HB Products HBPH-MK2 User manual

INSTRUCTION MANUAL

HBPH-MK2 –pH sensor

Suited for brine/NH3 Leakage detection

DIFFERENTIAL 2-WIRE (4-20 mA) pH Sensor

TABLE OF CONTENTS

General Information ......................................................................................................................................................................2

Specifications .................................................................................................................................................................................2

Installation .....................................................................................................................................................................................3

Cold Liquid applications.................................................................................................................................................................3

Electrical connection......................................................................................................................................................................4

Storage...........................................................................................................................................................................................4

Maintenance and calibration.........................................................................................................................................................4

Calibrating the Sensor....................................................................................................................................................................5

Checking the Sensor.......................................................................................................................................................................5

Probe Cleaning...............................................................................................................................................................................6

Replacement of Salt Bridge............................................................................................................................................................7

Troubleshooting.............................................................................................................................................................................7

Parts and Accessories ....................................................................................................................................................................8

Sensor Return ................................................................................................................................................................................8

Further Information.......................................................................................................................................................................8

Included in the package

•Sensor with cable

•Replacement salt bridge

•Liquid for flushing and

filling

Salt bridge kit

Instructional manual- HBPH-MK2 –UK-004 Page 2

General Information

This manual covers HBPH sensor for pH measurement in brine.

The HBPH sensor features differential design for long lifetime, user serviceability and more accurate readings. In

typical installations these probes will last for years whereas the more common combination probe lasts only

months.

The sensor is a 2-wire device. It incorporates an encapsulated transmitter that outputs a 4-20 mA analog signal. It

is designed to connect directly to a PLC.

The output from a two-wire transmitter type is non-isolated and un-calibrated. The system must provide 24 VDC,

with the “low” input isolated from earth ground, and a means of calibrating for offset and span.

NOTE: Do not discard the protective cap that came with the sensor. If the sensor is removed from the process for

a longer period, thoroughly clean the sensor, put a piece of cotton ball with a few drops of water into the

protective cap and place it on the sensor. This keeps the junction from drying out which causes slow response

when the sensor is put back into operation or causes permanent damage to the sensor. Sensors should not be

left in dry lines or empty vessels for longer periods of time.

Do not store the sensor in a dry or humid location. When storing, check the protective cap regularly to make sure

the cotton ball remains moist. Improper storage of sensors voids the warranty.

Specifications

HBPH-2W-9-MKLT

Measurement Range

0 to 14.00 pH

Wetted Materials

Ryton®(PPS), glass, ceramic, titanium, Viton

Ambient Temperature

-15…+50°C

Liquid Temperature

-15…+95°C

Stability

0.03 pH/day

Resolution

0.01 pH

Sensitivity

< 0.005 pH

Output Span

1.14 mA/pH

Output Offset

12±1.0 mA @ pH 7

Mounting

1” NPT

Max. Flow Rate

3,0 m/sec (10 ft/sec)

Maximum Load

450 Ω

Temperature Limits

6,9 barg (100 psig) @ 65 °C, 2,75 barg (40 psig) @ 95°C

Power Supply Limit

24±4 VDC

Cable

4.6 m (15 ft)

Instructional manual- HBPH-MK2 –UK-004 Page 3

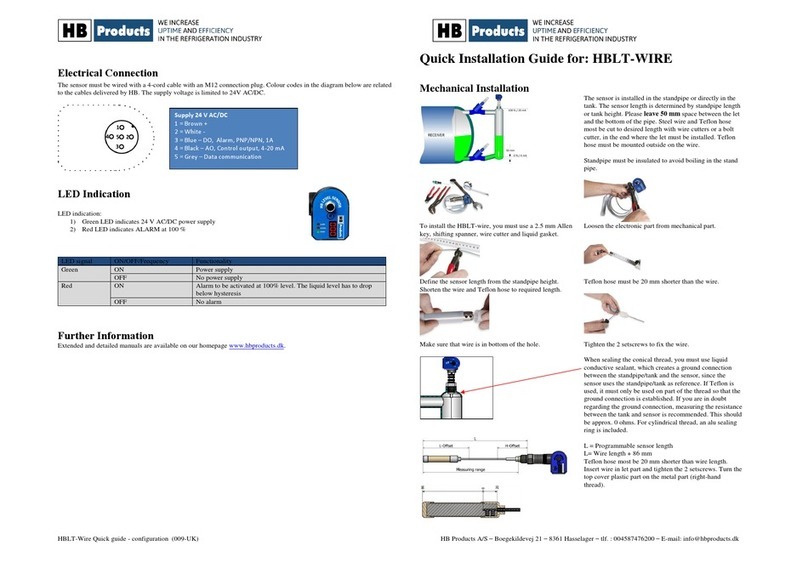

Installation

General Instructions

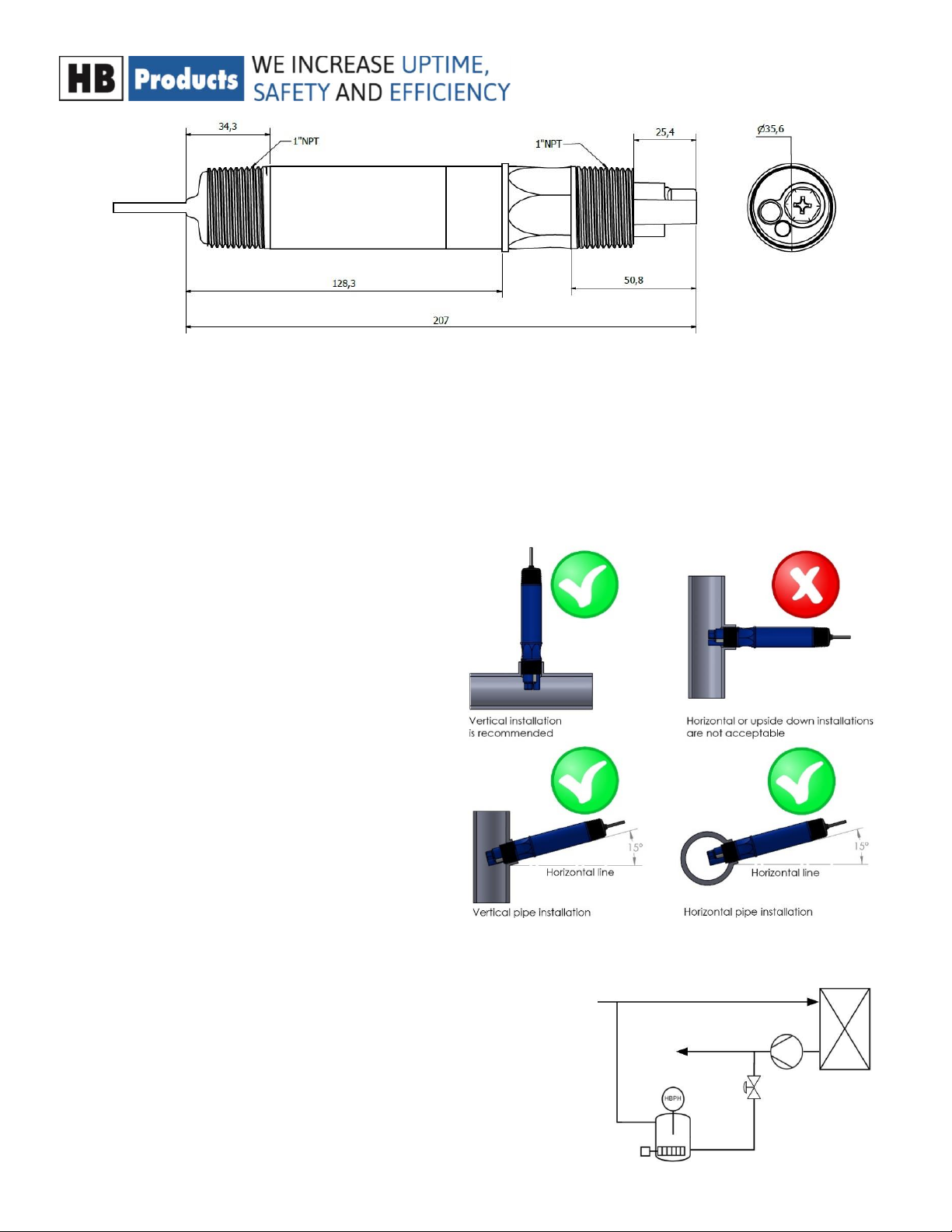

1. If the distance between the probe and the instrument is such that a direct connection is not

possible, the probe cable should be routed to a junction box with a terminal strip. The box should

be well sealed and away from corrosion danger. Be sure that you have enough slack cable to allow

for probe removal for calibration and servicing.

2. Route the interconnect cable from the

junction box to the instrument,

preferably in metal conduit. Do not run

the power cable or control cables in the

same conduit with the probe

interconnect cable.

3. Remove the protective plastic cap from

the end of the probe before placing in

service.

4. The sensor must be installed in direct

contact with the brine to be able to

measure the pH value. The preferred

mounting is from vertical and down to at

least 15° above horizontal. Trapped air

will disturb the measurement and must

be avoided

Cold Liquid applications

If there is a risk for brine temperatures falling below -15 °C, we

recommend using an additional system where a small amount

brine is bypassed into a pot with a built-in heating element and

thermostat controlling the temperature in a range of 0 to + 10°C .

Instructional manual- HBPH-MK2 –UK-004 Page 4

Electrical connection

HBPH probes have two wires: black and red. The red wire is to be connected to the +24 VDC terminal and

the black wire to the 24 VDC common terminal via the load in the loop.

Storage

1. Do not discard the protective cap that came with the sensor. If the sensor is removed from the

process for longer periods of time, thoroughly clean the sensor, put a piece of cotton ball with a

few drops of water into the protective cap and place it on the sensor with tape, this keeps the

junction from drying out which causes slow response when put back into operation or causes

permanent damage to the sensor. Sensors should not be left in dry lines or empty vessels for

longer periods of time.

2. Do not store the sensors in a dry or humid location. When storing, check the protective cap

regularly to make sure the cotton ball remains moist. Improper storage of sensors voids the

warranty.

Maintenance and calibration

The maintenance needed depends on your application and especially the accuracy required.

Precise measurement

If you use the sensor for a precise measurement of the pH value, you need frequent checks of the

calibration. The drift of the sensor is maximum 0.03pH per day but that is the maximum figure for a sensor

in high or low pH environments. Significant lower drift can be expected in neutral environments. Your

sensor verification frequency must reflect your needed accuracy.

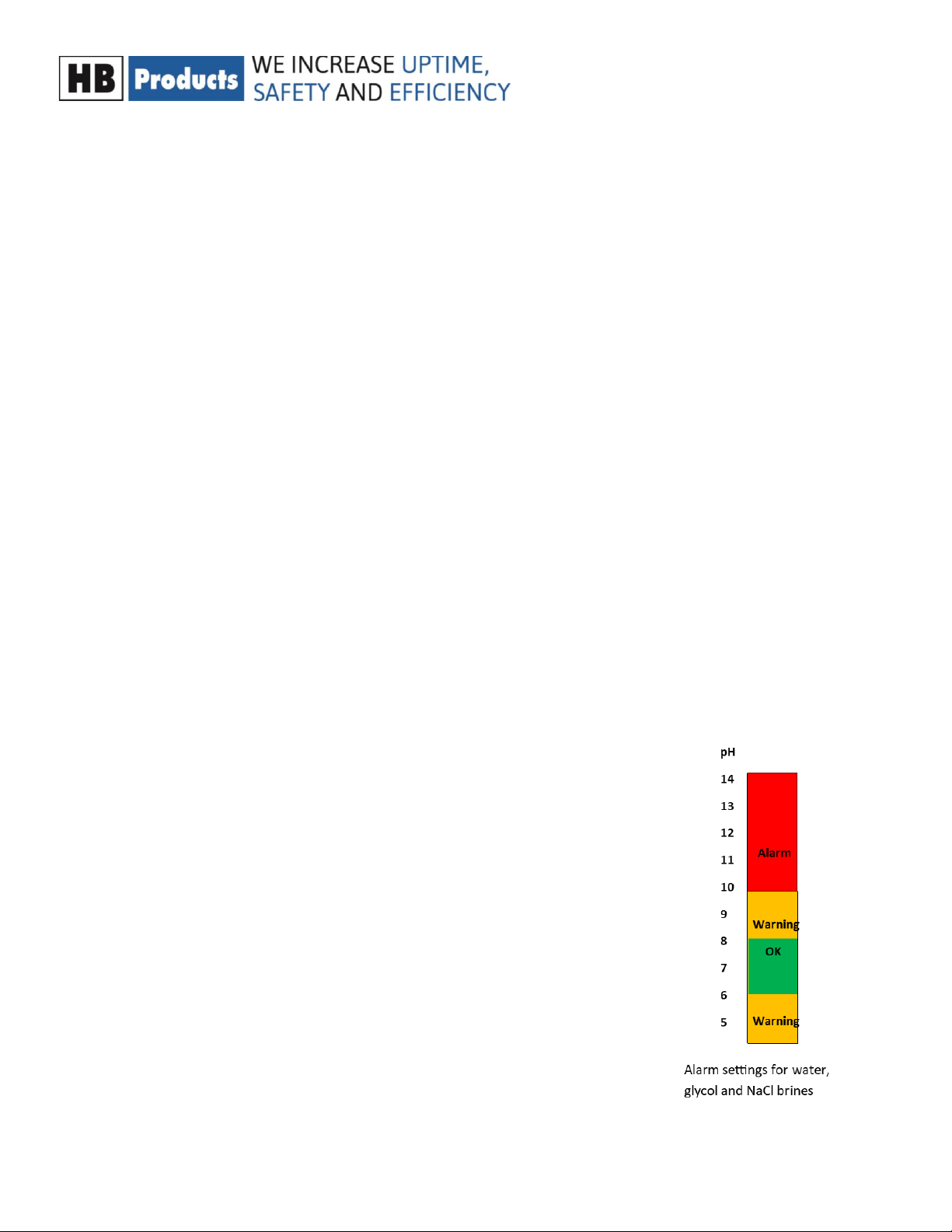

Leakage detection

When used for leakage detection the required accuracy is low and annual or

biannual checks should be sufficient, especially when a warning is used. For

brines with a pH value between 6 and 8 it is easy to detect ammonia. Leakage of

1ml/l will increase the pH value from 7 to 10. Brines using NaCl or glycols will

have a pH value like water around 7 and they can be set up with a dual level

warning/alarm system.

A dual level warning /alarm system contains a warning level at which you need

to check your sensor calibration and a second level where you stop due to

leakage. If you have a base pH value of 7 it will make sense to use a warning for

pH above 8 and pH below 6. The second level can then be an alarm at pH=9.

With such a system it is not necessary to make frequent checks and calibrations,

however we recommend an annual or biannual check of the calibration.

Instructional manual- HBPH-MK2 –UK-004 Page 5

Calibrating the Sensor

When you receive your sensor, it is not calibrated which is needed to provide a precise result. The sensor

calibration is made in the PLC, PC, display or were you translate your mA signal into a pH value. So, the

calibration is in principle a formula which calculate your pH value based on the mA signal. The parameters

in the formula are based on measurements done with two well-known solutions. Two pH buffer solutions,

7 pH and either 4 pH or 10 pH, and a DC milliammeter are required. The calculations below are done with

pH 7 and pH 10. The process is similar for other buffer pH values.

1. Disconnect the red wire at the instrument or power supply and connect it to the multimeter (-)

black.

2. Connect the multimeter (+) red to the instrument or power supply red wire output terminal.

3. Rinse the probe and place it in 7 pH buffer solution. Allow the temperature of the buffer and probe

to stabilize at room temperature.

4. Write down the reading on the multimeter as mApH7 (in the example called: ”mApH7”). The

reading should be between 11 and 13 mA. If not, the probe is defective, or the salt bridge needs to

be replaced

5. Rinse the probe and place it in 10 pH buffer solution. Allow the temperature of the buffer and

probe to stabilize at room temperature.

6. Write down the reading on the multimeter as mApH10 (in the example called: ”mApH10”).

7. Reinstall

The pH value is calculated using this formula: pH= K * mA signal + C

Example:

The two constants can be calculated like this for 7 and 10 pH solutions:

The noted currents for the two solutions in the example are: mApH7 =11.08mA and mApH10=14.47mA

K = (pH value1-pH value2) / (mApH7 - mApH10) =7 - 10 / 11.08 - 14.47 = -3/-3.39 =0.885

C = pH value1 - K* mApH7 = 7 –0,885 *11.08 = - 2.81

The formula looks like this: pH = 0.885 * mA signal - 2.81

Checking the Sensor

The operation of the 2-wire, 4-20 mA sensor can be checked by a few simple measurements. Two pH buffer

solutions, 7 pH and either 4 pH or 10 pH, and a DC milliammeter are required.

Instructional manual- HBPH-MK2 –UK-004 Page 6

1. Disconnect the red wire at the instrument or power supply and connect it to the multimeter (-)

black.

2. Connect the multimeter (+) red to the instrument or power supply red wire output terminal.

3. Rinse the probe and place it in 7 pH buffer. Allow the temperature of the buffer and probe to

stabilize at room temperature.

4. Check the offset of the probe by reading the multimeter. The reading should be between 11 and

13 mA. If not, the probe is defective, or the salt bridge needs to be replaced. If the offset is OK,

please note the exact reading and proceed to the next step.

5. Rinse the probe and place it in 4 pH or 10 pH buffer. Allow the temperature of the probe and

buffer to stabilize at room temperature. Now check the span of the probe by reading the

multimeter. If the probe is in 4 pH buffer, the reading should be between 2.75 and 3.5 lower than

the reading obtained in 7 pH buffer.

6. If the probe is in 10 pH buffer, the reading should be between 2.75 and 3.5 higher than the reading

obtained in 7 pH buffer.

7. If this test is not satisfied the probe is defective, or the salt bridge needs to be replaced.

8. If the span of the probe drops below 2.75mA than the probe still can be used. Adjustments will

have to be made to the receiving device to compensate for the low span.

Probe Cleaning

The probe should be kept reasonably clean to avoid measurement errors. Frequency of cleaning can only

be determined by experience. To clean proceed as follows:

1. Rinse with clean warm water.

2. Soak the end of the probe in warm water and dish detergent for 3 or 4 minutes.

3. Brush the end of the probe, particularly the three electrodes with a soft bristle brush such as a

toothbrush. Take care not to scratch the glass electrode.

4. If the probe is still not clean, it may have to be cleaned with acid. CAUTION: Do not acid clean

probes used in processes containing cyanide solutions. Some experimentation may be required to

determine the most suitable acid for your process. Use the most dilute acid, which is effective.

Normally 10 parts of water to one-part muriatic acid (HCl) is sufficient. Do not use hydrofluoric

acid.

5. Soak the probe for not more than 5 minutes in the chosen acid; then rinse thoroughly with clean

warm water and soak in water for 3-5 minutes.

6. Calibrate the system in accordance with the instrument instruction manual.

Instructional manual- HBPH-MK2 –UK-004 Page 7

Replacement of Salt Bridge

1. If the system cannot be calibrated after cleaning the probe, it may be necessary to replace the

standard cell solution and/or the salt bridge. A salt bridge kit is available from HB Products for this

purpose.

2. Hold the probe vertically electrodes up. Remove the used salt bridge. The salt bridge is a

hexagonal-shaped capsule that can be removed using a #3 Phillips screwdriver. ½” wrench or pliers

can also be used.

3. Discard the used salt bridge.

4. Dispose of the used solution inside the bridge chamber and rinse with pH 7 solution or distilled

water.

5. Refill the chamber with a reference solution supplied with the salt bridge, up to the tip of the

electrode inside the chamber. DO NOT OVERFILL. It is important to leave space for the salt bridge

thread and a small amount of air.

6. Screw the new salt bridge into the cavity until finger tight. If needed, use a #3 Phillips screwdriver

to make sure that the salt bridge edges are aligned with the front of the probe face.

Troubleshooting

A sensor that is not functioning properly will output a current that is out of range of the specifications

listed in Checking Sensor section.

The change in output with calibration standard constitutes the span. For a pH probe, the span between

pH 4 and pH 7 or between pH 7 and pH 10 should be between 2.75 and 3.5 mA.

Instructional manual- HBPH-MK2 –UK-004 Page 8

Issue:

Likely cause:

Troubleshooting:

The output of the sensor DOES

change between pH buffers but not

as good (quick) as it should (or did)

before.

Span less than 0.9mA/pH

The process electrode (glass bulb) is

coated with scaling or biofouling

A coated electrode will create a

narrower span

If the coating is from scaling then soaking the

probe in a weak acid (e.g. vinegar or 0.1M

HCl) will remove the scale. If the coating is

from fouling then soaking the probe in

bleach will clear it.

The offset is outside of spec:

11mA > pH7 > 13mA

The reference solution has been

contaminated with the process or

the salt bridge has fouled

Salt bridge replacement is needed

The pH reading DOES NOT change

at all when changing from one

calibration solution to another

The process electrode is inoperable

(likely cracked or broken) or the

printed circuit board (PCB) has

failed

Sensor is non-repairable

The output is outside of 4-20mA

The sensor electronic has failed

Sensor is non-repairable

Parts and Accessories

Description

Part #

3-pack salt bridge replacement kit

HBPH-SB-KIT

Controller for pH Sensor

HBPH-C1

Controller for pH Sensor

HBPH-C1-ENC

Sensor Return

If you are returning a probe for inspection, enclose description of the problem. Pack the probe adequately

to avoid damage to the glass electrode and ensure that it will not be exposed to temperatures below -15°C.

HB Products cannot be responsible for shipping damage or for damage due to frozen electrodes. For safety

reasons, HB Products cannot accept probes which have not been thoroughly cleaned to remove all process

material and put a piece of cotton ball with a few drops of water into the protective cap and place it on the

sensor with tape to prevent it from drying out.

Further Information

For further information, please visit our website, www.hbproducts.dk, or send an email to: s[email protected]k.

HB Products A/S –Bøgekildevej 21 –DK8361 Hasselager –support@hbproducts.dk –www.hbproducts.dk

This manual suits for next models

2

Table of contents

Other HB Products Accessories manuals

HB Products

HB Products HBLT User manual

HB Products

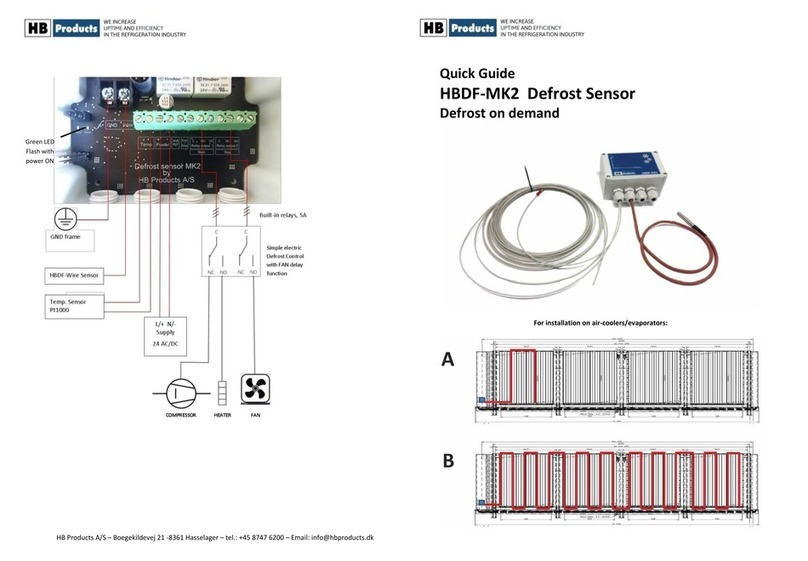

HB Products HBDF User manual

HB Products

HB Products HBLC User manual

HB Products

HB Products HBCP User manual

HB Products

HB Products SLCD-M1/_Ex Series User manual

HB Products

HB Products HBIB Use and care manual

HB Products

HB Products HBOC User manual

HB Products

HB Products HBX Vapor Quality sensor Operator's manual

HB Products

HB Products HBLT-WIRE User manual

HB Products

HB Products HBDF-MK2 User manual