit. The

low extension forces produce a force that closes the restraint system. An additional system (such as a

gas spring or leg spring) is therefore required to drive the opening motion and keep the restraint system

(such as the bar) open.

3.2.3 Type DL (EX): Blocking against extension with comfort lock

The hydraulic locking unit is connected via the rod ends (1) and (11) to the ride’s restraint system (such

as the shoulder bar mechanism).

14/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

Comfort locking

When the restraint system is open, the double-sided locking of valve V2 (2) prevents the hydraulic

cylinder (7) from retracting under load. Riders can use the restraint system as a handhold when

entering and exiting the ride. Further closing of the restraint system too tightly is prevented while

the ride is running. Both functions enhance rider comfort.

Closing the restraint

system

When valve V2 (2) is energized, the restraint system can be closed. When the restraint system is closed,

the piston rod (9) of the hydraulic cylinder (7) retracts, lling the hydraulic accumulator (6). A hydraulic

pressure is built up and maintained in the process. The restraint system is closed.

The piston rod (9) is prevented from extending by the non-energized check valve V1 (5), and the

restraint system cannot be opened.

Primary function:

Locking the restraint

system

When the restraint system has reached its end position, valve V2 (2) is de-energized. The piston rod (9)

can neither retract nor extend. The restraint system is thus locked, and can be neither opened nor closed.

Secondary function:

Opening the restraint

system

The hydraulic locking unit acts as a bar drive. The piston rod (9) extends by extension force as soon as

V1 (4) is energized and thereby opened. The hydraulic pressure is relieved, and the restraint system bar is

actively opened.

3.2.4 Type DL (RE): Blocking against retraction with comfort lock

The hydraulic locking unit is connected via the rod ends (1) and (11) to the ride’s restraint system (such

as the shoulder bar mechanism).

Comfort locking

When the restraint system is open, the double-sided locking of valve V2 (2) prevents the hydraulic

cylinder (7) from retracting under load. Riders can use the restraint system as a handhold when

entering and exiting the ride. Further closing of the restraint system too tightly is prevented while

the ride is running. Both functions enhance rider comfort.

Closing the restraint

system

When valve V1 (5) is energized, the restraint system can be closed. When the restraint system is closed,

the piston rod (9) of the hydraulic cylinder (7) is extended. The hydraulic pressure in the accumulator (6)

is relieved, ensuring correct internal ow of hydraulic uid.

The piston rod (9) is prevented from retracting by the non-energized check valve V2 (2), and the

restraint system cannot be opened.

Primary function:

Locking the restraint

system

When the restraint system is closed, the piston rod (9) of the hydraulic cylinder (7) is extended and

locked to stop it retracting. The hydraulic pressure in the accumulator (6) is relieved, and holds the

piston rod in position hydraulically.

When the restraint system has reached its end position, valve V1 (5) is de-energized. The piston rod (9)

can neither retract nor extend. The restraint system is thus locked, and can be neither opened nor closed.

Secondary function:

Opening the restraint

system

Type DL (RE) locking units always generate very low piston extension forces by design. When valves

V1 (5) and V2 (2) are energized, and thereby opened, the piston rod (9) of the hydraulic cylinder (7)

remains extended, and can only be retracted by an additional system.

It is not possible to drive the restraint system's opening motion by way of the locking unit. The low

extension forces produce a force that closes the restraint system. An additional system (such as a gas

spring or leg spring) is therefore required to drive the opening motion and keep the restraint system

open.

HAWE Hydraulik SE B 6052-21 - 11-2021 - 1.7 15/63

3.3 Instructions for the ride manufacturer

All of the necessary safety equipment, safety functions and the safety controller should be provided

by the machine manufacturer.

The following functions must be assured on the ride/machine, and supplemented with other measures

according to your own risk assessment:

Personal safety ■Malfunctions on the ride can be safely remedied, and do not pose a risk to the hydraulic locking unit.

■The ride in which the hydraulic locking unit is installed fully complies with all legal requirements.

■A failure of the electrical power supply to the hydraulic locking unit does not pose any risk.

■A main switch and an emergency stop function are integrated into the ride, or in a higher-level

control system.

■It is not possible for persons to reach into the hazard zone of the hydraulic locking unit.

■Persons cannot be endangered by movement of the restraint system.

■Persons cannot randomly or unintentionally open the restraint system/hydraulic locking unit.

■Persons cannot burn themselves on hot surfaces. After the hydraulic locking unit has been installed in

the ride, place signs to identify hot surfaces that could endanger persons.

Construction and control Maximum loads in drawings and product documentation are calculated according to DINEN13814.

For locking units on seat classes* 4 and 5 a 70/30 load distribution was applied, and for locking

units on seat class* 3 a direct load of 100%. The loads relate to the linear forces acting directly on

the piston rod of the hydraulic locking unit.

If the restraint system is not safeguarded by redundancy, the maximum permissible holding forces

must be recalculated. Get in touch with HAWE Micro Fluid GmbH.

*Seat classes dened in DINEN13814

Installation and control of the hydraulic locking unit is to be implemented by the ride manufacturer.

The following supplementary functions and design measures should be added according to your own risk

assessment, and must be integrated into the ride control system.

■The hydraulic locking unit must not be used as a mechanical end stop for the bar structure.

■Pay attention to the specic seat kinematics of the ride.

■The limits specied in the technical data sheets (especially the retraction and extension speeds) must

not be exceeded.

■Observe the requirements of DIN EN 13814 and the HAWE Load Case Denition.

■Protect the hydraulic locking unit against harmful environmental effects resulting from the construc-

tion of the ride or seat, such as very salty water, water containing chemical additives, or other caustic

and corrosive liquids.

■Note that if type RE is installed, an opening aid (such as a gas spring or leg spring) is required to

drive the opening motion and to keep the restraint system open.

■Note that if type DL (EX) is installed the necessary holding forces and leak-proong for locking in the

locking direction (primary function) are assured solely by valve V1.

■Note that if type DL (RE) is installed the necessary holding forces and leak-proong for locking in the

locking direction (primary function) are assured solely by valve V2.

■Monitor the emergency override button on (V1) and (V2) so that the lock cannot be released uninten-

tionally.

■The control system must ensure that the 2/2-way valve is prevented from being energized, and

thereby opening, while the ride is running.

■Observe the switching logic on page 18.

- V2 on type DL (EX) acts solely for comfort locking.

- V1 on type DL (RE) acts solely for comfort locking.

16/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

■If more than one hydraulic locking unit is installed per restraint system, the valves of all the relevant

locking units must be actuated when the restraint is opened.

■If the emergency override is used, overriding of all relevant locking units must be initiated simultane-

ously.

Operating modes ■The ride manufacturer must specify the modes for safe operation of the hydraulic locking unit within

the ride.

Aids and tools Provide the following aids, tools and materials:

■Mobile battery unit to open the hydraulic locking unit without power supply.

■Note the type-specic design of the auxiliary tool to operate the button(s) (3 and 4) of the 2/2-way

valve (= emergency override).

HAWE Hydraulik SE B 6052-21 - 11-2021 - 1.7 17/63

Function sequences Integrate the following switching logic in your ride control system.

Type V1 V2

Retract piston rod 0 -

Close and lock restraint system 0 -

Extend piston rod 1 -

EX

Opening the restraint system 1 -

Extend piston rod 0 -

Close and lock restraint system 0 -

Retract piston rod*

*Additional retraction system required (such as a gas spring)

1 -

RE

Opening the restraint system 1 -

Retract piston rod 0 1

Restraint system can be closed 0 1

Extend piston rod, piston rod movable in both directions 1 1

Opening the restraint system 1 1

DL (EX)

Restraint system locked

- for ride

- for entry and exit assist when using the comfort function

0 0

Extend piston rod 1 0

Restraint system can be closed 1 0

Extend piston rod, piston rod movable in both directions 1 1

Opening the restraint system 1 1

DL (RE)

Restraint system locked

- for ride

- for entry and exit assist when using the comfort function

0 0

*For startup and service

3.4 Markings

(1) Engraved type identifi-

er

The type identifier is engraved on the valve block of the hydraulic locking unit. The type identifier shows

the following information:

■Item number (86X-XXXX-X)

■1050 Test passed (T)

■Serial number (ZZZZ)

■Date of manufacture (year.month.day)

■Pressure P2 in bar

(2) Data matrix code The data matrix code is located on the side of the cylinder. The following information is encrypted in the

data matrix code:

■Item number

■Order number

■Serial number

■Date of manufacture

18/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

4Transport and storage

Observe the following safety instructions additionally to the safety instructions in chapter For your

safety.

CAUTION

Personal injury from tipping and falling loads

The pallet or skeleton container may tip and/or fall during transport. Hands and feet can be crushed.

►Adhere to the symbols on the packaging.

►Carefully transport the pallets or skeleton containers as near as possible to the installation location

using approved transport equipment.

►Select transport equipment that has the capacity to transport the maximum load safely.

►Wear protective clothing.

WARNING

Danger to life due to negligence when transporting the hydraulic locking unit

Damage to the gas valves on preloaded pressure vessels, or to the pressure vessels themselves, can cause

hydraulic uid or nitrogen to escape at high pressure and penetrate deep into the body via the skin and

eyes. This can lead to severe and irreparable injury, or even death.

►Transport to be carried out only by instructed personnel.

►Do not subject gas valves to any load.

►Avoid shock impact on the gas valve.

4.1 Transport equipment

Only tested and approved aids may be used.

DAMAGE

Preventing damage in transit

►Remove the hydraulic locking units individually from the packaging.

►Do not subject gas valves to any load.

►Protect gas valves for shipping by padding.

4.2 Checking the delivery

Scope of delivery: ■Assembled hydraulic locking unit lled with hydraulic uid, with a double-acting cylinder and a piston

type accumulator preloaded with nitrogen

Supplied separately by

email:

■Assembly instructions

■Product specic technical data sheet

■Product specic technical drawings

Not included: ■Aid for assembling the rod ends on the base side

■Tool to actuate the emergency release

HAWE Hydraulik SE B 6052-21 - 11-2021 - 1.7 19/63

■Fastening pins and bushings

■Electrical cables

Unpacking 1. Remove each hydraulic locking unit from the package separately:

■Hold by the rod ends.

2. Remove the packaging without scratching the piston rods.

3. Check the hydraulic locking unit for completeness and transport

damage:

■If you discover damage, refuse the delivery or accept it with

reservation.

■Note the transport damage on the transport documents or on

the forwarder’s delivery note.

4. Dispose of the hydraulic locking unit’s packaging in a manner that complies with local regulations.

DAMAGE

For any defect found, le a complaint immediately with:

HAWE Micro Fluid GmbH

Borsigstraße 11

93092 Barbing, Germany

Tel.: +49 89 379100-6000

Claims for damage compensation can only be enforced during the applicable notification periods. HAWE

will not accept any liability for retrospective claims.

4.3 Storage

DAMAGE

Property damage from incorrect storage

Incorrect storage can lead to damage. Refer to the technical data.

Store the locking unit and its individual components as follows:

■In disassembled state: Store only with the piston rod extended by 5 to 10mm.

■In installed state: Do not lock the restraint system against the locking direction.

■Store in a dry and dust-free place.

■Protect from sunlight (UV radiation) and corrosion (such as very salty water).

■Protect from mechanical damage and damp.

■Do not store near ignition and heat sources.

■Note all additional specifications by the ride manufacturer.

20/63 B 6052-21 - 11-2021 - 1.7 HAWE Hydraulik SE

This manual suits for next models

1

Table of contents

Other HAWE Hydraulik Power Pack manuals

HAWE Hydraulik

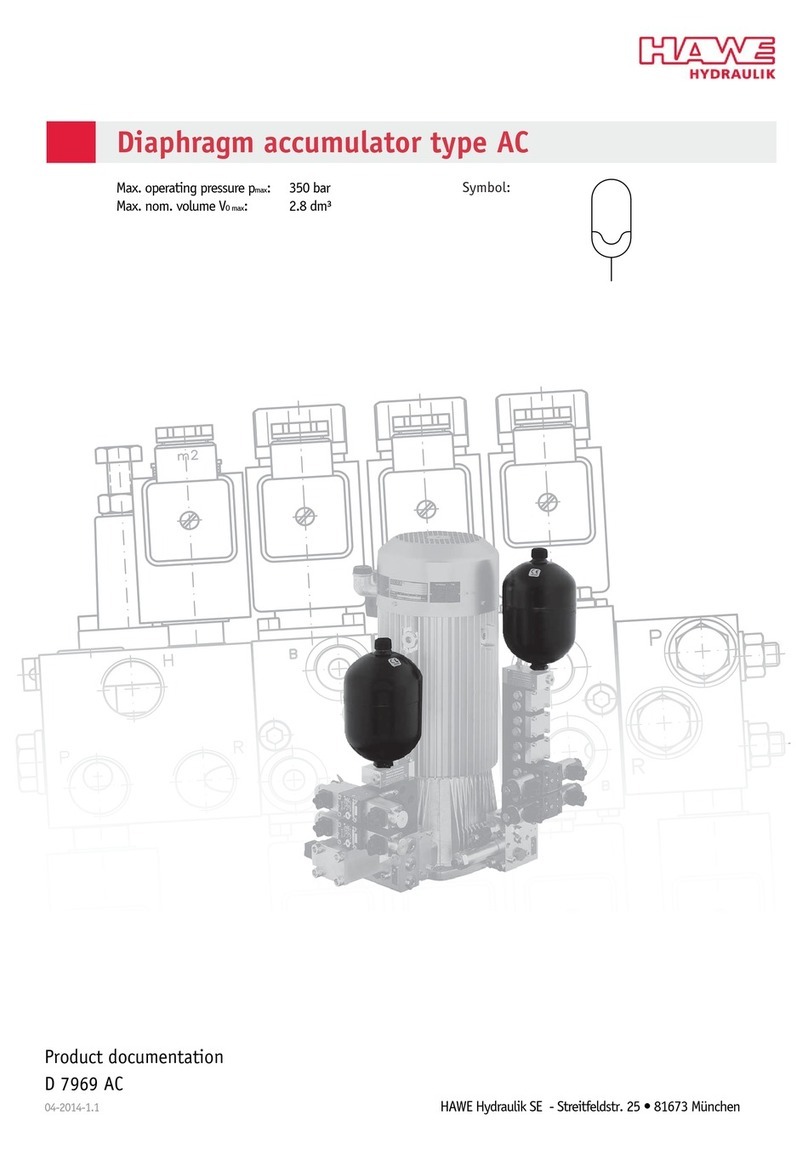

HAWE Hydraulik AC Series Operator's manual

HAWE Hydraulik

HAWE Hydraulik HR 050 User manual

HAWE Hydraulik

HAWE Hydraulik D 7969 AC Operator's manual

HAWE Hydraulik

HAWE Hydraulik HICON User manual

HAWE Hydraulik

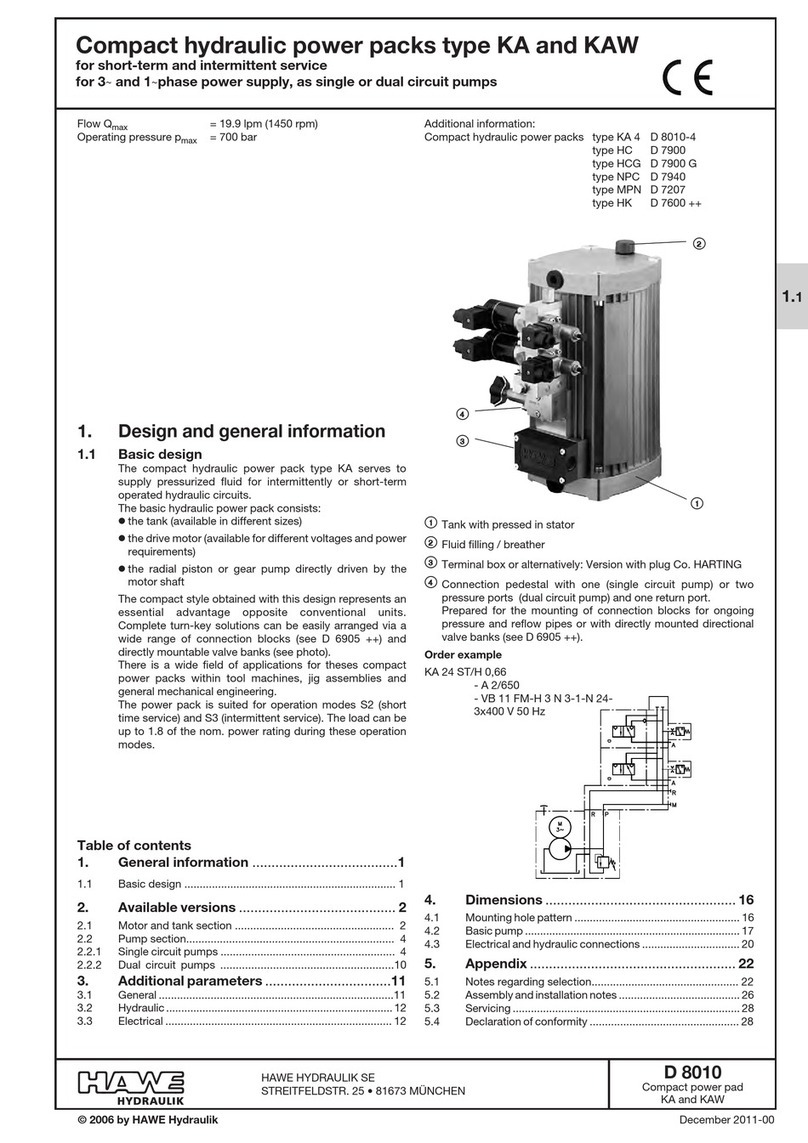

HAWE Hydraulik KA2 User manual

HAWE Hydraulik

HAWE Hydraulik A 100 User manual

HAWE Hydraulik

HAWE Hydraulik INKA 1 User manual

HAWE Hydraulik

HAWE Hydraulik KA User manual