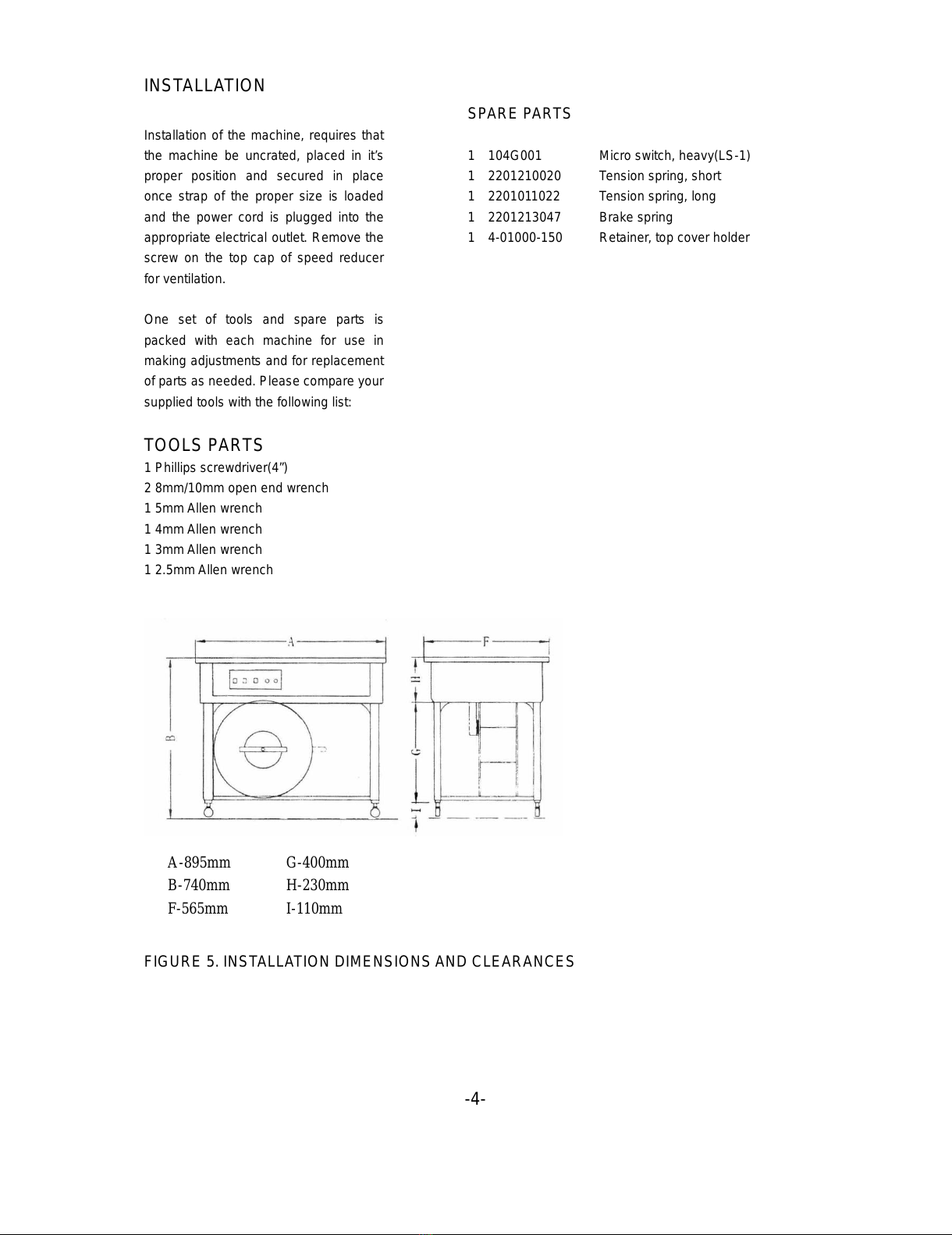

5. Replace the Plastic B and reinstall the Reel nut hand

wheel.

6. At this time the securing straps can be removed from the

coil of strap.

7. Place the dispenser assembly back into the rearend of

the machine, Make sure the assembly is placed in

properly. The Reel nut hand wheel should be positioned

to the right. This can be verified by noting that the drag

arm of the friction brake contacts the Plastic flange A.

8. When installed, close the rear panel door.

1. Open the right-hand door and pull about 3 feet (1M)of

strap from the coil.

2. Thread the strap through the looper (B), pass it under

roller (C) and allow it to exit the cabinet. Close the

right-hand door.

3. Pull up on the strap, then insert the lead-end between

the guide and roller (D).

4. Continue to push the strap through the head until it

can be seen at point (E).

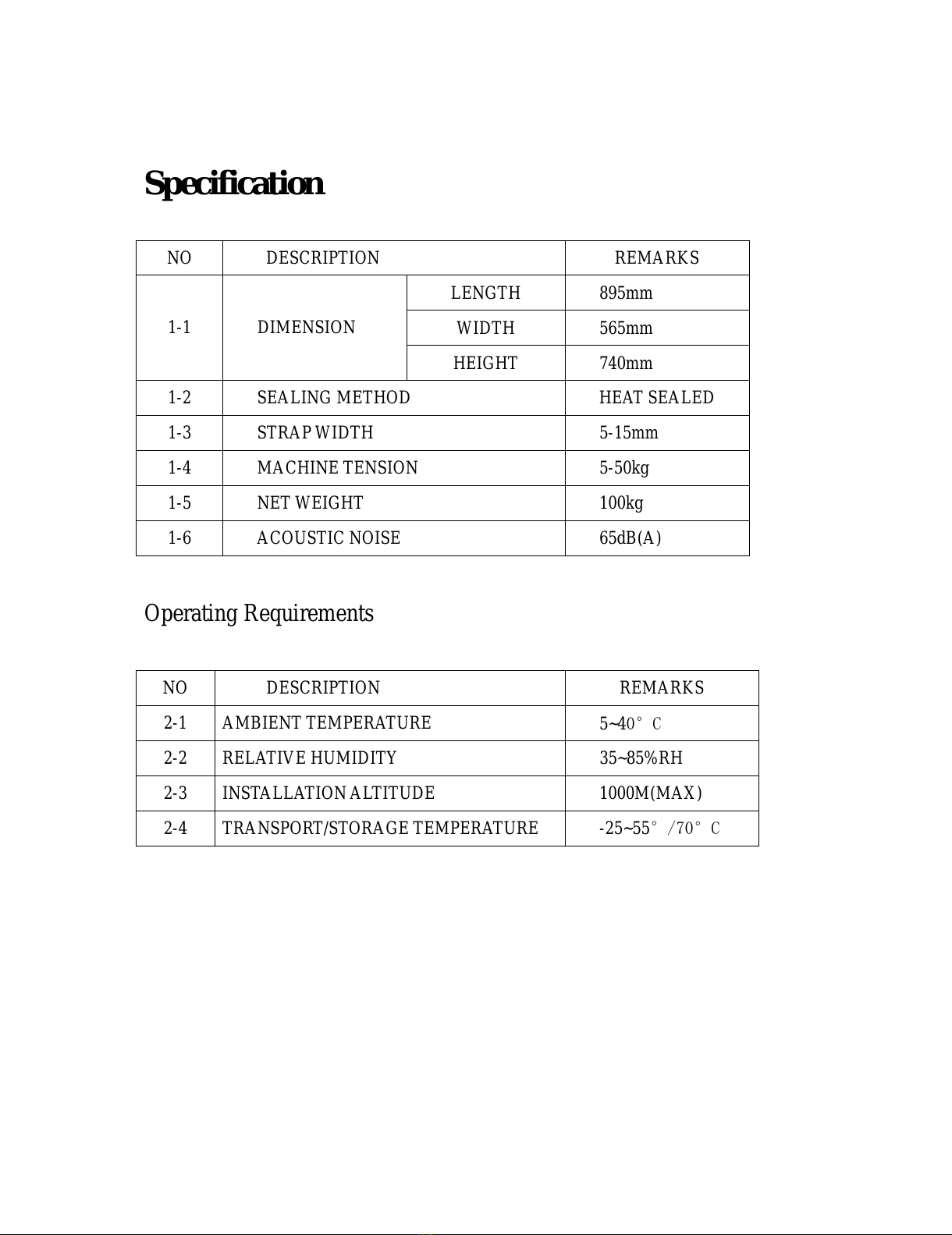

FLANGE

PLASTIC

REEL CENTER

CLAW

REEL UNT

HANDWHEEL

Y-TYPE

WASHER

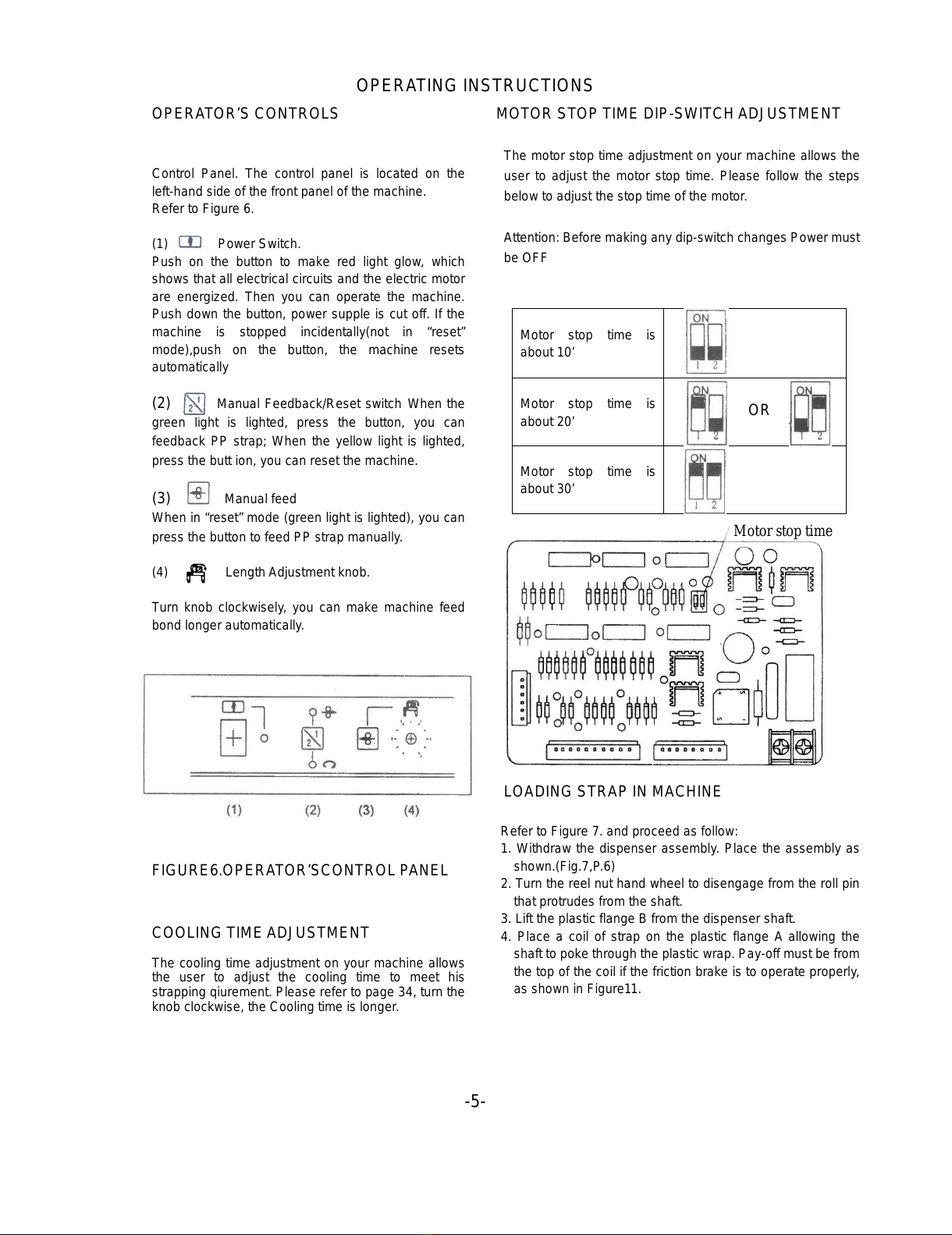

FIGURE 7. DISPENSER ASSEMBLY

DISPENSER

SHAFT

PLASTIC

FLANGEA

PIN

FIGURE 9. STRAP THREADING DIAGRAM

STRAPPING CYCLE

The machine is now ready for strapping a

package.

To operate the EXS-206, proceed as follow:

1. Push the power switch to the “NO” position and

allow the hot knife 5 seconds to reach operating

temperature.

2. Place a package on the table top, directly above

the sealing head. Allow the package to contact

the two package stops.

3. Grasp the strap on the left side on the package,

bring it over the package and insert the lead-end

into the strap closes LS1, the strap will be

tensioned, welded and then released, all

automatically. “CAUTION!!” Be sure to keep

fingers from beneath the strap.

Please follow instruction below to adjust the Reel center

claw (part NO. #4-07000-130) for various inner coils.

Refer to Fig. 8:

1. For 200mm inner coil diameter, position 2 holes on

the Reel center claw ( Item 6 ) to #1 and #3 holes of

the Plastic Flange A (Item 7).

2. For 230mm inner coil diameter, position 2 holes on

the Reel center claw ( Item 6 ) to #2 and #4 holes of

the Plastic Flange A (Item 7).

3. For 280mm inner coil diameter, position 2 holes on

the Reel center claw ( Item 6 ) to #3 and #5 holes of

the Plastic Flange A (Item 7).

FIGURE 8. THREADING STRAP THROUGH MACHINE

4. Remove the strapped package and note the

length of the strap fed out for the next cycle.

Adjust the time as needed.

5. Note the condition of the weld and the tension of

the tie on the package, If the condition of the weld

or the level of tension is unsatisfactory, adjust the

hot knife temperature or the tension level as

needed. Ref: Operating Adjustments.

The threading procedure involves routing strap from the

dispenser and up through the strapping head.

Refer to Figure 9 and proceed as follows: -6-