GRAPHTEC F-MARK2 User manual

This Guide Outlines the Key Functions for a Smooth Operation:

A- Calibrating the CCD Camera White Point using Provided Black Media

B- Calibrating and Adjusting the Cutter’s Position

C- Designing Templates for the F-MARK2

D- iMark Software Overview

A - Calibrating the CCD Camera White Point using Provided Black Media

Chapter 16: How to Calibrate the F-MARK2 ( Starting on page 37)

•Launch the iMark Software

•Manually load the black calibration sheet. While loading the sheet note the

positioning using the iMark software camera viewer window screen.

( you should only see the black sheet - nothing else should be seen)

•Initialize the CE7000 cutter making sure to select Roll 2 on the control panel

( always initialize cutter with Roll 2 )

•Adjust the blade to the thickness of the material being cut

( use loupe from the accessories kit to make ne adjustments )

Refer to Image A

•Load the blade holder on tool position one (the slot furthest back) Refer to Image B

•Set the recommended Force Settings between 9-12, depending on media.

F-MARK2

Key Functions & Simplied Operation For Smooth Workow

This quick guide works best when the following has been completed:

• Basic installation of the F-MARK2 unit as outlined in the User’s Manual instructions

•

Installation of the latest version of iMark Plus Software available for downloading at:

www.graphtecamerica.com/software

The User’s Manual for the machine & software will guide you through the complete process.

Please note that the Setup User’s Manual also covers a Troubleshooting Section, so in the

event you run into issues, please refer to the manual before contacting Technical Support.

Graphtec also provides helpful Video Training Videos for the F-MARK2 on our website.

Click on the QR Code below or view the tutorials at www.graphtecamerica.com/videos

SIMPLIFIED BASIC OPERATION WORKFLOW

The CE7000 will cut a small square. Peel o the square from the sheet.

You should be left with a square cut showing the white liner.

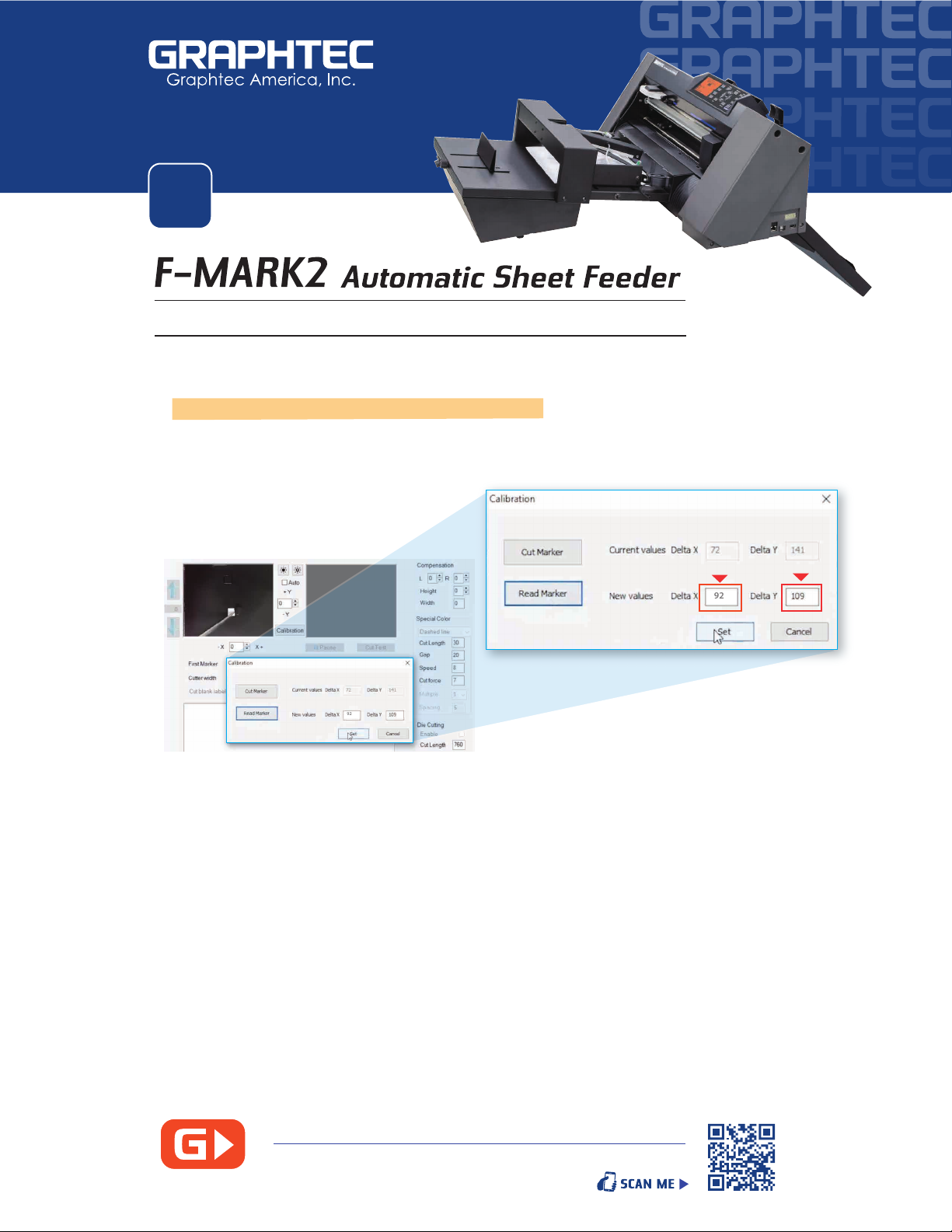

Go back in the iMark Software and click Read Marker.

Once completed, the Delta X should read a value between 90 -120

while the Delta Y box should read a value between 95 - 135.

Conrm the values by clicking on Set , Then click on the Xto Exit,

The X and Y values you input will be saved to the computer .

( If the values are dierent, repeat calibration. Also, make sure you have sucient lighting )

NOTE: Camera calibration will need to be performed every time changes occur.

When the computer is shut o, when the F-MARK2 is disconnected from

the USB port or if the software stops communicating.

1

2

This Guide Outlines the Key Functions for a Smooth Operation:

A- Calibrating the CCD Camera White Point using Provided Black Media

B- Calibrating and Adjusting the Cutter’s Position

C- Designing Templates for the F-MARK2

D- iMark Software Overview

A - Calibrating the CCD Camera White Point using Provided Black Media

Chapter 16: How to Calibrate the F-MARK2 ( Starting on page 37)

•Launch the iMark Software

•Manually load the black calibration sheet. While loading the sheet note the

positioning using the iMark software camera viewer window screen.

( you should only see the black sheet - nothing else should be seen)

•Initialize the CE7000 cutter making sure to select Roll 2 on the control panel

( always initialize cutter with Roll 2 )

•Adjust the blade to the thickness of the material being cut

( use loupe from the accessories kit to make ne adjustments )

Refer to Image A

•Load the blade holder on tool position one (the slot furthest back) Refer to Image B

•Set the recommended Force Settings between 9-12, depending on media.

Key Functions & Simplied Operation For Smooth Workow

This quick guide works best when the following has been completed:

• Basic installation of the F-MARK2 unit as outlined in the User’s Manual instructions

•

Installation of the latest version of iMark Plus Software available for downloading at:

www.graphtecamerica.com/software

The User’s Manual for the machine & software will guide you through the complete process.

Please note that the Setup User’s Manual also covers a Troubleshooting Section, so in the

event you run into issues, please refer to the manual before contacting Technical Support.

Graphtec also provides helpful Video Training Videos for the F-MARK2 on our website.

Click on the QR Code below or view the tutorials at www.graphtecamerica.com/videos

SIMPLIFIED BASIC OPERATION WORKFLOW

Image A Image B

The CE7000 will cut a small square. Peel o the square from the sheet.

You should be left with a square cut showing the white liner.

Go back in the iMark Software and click Read Marker.

Once completed, the Delta X should read a value between 90 -120

while the Delta Y box should read a value between 95 - 135.

Conrm the values by clicking on Set , Then click on the Xto Exit,

The X and Y values you input will be saved to the computer .

( If the values are dierent, repeat calibration. Also, make sure you have sucient lighting )

NOTE: Camera calibration will need to be performed every time changes occur.

When the computer is shut o, when the F-MARK2 is disconnected from

the USB port or if the software stops communicating.

2

This Guide Outlines the Key Functions for a Smooth Operation:

A- Calibrating the CCD Camera White Point using Provided Black Media

B- Calibrating and Adjusting the Cutter’s Position

C- Designing Templates for the F-MARK2

D- iMark Software Overview

A - Calibrating the CCD Camera White Point using Provided Black Media

Chapter 16: How to Calibrate the F-MARK2 ( Starting on page 37)

•Launch the iMark Software

•Manually load the black calibration sheet. While loading the sheet note the

positioning using the iMark software camera viewer window screen.

( you should only see the black sheet - nothing else should be seen)

•Initialize the CE7000 cutter making sure to select Roll 2 on the control panel

( always initialize cutter with Roll 2 )

•Adjust the blade to the thickness of the material being cut

( use loupe from the accessories kit to make ne adjustments )

Refer to Image A

•Load the blade holder on tool position one (the slot furthest back) Refer to Image B

•Set the recommended Force Settings between 9-12, depending on media.

Key Functions & Simplied Operation For Smooth Workow

This quick guide works best when the following has been completed:

• Basic installation of the F-MARK2 unit as outlined in the User’s Manual instructions

•

Installation of the latest version of iMark Plus Software available for downloading at:

www.graphtecamerica.com/software

The User’s Manual for the machine & software will guide you through the complete process.

Please note that the Setup User’s Manual also covers a Troubleshooting Section, so in the

event you run into issues, please refer to the manual before contacting Technical Support.

Graphtec also provides helpful Video Training Videos for the F-MARK2 on our website.

Click on the QR Code below or view the tutorials at www.graphtecamerica.com/videos

SIMPLIFIED BASIC OPERATION WORKFLOW

The CE7000 will cut a small square. Peel o the square from the sheet.

You should be left with a square cut showing the white liner.

Go back in the iMark Software and click Read Marker.

Once completed, the Delta X should read a value between 90 -120

while the Delta Y box should read a value between 95 - 135.

Conrm the values by clicking on Set , Then click on the Xto Exit,

The X and Y values you input will be saved to the computer .

( If the values are dierent, repeat calibration. Also, make sure you have sucient lighting )

NOTE: Camera calibration will need to be performed every time changes occur.

When the computer is shut o, when the F-MARK2 is disconnected from

the USB port or if the software stops communicating.

•

•

•

•

•

•

3

In the iMark Plus Software, click on the Calibration Button

( be careful not to have the Dashed Line enabled )

Calibration windows will display two options: Cut Marker or Read Marker

Click on Cut Marker

92

92

Calibrating the CCD Camera White Point

CLICK HERE or use QR CODE view STEP by STEP video

SIMPLIFIED BASIC OPERATION WORKFLOW

B -

The User’s Manual suggests using the provided X- Y Calibration Sheet for adjustments.

To increase accuracy, it also suggests using the current job to perform the calibration

• Turn on the Power for the CE7000 Cutter.

- Open iMark software,

- Feed a printed job into the cutter and align it with the rst registration mark.

(closest to leading edge) going into the cutter rst.

- Check camera in software to position rst marker in the middle of the screen.

- Position the right roller accordingly and bring rollers down to help hold.

- Using this sheet position, align the feeder and side alignment guides

• After aligning the feeder remove the sheet and place on feeder.

- Adjust rear media guide

- Position blower fans

- Initialize cutter

- Open cut job

•Enter rst marker value

- Perform a cut test to start calibration allowing cutter to make at least 2 cuts.

- Pause the cutter ( press PAUSE button on cutter)

- Clear the job on the control panel

•Unload the sheet,

- Check the cutting results

- Using calibration sheet as reference, adjust X/Y position.

- Adjust force if necessary

- Load the sheet again and retry until calibrated.

•Once calibrated you are ready to proceed with your loaded job.

•Refer to the User’s Manual for further explanation if needed

CLICK HERE or use QR CODE view STEP by STEP video

4

Calibrating & Adjusting the Cutter Position

SIMPLIFIED BASIC OPERATION WORKFLOW

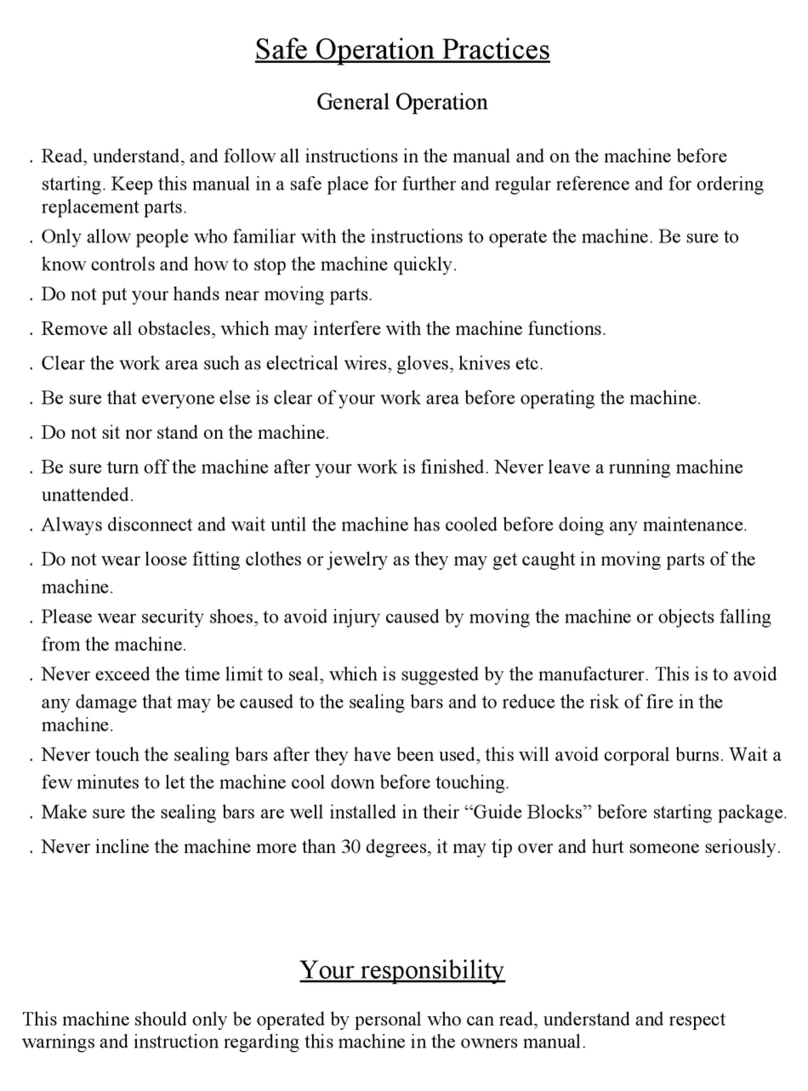

C - Designing Templates for the F-MARK2

5

Design Orientation must be Landscape for 11”x17”- 12”x18” - 13”x19”

Design Orientation must be Portrait for 8.5“x11” - 8.5”x14”

Leading Edge and Feeding Direction is always RIGHT to LEFT

Registration Mark Parameters

A. Two Registration Marks are required along the bottom or Lower Edge of the media.

B. Registration Marks are 4mm Black Squares

C. Distance from the Leading Edge to First Registration Mark is a minimum of 40mm

D. Distance from Trailing Edge to Second Registration Mark is a minimum of 20mm

E. Distance from Lower Edge of media to Registration Marks is a minimum of 6mm

Cutting Parameters

1. Minimum distance from leading edge to cut line depends on the cut:

a. Kiss Cut (Half Cutting) minimum 20mm (30mm is recommended)

b. Perf Cut ( Dashed Line) minimum 25mm (35m is recommended)

2. Minimum distance from the Trailing Edge is 5mm (15mm is recommended)

3. Minimum distance from Top Edge of media to cut line is 5mm (15mm is recommended)

4. Minimum distance from Lower Edge of media to graphics is 15mm (or 5mm from crop marks)

FEEDING DIRECTION

FEEDING DIRECTIONFEEDING DIRECTION

Leading Edge

Lower Edge

Trailing Edge

1st Registration Mark 2nd Registration Mark

SIMPLIFIED BASIC OPERATION WORKFLOW

Application Terminology

Half Cut or Kiss Cut:

Cutting to the liner of adhesive media.

Controlled in Section 4 of the iMark Software

Dashed Line:

Cutting all the way through the media.

Controlled in Section 8 of the iMark Software. See Pg. 24-25 of Software User’s Manual.

Special Color:

Magenta lines will always be cut rst. For jobs with both crease and dashed lines,

creases indicated with Magenta color will be cut rst, then the dashed lines.

Controlled in Section 7 of the iMark Software. See Pg. 26 of Software User’s Manual

6

To make things easier, the iMark Software panel is broken down into

dierent sections for each function. See Pg. 1 of Software User’s Manual

Current camera view

Last camera shot

Calibration commands

Common commands area

Preview area

Status display bar

Dashed line panel

Compensation

Mechanical movement of unit

Other Functions

12

3

4

5

6

7

8

9

10

11

D - iMark Software Overview

Special color panel

(Active when les contain magenta lines)

Table of contents

Popular Packaging Equipment manuals by other brands

Fromm

Fromm TP-601D1 Operation manual & spare parts list

XtraVac

XtraVac 860A8 Safe Operation Practices

siat

siat F1 Instruction manual and spare parts list

Pregis

Pregis Quantum Pro 4068969 user manual

Atlanta Attachment Company

Atlanta Attachment Company 1390BX Technical Manual & Parts Lists

Minipack-Torre

Minipack-Torre RP40 Installation, operation and maintenance