2

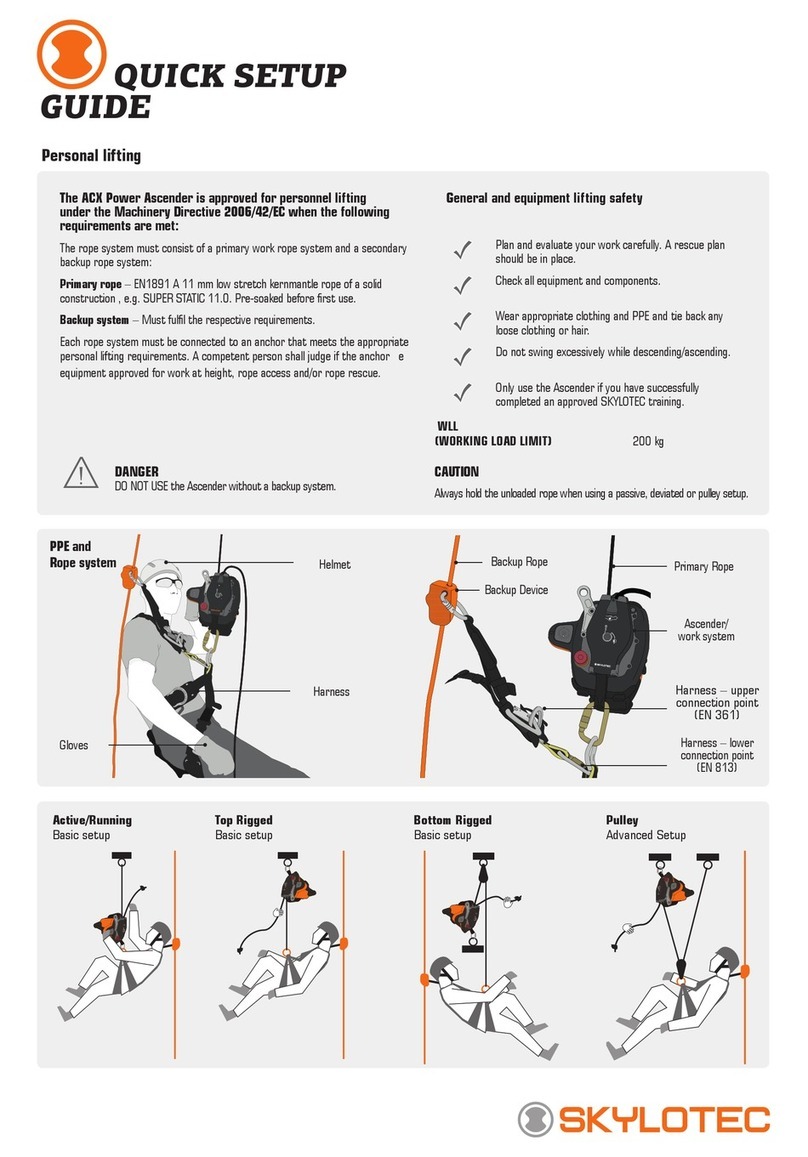

GB Instruction for Use 4

Descending and Rescue-Device with lifting function

According to EN 341 Class A and EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

DE Gebrauchsanweisung 26

Abseil- und Rettungsgerät mit Zugfunktion

In Übereinstimmung mit EN 341 Klasse A und EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

IT Istruzioni per l’uso 48

Dispositivo di discesa e salvataggio con funzione di sollevamento

Ai sensi della direttiva EN 341 classe A ed EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

FR Instructions d’utilisation 70

Appareil de descente et de sauvetage avec fonction de levage

Conforme aux normes EN 341 classe A et EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

ES Instrucciones de uso 92

Dispositivos de descenso y rescate con función de elevación

Según EN 341 clase A y EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

PT Instruções de utilização 114

Dispositivo de Descida e Salvamento com função de elevação

Em conformidade com a norma EN 341 Classe A e EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

NL Gebruiksaanwijzing 136

Afdaal- en reddingsapparaat met heffunctie

Volgens EN 341 Klasse A en EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

DK Brugsanvisning 158

Nedfirings- og redningsudstyr med løftefunktion

I overensstemmelse med EN 341 Klasse A og EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

NO Bruksanvisning 180

Nedstignings- og redningsenhet med løftefunksjon

I samsvar med EN 341 klasse A og EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

FI Käyttöohje 202

Laskeutumis- ja pelastautumislaite nostotoiminnolla

EN 341 luokan A- ja EN 1496-, ANSI/ASSE Z359.4-2013-, CSA Z259.2.3 -standardin mukainen.

SE Bruksanvisning 224

Nedfirnings- och räddningsutrustning med lyftfunktion

Följer EN 341 klass A och EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3

GR 246

Σύμφωνα με το πρότυπο EN 341 Κατηγορία A και EN 1496, ANSI/ASSE Z359.4-2013, CSA Z259.2.3