Healthcraft SP-SI User manual

SuperPole™ with Safety Island™

Technical Specifications:

1234

M

I

N

ASSISTANCE LEVEL M

A

X

Features and Benefits

H

H

HealthCraft Products Inc., 2790 Fenton Road, Ottawa, Ontario, Canada K1T 3T7

Toll Free: (888) 619-9992 Tel: (613) 822-1885 Fax: (613) 822-1886

360 Degree Support

360 Degree Support

– Effective ring design provides continuous support

to make small, safe steps, reducing unnecessary reaching and twisting.

Ring & tray will not spin freely around the pole, providing fixed support

and an ideal weight bearing surface when gripping strength is weak.

Convenient

Convenient

– Easy to clean tray can be accessed from around the

SuperPole™. Perfect for reading material, medication or items needed

within arms reach. The Safety Island™ will mount to the SuperPole™ at

virtually any height.

Ideal for Kitchens

Ideal for Kitchens

– Install in the center of the kitchen to create secure

support when moving between chair, table, sink or counter. Use the tray

to place meals while moving from cooking surface to kitchen table.

Tubular Ring

Tray

Floor to Ceiling Range

Uni-Fit Extender™

SuperPole™Ultra

Ceiling Plate Extender™

Pole Material

Grip Material

Expansion Mechanism

Weight Capacity

Assistance Level

Typically 28-38"/71-97cm from floor, 18"/46cm diameter, 1.25"/3.175cm diameter

tube for easy gripping.

14"/36cm diameter A.B.S. tray, easy to wipe clean. Weight capacity 15lbs/7kg.

93-99"/236-251cm (standard).

Increase floor to ceiling range to 100-120"/254-305cm. Sold separately. NOT TO

BE USED WITH SUPERTRAPEZE™.

NOT TO BE USED WITH SAFETY ISLAND™.

Allows standard ceiling plate (20”/51cm length) to span 30”/76cm with holes for

ceiling attachment to 24”/61cm ceiling beam centers. Sold separately.

Heavy gauge steel, 1.5"/3.81cm diameter. High temperature baked powder coat

gloss white enamel.

Grey, premium high quality grip, 20"/51 cm long. Does not contain natural dried

rubber or latex. Washable.

Steel jackscrew, zinc plated, 1-1/8" fine cut thread.

250lbs/113kg. Bariatric model 450lbs/205kg capacity.

A unique circular ring with a tray that mounts at any height to the

SuperPole™. Combines the fixed support benefits of a grab bar with the

simplicity and convenience of a tray.

HospitalBathroomBedroom

Call to Order: (919) 844-9402

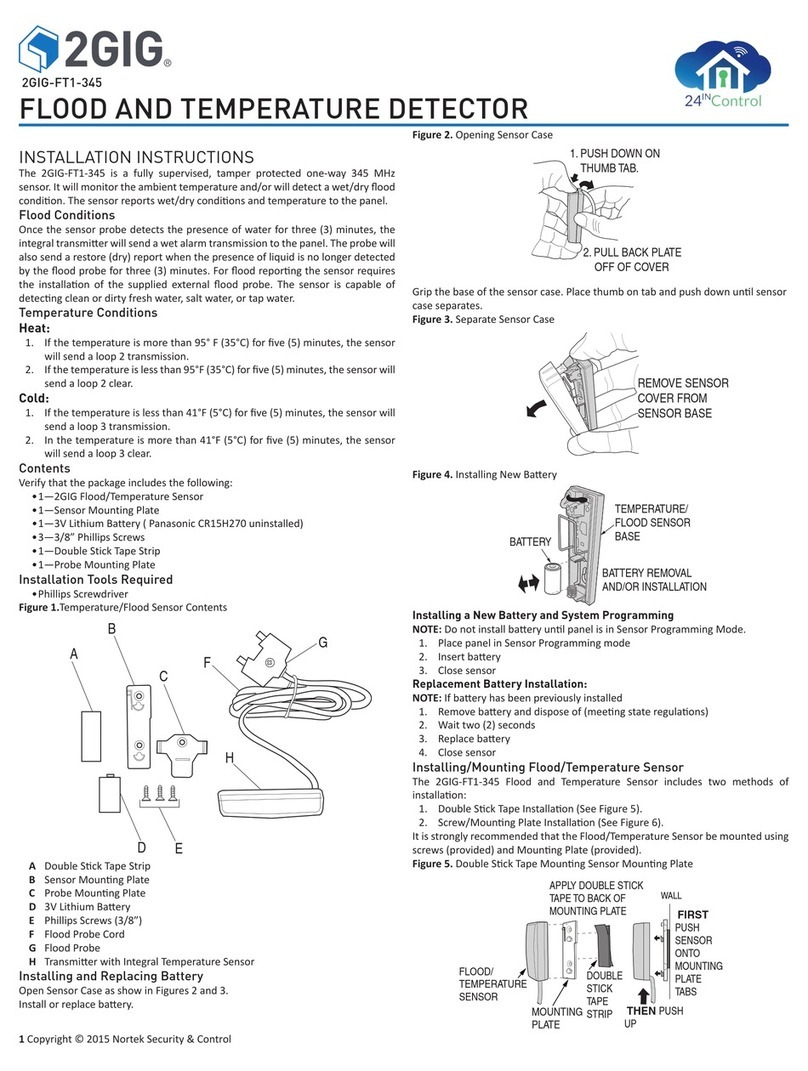

INSTALLATION

INSTRUCTIONS

Model SP-SI

"Innovative Products for Independent Living"

TM/MC

SuperPole

TM

Safety Island

TM

CAUTION

RISK OF INJURY!

Understand these instructions prior to using product.

Also, refer to the SuperPole

TM

System instructions.

HealthCraft Products Inc., 2790 Fenton Rd., Ottawa, Ontario, Canada, K1T 3T7

Copyright 2004. Specifications subject to change without notice.

Prior to installing the Safety Island

TM

option, we strongly

recommend that you first read through these instructions.

We would also recommend that you set aside a space on

the floor or a table to prepare the SuperPole

TM

System prior

to raising the pole for final installation.

D1. See steps A1 and A2 on page 2. Complete these

instructions and then continue with step D2.

D2. Unpack the Safety Island

TM

unit (27). Slide the Safety

Island

TM

unit (27) onto the pole assembly (2) as shown in

Figure D1 (side of tray on top of spokes to go onto pole

first). Slide it on as straight as possible to avoid scratching

the paint on the pole.

D3. See steps A3, A4, and A5 on page 2. Complete these

instructions and then continue with step D4.

D4. The next step is to fix the Safety Island

TM

to the pole as

shown in Figure D2. It is recommended that the tubular ring

of the Safety Island

TM

is approximately 28" - 36" from the

floor (this height is determined by the height of the user -

consult your therapist).

Fasten the Safety Island

TM

to the pole by installing and

tightening the three set screws (28) with the provided hex

key wrench (29). You will need to slide the spring ring (30)

downwards to gain access to the screw holes.

IMPORTANT - These screws MUST be tightened until they

are flush with the collar or injury may result. NOTE: By

tightening the set screws, the cone points will penentrate

the pole for positive engagement, thereby leaving

permanent indentations in the pole. BE CERTAIN THE

SAFETY ISLAND

TM

IS AT THE CORRECT HEIGHT AND

ORIENTATION BEFORE PROCEEDING.

D5. Slide the spring collar upwards on the Safety Island

TM

collar as shown (Figure D3) to retain the set screws (28)

while in service. Inspect frequently to ensure screws and

collar are tight.

D6. See steps A2 to A9 on page 2. Complete these

instructions to finish the installation of your Safety Island

TM

.

FIGURE D1

227

SLIDE ONTO POLE

FIGURE D2

D1

INCORRECT!

CORRECT!

Ensure all three set screws

are screwed in completely

until back end of screw is

flush as shown.

TUBULAR RING

HEIGHT RANGE

FROM FLOOR

28"-36"

SET HEIGHT AND TIGHTEN SCREWS

FIGURE D3

Slide the spring collar

upwards over as shown

to retain the screws whle

in service.

INSTALL SPRING COLLAR

28

29 30

HealthCraft Products Inc., Ottawa, Ontario, Canada. Copyright 2006. Specifications subject to change without notice. Page 1 of 8

www.healthcraftproducts.com

SuperPole™System

Installation Instructions: SP-S, SP-HD, SPB-S,

SPB-HD, STP-S, STP-SPB-AK

THANK YOU...

Thank you for purchasing the SuperPole™ System. We are confident

that you will find the unique design and durable construction of this

HealthCraft™ product to be of great assistance in your daily routine.

To fully enjoy your SuperPole™ System, please take a few moments

to read these instructions. You should store these instructions in a

safe place for future reference.

SAFETY CONSIDERATIONS

CAUTION: It is your responsibility to see that your SuperPole™

System is properly assembled, installed, and cared for. Failure to

follow instructions in this manual could result in serious injury.

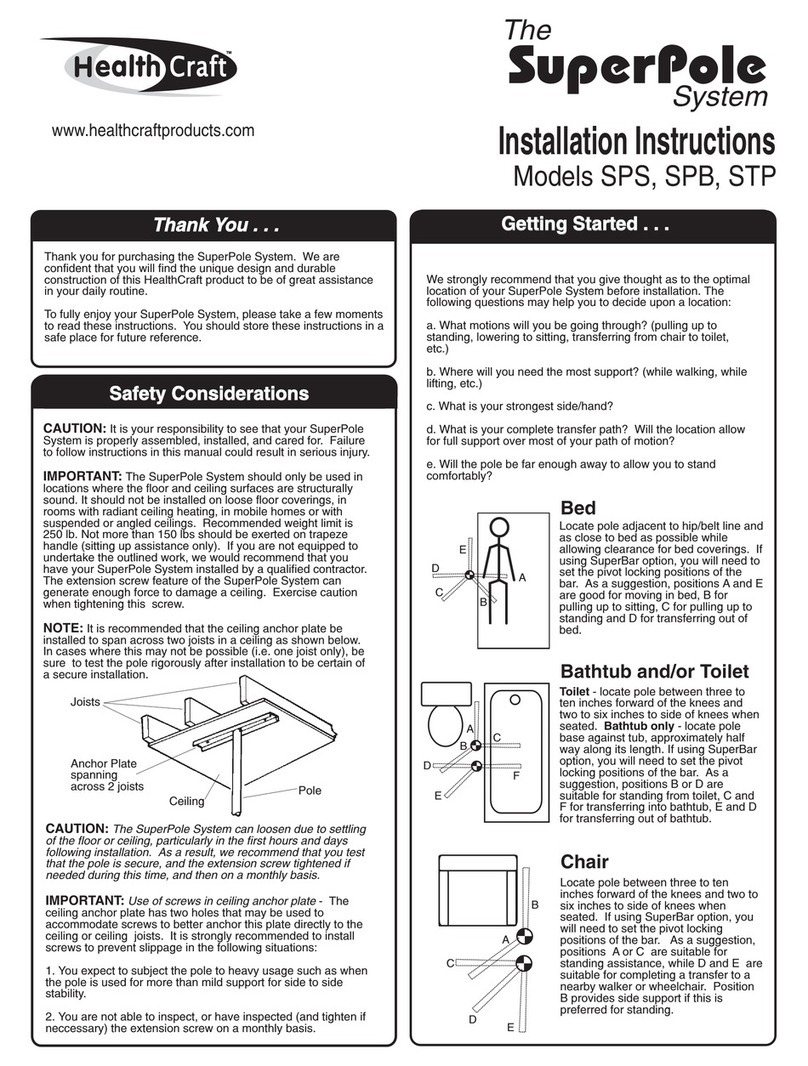

SUPERPOLE™ INSTALLATION / MAINTENANCE

The SuperPole™ System should only be used in locations where the

floor and ceiling surfaces are structurally sound. It should not be

installed on loose floor coverings, in rooms with radiant ceiling heating,

in mobile homes or with suspended or angled ceilings. Recommended

weight limit is 250 lbs. Not more than 150 lbs should be exerted on

trapeze handle (sitting up assistance only). If you are not equipped to

undertake the outlined work, we would recommend that you have your

SuperPole™ System installed by a qualified contractor. The extension

screw feature of the SuperPole™ System can generate enough force

to damage a ceiling. Exercise caution when tightening this screw.

CAUTION: The SuperPole™ System can loosen due to settling of the

floor or ceiling, particularly in the first hours and days following installa-

tion and sometimes with a change of season. As a result, we recom-

mend that you test that the pole is secure, and the extension screw

tightened if needed during this time, and then on a monthly basis.

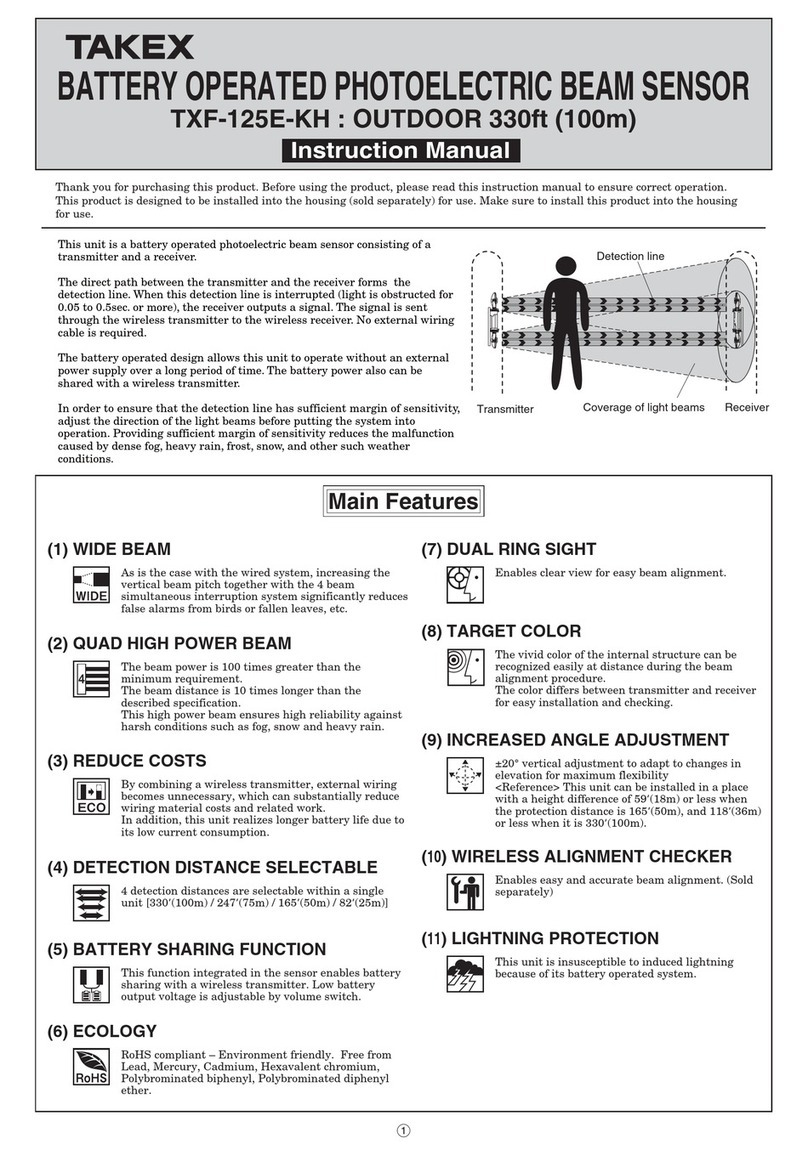

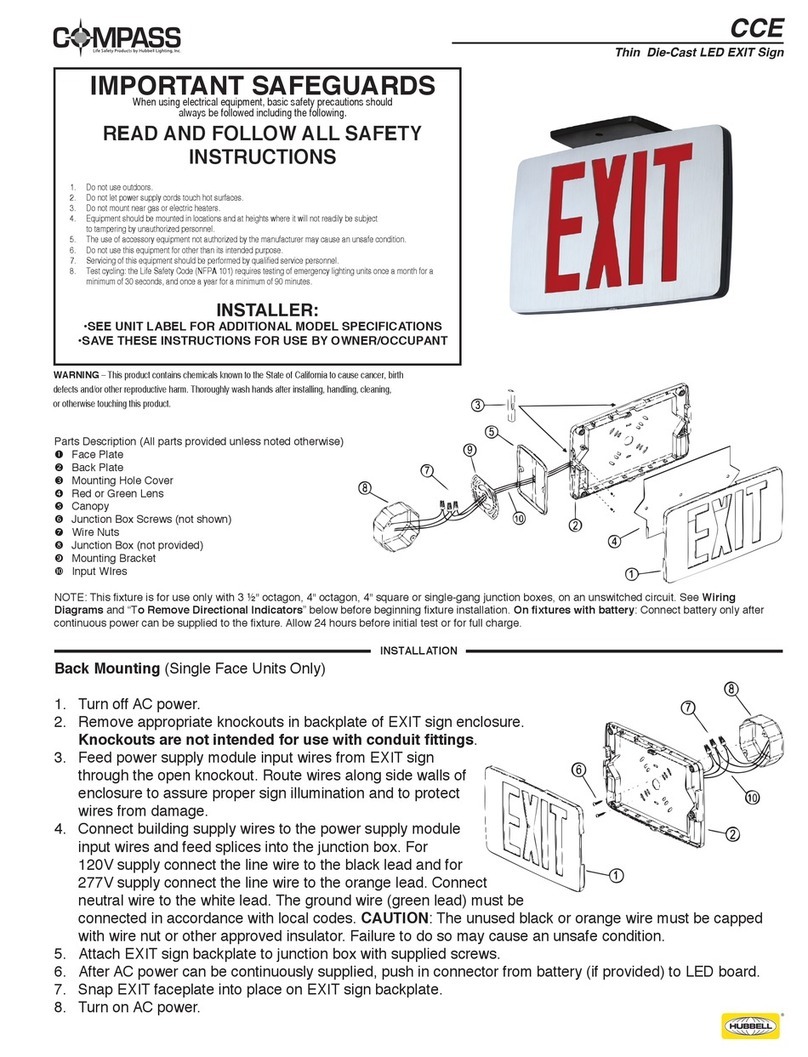

CEILING ANCHOR PLATE

It is recommended that the ceiling anchor plate be installed to span

across two joists in a ceiling as shown above. In cases where this may

not be possible (i.e. one joist only), be sure to test the pole rigorously

after installation to be certain of a secure installation.

IMPORTANT: The ceiling anchor plate has two holes that may be used

to accommodate screws to better anchor this plate directly to the

ceiling or ceiling joists. It is strongly recommended to install screws to

prevent slippage in the following situations:

1. You expect to subject the pole to heavy usage such as when the

pole is used for more than mild support for side to side stability.

2. You are not able to inspect, or have inspected (and tighten if necces-

sary) the exension screw on a monthly basis.

WARNING - PATIENT ENTRAPMENT!

The potential risk of entrapment (limb, neck, head, torso) between the

pole and adjacent item (i.e. bed) can be reduced or avoided by the

following strategies:

1. Situate the pole at a distance that is considerably smaller or larger

than that which could result in entrapment.

2. Consider situations that could change with time or usage such as

mattress compression, patient movement, bed position changes due

to electrically powered beds, etc.

3. Realize that this product is not intended as a physical constraint or

barrier to exiting the bed.

GETTING STARTED

We strongly recommend that you give thought as to the optimal

location of your SuperPole™ System before installation. The follow-

ing questions may help you to decide upon a location:

a. What motions will you be going through? (pulling up to standing,

lowering to sitting, transferring from chair to toilet, etc.)

b. Where will you need the most support? (while walking, while

lifting, etc.)

c. What is your strongest side/hand?

d. What is your complete transfer path? Will the location allow for full

support over most of your path of motion?

e. Will the pole be far enough away to allow you to stand comfort-

ably?

SUPERPOLE™ PLACEMENT

BEDROOM

Locate pole adjacent to hip/belt line and as close to bed as possible

while allowing clearance for bed coverings. If using SuperBar™

option, you will need to set the pivot locking positions of the bar. As

a suggestion, positions A and E are good for moving in bed, B for

pulling up to sitting, C for pulling up to standing and D for transferring

out of bed.

TOILET and / or BATHTUB

Toilet - locate pole between three to ten inches forward of the knees

and two to six inches to side of knees when seated. Bathtub only -

locate pole base against tub, approximately half way along its length.

If using SuperBar™ option, you will need to set the pivot locking

positions of the bar. As a suggestion, positions B or D are suitable

for standing from toilet, C and F for transferring into bathtub, E and

D for transferring out of bathtub.

CHAIR

Locate pole between three to ten inches forward of the knees and

two to six inches to side of knees when seated. If using SuperBar™

option, you will need to set the pivot locking positions of the bar. As

a suggestion, positions A or C are suitable for standing assistance,

while D and E are suitable for completing a transfer to a nearby

walker or wheelchair. Position B provides side support if this is

preferred for standing.

CD

E

B

A

BA

C

E

D

F

B

A

C

E

D

Ceiling

Anchor Plate

spanning

across 2 joists

Joist

Ceiling

Pole

Figure 1.

Figure 2.

Figure 3.

Correct! LevelIncorrect!

Figure 4.

HealthCraft Products Inc., Ottawa, Ontario, Canada. Copyright 2006. Specifications subject to change without notice. Page 2 of 8

FOR SUPERPOLE™ INSTALLATION, CONTINUE BELOW...

Prior to installing the SuperPole™, we strongly recommend that you

first read through these instructions.

SUPERPOLE™ PREPARATION

A1. Unpack the ceiling anchor plate (1) from the rectangular box, and

the pole assembly (2) from the cardboard tube (remove staples to

avoid scratching the paint on the pole). Remove the clevis pin (3) from

the pole receptacle in the center of the ceiling anchor plate.

A2. Slide the top end of the pole (2) onto the receptacle of the ceiling

anchor plate (1) as shown in Figure 1. Align the locking pin holes of

the pole and the receptacle. Insert the clevis pin (3) removed in step

A1, and secure with nylon washer (4) and hitch pin (5).

A3. Raising the Pole. Place the circular base (7) on the floor at the

intended location of the SuperPole™ as shown in Figure 2. The

SuperPole™ is most easily raised by holding the pole up at an angle,

inserting the stem on the bottom of the extension screw (8) into the

hole on the circular base (7), and then pivoting the pole up above the

base plate as shown in Figure 3.

HINT - to prepare, set the extension screw (8) such that the distance

from the top of the ceiling anchor plate (1) to the bottom of the

extension screw is about two inches less than the actual floor to

ceiling height. You may need to unscrew the jam nut (9) downward to

allow the extension screw to rotate.

A4. Set the SuperPole™ to a true vertical position. This may be

facilitated using a construction level, plumb bob, or by visually

comparing the pole with other vertical line features in the room such

as wall corners, etc.

HINT - It is easier to swing the pole up from one of the sides of the

ceiling anchor plate as shown in Figure 3. If the ceiling anchor plate

hits the ceiling prior to reaching vertical you will need to shorten the

length of the extension screw.

SUPERPOLE™ INSTALLATION

A5. While the cover sleeve (6) is held up, insert a bar such as the

shaft of a screwdriver, through the drive hole at the bottom of the

extension screw. Turn the extension screw (clockwise) as shown in

step 1 of Figure 4 to make the ceiling anchor plate contact the ceiling.

IMPORTANT - The ceiling anchor plate must be made to contact the

ceiling squarely. This can be facilitated by having a second person

hold the pole exactly vertical while turning the extension screw.

Continue turning the extension screw until the anchor plate contacts

the ceiling squarely. From this point continue to turn the extension

screw approximately two to five turns until the SuperPole™ is secure

and ready for testing in step A6.

TESTING INSTALLATION

A6. Test the SuperPole™ by firmly holding onto the pole at mid-height

and rigorously attempting to force the pole from side to side. Use

considerable body weight momentum to conduct an aggressive test.

If either the base, or the ceiling anchor plate appear to slide or shift,

tighten the extension screw one more turn and repeat the test until the

pole will not move during this test.

EXTENSION SCREW

A7. IMPORTANT - Lock extension screw after installing pole by

turning jam nut (9) up until touching the bottom of the pole, then,

simultaneously turning jam nut (9) and extension screw (8)

backwards until jammed tight as shown in steps 2 & 3 of Figure 4.

When finally tight, remove the turning rod, slide the cover sleeve

down to cover the extension screw.

Your SuperPole™ is now installed.

1

2

7

6

6

8

5

4

9

98

3

(1) (2) (3)

SUPERTRAPEZE™

INSTRUCTIONS

BEGIN ON

PAGE 6

SUPERBAR™

INSTRUCTIONS

BEGIN ON

PAGE 4

HealthCraft Products Inc., Ottawa, Ontario, Canada. Copyright 2006. Specifications subject to change without notice. Page 3 of 8

PARTS DIAGRAM: POLE / CEILING ANCHOR PLATE

ASSEMBLY

PARTS DIAGRAM: POLE / EXTENSION SCREW /

BASE PLATE ASSEMBLY

SP 402 Base Plate Assembly

SP 112P Base Plate

SP 118 Base Plate Rubber

SP 403 Ceiling Anchor Plate Assembly

SP 115 Top Plate

SP 117 Top Rubber

HW 302 Clevis Pin

HW 318 Nylon Washer

HW 323 Hitch Pin

SP 500 SuperPole™ Parts Pack

DC 100 Instructions, SuperPole™

SP-P Pole Assembly

SP 113P Pole

GR 101 Grip, 20” long

SP 114 Plastic, Cover Sleeve

SP 107E Extension Screw

SP 105E Collar

SP 172E Jam Nut

SP 145 Plastic Washer

PARTS DIAGRAM: SUPERPOLE™

HW 323 Hitch Pin

HW 302 Clevis Pin

HW 318 Nylon Washer

SP 117 Top Rubber

SP 115P Top Plate

SP 115PA Top Plate, Heavy Duty

SP 115PB Top Plate, Ultra

GR 101 Grip, 20” long

SP 113P Pole

SP 113PA Pole, Heavy Duty

SP-P Pole Assembly

SP 402 Base Plate Assembly

SP 403 Ceiling Anchor Plate Assembly

SP 500 SuperPole Parts Pack

SP 114 Plastic Cover Sleeve

SP 113P Pole

SP 113PA Pole, Heavy Duty

SP 107E Extension Screw

SP 172E Jam Nut

SP 105E Threaded Collar

SP 105EB Threaded Collar, Heavy Duty

SP 105EC Threaded Collar, Ultra

SP 145 Base Washer

SP 112P Base Plate

SP 118 Base Plate Rubber

Figure 5.

Figure 7.

Figure 8.

UNINSTALLED POLE,

HEIGHT OF BAR

INSTALLED POLE,

HEIGHT OF BAR

HealthCraft Products Inc., Ottawa, Ontario, Canada. Copyright 2006. Specifications subject to change without notice. Page 4 of 8

11

12

10

13

Figure 6.

10

14

13

6

2

17

HEIGHT OF HAND RAIL

Spring

Ring

Installed

Locking

Positions

ROTATIONAL

LOCKING POSITION

2

14

16

15

1

24

86

3

7

5

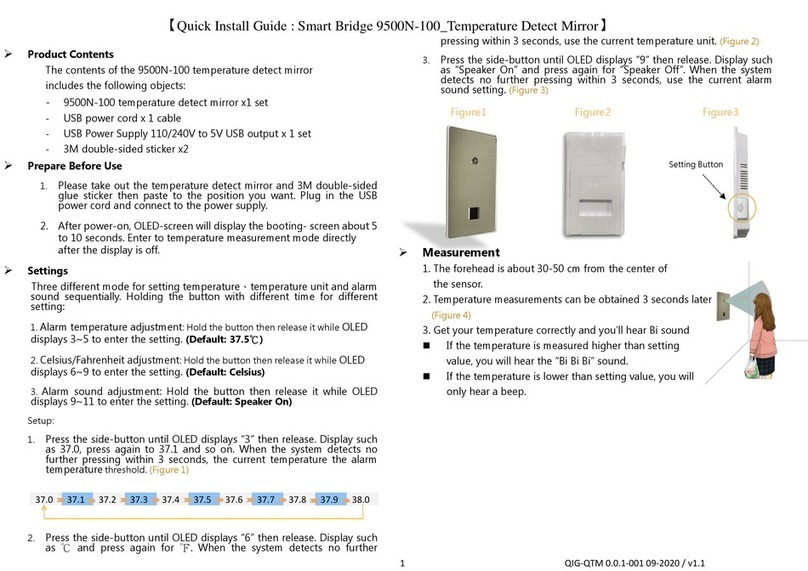

SUPERPOLE™ PREPARATION

B1. See steps A1 and A2 on page 2. Complete these instructions and

then continue with step B2.

SUPERBAR™ PREPARATION

B2. Unpack the SuperBar™ hand rail unit (10). Using the small hex

key wrench (11) and countersunk screw (12), attach one white plastic

pivot bushing (13) to top side of the SuperBar™ hand rail unit as

shown in Figure 5. Set aside the other plastic pivot bushing and

screw. Remove the cover sleeve (6) from the pole assembly (2).

B3. Slide the SuperBar™ hand rail unit (10) onto the pole assembly

(2) as shown in Figure 6 (side with attached pivot bushing to go on

first). Slide it on as straight as possible to avoid scratching the pole.

B4. Unpack and slide the grooved collar (14) onto the pole (2) as

shown in Figure 6. Gently slide the collar up the pole to avoid scratch-

ing the pole. Next slide the other white plastic pivot bushing (13) and

the cover sleeve (6) (removed in step B2) up the pole (2).

IMPORTANT- The next step is to fix the grooved collar (14) to the

pole (2). The position of the grooved collar determines the height of

the bar and the rotational locking position of the bar.

Alternate Installation Option

Steps B5 and B6 can be completed after the pole has been raised in

place (steps A3 to A7 on page 2) to better determine optimal height

and locking positions of the SuperBar™. You may also install just one

set screw to test a height/angle setting of the SuperBar™.

BE CERTAIN THAT THE GROOVED COLLAR IS AT THE

CORRECT HEIGHT AND ORIENTATION BEFORE PROCEEDING.

SUPERBAR™ INSTALLATION

B5. Once the grooved collar (14) has been set to its desired location,

fasten the grooved collar to the pole (2) by installing and tightening

the three set screws (15) with the larger hex key wrench (16). You will

need to slide the spring collar (17) upward to gain access to the screw

holes. IMPORTANT - These screws MUST be tightened until the

back end of the screw is flush with the collar or injury may result.

By tightening these set screws, the cone points will penetrate the pole

for positive engagement, thereby leaving permanent indentations in

the pole (refer to Figure 8).

NOTE! Should you need to change the position of the height/angle

setting, we recommend that you change the height by at least one

inch. This will avoid set screw indentations from being too close to

each other and thereby weakening the pole.

B6. Next, slide the spring collar (17) downward on the grooved collar

(14) as shown in Figure 8 to retain set screws (15) while in service.

Inspect frequently to ensure screws and collar are tight.

B7. Install the remaining white plastic pivot bushing (13) and secure it

with the countersunk screw (12) using the small hex key wrench (11).

B8. See steps A3 to A7 on page 2. Complete these instructions to

finish the installation of your SuperPole™ with SuperBar™.

Your SuperPole™ with SuperBar™ is now installed.

1. Height of Hand Rail - The height at which you fix the

grooved collar determines the height of the SuperBar™ hand

rail unit (10). Consider the optimal height of the bar from

sitting and standing positions. The height of the bar will

change as the pole is installed (dependant on the difference

in height between the ceiling and the pole - see Figure 7).

2. Rotational Locking Position - Each of the grooves

correspond to a rotational locking position of the hand rail unit

(refer to Figure 8). You will want to fix the grooves to have the

hand rail lock in the most advantageous positions for your

assistance as discussed on page 1 ("Getting Started").

SUPERBAR™ INSTRUCTIONS

Prior to installing the SuperPole™ with SuperBar™, we

recommend that you first read through these instructions.

PARTS DIAGRAM: POLE / EXTENSION SCREW /

BASE PLATE ASSEMBLY

PARTS DIAGRAM: SUPERBAR™

HealthCraft Products Inc., Ottawa, Ontario, Canada. Copyright 2006. Specifications subject to change without notice. Page 5 of 8

PARTS DIAGRAM: POLE / CEILING ANCHOR PLATE

ASSEMBLY

SP 102 Pivot Bushing (x2)

HW 100

FHSCS #8-32x⅜”

18-8 SS Screws (x2)

GR 100

Grip, 16” long

HW 112 Set Screw

5/16”-24x3/8

Cone Point (x3)

SP 170E

Spring Ring

SP 116P T Bar

SP 106E

Collar

HW 300

Hew Key Wrench

3/32” short arm

HW 320 Hex Key Wrench

5/32” long arm

SP 501 SuperBar™ Parts Pack

DC 100 Instructions, SuperPole™

HW 100 FHSCS #8-32x⅜”

18-8 SS Screws (x2)

HW 300 Hew Key Wrench

3/32” short arm

HW 112 Set Screw, 5/16”-24x⅜”

Cone Point (x3)

HW 320 Hex Key Wrench

5/32” long arm

SPB SuperBar™

SP 116P T Bar

GR100 Grip, 16” long

SP 102 Pivot Bushing (x2)

SP 106E Collar

SP 170E Spring Ring

SP 501 SuperBar™ Parts Pack

PARTS DIAGRAM: SUPERPOLE™ with SUPERBAR™

GR 101 Grip, 20” long

SP 402 Base Plate Assembly

SP 112P Base Plate

SP 118 Base Plate Rubber

SP 403 Ceiling Anchor Plate Assembly

SP 115 Top Plate

SP 117 Top Rubber

HW 302 Clevis Pin

HW 318 Nylon Washer

HW 323 Hitch Pin

SP-P Pole Assembly

SP 113P Pole

GR 101 Grip, 20” long

SP 114 Plastic, Cover Sleeve

SP 107E Extension Screw

SP 105E Collar

SP 172E Jam Nut

SP 145 Plastic Washer

HW 323 Hitch Pin

HW 302 Clevis Pin

HW 318 Nylon Washer

SP 117 Top Rubber

SP 115P Top Plate

SP 115PA Top Plate, Heavy Duty

SP 115PB Top Plate, Ultra

SP 113P Pole

SP 113PA Pole, Heavy Duty

SP-P Pole Assembly

SP 402 Base Plate Assembly

SP 403 Ceiling Anchor Plate Assembly

SPB SuperBar™

SP 114 Plastic Cover Sleeve

SP 113P Pole

SP 113PA Pole, Heavy Duty

SP 107E Extension Screw

SP 172E Jam Nut

SP 105E Threaded Collar

SP 105EB Threaded Collar, Heavy Duty

SP 105EC Threaded Collar, Ultra

SP 145 Plastic Washer

SP 112P Base Plate

SP 118 Base Plate Rubber

Figure 9.

21

2

20

Figure 10.

Figure 11.

Figure 12.

HealthCraft Products Inc., Ottawa, Ontario, Canada. Copyright 2006. Specifications subject to change without notice. Page 6 of 8

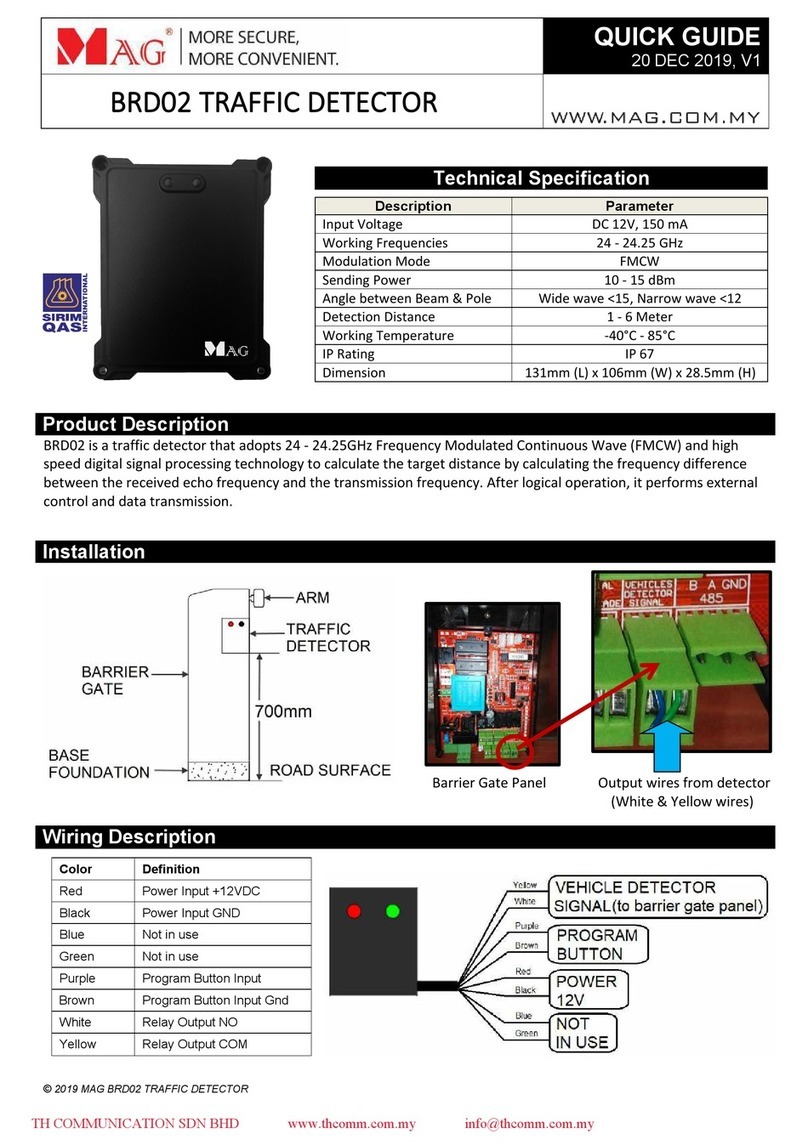

SUPERPOLE™ PREPARATION

C1. See step A1 on page 2. Complete these instructions and then

continue with step C2.

SUPERTRAPEZE™ PREPARATION

C2. Unpack the support arm (20) from the rectangular box. Slide

support arm (20) onto the top end of the pole (2) such that the strap

hook is down as shown in Figure 9. Move it gently down the pole until

it rests against the top of the grey grip (21).

C3. Determine Location of Pole (bedside use) - Refer to Figure 10.

The actual user of the SuperTrapeze™ should lie down in bed in their

normal resting position. The location of the pole alongside the bed is

recommended to be directly beside the hip/belt line as shown. Also,

it is recommended to situate the pole as close to the side of the bed

as possible while leaving enough clearance for the bed coverings.

SUPERPOLE™ INSTALLATION

C4. See steps A2 through A7 on page 2. These steps will guide you

to raise and secure the pole in the location as determined in steps C3.

Complete these instructions and then continue with step C5.

SUPERTRAPEZE™ INSTALLATION

C5. Once the pole has been installed beside the bed, hold the trapeze

handle under the support arm, such that the upper rail of the handle

is closest to the head of the bed as shown in Figure 10. Next, open

the loop on the end of the trapeze strap (22), rotate the strap 180

degrees, and slide it on to the upper rail of the trapeze handle (23) as

shown in Figure 11. Slide it past the grip and along the trapeze tube

until it reaches the top bend of the trapeze as shown in Figure 11.

SETTING HEIGHT OF SUPPORT ARM

C6. Using a tape measure, make a small pencil mark on the pole at a

suggested height of 84" from the floor as shown in Figure 10. Have

the actual user lie down in bed in their normal lying position with their

hands placed palm down on their thighs. Locate the cone point set

screws (25) and allen wrench (24) and have them close at hand.

Gently slide the support arm up the pole until the top of the barrel

reaches the 84" mark as shown by "Y" in Figure 10. Next, swing the

support arm so that the strap hangs directly over the palms of the user

as shown by "X". Secure the support arm to the pole with one of the

set screws (25) and allen wrench (24) as shown in Figure 12.

SETTING HEIGHT OF TRAPEZE HANDLE

C7. Set the trapeze at an appropriate height by adjusting the length of

the strap. This is done by pulling some slack through the cross pieces

of the strap buckle and pulling the buckle down to shorten the strap,

or sliding it up to lengthen the strap. The trapeze handle is at an

appropriate height when ones fingers can comfortably grasp around

the bottom rail of the trapeze when lying down in bed as shown by "Z"

in Figure 10.

TESTING THE LOCATION

C8. Have the user gently try the installed location of the trapeze

handle and pole. Ensure that the trapeze handle is not too close to

allow a comfortable sit up action. Should the trapeze support arm

need to be moved, remove the set screw installed in step C6, and lift

the support arm up by at least one inch and reinstall the screw with

the arm at a new angle to avoid the set screw being too close to the

previous indent created in the pole by step C6.

SECURE SUPPORT ARM

C9. Once the trapeze has been confirmed as the correct location, fully

install all three set screws. IMPORTANT - The set screws should be

installed such that the back end of the screw is flush with the outer

surface of the support arm or injury may result. Slide the spring collar

(26) down over the top of support arm as shown to retain the screws

in service.

Your SuperPole™ with SuperTrapeze™ is now installed.

25

24

22

26

23

Y=84”

X

Z

SUPERTRAPEZE™ INSTRUCTIONS

Prior to installing the SuperPole™ with SuperTrapeze™,

we recommend that you first read these instructions.

STP SuperTrapeze™

SP 123P Trapeze Arm

SP 170E Spring Ring

HW 500 Plug

SP 124P Trapeze handle

GR 102 Grip, 6” long

GR 103 Grip, 10” long

SP 125 Strap

HW 305 Buckle

SP 501 SuperTrapeze™ Parts Pack

HW 500

Plug

SP 123P

Trapeze Arm

SP 125A

Strap

HW 305

Buckle

GR 103

Grip, 10” long

GR 102

Grip, 6” long

SP 170E

Spring Ring

HW 112

Set Screw,

5/16”-24x⅜”

Cone Point (x3)

HW 320

Hex Key Wrench

5/32” long arm

SP 409

E-Handle

PARTS DIAGRAM: POLE / EXTENSION SCREW /

BASE PLATE ASSEMBLY

PARTS DIAGRAM: SUPERTRAPEZE™

HealthCraft Products Inc., Ottawa, Ontario, Canada. Copyright 2006. Specifications subject to change without notice. Page 7 of 8

PARTS DIAGRAM: POLE / CEILING ANCHOR PLATE

ASSEMBLY

PARTS DIAGRAM: SUPERPOLE™ with SUPERTRAPEZE™

SP 501 SuperTrapeze™ Parts Pack

DC 100 Instructions, SuperPole™

HW 112 Set Screw, 5/16”-24x⅜”

Cone Point (x3)

HW 320 Hex Key Wrench

5/32” long arm

GR 101 Grip, 20” long

SP 402 Base Plate Assembly

SP 112P Base Plate

SP 118 Base Plate Rubber

SP 403 Ceiling Anchor Plate Assembly

SP 115 Top Plate

SP 117 Top Rubber

HW 302 Clevis Pin

HW 318 Nylon Washer

HW 323 Hitch Pin

SP-P Pole Assembly

SP 113P Pole

GR 101 Grip, 20” long

SP 114 Plastic, Cover Sleeve

SP 107E Extension Screw

SP 105E Collar

SP 172E Jam Nut

SP 145 Plastic Washer

HW 323 Hitch Pin

HW 302 Clevis Pin

HW 318 Nylon Washer

SP 117 Top Rubber

SP 115P Top Plate

SP 115PA Top Plate, Heavy Duty

SP 115PB Top Plate, Ultra

SP 113P Pole

SP 113PA Pole, Heavy Duty

SP-P Pole Assembly

SP 402 Base Plate Assembly

SP 403 Ceiling Anchor Plate Assembly

STP SuperTrapeze™

SP 114 Plastic Cover Sleeve

SP 113P Pole

SP 113PA Pole, Heavy Duty

SP 107E Extension Screw

SP 172E Jam Nut

SP 105E Threaded Collar

SP 105EB Threaded Collar, Heavy Duty

SP 105EC Threaded Collar, Ultra

SP 145 Plastic Washer

SP 112P Base Plate

SP 118 Base Plate Rubber

Joist

HealthCraft Products Inc., Ottawa, Ontario, Canada. Copyright 2006. Specifications subject to change without notice. Page 8 of 8

www.healthcraftproducts.com

SuperPole™Accessories

& Custom Options

Add a Safety Island™! Add a SuperTray™!

Uni-Fit Extender™Ceiling Plate Extender™

The SuperTray™ is easy to

install, remove and adjust in

height or position. It is a

compact alternative to bulky

floor based over bed tables.

The SuperTray™ can be

removed from the metal

frame and used to transfer

meals from the kitchen.

NOTE: SuperTray™ not to be

used as a weight bearing

surface.

The SuperTray™ simply snaps to the SuperPole™ to

provide the convenience of a bed-side or over bed table.

Ideal For Kitchens. Install

in the center of the kitchen

for support when moving

between chair, table, sink,

or counter. Use the tray to

place items while moving

from cooking surface to

kitchen table.

The Safety Island™ is a unique circular ring with a tray

that mounts at any height to the SuperPole™.

The Uni-Fit Extender™ is added to the SuperPole™ to increase its

height range from 93-99” to 100-120“.

NOTE: Not to be used with the SuperTrapeze™.

The Ceiling Plate Extender™ is added to the standard SuperPole™

ceiling plate to increase its span from 20” to 30”. It may be used in

cases where the SuperPole™ is expected to be subjected to more

aggressive use, or where ceiling structural beams have increased

spacing (such as 24” between centers).

Ceiling

Standard

SuperPole™

Uni-Fit

Extender™

Pole

Standard Ceiling

Anchor Plate

Joist

Ceiling

Pole

Uni-Fit

Extender™

Ceiling Plate

Extender™

Standard Ceiling

Anchor Plate

24”

Sold as SuperPole™ with Safety

Island™, or add Safety Island™

to an existing SuperPole™.

Sold as SuperPole™ with

SuperTray™, or add SuperTray™

to an existing SuperPole™.

STOVE

REFRIGERATOR

SINK

This manual suits for next models

6

Table of contents

Other Healthcraft Security Sensor manuals