USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

9

Pool Chemistry

The table below summarizes the levels that are recommended by The Association of Pool and Spa

Professionals (APSP). It is important to maintain these levels in order to prevent corrosion or scaling

and to ensure maximum performance from your AQR100 chlorine generator. Your authorizedAQR100

dealer or most pool stores can provide you with the chemicals and procedures to adjust the water

chemistry as well.

Note that pool water emanating from wells and municipal water supplies, along with the introduction

of environmental contaminants, can contain chemistries that are deleterious to the life expectancy

of the Cell.

Salt 1500 to 4500 ppm (3200 ideal)

Free Chlorine 1.0 to 3.0 ppm

pH 7.2 to 7.8

Cyanuric Acid

(Stabilizer) Outdoor Pools 30-50 ppm

Indoor Pools - 0 ppm

Total Alkalinity 80 to 120 ppm

Calcium Hardness 200 to 400 ppm

Metals 0 ppm

Saturation Index -.2 to .2 (0 best)

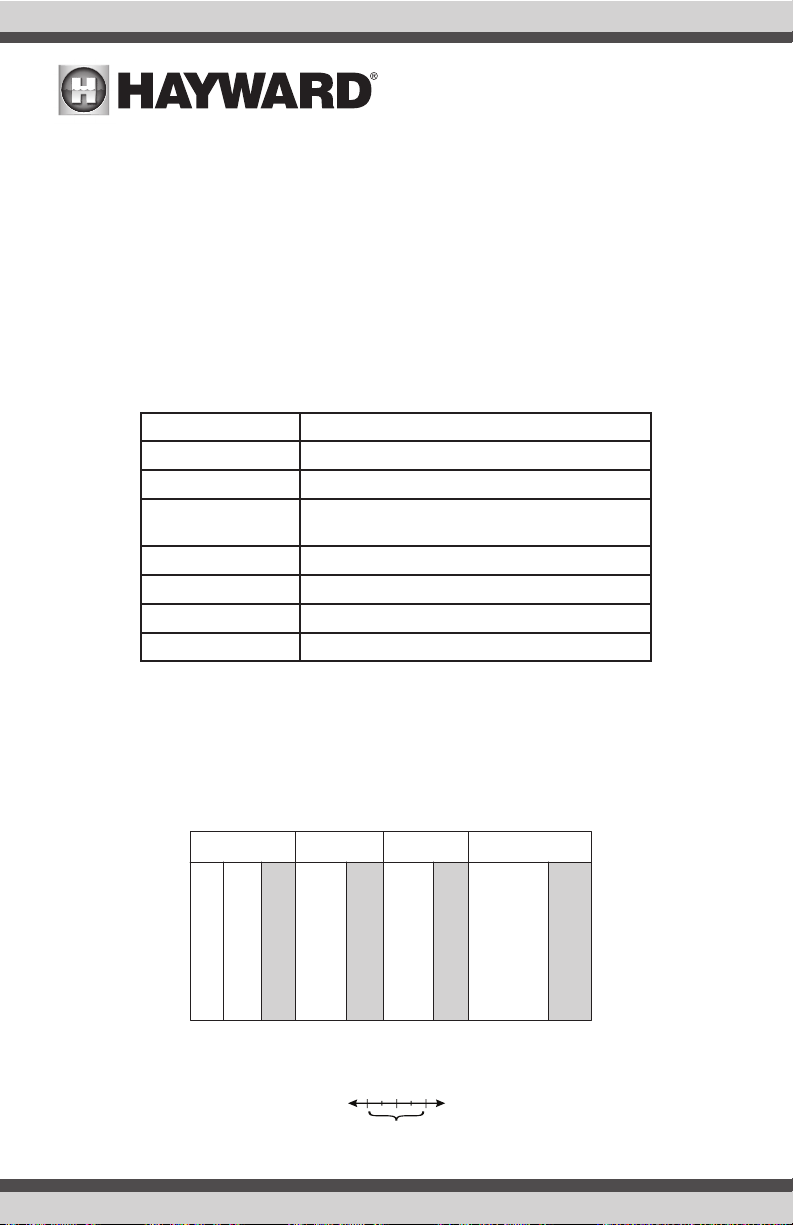

Saturation index

The saturation index (Si) relates to the calcium and alkalinity in the water and is an indicator of the

pool water “balance”. Your water is properly balanced if the Si is 0 ± 0.2. If the Si is below -0.2,

the water is corrosive and plaster pool walls will be dissolved into the water. If the Si is above +0.2,

scaling and staining will occur. Use the chart below to determine the saturation index.

Si = pH + Ti + Ci + Ai - TDS

Hardness

Calcium

75

100

125

150

200

250

300

400

600

800

Total Dissolved

Solids

Total

alkalinity

°C °F Ti Ci Ai TDS

12

16

19

24

29

34

39

53

60

66

76

84

94

102

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.5

1.6

1.7

1.8

1.9

2.0

2.1

2.2

2.4

2.5

75

100

125

150

200

250

300

400

600

800

1.9

2.0

2.1

2.2

2.3

2.4

2.5

2.6

2.8

2.9

0-1000

1001-2000

2001-3000

3001-4000

4001-5000

12.10

12.29

12.35

12.41

12.44

Use: Measure the pH of the pool water, the temperature, water hardness, total alkalinity,

and total dissolved solids. Use the table above to determine Ti, Ci, Ai, and TDS in the

formula shown above. If the Si is equal to 0.2 or more, stains may appear. If the Si is

equal to -0.2 or less, corrosion or deterioration may occur.

Corrosion Stain

Ok

-0.2 0.2

CHEMICAL IDEAL LEVELS