HB Products HBLC Series User manual

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 1 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Instruction manual

HBLC-XXX-x-x –LEVEL SENSOR

For analogue measurements of CO2 or HFC in refrigeration systems

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 2 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Table of contents

Safety Instructions...........................................................................3

Introduction..................................................................................... 4

Measurement Principle ...................................................................4

Design and Function ........................................................................4

Technical data..................................................................................5

Application Examples ......................................................................5

Installation Instructions...................................................................6

Power connection............................................................................6

Installation guide .............................................................................7

LED indication.................................................................................. 8

Alarm Reset & Calibration ...............................................................8

Installation of HB Configurations Tool.............................................9

PC Configuration..............................................................................9

Fault detection ................................................................................9

Sensor Repair.................................................................................10

Spare parts.....................................................................................11

Further information’s ....................................................................11

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 3 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Safety Instructions

CAUTION! Always read the instruction manual before commencing work! Heed all warnings to the letter!

Installation of the sensor requires technical knowledge of both refrigeration and electronics. Only qualified

personnel should work with the product. The technician must be aware of the consequences of an

improperly installed sensor, and must be committed to adhering to the applicable local legislation.

If changes are made to type-approved equipment, this type approval becomes void. The product's input

and output, as well as its accessories, may only be connected as shown in this guide. HB Products assumes

no responsibility for damages resulting from not adhering to the above.

Explanation of the symbol for safety instructions. In this guide, the symbol below is used to point out

important safety instructions for the user. It will always be found in the chapters where the information is

relevant. The safety instructions and the warnings in particular, must always be read and adhered to.

CAUTION! Refers to a possible limitation of functionality or risk in usage.

NOTE! Contains important information about the product and provides further tips.

The person responsible for operation must comply with all the legislative requirements with

regards to accident prevention, and take all necessary care to avoid damage to both people

and materials.

Intended use, conditions of use. The level sensor is designed for continuous measurement of liquid CO2 or

HFC in refrigeration systems. If the sensor is to be used for a different application and if the operation of

the product in this application is considered to be problematic, prior approval must be obtained from HB

Products.

Prevention of collateral damage Make sure that only qualified personnel work with the sensor and that all

necessary precautions are taken before attempting to make replacements or repairs, so as to avoid any

collateral damage.

Disposal instructions: The sensor is constructed so that the modules can easily be removed and sorted for

disposal.

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 4 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Introduction

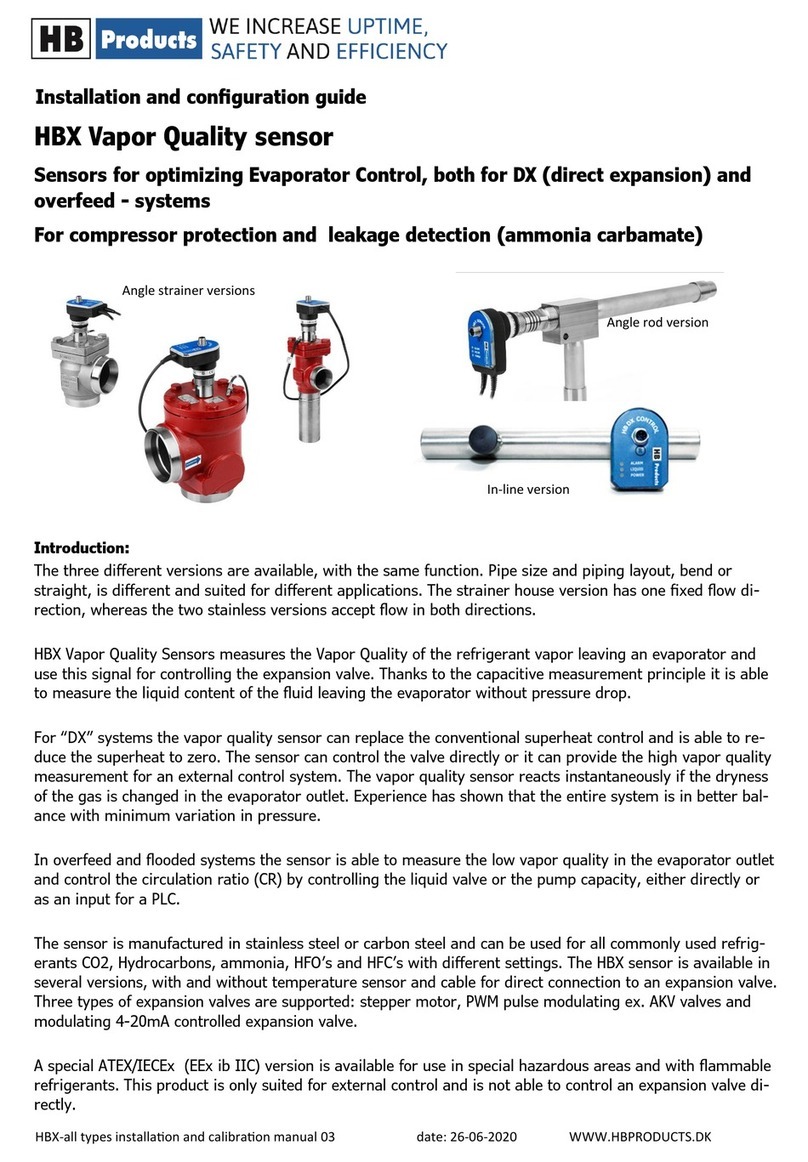

HBLC-XXX is an intelligent sensor with a built-in

microprocessor. It is designed for continuous

level measurement of liquid CO2 or HFC

refrigerant in refrigeration systems.

The sensor emits a 4-20mA analogue signal,

which is proportional to the liquid level.

The construction of the sensor makes it suitable

for systems with pressure of up to 150 bar.

Measurement Principle

The sensor is a capacitive sensor. The capacitive measurement principle is based on the electrical

properties in the proximity of a capacitor. A capacitor is an electrical component that is capable of building

and sustaining an electrical charge.

A capacitor basically consists of two plates.

When a charge is applied to a plate, the other

plate will be charged with the opposite polarity

and retain the charge until it has been grounded.

The magnitude of the charge (the capacitance)

that can be generated depends, among other

things, on what is found between the plates.

The substance between the plates is referred to

as a dielectric.

Rather than the two plates, the sensor for level

measurement is shaped as a cylindrical rod.

When liquid covers the sensor, the measured

capacity is changed.

The conductivity of a material can vary depending

on temperature, chemical composition, and the

homogeneity of the material, and therefore it can

in some cases require a different factory

calibration.

HB Products sensors are calibrated so that they differentiate between conductive and non-conductive

liquids.

In refrigeration systems, oil, HFC and liquid CO2 are not regarded as conductive fluids, whereas refrigerants

such as ammonia and brine are regarded as conductive.

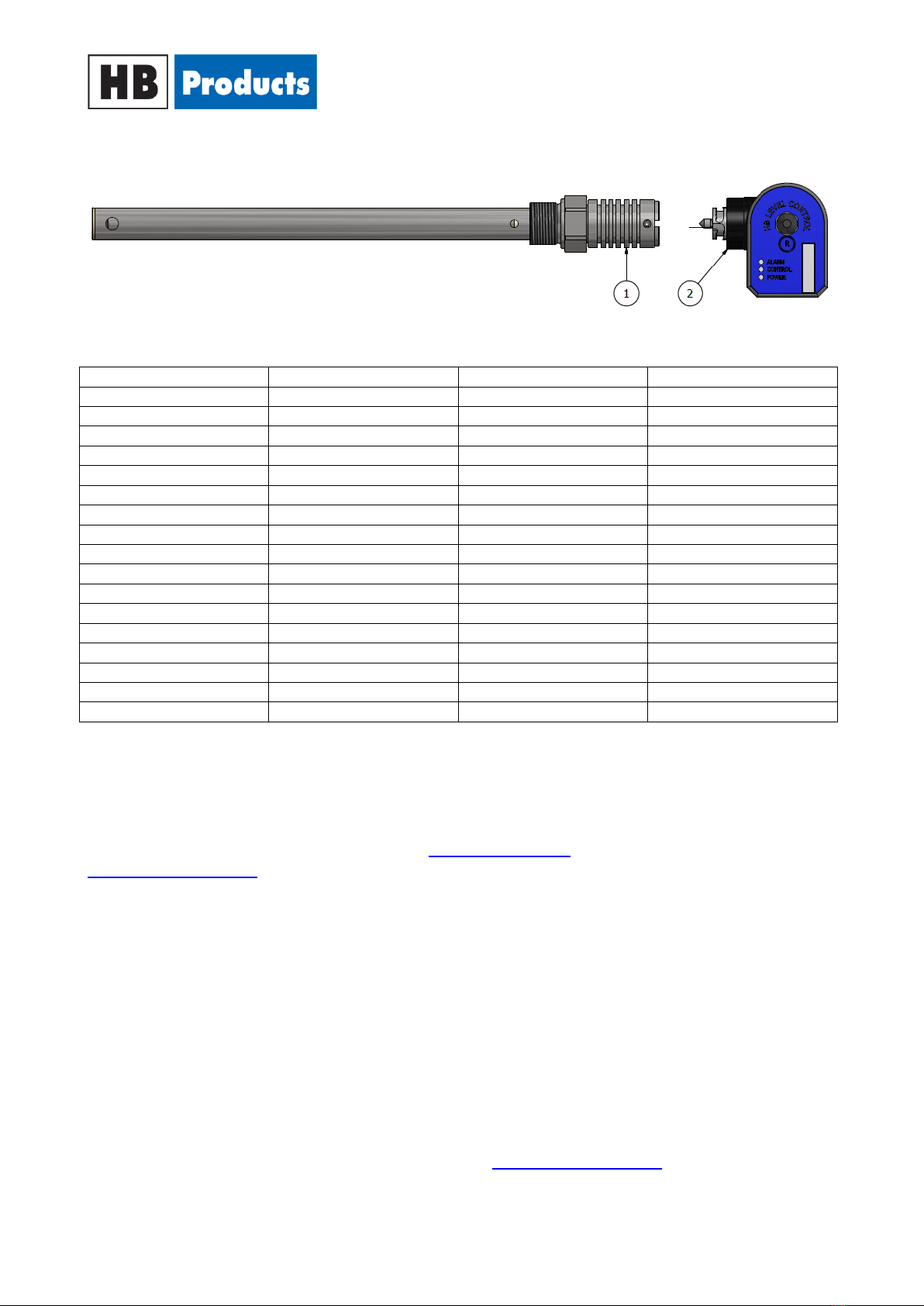

Design and Function

The sensor consists of a mechanical part and an electronic part. These are easily separated by loosening 2

grub screws or, for housings with mounting tabs, by pressing the sensor in towards the mechanical part and

turning the housing counter-clockwise until a wave washer pushes it from the mounted position. The

electronic part is designed in accordance with the IP65 waterproof rating and so as to resist vibrations.

The mechanical part is produced in AISI304/PTFE and tested to withstand high pressure.

The sensor is a very accurate analogue level transmitter for continuous measurement of liquid CO2 or HFC

on refrigerant plants. Additionally it may serve as high level switch, since the in-built switch function gives

an alarm signal at the 100% level.

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 5 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Technical data

Supply:

Supply: 24 V AC/DC ±10%*

Current draw: Max 50 mA

Plug: M12, 5 pins -

DIN 0627

Output:

Analogue output: 4-20 mA

Permitted load on potential

free contactless set 1A (24V DC)

Installation conditions:

Ambient temperature: -30…50°C

Refrigerant temperature: -55…+30°C

Max. operational pressure: 150 bar

Waterproof rating: IP65

Vibrations: IEC 68-2-6 (4g)

Authorisations:

EMC Emission: EN61000-3-2

EMC Immunity: EN61000-4-2

GOST R: No 0903044

Mechanical specifications:

Thread connection: ¾” NPT & BSPP

Materials - mechanical parts:AISI304/PTFE

Materials - electronic parts: Nylon 6 (PA)

Housing design: Front

Calibration & indication:

Calibration Press-button

LED indication: Green, yellow, and

red

Cable specification:

Supply cable, 5 meters: HBxC-M12/5

Cable size: 5 x 0,34 mm2

Cable glands: PG7 / M8

Plug type: Angle - 90°

Cable type: PVC-OB grey

Accessories:

Threaded 1” BSP adapter

with alu. gasket HBS/ADAP/8/2

Torque screwdriver: HBxC-Torque

for supply cable fixation (0,6Nm)

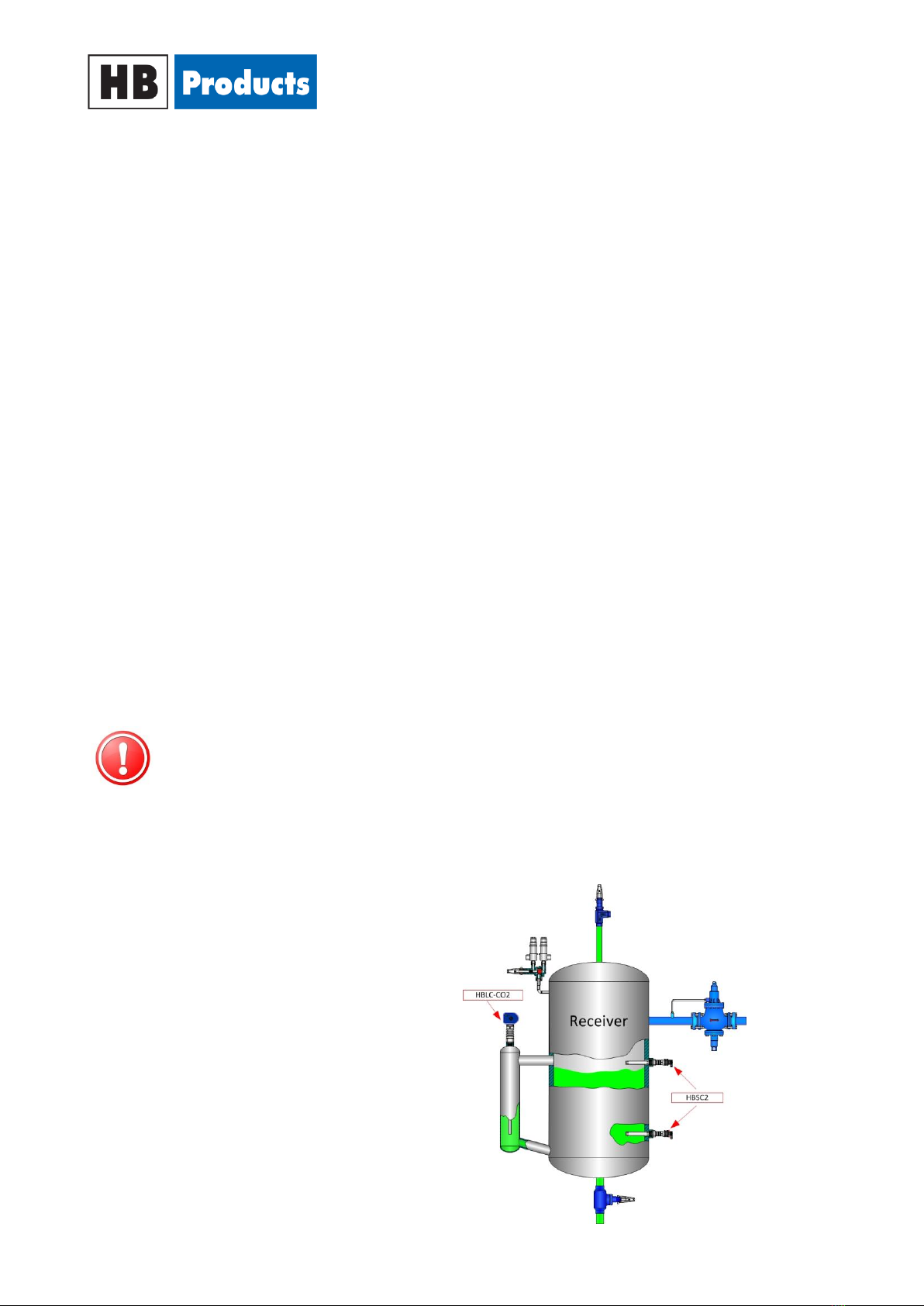

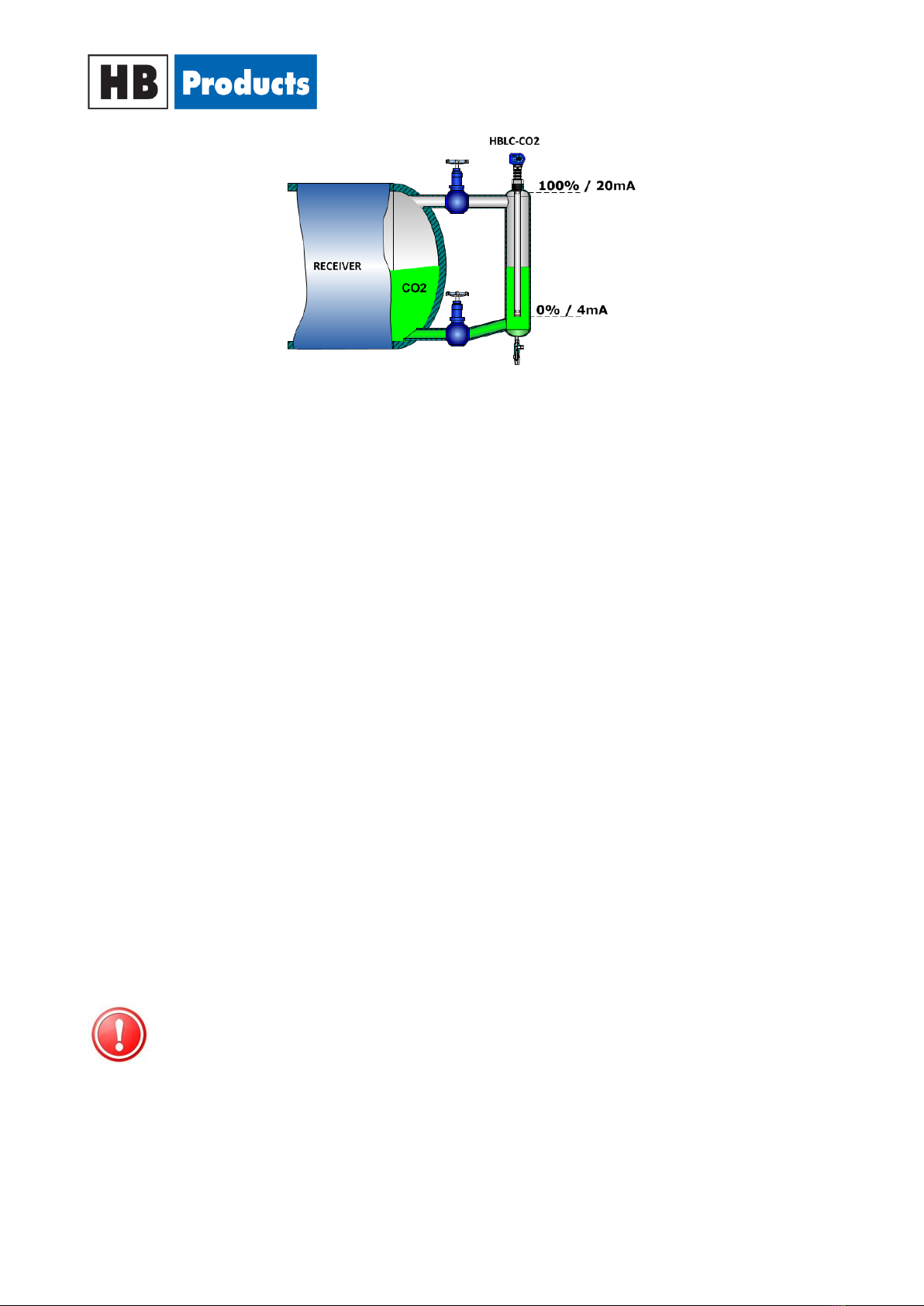

Application Examples

HBLC-xxx is designed for level measurement

of liquid CO2 or HFC in chillers, pump separators, coolers

and condensers. e.g.:

NOTE! All terminals are protected against improper termination with a supply voltage up to

40 V. If the supply voltage is greater than 40 V the electronics will be damaged.

Please note! Supply Voltage may differ from the data given in the manuals. Applicable will

always be that specified on the sensor label.

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 6 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Installation Instructions

The following applies to the design of the system:

1) It must be installed in a vertical position

2) The sensor should be installed in a stand pipe where the flow stream and turbulence are

minimised.

3) The sensor is installed and is supplied with a standard non-shielded cable.

If EMC is greater than described in EN 61326, a shielded cable must be used.

CAUTION! In case of welding work on the unit, please make sure that proper earthing is carried

out to avoid damaging the electronics.

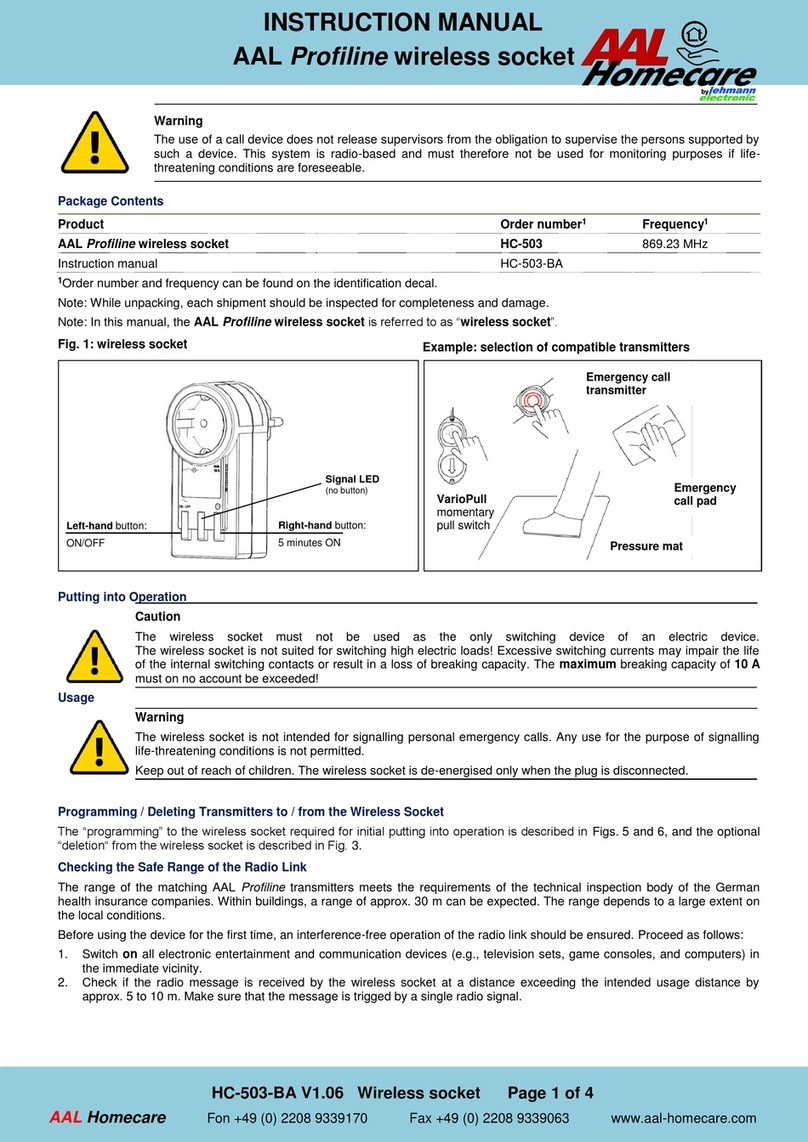

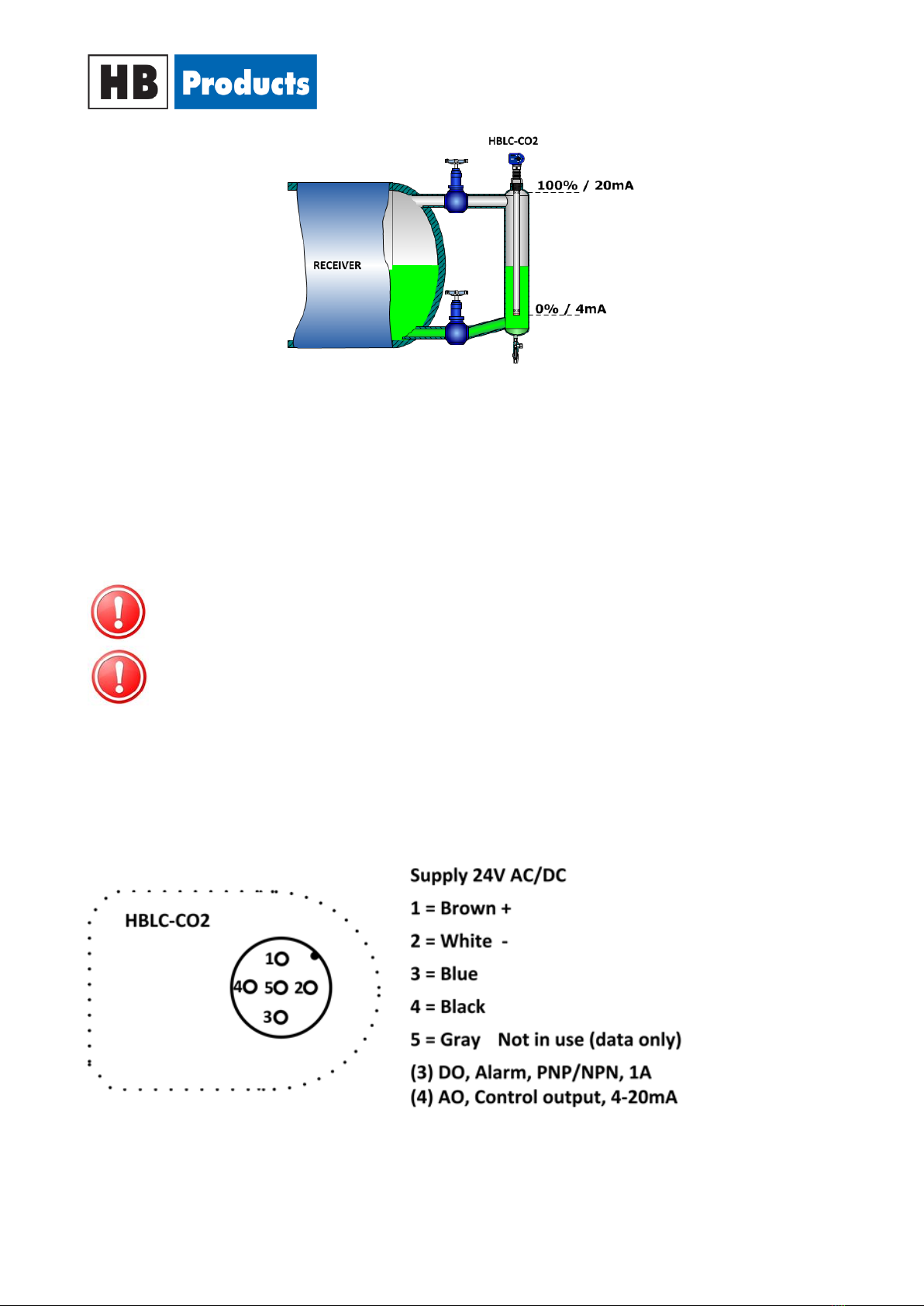

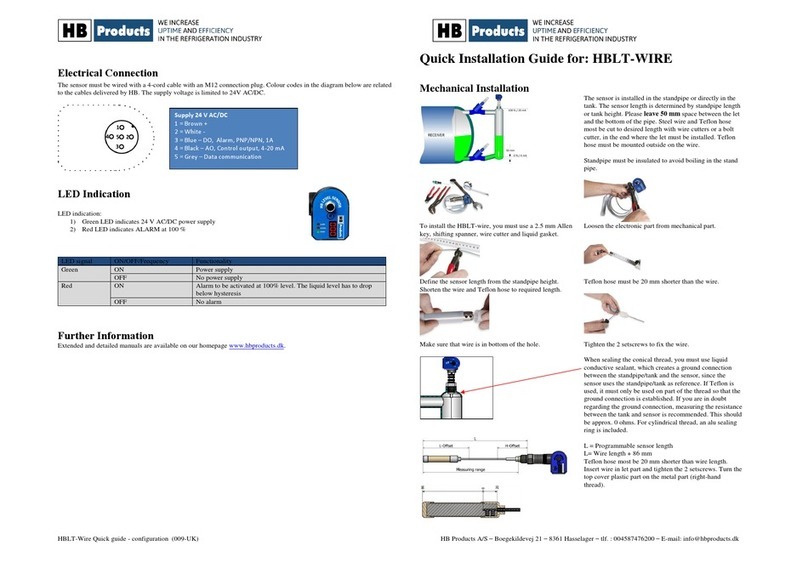

Power connection

The sensor must be wired with a 4 cord cable with a M12 connection plug

Colour codes in the below diagram are related to the cables offered by HB.

The supply voltage is limited to 24V AC/DC

NOTE! The sensor element must not touch the tank or other metal parts in its mounted

position. If so, the sensor will not give out a correct signal.

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 7 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

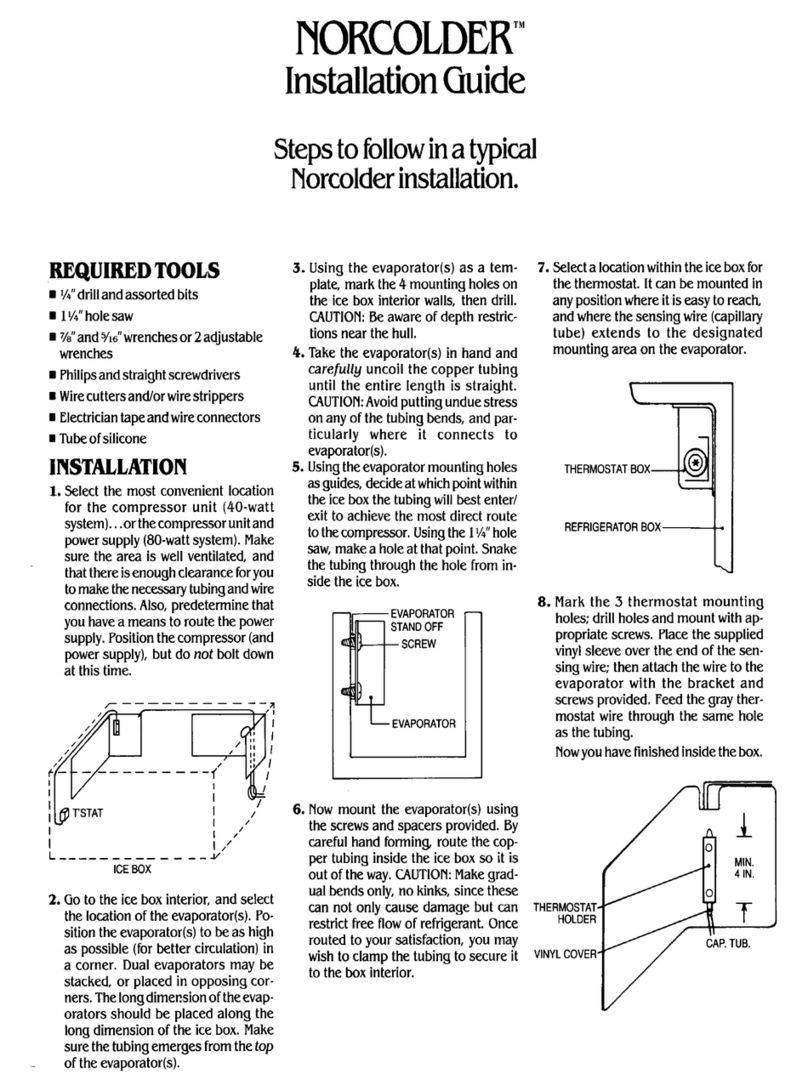

Installation guide

The sensor is installed in standpipe or directly in the container. Liquid gasket is applied to the thread.

To install the sensor, you must use a 2.5 mm Allen key,

shifting spanner, and gasket, depending on the type of

thread.

Loosen the two set screws that secure the electronic

part and the mechanical part.

Separate the electronic part from the mechanical part.

The hub of the two parts has been applied Molykote

ggrease type 111 silicone compound to minimize moisture

ppenetration. Do not wipe off the grease

Apply liquid gasket / Teflon to the conical thread.

Mount the electronic part in the container or standpipe

and tighten (80-150 Nm).

Mount the electronic part and tighten the two set

screws. Optionally apply Molykote grease 111

silicone compound before the two parts are

assembled.

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 8 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

LED indication

LED indication:

1) Green LED indicates 24 V AC/DC supply (blinks during operation)

2) Yellow LED –in connection with calibration

3) Red LED indicates ALARM at 100%

LED Signal

ON/OFF/Frequency

Functionality

Green

ON

Supply

OFF

No supply

Yellow

ON

Activated during calibration

OFF

Normal operation

Red

ON

Alarm is activated after 10 seconds with 100% level

OFF

No alarm

Alarm Reset & Calibration

Alarm Reset: The alarm is reset by pressing "R" for 5 seconds.

The level transmitter comes pre-calibrated for CO2 or HFC and calibration is normally not required unless a

high measurement accuracy is required.

Calibration instructions:

0% or 100% for calibration can be carried out independent of each other. We recommend only calibrating

at 0% if a high degree of accuracy is desired.

Instruction for 0% calibration:

1) The sensors calibration function should be connected via the HB tool. See instruction for PC

connection and configurations parameters in separate manuals. Connect the supply cable

2) Disconnect the power cable

3) Empty the tank

4) Activate "R" for 5 seconds to activate calibration mode = Yellow LED is on (ON) during the 5 second

activation and turns off (OFF) when calibration mode is activated.

5) Activate "R" once = Yellow LED blinks once. Afterwards, the green LED blinks to confirm calibration.

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 9 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

In case a smaller measurement area is desired, a recalibration can be performed.

6) Connect the PC Tool again and disconnect the calibration function in the tool.

7) Connect the power cable.

Instruction for 100% calibration:

1) The sensors calibration function should be connected via the HB tool. See instruction for PC

connection and configurations parameters in separate manuals. Connect the supply cable

2) The supply cable is connected

3) Fill the tank to 100%.

4) Activate "R" for 5 seconds to activate calibration mode = Yellow LED is on (ON) during the 5 second

activation and turns off (OFF) when calibration mode is activated.

5) Follow the instructions under "Configurations Instructions" regarding the installation of drivers in

the program.

6) Activate "R" twice = Yellow LED blinks twice. Afterwards, the green LED blinks to confirm

calibration.

7) Connect PC Tool again and disconnect the calibration function in tool.

8) Connect the power cable.

Installation of HB Configurations Tool

See separate manual.

PC Configuration

See separate manual.

Fault detection

General:

In case of fault, it is necessary to replace the electronic part only.

NOTE! Fault detection and/or changing the electronic function can be carried out without

releasing pressure from the system or disassembling the mechanical part of the sensor.

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 10 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

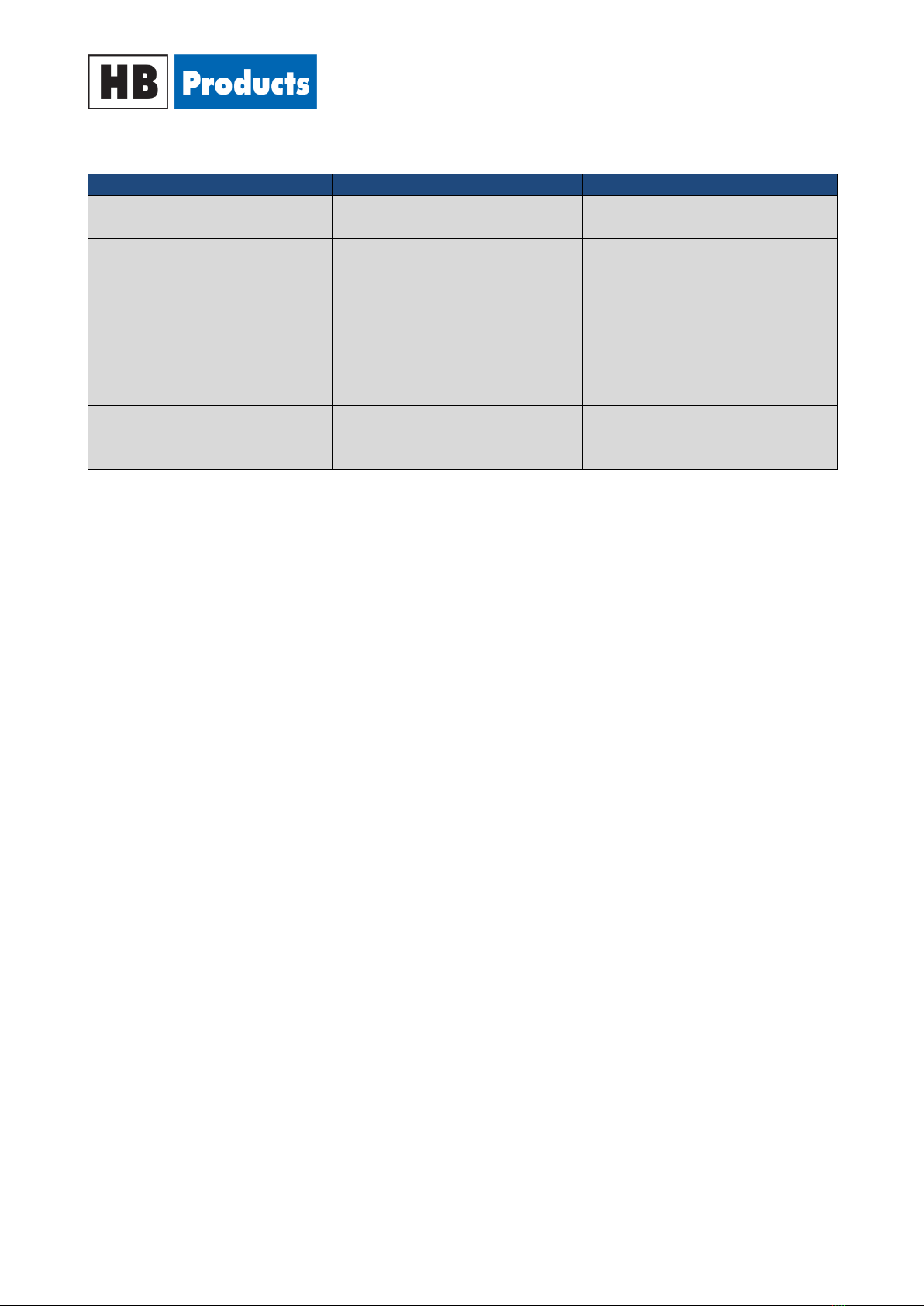

Fault detection

Fault

Reason

Correction of fault

No LED is lit / no function

No supply to the sensor or

defective cable/plug.

Check the power supply and the

supply cable.

No contact activation

There may be dirt between the

electronic housing and the

mechanical housing.

Separate the two parts and clean

the spring tip. Remember to apply

silicone grease to the spring tip so

as to avoid any problems with

moisture.

Delay in sensor activation

Can be caused by gas and

formation of foam in the system.

Check that the sensor is placed

optimally, so that gas and air are

avoided.

There is no correlation between

the output signal and the

measuring distance.

The sensor is not calibrated

correctly.

Perform calibration.

Sensor Repair

In case of faults with the sensor, it will typically be necessary to replace only the electronics.

Sensor electronics are fully encapsulated and can therefore not be repaired.

Complaint cases are handled by the HB products dealers/distributor.

Consideration must be given to the complaint procedures before returning the sensor.

Instruction manual –HBLC-xxx –Levelsensor (005-UK) 11 / 11

WE INCREASE

UPTIME AND EFFICIENCY

IN THE REFRIGERATION INDUSTRY

Spare parts

Position

Description

Specification

Part number

1

Mechanical parts

¾” NPT - 300 mm

HBLC-CO2-3-2-MEK

¾” NPT - 500 mm

HBLC-CO2-5-2-MEK

¾” NPT - 800 mm

HBLC-CO2-8-2-MEK

¾” NPT - 1000 mm

HBLC-CO2-10-2-MEK

¾” NPT - 1200 mm

HBLC-CO2-12-2-MEK

¾” NPT - 1400 mm

HBLC-CO2-14-2-MEK

¾” NPT - 1700 mm

HBLC-CO2-17-2-MEK

¾” NPT - 2500 mm

HBLC-CO2-25-2-MEK

¾” BSP - 300 mm

HBLC-CO2-3-6-MEK

¾” BSP - 500 mm

HBLC-CO2-5-6-MEK

¾” BSP - 800 mm

HBLC-CO2-8-6-MEK

¾” BSP - 1000 mm

HBLC-CO2-10-6-MEK

¾” BSP - 1200 mm

HBLC-CO2-12-6-MEK

¾” BSP - 1400 mm

HBLC-CO2-14-6-MEK

¾” BSP - 1700 mm

HBLC-CO2-17-6-MEK

¾” BSP - 2500 mm

HBLC-CO2-25-6-MEK

2

Electronic part

PC-programmable

HBLC-CO2-EL

Further information’s

For further information, please visit our website, www.hbproducts.dk or send an email to:

This manual suits for next models

17

Table of contents

Other HB Products Accessories manuals

HB Products

HB Products HBLT User manual

HB Products

HB Products HBCP User manual

HB Products

HB Products HBLT-WIRE User manual

HB Products

HB Products HBLC User manual

HB Products

HB Products HBLC User manual

HB Products

HB Products HBLT-A1 User manual

HB Products

HB Products HBPH-MK2 User manual

HB Products

HB Products HBOC User manual

HB Products

HB Products HBDF MK2 User manual

HB Products

HB Products HBDF-MK2 User manual