HB Products A/S –

www.hbproducts.dk –

[email protected] – tel.: +4587476

00

Quick guide – HBLC – rev. 001-

01

In order to set the control parameters the HB configuration tool is

needed

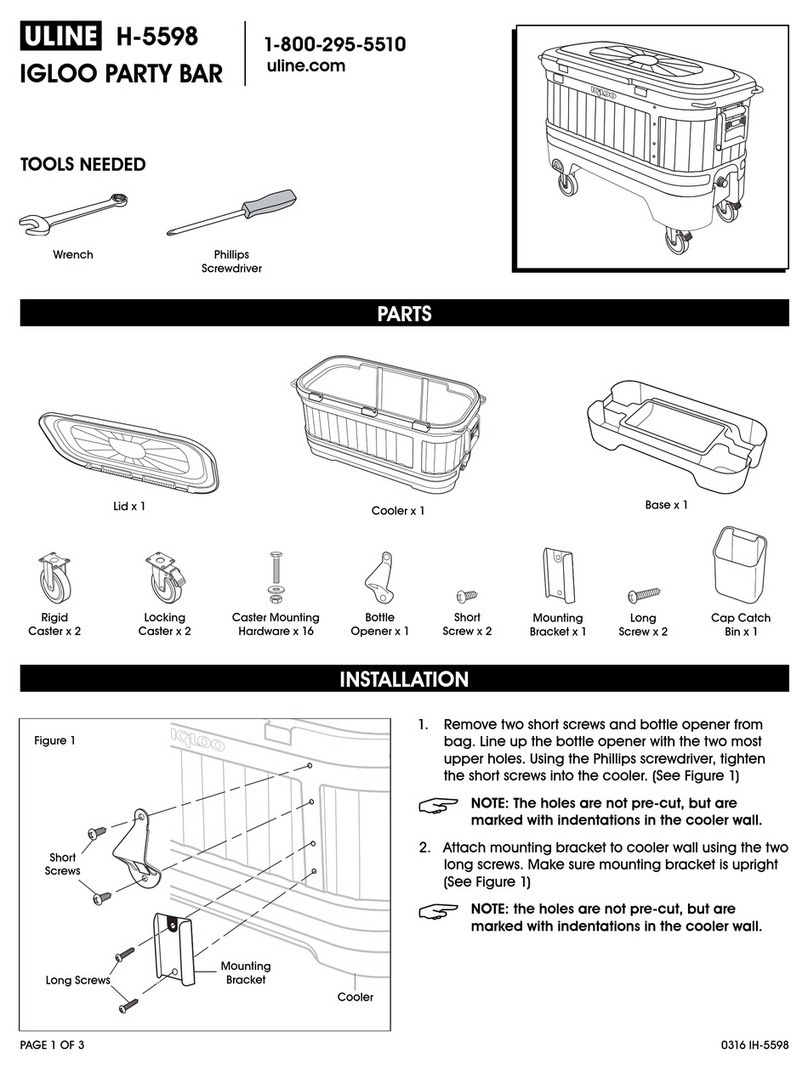

echanical specifications:

Ambient temperature: - 0…+50°C

Liquid temperature: -50…+100°C

Max. pressure: 100 bar

Material, mechanical: AISI304/PTFE

Thread connection: see packaging.

Electrical specifications:

Supply: 4 VDC

Current draw: Max 30 mA

Plug: DIN 06 7 – M1 /5 pins

Enclosure: IP65

Material, electronics: Nylon 6 (PA).

Download of software:

The tool can be downloaded for free. Request access to download the

NOTE! To be able to change the control parameters, it is necessary to

have a special USB/M1 configuration cable as well as the

configuration tool installed on a PC.

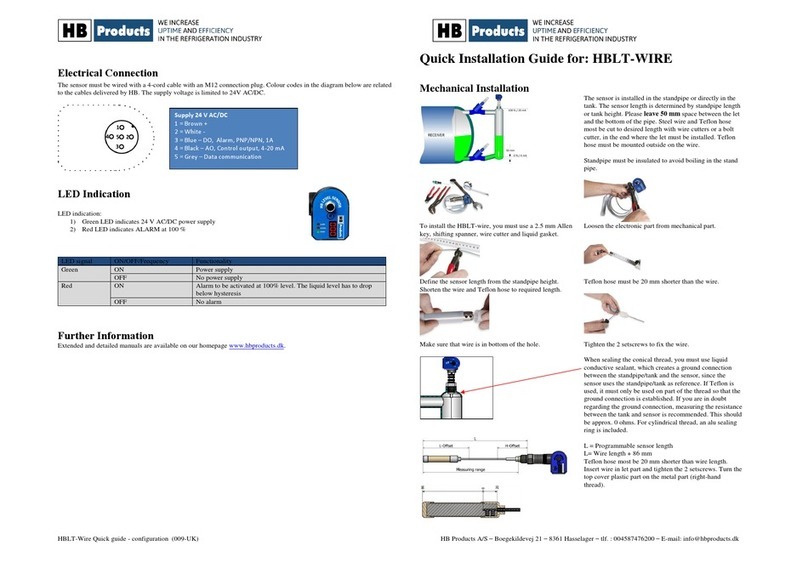

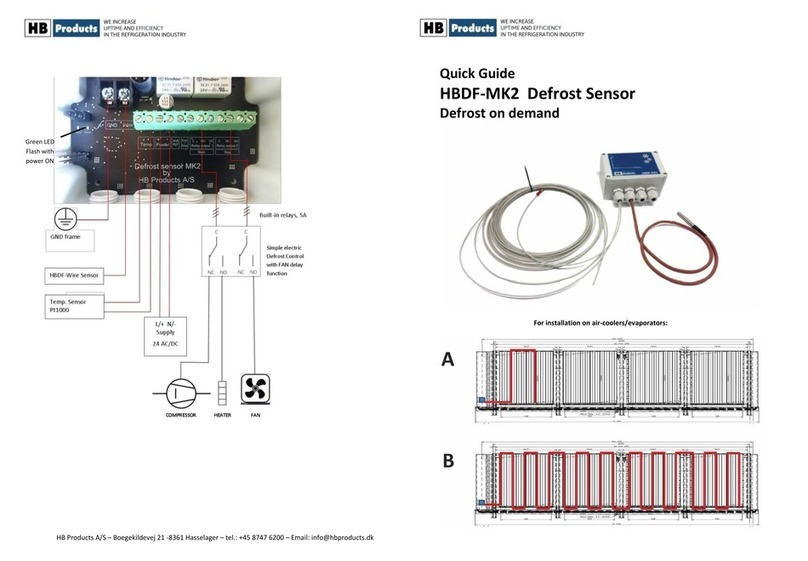

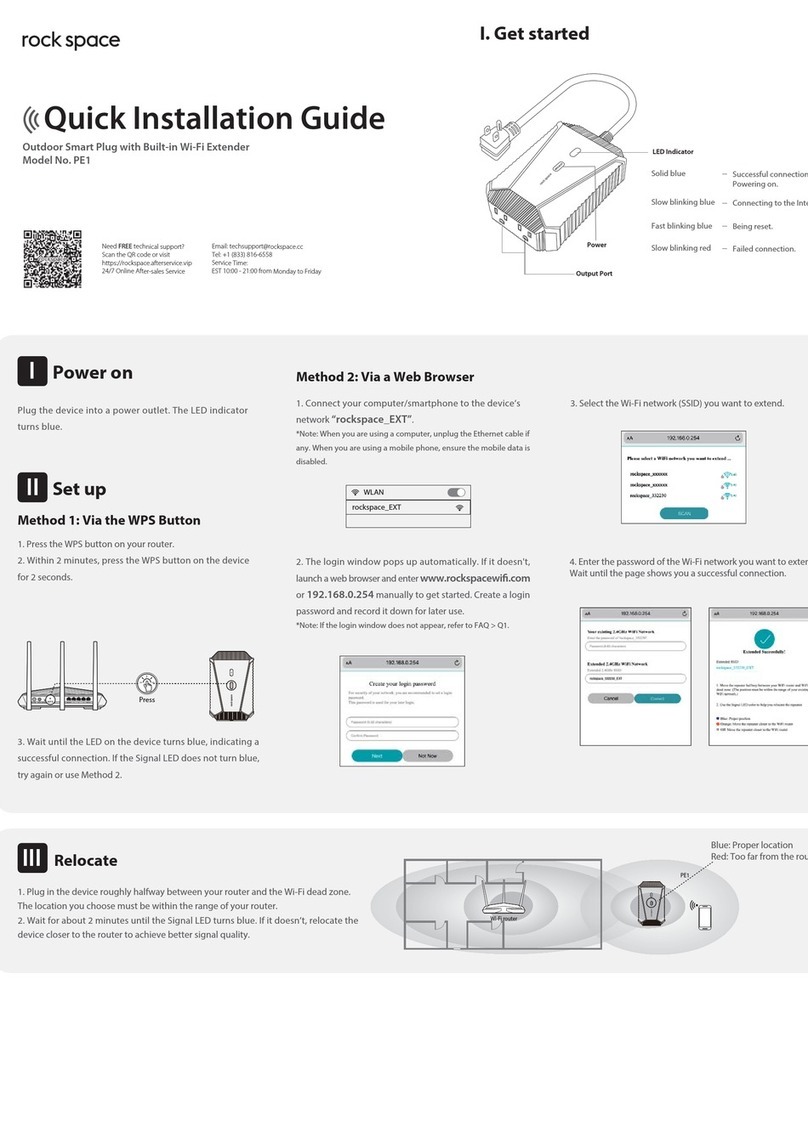

Installation guide:

It must be mounted vertically.

HBLC can be mounted on an overflow pipe or a pipe segment where

flow and turbulence are minimized.

HBLC can be delivered with cable (HBLC-V) for direct control of a

modulating motor valve, or alternatively without (HBLC-C). It is

supplied with a 5 pin connector cable with an M1 plug.

The HBLC-V can be coupled to any 4 VDC 4- 0 mA modulating valve

For termination to Siemens VS 661 valve:

1) White (GO) = sensor - signal

) Yellow (G) = sensor + signal

3) Grey (Y) = Feedback from the valve

LED activation:

1) Green LED indicates 4 V DC

supply; it blinks during operation. If

"run-in" is not used, this function

must be deactivated in the tool.

) Yellow LED indicates control. The

blink sequence indicates if the valve is closing or opening.

3) Red LED indicates high or low level alarm, depending on

configurations.

Caution! In case of welding work on the unit, the electronic part must

be removed. Welding work can damage the electronics. The

mechanical part of the sensor must not be installed in the pipe socket

during welding.

Note! All terminals are protected against improper termination

with a supply voltage up to 40 V. If the supply voltage is greater

than 40 V the electronics will be damaged.

Caution! Factory settings do not guarantee safe operation, since the

configuration parameters depend on the system design.

Note! Fault detection on the electronic function can be carried out

without releasing pressure from the system or disassembling the

mechanical part of the sensor.