HB Products HBX Operator's manual

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Installation and conguration guide

HBX Vapor Quality sensor

Sensors for optimizing Evaporator Control, both for DX (direct expansion) and

overfeed - systems

For compressor protection and leakage detection (ammonia carbamate)

Introduction:

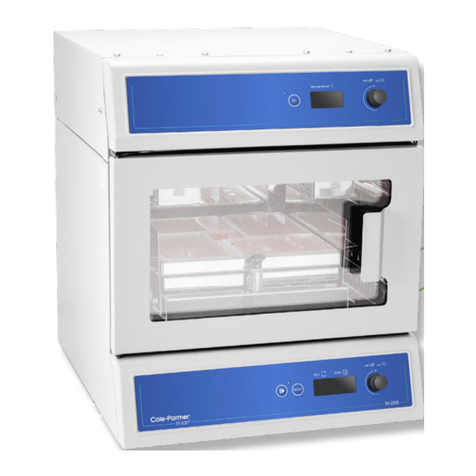

The three dierent versions are available, with the same function. Pipe size and piping layout, bend or

straight, is dierent and suited for dierent applications. The strainer house version has one xed ow di-

rection, whereas the two stainless versions accept ow in both directions.

HBX Vapor Quality Sensors measures the Vapor Quality of the refrigerant vapor leaving an evaporator and

use this signal for controlling the expansion valve. Thanks to the capacitive measurement principle it is able

to measure the liquid content of the uid leaving the evaporator without pressure drop.

For “DX” systems the vapor quality sensor can replace the conventional superheat control and is able to re-

duce the superheat to zero. The sensor can control the valve directly or it can provide the high vapor quality

measurement for an external control system. The vapor quality sensor reacts instantaneously if the dryness

of the gas is changed in the evaporator outlet. Experience has shown that the entire system is in better bal-

ance with minimum variation in pressure.

In overfeed and ooded systems the sensor is able to measure the low vapor quality in the evaporator outlet

and control the circulation ratio (CR) by controlling the liquid valve or the pump capacity, either directly or

as an input for a PLC.

The sensor is manufactured in stainless steel or carbon steel and can be used for all commonly used refrig-

erants CO2, Hydrocarbons, ammonia, HFO’s and HFC’s with dierent settings. The HBX sensor is available in

several versions, with and without temperature sensor and cable for direct connection to an expansion valve.

Three types of expansion valves are supported: stepper motor, PWM pulse modulating ex. AKV valves and

modulating 4-20mA controlled expansion valve.

A special ATEX/IECEx (EEx ib IIC) version is available for use in special hazardous areas and with ammable

refrigerants. This product is only suited for external control and is not able to control an expansion valve di-

rectly.

Angle rod version

In-line version

Angle strainer versions

2

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Table of Contents

Introducon............................................................................................... 1

Safety Instrucon ...................................................................................... 2

Applicaon and mounng strainer house version .................................... 3

Applicaon and mounng straight pipe version ....................................... 4

Applicaon and mounng angle rod version ............................................ 5

Installaon of temperature sensor............................................................ 6

Removal of electrical unit.......................................................................... 7

Sensor conguraon ................................................................................. 7

How to use the sensor............................................................................... 8

How to setup the sensor as input for a PLC .............................................. 9

Advanced sengs for sensor as input for PLC input............................... 10

Using the sensor for ooded operaon together with a PLC ................. 11

Operang a batch freezing process......................................................... 11

Using the alarm funcon for leakage control and comp. protecon ...... 11

Calibraon of sensor ............................................................................... 12

How does the expansion valve control loop work for DX operaon…..…14

How to setup the sensor as direct controller—basic sengs................. 16

How to setup the sensor as direct controller—Advanced sengs ......... 17

Controlling a ooded or semi ooded evaporator ................................. 18

Connecng diagram stepper motor ........................................................ 19

Connecng diagram motor valve ............................................................ 20

Connecng diagram pulse modulang.................................................... 21

Connecng diagram PLC and ATEX/Ex/IECEx ......................................... 22

Remote seng ........................................................................................ 23

LED indicaons on sensor head............................................................... 24

Use of the sensor with other refrigerants ............................................... 24

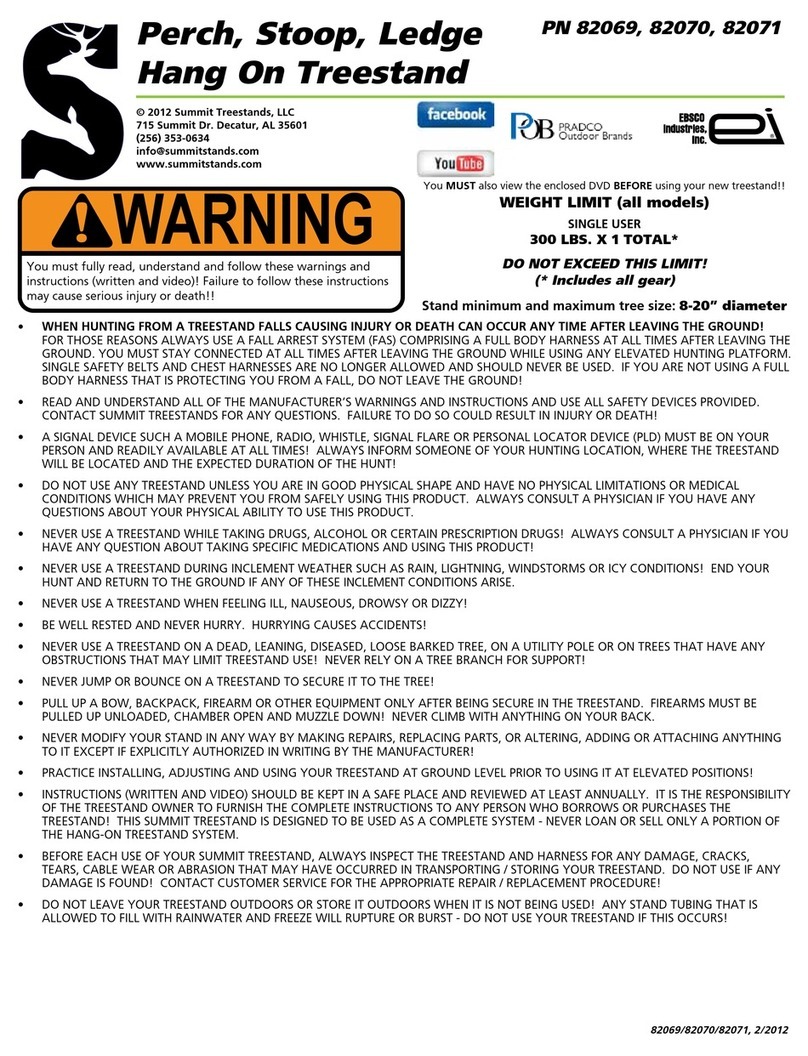

Safety Instructions

CAUTION! Read this setup guide before installing and using the HBX Sensor.

Installation of HBX sensor must be carried out by a trained professional with in-depth knowledge of both refrigera-

tion and electronics. Improper installation and use of the HBX Sensor may result in damage to material and/or peo-

ple. The installation and use of the HBX Sensor must be done according to local regulation.

Altering type-approved equipment voids the type approval. The product's input and output, as well as its accesso-

ries, may only be connected as described in this guide. HB Products assumes no liability for damages resulting from

failing to follow the instructions in this setup guide.

Intended use. The purpose of the HBX sensor is refrigerant measurement and control.

If the HBX is to be used in a different way, prior, written consent must be obtained from HB Products.

Repair: Any repair must be carried out by a trained professional.

Disposal instructions: The HBX is designed for long life operation. If or when it becomes necessary to dispose of

the sensor it must be done according to local regulation.

CAUTION! This symbol refers to a possible limitation of functionality or risk in usage.

NOTE! Contains important additional information about the product and provides further advice.

CAUTION! Factory sengs do not guarantee safe operaon since the conguraon

parameters depend on the system design

3

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Up

Flow direcon

Flow direcon

H

H

H

Risk of trapped refrigerant

around the sensor disturbs the

measurement when lid points

downwards

Application and mounting instruction

Sensor mounted in a strainer house (HBX-xxx-ST)

The HBX-sensor is mounted after the evaporator and is able to measure the Vapor Quality (dryness) from 0.2 to 1. The

output can be used as input to a PLC or it can control the expansion valve directly or both. The sensor is mounted in a

strainer house where the strainer is replaced by the sensor. Compared to the original strainer the ow direction is

opposite and the mounting is upside down.

The sensor have to be mounted in downward sloping pipes to ensure drainage of refrigerant, and oil. The lid needs to

be upwards as other mountings will be sensitive to oil contamination and trapped refrigerant during startup.

When the sensor is welded into the plant the lid and sensor have to be removed. After the welding the piping have

to be checked for welding debris and deformations which might disturb the measurement. The distance between

the sensor element and the wall has to be uniform.

The lid with sensor is reassembled and the bolts are tightened according to the table.

HRemove lid with sensor

before welding

Max torque for bolts

H

Flow direcon

4

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

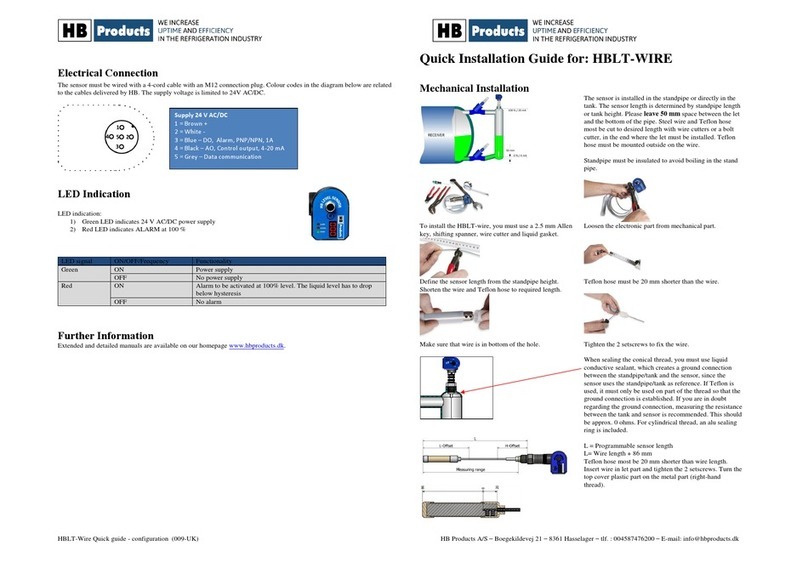

Application and mounting instruction

Sensor mounted in a straight pipe HBX in-line

The HBX-sensor is mounted after the evaporator and is able to measure the Vapor Quality (dryness) from 0.2 to 1. The

output can be used as input to a PLC or it can control the expansion valve directly or both. This sensor version is

mounted in a straight pipe and it accepts ow in both directions.

The sensor can be mounted in dierent positions as long as you make sure there is no trapped refrigerant inside the

sensor during startup. Mounting the sensor with the electronic unit pointing downwards is not ideal as the connectors

might disturb the liquid ow in the bottom of the pipe and make the measurement unprecise.

The electrical unit can be mounted on either of the two connecting points

When the sensor is welded into the plant the electronic unit

has to be removed in order to protect it from the heat. The

studs have to be cooled during welding as they include O-rings

which does not tolerate temperature beyond 100°C (212°F). A

wet cloth is normally sucient to cool the studs.

Remove electronic unit be-

fore welding or soldering and

cool the studs ex. with a wet

cloth.

With the sensor downwards the

internal connections will disturb

the liquid ow in the bottom of

the pipe. The measurements

might be unprecise

Apply

cooling

When mounted horizontally

make sure refrigerant and

oil is drained for instance by

inclining the sensor 1

This mounting

will suer from

trapped refrig-

erant in the

sensor tube

5

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

HBX

Flow direcon

Angle minimum 30 downwards

Evaporator

Application and mounting instruction

Angle rod version

The sensor accepts ow in both directions, but has to be mounted in downward sloping pipes to ensure drainage of

refrigerant, and oil. The sensor can be mounted in dierent positions. But some will be sensitive to oil contamination

and trapped refrigerant during startup. Make sure that the sensor rod inside the long pipe is free from trapped refrig-

erant and oil at any time. The sensor pipes have a larger dimension than stated in the specication, but is delivered

with reductions to t the specied pipe diameter. This is done to avoid pressure loss coming from a massive inner rod

lling some of the pipe and reducing the cross section

Workarounds for low mounted evaporator outlets

It is important to secure drainage of liquid refrigerant and oil as this could

aect the sensor and especially oil is dicult to remove with a low velocity

gas. Especially in small systems without oil separator, it is important to keep

the sensor free from oil to avoid it disturbing the measurement.

Both pipes should be angled minimum downwards 1 degree or designed with a

P-trap/drop-leg to secure drainage.

This mounting will suer

from trapped refrigerant in

the metal block, where the

sensor is mounted

This mounting will suer from

trapped refrigerant in the

sensor tube

This mounting will suer from

trapped refrigerant in the sensor

tube

H

Flow direcon

Flow direcon

Slope downwards

6

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Installing the Sensor

The sensor is installed in the outlet of the evaporator, as part of the sucon line. Soldering connecon, ngs and pipes are

made of stainless steel. The sensor part itself must be removed by unscrewing it from the steel block/base part before sol-

dering.

Unscrew the complete sensor part before solder-

ing.

Use two wrenches when dismantling and installing

the HBX-Sensor. One to turn the sensor and one on

to stabilize the steel block to avoid stress to the

soldering's.

Use thread sealant.

We recommend using liquid thread sealant when

installing the sensor

Insulate the entire

mechanical sensor

part with insulation

foam.

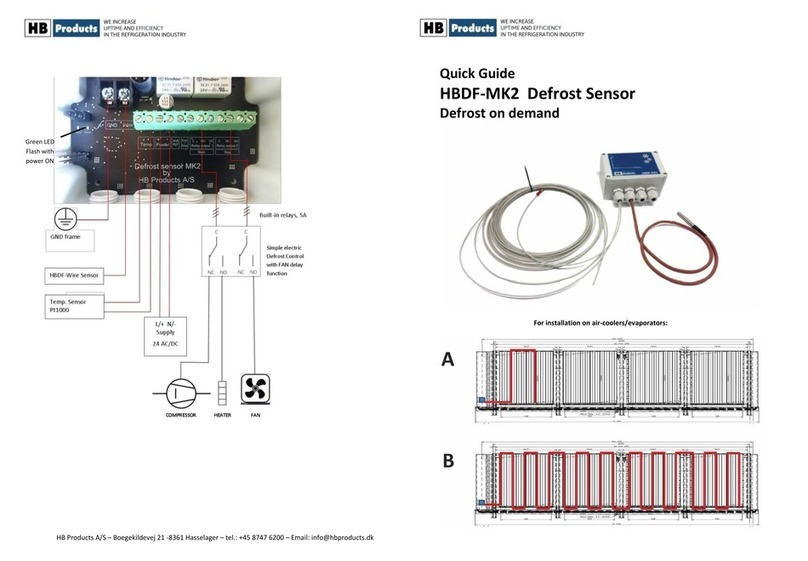

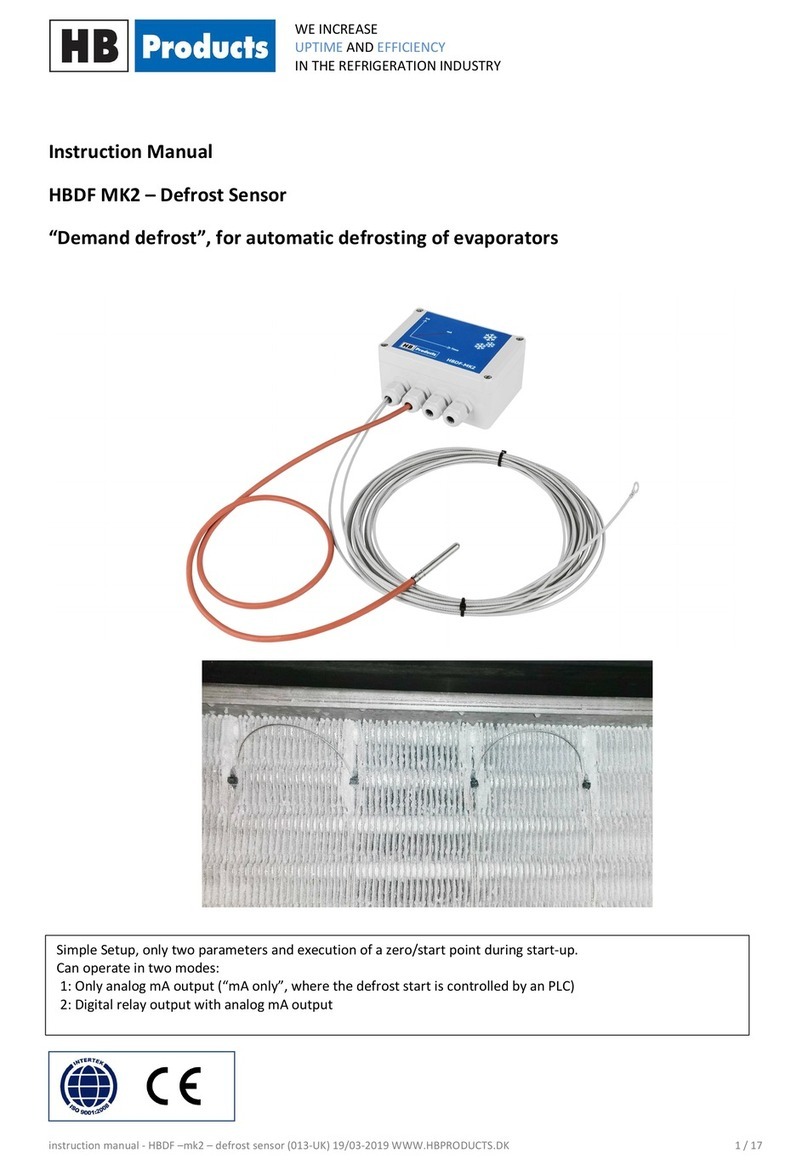

Temperature sensor installaon

Refrigeraon systems working with NH3 can operate well without a temperature sensor, but most other refrigerant benet

from temperature measurement. The temperature measurement is used for oseng the Zero point and makes the meas-

urement more accurate.

The sensor normally has a cable with a temperature sensor which has to be mounted to the pipework using cable es or to

the lid of the larger strainer models. The mounng on the outside of the pipe provides sucient accuracy. The temperature

sensor compensates for the change in the dielectrical constant with the temperature and make the measurement more ac-

curate when starng the system.

The temperature sensor should

be mounted to a pipe in posi-

tion 3 or 9 o’clock with cable

ties as shown.

For strainer houses the clip can

be used for attaching it to the

lid

7

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Sensor conguraon

All HBX sensors can be calibrated using a PC and a, M12 -USB cable. The soware can be downloaded freely on the HB

Products web page. The conguraon data can be stored in the sensor and will be there unl erased without power con-

necon—just like you store data on a memory sck. When you change a value /seng there will be put a check mark next

to it and that indicates you have changed something and need to store the data in the sensor.

When the sensor is mounted in a refrigeraon plant where it is dicult to reach or it is very cold you should consider us-

ing an M12 extension cable in your installaon. This allows for conguraon of your sensor where you have your M12/

M12 connecon.

PLC

Cable from HB sensor

USB

M12 female

M12 male

USB conguraon cable used for con-

necng all sensors with M12 con-

nector to a PC with the HB tool

order code HBxC-USB

Removal of the electrical unit

End view without electronic unit

The threaded union between the electronic and

mechanical part allows for fast removal and

remounng of the electronic element without

interfering with the pressurised system. No

tools are needed for the operaon.

8

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Setup — sensor or control

The sensor can operate in two very dierent modes

• As sensor input to a PLC, computer or other device that

uses the sensor signal

• A direct controller of an electrically controlled expansion

or liquid valve version with a cable output that can be set

up as a controller

Select Control/Sensor to select the mode

How to use the sensor

Two dierent versions

Two dierent versions exist

• A pure sensor version—without the controller capability

• A version which can both control an expansion valve with a simple input and act as a sensor together

with a PLC

The sensors that are able to control an expansion valve have a cable beside the temperature sensor cable,

which can be connected directly to the valve. The sensors which are specied only to provide a signal for a PLC

will only have the M12 connection. All sensors, except those for NH3 refrigeration, has a cable with a PT1000

temperature sensor, which measures the operating temperature and makes the needed compensations.

Alarm application

Some of the sensors can be used for providing an alarm when the liquid level is high or if ammonia carbamate

is detected. The sensor can still be used for measuring vapor quality and control a liquid valve either directly or

via a PLC

Stop-

start

Power

24VDC

PLC

Sensor only version

Controller and sensor

version

PLC

See page 9 and

forward

See page 14 and

forward

9

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Typical values for DX operation

When the sensor is not operating as a controller some of the parameters are irrelevant and the boxes are inactive

and shown in grey.

1. Set lter time to 2 seconds. The lter time is the period of time over which the X measurement is averaged.

The longer the range the smoother the measurement becomes, but the risk is that the system becomes too

slow.

2. Run in signal (digital input pin 5) is used as external start and stop when operating as a controller and

should be set to OFF

3. Zero cal. function: Choose ”ON” if you want to use the push bottom ”R” for zero calibration

4. The “Alarm setting in “X” “ and “Alarm delay in seconds” can be used, but normally the alarm is pro-

grammed in the PLC directly based on the mA signal.

5. The temperature compensation function is set to “Temp oset” unless you don’t want this functionality. This

only applies if the sensor has

a temperature sensor

6. “Select refrigerant type” is

for information only and

should not be used for chang-

ing refrigerant as it does not

change the important set-

tings, and the sensor will not

provide the correct measure-

ments. If your refrigerant is

not correct you need a com-

plete settings le - please con-

tact HB-products for this.

7. After changing settings push

the button ”Save to sen-

sor” (the message ”OK” on the

screen indicates that the set-

tings are saved)

8. Go to next page: Advanced

settings

How to setup the sensor as input for PLC

When using the sensor as input to a PLC the analog output

is used. The output can be scaled by adjusting a parame-

ter. Dry gas will always be 4 mA but the “X measuring

scale” found in the Calibration tab denes the 20 mA point

The ”X measuring scale” can be changed in the calibraon tab

10

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

When the sensor is used as input for a PLC only the

relay function can be modien in the advance set-

tings' tab

1. Alarm output, NO (normally open) or NC

(normally closed) , default is ”NC” (Fail safe

function)

2. After Changing settings push the button ”Save

to sensor” (a message ”OK” on the screen

indicates that the settings are saved)

3. Save settings le is used to save all the set-

tings as a txt le

4. Load settings le is used to set up all parame-

ters from an existing txt le (copy data to a

new sensor)

Advanced settings for sensor as input for PLC

Tick o here for geng

access to selecon of

applicaon

Tick o

Set minimum

value here

Tick o here

and select

sensor type

Click here to

store the data

in the sensor

Under the calibration tab, the sensor can to be set to ooded operation called “HBX-CR” or DX but it does not really

matter when used for PLC input only.

How to change the “X measuring scale”

You start by ticking o the three small boxes to the right. At the same time you can change the operation range

from minimum in the box called “X measuring scale” to maximum called “Dry sensor” When you are done changing

the parameters, you store them in the sensor by clicking on “X scale calculation”

11

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Using the sensor for ooded operaon together with a PLC

The output of the sensor can be used for controlling a liquid valve directly or the analog output in pin 4 can be used as

input to the PLC. The signal is scaled linearly from 4 to 20 mA where 4 mA is sent for the “dry sensor” and the 20 mA

for the minimum “X measuring scale”.

An Example:

If you set the minimum to 0.50 and maximum to 1.00 you will get 16 mA for “degree of dryness “X” of 0.625

AO signal: 20— 16* ( 0.625-0,5) / (1,0-0,5) =16 mA on pin 4

Operang a batch freezing process

Batch freezing is dicult to control due to a large capacity variaon throughout the cycle. A way to control the process

it to start the freezing cycle as ooded and end it as DX. It

requires a PLC to control the expansion/liquid valve and make

a graduate change of the circulaon rao from 3 to 1, which

is equal to changing the X value from 0,3 to 1 as this formula

can be used: X=1/CR

The advantage of this way of controlling is increase the cool-

ing capacity in the last part of the cycle and avoid slug ow in

risers due to overfeeding. The DX operaon at the end re-

duce the pressure drop and lowers the energy consumpon.

The graph show how the X and CR value can be adjusted

during the cycle.

Using the alarm funcon for leakage control and compressor protecon

Some sensors can provide a digital output signal on pin 3 when the alarm level is reached.

This can be used for leakage control in a CO2/NH3 system where ammonia carbamate

will be created or for compressor protecon.

For leakage control the “Alarm seng in X” have to be set 20% below the normal oper-

ang point so for DX operaon it could be 0.8.

For compressor protecon the “Alarm seng in X” have to be set at around 0.97 to 0.98

depending on the system.

The “alarm delay in sec.” have to reect the system and have to be as low as possible.

The “alarm relay funcon” can be adjusted to either deliver a digital output or remove

the signal when the limit is passed

Current for

minimum “X”

Range

(20-4 )mA

minimum

maximum

X

minimum

Basic sengs

Advanced sengs

Cycle me in %

12

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Calibraon of sensor for DX operaon

The sensor is delivered with a basic calibraon for the refrigerant you specied when ordering. The sensor can be used

directly without further calibraon. You can check the calibraon as described below. If the calibraon is not opmal the

accuracy can be improved by making a simple dry calibraon at normal operang temperature, when the system has

been operang for some hours. The calibraon procedure is described in the secon below. The calibraon will depend

on

• Refrigerant

• Sensor and pipe dimensions

• Operang temperature (the temperature sensor will eliminate the inuence of the temperature)

How to check your calibraon and make a new calibraon of sensor controlling an expansion valve

Start your refrigeraon system and let it reach normal operang temperature.

Make sure the sensor is completely dry which can be done in dierent ways depending on your system

• If possible close the expansion valve manually and wait 1 minute for the system to evaporate all the

refrigerant

• Set the “degree of dryness “X” to 1.00 and the “Minimum valve opening in %“ to 0 this is done with the HB

tool as described before. Wait for 2 minutes

a. Disconnect the M12 plug and connect a PC with the HB tool with an USB/M12 cable.

b. Check that the control bar at the boom of the page indicates 0%

c. Select the “calibraon” tab and you get the picture shown.

d. Your calibraon is perfect if you don’t get a lower “Actual measurement in pF” than the value stated in the eld

“Dry calibraon in pF”. If the “Actual measurement in pF” is lower you need to make a new calibraon. This is done

by clicking on the “Dry sensor calibraon” boom. If the “Dry calibraon in pF” sll is higher than the “Actual

measurement in pF” click the buon once again.

e. When the calibraon is perfect, set the

“degree of dryness “X” back to normal, and

the “Minimum valve opening in %“ to normal

and then unplug the PC, reconnect the nor

mal M12 plug .

13

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

How to check your calibraon and make a new calibraon while sensor is connected

to PLC

Start your refrigeraon system and let it reach normal operang temperature.

Make sure the sensor is completely dry by closing the expansion valve manually and wait for the system to evapo-

rate all the refrigerant

3. Read the minimum “Actual measurement in pF” either from the PLC or by connecng a PC directly to the sensor

4. Your calibraon is perfect if you don’t get a lower “Actual measurement in pF” than the value stated in the eld

“Dry calibraon in pF” if the “Actual measurement in pF” is lower you need to make a calibraon. This is done by

clicking on the “Dry sensor calibraon” buon. If the “Dry calibraon in pF” sll is not lower than the “Actual

measurement in pF” click the buon once again.

Calibraon using a splier box

When using a splier box it is possible to run the refrigeraon system and connect a PC to the sensor at the same me.

The splier box is not suited for normal operaon, but only for installaon and modicaon. The splier box is connect-

ed to the M12 plug on the HBX sensor and then both the pc and the normal M12 plug can be connected.

Calibraon of sensor operang in ooded systems

Dry calibraon of the sensor is not crical when used in a ooded system and it is not needed to calibrate the sensor. If

you like to do a calibraon is similar to DX operaon. Note before making a dry calibraon the maximum “Dry sensor” X

value have to be set to 1.00. If the maximum is set to a value lower than that please contact HB product support depart-

ment as calibraon is not straight forward and requires a special uid or the correct gas/liquid mixture.

14

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

How does the expansion valve control loop work for DX operation

From stop to start

To start the process you need to activate the run in signal by applying 5-24 V on pin 5 when you remove the voltage

the system will stop. If this signal is not set the automatic dry-out is not enabled. The run in signal should be applied

when the compressor starts to benet from the start up process with a dry out period.

Dry out period and kickstart period

The controller will open the expansion valve to dry out the sensor and start the process. This function is only active if

the sensor basic setting “run in signal” is set to “ON” The idea behind the dry out and kickstart function is to ensure a

rapid start up to avoid compressor cut out due to low pressure and avoid very low evaporator temperatures. The pro-

cess can be started by a fast opening of the expansion valve to generate a high gas ow from the evaporator through

the sensor and removing potential liquid refrigerant and oil. The opening of the expansion valve also prevents the sys-

tem from shutting down due to low suction pressure.

When a plate heat exchanger is used we recommend to kick-

start process to avoid freezing. Without kickstarting the very

low suction pressure might result in local freezing on the

secondary side and damage the heat exchanger.

The dry out run for a period specied in the parameter:

“Dry out function in sec” and is ramped up with the speed

set in the parameter: “Ramp dry out % in sec”. When the

dry out is done, ramp up to normal operation will begin.

If the system usually is dry after a stop or defrost, the peri-

od can also be used as a kickstart period. This is typically

needed in small system and especially in heat pumps where

the compressor has a tendency to drop out due to low suc-

tion pressure. Here you can try to increase the opening until

it works. Note you might hit the low level alarm limit.

Ramping up capacity

The system will start slowly due to a PI controller which will ramp up the capacity depending on the settings. The “P-

band in %” specify the target for the expansion valve opening and the “I-factor in sec” specify how long time it takes

to reach the target.

80%

Valve Opening

100%

60%

40%

20%

+5°K

LL Alarm...0.900

Set.point.0.980

Start with

Wet sensor

Dry sensor

Wet sensor

Vapor Quality

”X”

Voltage/signal on pin 5, Start/Stop Signal

applied when the compressor starts/stops

0%

Time

24V

0

Ramping up capacityDry out

and

kick-

start

period

stop Normal operaon stop

Valve opening

Sucon temperature

with kick start

Sucon temperature

with slow start up

Time

Temperature

15

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

What then happens is that the controller starts opening the expansion valve at “valve speed 2 open % in sec”

which means more and more liquid is sent to the evaporator. After a period the maximum capacity is reached and

the HBX sensor begins to detect liquid and the opening of the expansion valve is reduced to “valve speed 1 open %

in sec”. At this point the X value passes 1, where X value is a measure for the vapor quality where X=0 is all liquid

and X=1 is dry gas.

With the reduced valve opening speed the capacity will still increase until the setpoint “Degree of dryness “X” ” is

reached. After this point the controller will open and close the valve to maintain a stable “X “value.

Normal operation and stopping

The normal operation will continue until the system is stopped by removing the voltage on pin 5 for defrost or a

regular stop. After stop, the process will restart with a new dry out period, which is important for a smooth opera-

tion.

What happens when the process is disturbed

If something happens with the complete system which results in liquid in the evaporator outlet there is a build in

safety system that protects the compressor. If the sensor measures a “X” value lower than the “low limit safety

alarm in “X”” the valve will be closed rapidly until setpoint “Degree of dryness “X” ” is reached again. The speed

can be adjusted in the parameter: “Low Limit Valve close %/sec” and is as default set very high for safety rea-

sons—it might lead to unstable operation. If the system has an accumulator before the compressor the “Low Limit

Valve close%/sec” can be set to a lower value e.g. 0.8 instead of the default 0.9 to avoid instability. The gure be-

low shows what happens when the low limit safety alarm is hit.

To make sure the compressor is not shut down due to too low suction pressure there is a parameter: “Minimum

valve opening in %” in the system. There is also a parameter: “Maximum valve opening in %” which is there to

limit the liquid injection if the valve is too large.

How does the control loop work for ooded operation

The sensor can control a liquid valve or a circulation pump directly in a similar matter as for an expansion valve in

DX operation. The control loop can work with any vapor quality all the way to X=0 (all liquids) if needed.

HB-products support can help you with setting up the system.

Min. Valve opening

80%

Valve Opening

100%

60%

40%

20%

Valve opening/closing me

”X”

+5°K

LL Alarm...0.900

Set.point.0.980

Start with

Wet sensor

Dry sensor

Wet sensor

Vapor Quality

”X”

DI, Start/Stop Signal, Run-In…..pin 5

0%

Time

Valve Speed 2 Valve Speed 1

ON

OFF

Valve Close

Low Limit Safety Alarm at ”X” 0.9

Closing the liquid Valve to minimum Valve

opening (Ramp me controlled)

Valve Open

Speed 2

Valve Closing

Speed

Open

Speed 1

Dry out and kick-

start period

16

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

1. Set the desired degree of dryness, ”X” value. For DX operation a good starting point would be 0.98 the clos-

er to 1 you go the dryer the gas will be. The X value is the Vol% of liquid

2. Set the P-band to 10% as a starting point. If the value is set higher the valve will react slower

3. Set the I-factor to 40 sec as a starting point. This means the system will ramp up over a period of 40 sec-

onds. If the I value is set higher the system will be very slow

4. Set lter time to 5 seconds. The lter time is the period of time over which the X measurement is averaged

over. Increased lter time smoothens the measurement, but the risk is that the system becomes too slow.

5. Run in signal (digital input pin 5) is used as external start and stop signal when set to ”ON”. This is im-

portant. If set to “OFF” the dry-out will not work and there is a risk that the control system will not really

start up because the sensor is wet to begin with.

6. Zero cal. function: Choose ”ON” if you want to use the push button ”R” for zero calibration. Default is “OFF”

7. The “Alarm setting in “X” “ is 0.8 as default, and the “Alarm delay in seconds” is as default 10 sec. The

alarm is normally only used when the sensor act as leakage control or as compressor protection—se special

section

8. If the sensor has a temperature sensor it has to be mounted according to the installation guide and the

“Temp. comp. function” should be set to “Temp. oset” This activates the temperature compensation and

gets a more accurate “X” measurement

9. “Select refrigerant type” is for information only and should not be used for changing refrigerant as it does

not change the important settings, and the sensor will not provide the correct measurements. If your refrig-

erant is not correct you need a complete settings le - please contact HB-products for this.

10. After changing settings push the button ”Save to sensor” (the message ”OK” on the screen indicates that the

settings are saved)

11. Go to next page: Advanced settings

How to setup the sensor as direct controller of an expansion valve.

Typical values for DX operation

17

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

1. Valve speed 1 opening time in sec., Default is 0.2 sec. and a good starting point

2. Valve speed 2 opening time in sec. Used for fast opening during start-up , Default is 0.5sec.

3. Valve speed closing time in sec., default is 0.3 sec. and a good starting point

4. Dry out time function in sec., This function opens the expansion valve to dry-out the sensor after a stop or de-

frost, and is essential for a good starting process. Default is 20 sec. and a good starting point

5. Ramp dry-out %, degree of valve opening in % per second (safe function to minimize hydraulic shock) 2 % is a

good starting point. The function can also be used a kickstart function if the compressor tends to stop due to low

pressure. This function is typically needed for smaller heat pumps.

6. Alarm output, NO (normally open) or NC (normally closed) , default is ”NC” (Fail safe function) This setting is

linked to the alarm on the previous page and is normally only used when the sensor act as leakage control or as

compressor protection—se special section

7. Minimum valve opening in % (ensures against stops due to low suction pressure) 10 % is a good starting point

8. Maximum valve opening in %, normally set to 100% but a lower number is used for oversized valves

9. Low limit safety alarm in ”X” value, default value is 0.9 This is a safety function which closes the expansion valve

rapidly to minimum opening in order to protect the compressor. 0.9 or 0.85 are a good starting points for DX.

Choose 0.85 if you have a system with large capacity variations. For ooded operation the setpoint have to be

10% lower than the “degree of dryness, ”X”

10. Low limit valve close time in sec., default value is 5% per second used for fast closing when the sensor getting

wet, 5% is a good starting point

11. After Changing settings push the button ”Save to sensor” (a message ”OK” on the screen indicates that the set-

tings are saved)

12. Check all settings by push the button ”Show sensor settings”

13. Save settings le is used to save all the settings as a txt le

14. Load settings le is used to set up all parameters from an existing .hbp le (copy data to a new sensor )The con-

tent can be read in a text program like MS word+

Advanced settings for sensor as direct controller of an expansion valve.

Stepper motor sengs only ap-

pear in sensors with built-in

stepper motor print.

Can be used for all valve types,

stepper motor sengs must

match manufacturer's instruc-

ons.

Displayed sengs are for a Carel

EV2 valve. There is an instruc-

on manual describing how to

setup and connect dierent

valves on hbproducts.dk

If you need further help, please

contact sup-

port@hbproducts.dk

18

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

Controlling a ooded or semi ooded evaporator

The sensor can be used direct control of a liquid valve in an overfeed system.

The sengs are similar to the DX system but a few sengs have to be dier-

ent .

The degree of dryness “X” have to be lower and the rule of thumb is that the

CR (circulaon rao) is CR=1/”X” so if you aim for CR = 2 put in 1/2 = 0.5 as The

degree of dryness “X”

The remaining parameters in basic sengs can be the same as for DX

For the advanced sengs, the “Low limit safety alarm in “X” har to be set ap-

prox. 10 % lower than the “degree of dryness “X” . An example: for a value

“degree of dryness “X” = 0.6 you choose around 0.54. If you have a system

with large variaons in load you need a large gap between the two values than

if you have a very stabile system. If the “Low limit safety alarm in “X” is too

close to the “degree of dryness “X” there is a risk that the system becomes

unstable because you hit the limit and the liquid valve will close rapidly.

Under the calibraon tab, the sensor has to be set to ooded operaon called

“HBX-CR” which is normally done at delivery. If this is not done or the sensor

has to be used for another purpose it can be changed here. You start by cking

o the three small boxes to the right. Then the large input boxes come to live

and you can change the applicaon to “HBX-CR” for ooded operaons and set

the sensor type if wrong. At the same me you can change the operaon range

from minimum in the box called “X measuring scale” to maximum called “Dry

sensor”. When you are done changing the parameters, you store them in the

sensor by clicking on “X scale calculaon”.

Tick o here for geng

access to selecon of

applicaon

Tick o and

select applica-

on to HBX-CR

here

Set minimum

value here

Set maximum

x value here

Tick o here

and select

sensor type

Click here to

store the data

in the sensor

19

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

+24V DC or AC

- Common

AI Remote sengs*/DO Alarm

AO,4-20 mA level **

DI start stop

4

1

5

3

2

R

1

5

4

3

2

ALARM

LIQUID

POWER

PLC

+

-

AO

AI

DO

Run IN signal 5 to 24 V

Temperature sensor PT1000

Should be mounted on the outside of

the tube in posion 3 or 9 o´clock with

cable es

Color coding

A+ = yellow(2)

A- = white (4)

B- = green (1)

B+= brown (3)

Connecon diagram for HBX/S (stepper motor) with tempera-

ture compensaon — here shown with Carel E2V

• Under ”advanced sengs” the stepper motor sengs

for the valve should be specied

• Analog output see page 19

*Please see appendix for descripon of remote sengs

** When the sensor is very wet it will deliver 22 mA

20

HBX-all types installaon and calibraon manual 03 date: 26-06-2020 WWW.HBPRODUCTS.DK

AO = Gray , 4-20 mA

- Common

AI Remote sengs*/DO Alarm

AO,4-20 mA level vapor quality**

DI start stop

4

1

5

3

2

R

1

5

4

3

2

ALARM

LIQUID

POWER

PLC

+

-

AO

AI

DO

Run IN signal 5 to 24 V

Motor valve: 4-20 mA 24 V DC, max 24 W

3 wire connecon

Connecon diagram for HBX/C motor valve— here shown with Siemens MVS661

-common

+ supply

mA input

mAoutput posion

Open/Close valve

G0

G

Y

M

U

ZC

+24V DC or AC

+ = Brown Supply

- = White common

Manual open/close

Close

Open

MVS661 motor valve

Opportunies when used as controller:

• Addional analog output showing Vapor Quality, 4-20mA (sensor pin.

4).

• Change set-value by remote seng, 4-20mA (sensor pin. 3).

• Controller funcon may be monitored by data logging of the valve

posion, as shown by measuring the valve opening signal on MVS661

terminal U (4-20mA/0-10V)

• Analog output see page 19

*Please see appendix for descripon of remote sengs

** When the sensor is very wet it will deliver 22 mA

Important informaon on motor valves

Some motor valves does not work properly when mounted in a cold room.

Please check supplier specicaon.

Table of contents

Other HB Products Accessories manuals

HB Products

HB Products HBIB Use and care manual

HB Products

HB Products HBX Vapor Quality sensor Operator's manual

HB Products

HB Products HBDF-MK2 User manual

HB Products

HB Products HBDF User manual

HB Products

HB Products HBCP User manual

HB Products

HB Products HBLT User manual

HB Products

HB Products HBLC User manual

HB Products

HB Products SLCD-M1/_Ex Series User manual

HB Products

HB Products HBLT-A1 User manual

HB Products

HB Products HBDF MK2 User manual