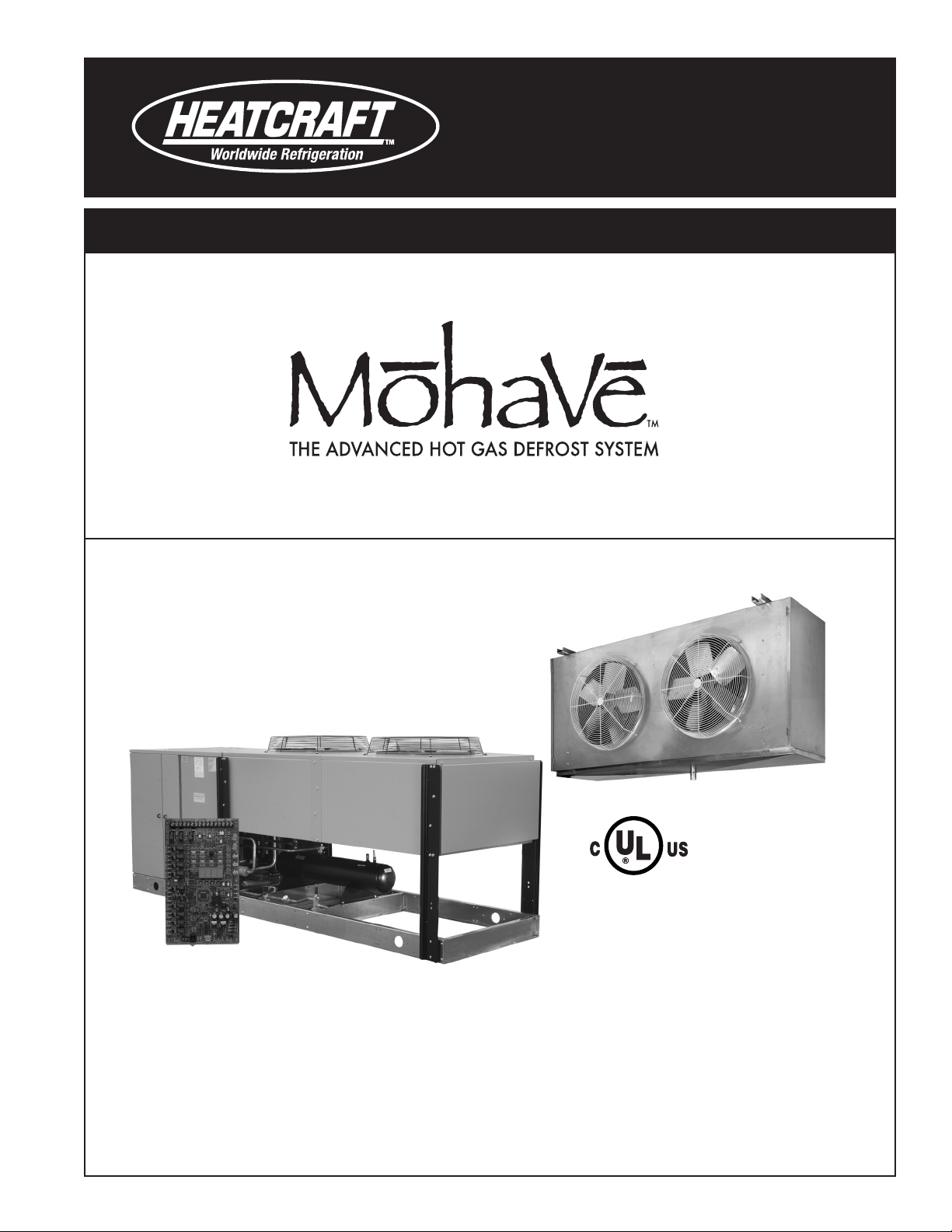

Heatcraft Mohave Guide

H-IM-HGD0 FEBRUARY 2021 Part Number 25007401

Installation, Start-Up, Operation and

Troubleshooting with Wiring Diagrams

Mohave Hot Gas Defrost

Installation

& Operation

Replaces June 2017

2

Controller Quick Reference Guide.............................................................................3-5

Receiving and Inspection

General Safety Information...................................................................................... 6

Warranty Statement............................................................................................... 6

System and Components ....................................................................................... 7

Installation

Unit Cooler Installation............................................................................................ 8

Placement ............................................................................................... 9

Condensate Lines................................................................................... 10

Condensing Unit Installation

Rigging .............................................................................................. 11

Field Piping Guidelines........................................................................12-24

Optional Controls ...............................................................................25-26

System Wiring...................................................................................27-39

Operation

Hot Gas Unit Cooler Typical Factory Piping .............................................................. 40

Hot Gas Condensing Unit Typical Factory Piping ....................................................... 41

Refrigeration Operation ...................................................................................42-43

Defrost Operation ..............................................................................44-47

Evacuation & Leak Detection ................................................................................ 48

Check Out & Start-Up.......................................................................................... 49

Program Review................................................................................50-51

Monitoring & Reviewing Operation Values ............................................................... 52

Error and Alarm Details......................................................................................... 53

Refrigerant Charging.......................................................................................54-55

Operational Check Out ......................................................................................... 56

Refrigeration Oils .................................................................................... 57

Troubleshooting.................................................................................58-60

Preventive Maintenance ..................................................................................61-62

InterLink Service Parts ......................................................................................... 63

Service Record ...................................................................................... 64

Factory Default Settings...................................................................................65-68

Mohave Control Board Comparison........................................................................69

Electronic Pressure Regulator Comparison .............................................................. 70

Modbus Definitions.........................................................................................71-74

Table of Contents

© 2021 Heatcraft Refrigeration Products LLC

3

Controller Quick Reference Guide

Program

Review

Clear/

Test

Reset

Time

Monitor

Enter

Selection

Knob

Force

Service

Force

Defrost

MODE DESCRIPTION

OFF Compressor Off

COOL Compressor On in Cooling Normal Cooling Operation

PMPD System in Pump Down Mode

SERV Service Mode, System is Off

DELY Time Delay

DEF1 Defrost Stage 1

Pre-Defrost or ByPass Mode

DEF2 Defrost Stage 2

Defrost Mode

DEF3 Defrost Stage 3

Post Defrost Equalization or Drain Down Mode

FREZ Refreeze Mode

TEST Test Mode

SERV Service Mode

EVAC Evacuation Mode

Operating Modes

The Mohave™Hot Gas Controller is located inside the condensing unit electrical panel. The

Service Switch is adjacent to the controller on the side of the enclosure.

Service Switch

This toggle switch may be placed in the “on” position to force the system into Service Mode. The compressor will pump down and shut off. The evaporator fans will de-energize.

The system can be left in service.

Control Buttons

Program Review: Review or Change the Program Settings

Enter: Accepts changes into memory

Monitor: View Current Operating Conditions of the System

Reset Time: Resets the time clocks of the microprocessor to 0.

Clear/Test: Clear ignores program selections prior to pressing

Enter and terminates Service Mode. Test causes the system to

cycle through all of the outputs for troubleshooting.

Select Knob: Used for Cycling through Monitoring and

Programming Parameters.

Force Service: Press this button twice to cause the system to

pump down and remain off until the Clear button is pressed.

Force Defrost: System will pump down and begin a defrost cycle. This will not effect the normally scheduled defrosts.

4

DISPLAY DESCRIPTION FACTORY

DEFAULT

CLKH Set the Time of Day clock hour value None

CLKM Set the Time of Day clock minute value None

°F °C Set Fahrenheit or Celsius temperature units (°F or °C) °F

1224 Set Time display method (12 hr. or 24 hr.) 12 hr

ALRT Set the Alarm Time (2 to 120 minutes) 20 min

RTDF* Defrost Schedule based on Compressor Runtime OFF

DF01 Set Defrost 1 starting time (12:00 am to 12:00 pm in 30 minute increments) 12:00AM

DF02 Set Defrost 2 starting time 6:00AM

DF03 Set Defrost 3 starting time 12:00PM

DF04 Set Defrost 4 starting time 6:00PM

DF05-DF12 Set Defrost XX starting time --- ---

APPL** Set Application type (Med., Low) Med Temp

REFR Set Refrigerant type (R-22, R-404A, R-507, R-407A, R-407C, R-407F, R-448A and R-449A)” R-404A

MODL Set Model Number 1502

XPRT Expert Mode (To Access Additional Program Parameters (On, Off) Off

Program Review Menu

Monitor Display Menu

DISPLAY DESCRIPTION

VALP

Defrost Regulator Valve percent of opening (0 to 100%)

SUPH

Superheat (°F.) measured at inlet of Suction Accumulator

SucT

Suction Temperature (°F.) at inlet of Suction Accumulator

SucP

Suction Pressure (PSIG/”HG) at inlet of Suction Accumulator

SSuc

Saturated Suction Temperature (°F.) at inlet of Suction Accumulator

LIQP

Liquid Pressure (PSIG) measured between Receiver and Condenser

AMBT

Ambient Air Temperature (°F.) measured entering condenser coil

AUXT

Auxiliary Probe Temperature (°F.)

E1DT

Evaporator 1 Defrost Sensor Termination Temp (°F.) at outlet of Evaporator 1

E2DT

Evaporator 2 Defrost Sensor Termination Temp (°F.) at outlet of Evaporator 2

ACIN

Control Board voltage (24VAC nominal)

TMMS

Current time minutes and seconds

TMHM

Current time hours and minutes

CCYC

Compressor Cycles since Midnight

RnTM

Compressor Run Time since Midnight

DFTM

Duration Time of Last Defrost

ETLD

Elapsed Time since last Defrost (HH.MM)

RTLD

Run Time since last Defrost (HH.MM)

VERS

Software version

Controller Quick Reference Guide

(See Program Review Section for additional information) *Software V1.04 and higher.

**Menu re-ordered Software V2.05 and higher

5

Forced Output Menu

DISPLAY DESCRIPTION

EVPF Evaporator Fan Contactor

LIQS Liquid Line Solenoid

EVPH Evaporator Pan Heater

FAN4 Condenser Fan 4 Contactor

FAN3 Condenser Fan 3 Contactor

FAN2 Condenser Fan 2 Contactor

FAN1 Condenser Fan 1 Contactor

COMP Compressor Contactor

BYPV Bypass Solenoid

SucS Suction Stop Solenoid

DEFS Defrost Solenoid

3WAY 3-Way Valve Solenoid

ALRM Alarm Contacts

VALS Regulator Valve Control

EVAC Activate all Solenoids, Open the Pressure Regulator Valve

DISPLAY DESCRIPTION

Alr1 Persistent input sensor/transducer failure

Alr2 Combines Err4 and Err8, system off

Alr3 Repeated Safety Circuit Open condition

Alr4 Prolonged Cooling Startup Failure

DISPLAY DESCRIPTION

Err1 Suction temperature sensor open or short

Err2 Ambient temp sensor open or short

Err3 Auxiliary temp sensor open or short

Err4 Suction Pressure sensor open or short

Err5 Liquid Pressure sensor open or short

Err6 Evap 1 defrost temp sensor open or short

Err7 Evap 2 defrost temp sensor open or short

Err8 Redundant Low Pressure Switch Malfunction detected

Err9 Safety Circuit interruption during normal operation

Er10 Prolonged Low Suction Pressure during cooling

Er11 Low Suction Pressure startup failure

Er12 High Suction Pressure startup failure

Er13 Post Defrost pump down error

System Alarms

System Errors

Controller Quick Reference Guide

6

General Safety Information

1. Installation and maintenance to be performed only by

qualified personnel who are familiar with this type of

equipment.

2. Some units are pressurized with dry air or inert gas.

All units must be evacuated before charging the system

with refrigerant.

3. Make sure that all field wiring conforms to the requirements

of the equipment and all applicable national and local codes.

4. Avoid contact with sharp edges and coil surfaces.

They are a potential injury hazard.

5. Make sure all power sources are disconnected before any

service work is done on units.

WARNING: Refrigerant can be harmful if it is inhaled. Refrigerant must be used and recovered responsibly.

Failure to follow this warning may result in personal injury or death.

Inspection

Responsibility should be assigned to a dependable individual at the job site to receive

material. Each shipment should be carefully checked against the bill of lading. The

shipping receipt should not be signed until all items listed on the bill of lading have

been accounted. Check carefully for concealed damage. Any shortage or damages

should be reported to the delivering carrier. Damaged material becomes the delivering

carrier’s responsibility, and should not be returned to the manufacturer unless prior

approval is given to do so. When uncrating, care should be taken to prevent damage.

Heavy equipment should be left on its shipping base until it has been moved to the

final location. Check the serial tag information with invoice. Report any discrepancies

to your Heatcraft Refrigeration Products Sales Representative.

Warranty Statement

Seller warrants to its direct purchasers that products, including Service Parts,

manufactured by SELLER shall be of a merchantable quality, free of defects in

material or workmanship, under normal use and service for a period of one (1) year

from date of original installation, or eighteen (18) months from date

of shipment by SELLER, whichever first occurs. Any product covered by this order

found to Seller’s satisfaction to be defective upon examination at Seller’s factory will at

SELLER’s option, be repaired or replaced and returned to Buyer via lowest common

carrier, or SELLER may at its option grant Buyer a credit for the purchase price of the

defective article. Upon return of a defective product to SELLER’s plant, freight prepaid,

by Buyer, correction of such defect by repair or replacement, and return freight via

lowest common carrier, shall constitute full performance by SELLER of its obligations

hereunder.

SELLER shall have no liability for expenses incurred for repairs made by Buyer

except by prior, written authorization. Every claim on account of breach of warranty

shall be made to SELLER in writing within the warranty period specified above –

otherwise such claim shall be deemed waived. Seller shall have no warranty obligation

whatsoever if its products have been subjected to alteration, misuse, negligence,

free chemicals in system, corrosive atmosphere, accident, or if operation is contrary

to SELLER’s or manufacturer’s recommendations, or if the serial number has been

altered, defaced, or removed.

MOTOR COMPRESSORS:

Motor compressors furnished by SELLER are subject to the standard warranty

terms set forth above, except that motor compressor replacements or exchanges

shall be made through the nearest authorized wholesaler of the motor compressor

manufacturer (not at SELLER’s factory) and no freight shall be allowed for

transportation of the motor compressor to and from the wholesaler. The replacement

motor compressor shall be identical to the model of the motor compressor being

replaced. Additional charges which may be incurred throughout the substitution of

other than identical replacements are not covered by this warranty. An optional, non

assignable, four (4) year extended compressor warranty may be purchased within

the boundaries of the United Sates of America, its territories and possessions, and

Canada. With this extended compressor warranty, replacements are administered

by an authorized compressor distributor only. Replacements within the first year of

the warranty area available through the distributor; the second through fifth years,

the purchaser must submit a proof-of-purchase of a compressor and supply it to

Heatcraft Refrigeration Products Warranty Claims for reimbursement.

Seller makes no express warranties except as noted above. All implied warranties

are limited to the duration of the Express Warranty. Liability for incidental and

consequential damages is excluded.

The forgoing is in lieu of all other warranties, express or implied, notwithstanding the

provisions of the uniform commercial code, the Magnuson-Moss Warranty - Federal

Trade Commission Improvement Act, or any other statutory or common law, federal

or state.

SELLER makes no warranty, express or implied, of fitness for any particular purpose,

or of any nature whatsoever, with respect to products manufactures or sold by seller

hereunder, except as specifically set forth above and on the face hereof. It is expressly

understood and agreed that SELLER shall not be liable to buyer, or any customer of

buyer, for direct or indirect, special, incidental, consequential or penal damages, or

for any expenses incurred by reason of the use or misuse by buyer or third parties of

said products. To the extent said products may be considered "consumer products,"

As defined in Sec. 101 of the Magnuson-Moss Warranty - Federal Trade Commission

Improvement Act, SELLER makes no warranty of any kind, express or implied, to

"consumers," except as specifically set forth above and on the face hereof.

The following conditions should be adhered to when installing this unit to maintain the

manufacturers warranty:

(a) System piping must be in accordance with good

refrigeration practices.

(b) Inert gas must be charged into the piping during brazing.

(c) The power supply to the unit must meet the following conditions:

A. Three phase voltages must be +/-

10% of nameplate ratings. Single

phase must be within +10% or

-5% of nameplate ratings.

B. Phase imbalance cannot exceed 2%.

(d) All control and safety switch circuits must be properly connected

according to the wiring diagram.

(e) The factory installed wiring must not be changed without written

factory approval.

(f) All equipment is installed in accordance with Heatcraft Refrigeration

Products specified minimum clearances.

(g) Devices not provided by Heatcraft shall not be connected to the

Mohave controller without written factory approval

(h) Refrigerant line runs between condensing unit and evaporator(s) shall

not exceed 200 ft without written factory approval

7

Condensing Unit

(Vertical Air Discharge Design)

Standard Features:

• Electronic Hot Gas Defrost Controller includes Defrost Initiation and

Termination Control, Pressure Fan Cycling for Head Pressure Control, Ambient

Fan Cycling Option, Anti-Short Cycling Protection, and Low Pressure Control

• Electronic Pressure Regulator for Defrost Control

• Suction Accumulator

• High Pressure and Redundant Low Pressure Control

• Oil Pressure Safety Control

• High Efficiency Copeland Discus Compressors with POE oil

• Thermally Protected Permanently Lubricated Ball Bearing Condenser Fan

Motors

• Electrical Controls located in easily accessible control box with a hinged cover

• Receivers are sized for sufficient pump down capacity with inlet and outlet

service valves

• Cabinet is constructed from painted galvanized steel

• Convenient Access Panels for easy servicing to internal components

• Suction and Discharge Vibration Eliminators

• Separate Sub-cooling Circuit.

• Replaceable Liquid Line Filter Drier

• Replaceable Core Suction Filter

• Sight Glass

• Compressor Head Fan on L6 Models

• MODBUS RS-485 (Inherent on control board)

Optional Features:

• Head Pressure Valves (ORI/ORD)

• Oil Separator

• Insulated and Heated Receiver

• Fused Disconnect Switch

• Non-fused Disconnect Switch

• Coated Condenser Coils for protection against harsh environments (Consult

factory)

• Phase Loss Monitor

• Mounted Evaporator Control Contactors

• Remote Monitoring (RRC) Wireless Transmitter

• Variable Frequency Drive Package for Condenser Motors (Consult factory)

• Demand Cooling (Required for R-407A, R-407F, R-448A, and R-449A L6

models)

Evaporators

(Medium Profile & High Profile Unit Coolers)

Standard Features:

• All Components are factory installed and wired

• Power Supply Independent from Condensing Unit

• Mounted Fan Control Contactors and Drain Pan Heater Contactors if specified

• Four or Six Fins Per Inch Models

• Mounted TXV and Distributor Nozzle

• Mounted Check Valves

• Mounted Liquid Line Solenoid

• Suction P-Trap

• Thermally Protected Permanently Lubricated Evaporator Fan Motors

• Mounted Electric Drain Pan Heaters

• Insulated Drain Pan (Low Temperature Systems)

Optional Features:

• Mounted Hot Gas Drain Pan Loop

• Evaporator Powered from Condensing Unit

System and Components

8

top and the ceiling with an NSF listed sealant and ends of open hanger channels must

be sealed to prevent accumulation of foreign matter.

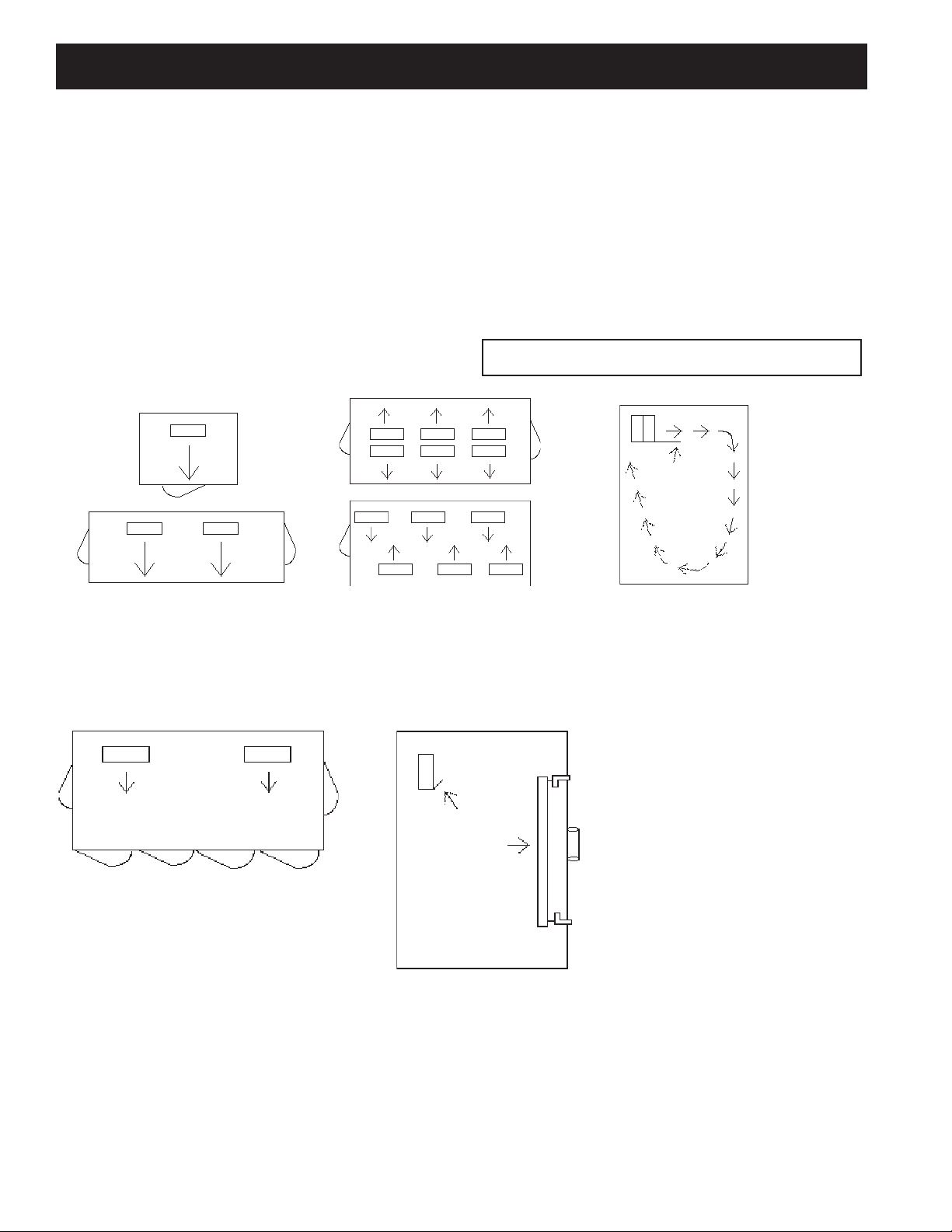

When locating unit coolers in a cooler or freezer, refer to Figure 1-2 for guidelines.

Unit Cooler Installation

Most evaporators can be mounted with rod hangers, lag screws, or bolts. Use 5/16"

bolt and washers or rod for up to 250 pounds, 3/8" for up to 600 pounds and

5/8" for over 600 pounds. Care should be taken to mount the units level so that

condensate drains properly. Adequate support must be provided to hold the weight of

the unit.

When using rod hangers, allow adequate space between the top of the unit and the

ceiling for cleaning. To comply with NSF Standard 7, the area above the unit cooler

must be sealed or exposed in such a way to facilitate hand cleaning without the use

of tools. When lagging or bolting the unit flush to the ceiling, seal the joint between the

Figure 1. Large Coolers and Freezers Placement.

Where one wall evaporator mounting is

satisfactory.

Elevation view of glass display door cooler or

freezer. Be sure air discharge blows above, not

directly at doors. Provide baffle if door extends

above blower level.

Baffled Unit

Cooler or Freezer with Glass Display

Doors

Glass

Display

Door

Baffle

NOTE: Always avoid placement of Unit Coolers

directly above doors and door openings.

Cooler or Freezers where one wall will not

accommodate all required evaporators

or where air throw distance must be

considered.

Allow sufficient space between rear

of Unit Cooler and wall to permit free

return of air.

Unit Cooler Installation

9

One evaporator

Unit Coolers (continued)

Recommended Unit Cooler Placement

Some general rules for evaporator placement which must be followed are:

1. The air pattern must cover the entire room

2. NEVER locate evaporators over doors

3. Location of aisles, racks, etc. must be known

4. Location relative to compressors for minimum pipe runs

5. Location of condensate drains for minimum run.

The size and shape of the storage will generally determine the type and number of

evaporators to be used and their location. The following are some typical examples:

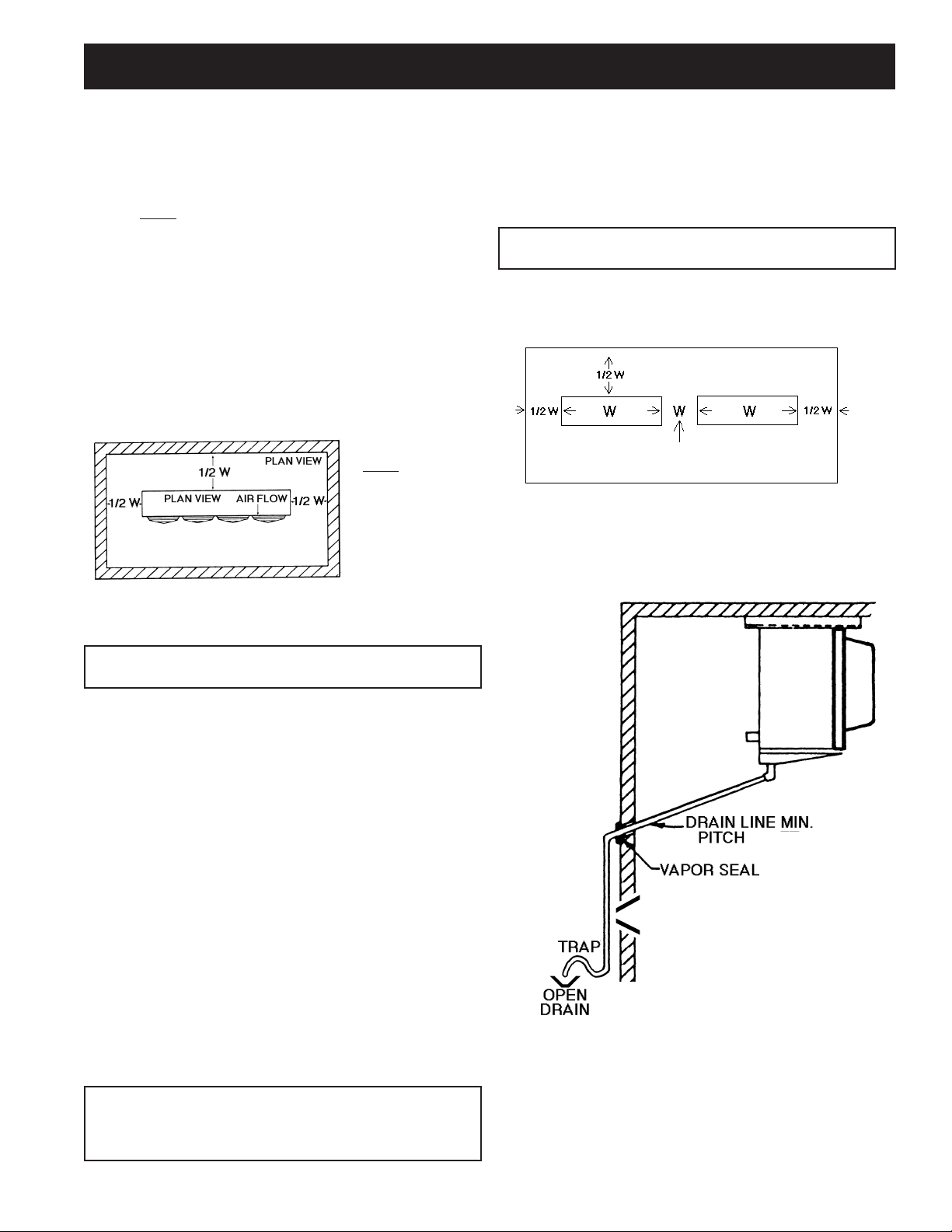

Minimum Unit Clearances

Figure 2. Medium Profile and Large Unit Coolers

NOTE:

W = Total width

of evaporator

coil surface.

Two evaporators

Unit Cooler Installation & Condensate Lines

WARNING: All power must be disconnected before cleaning.

Drain pan also serves as cover of hazardous moving

parts. Operation of unit without drain pan constitutes

a hazard.

Condensate Drain Lines

Either copper or steel drain lines should be used and properly protected from

freezing. In running drain lines, provide a minimum 4 inches per foot pitch for proper

drainage. Drain lines should be at least as large as the evaporator drain connection.

All plumbing connections should be made in accordance with local plumbing codes.

All condensate drain lines must be trapped, and run to an open drain. They must

never be connected directly to the sewer system. Traps in the drain line must be

located in a warm ambient. We recommend a trap on each evaporator drain line

prior to any tee connections. Traps located outside, or extensive outside runs of

drain line must be wrapped with a drain line heater. The heater should be connected

so that it operates continuously. It is recommended that the drain line be insulated

to prevent heat loss. A heat input of 20 watts per linear foot of drain line for 0˚F

(-18˚C) room applications and 30 watts per linear foot for -20˚F (-29˚C) rooms is

satisfactory. In freezers, the evaporator drain pan fitting should be included when

heating and insulating the drain line.

Inspect drain pan periodically to insure free drainage of condensate. If drain pan

contains standing water, check for proper installation. The drain pan should be

cleaned regularly with warm soapy water.

Condensate Drain Lines

NOTE: Always trap single evaporator system drain

lines individually to prevent humidity migration.

Traps on low temperature units must be outside of refrigerated enclosures. Traps

subject to freezing temperatures must be wrapped with heat tape and insulated.

NOTE: Leave space equal to unit height between bottom of unit and product.

Do not stack product in front of fans.

- 1/4” / FT

10

The most important consideration which must be taken into account when deciding

upon the location of air-cooled equipment is the provision for a supply of ambient

air to the condenser, and removal of heated air from the condensing unit or remote

condenser area. Where this essential requirement is not adhered to, it will result in

higher head pressures, which cause poor operation and potential failure of equipment.

Units must not be located in the vicinity of steam, hot air or fume exhausts. Corrosive

atmospheres require custom designed condensers.

Another consideration which must be taken is that the unit should be mounted away

from noise sensitive spaces and must have adequate support to avoid vibration

and noise transmission into the building. Units should be mounted over corridors,

utility areas, rest rooms and other auxiliary areas where high levels of sound are

not an important factor. Sound and structural consultants should be retained for

recommendations.

Space and Location Requirements for Condensing Units and Remote Condensers

Units in Pits

The top of the unit should be level with the top of the pit, and side distance

increased to “2W”.

If the top of the unit is not level with the top of pit, discharge cones or stacks

must be used to raise discharge air to the top of the pit. This is a minimum

requirement.

Decorative Fences

Fences must have 50% free area, with 1 foot undercut, a “W” minimum

clearance, and must not exceed the top of unit. If these requirements are

not met, unit must be installed as indicated for “Units in pits”.

Walls or Obstructions

The unit should be located so that air may circulate freely and not be

recirculated. For proper air flow and access all sides of the unit should be a

minimum of “W” away from any wall or obstruction. It is preferred that this

distance be increased whenever possible. Care should be taken to see that

ample room is left for maintenance work through access doors and panels.

Overhead obstructions are not permitted. When the unit is in an area where it is

enclosed by three walls the unit must be installed as indicated for units in a pit.

Multiple Units

For units placed side by side, the minimum distance between units is

the width of the largest unit. If units are placed end to end, the minimum

distance between units is 4 feet.

Walls or Obstructions for Horizontal Air Flow Multiple Units with Horizontal Air Flow

* “W” = Total width of the condensing unit or condenser.

Space & Location Requirements for Air Cooled Condensing Units and Remote Condensers

Condensing Unit Installation

11

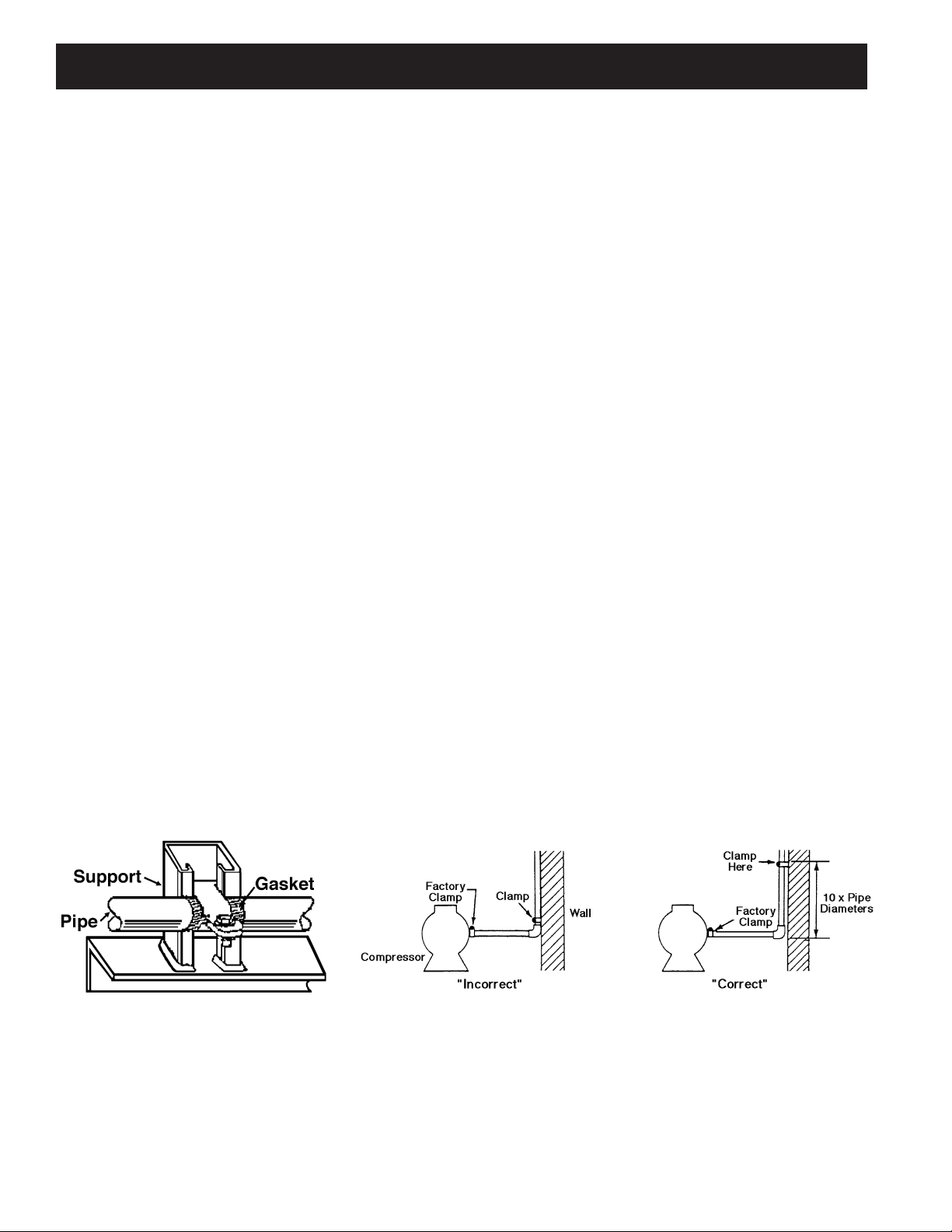

Figure 3. Spring Mount

Figure 5. Spring Mount

Figure 4. Solid Mount for Mobile or Deep

Sump Application.

Condensing Unit Rigging and Mounting

Rigging holes are provided on all units. Caution should be exercised when moving

these units. To prevent damage to the unit housing during rigging, cables or chains

used must be held apart by spacer bars. The mounting platform or base should be

level and located so as to permit free access of supply air.

Ground Mounting

Concrete slab raised six inches above ground level provides a suitable base. Raising

the base above ground level provides some protection from ground water and wind

blown matter. Before tightening mounting bolts, recheck level of unit. The unit should

in all cases be located with a clear space in all directions that is at a minimum, equal

to the height of the unit above the mounting surface. A condensing unit mounted in

a corner formed by two walls, may result in discharge air recirculation with resulting

loss of capacity.

Roof Mounting

Due to the weight of the units, a structural analysis by a qualified engineer may be

required before mounting. Roof mounted units should be installed level on steel

channels or an I-beam frame capable of supporting the weight of the unit. Vibration

absorbing pads or springs should be installed between the condensing unit legs or

frame and the roof mounting assembly.

Access

Provide adequate space at the compressor end of the unit for servicing. Provide

adequate space on the connection side to permit service of components.

Spring Mounted Compressor

Compressors are secured rigidly to make sure there is no transit damage. Before

operating the unit, it is necessary to follow these steps:

a. Remove the upper nuts and washers.

b. Discard the shipping spacers.

c. Install the neoprene spacers. (Spacers located in the electrical panel or

tied to compressor.)

d. Replace the upper mounting nuts and washers.

e. Allow 1/16 inch space between the mounting nut/

washer and the neoprene spacer. See Figure 3 below.

Rigid Mounted Compressor

Some products use rigid mounted compressors. Check the compressor mounting bolts

to insure they have not vibrated loose during shipment. See Figure 3 and 5 below.

Condensing Unit Installation

12

Recommended Refrigerant Piping Practices

The system as supplied by Heatcraft Refrigeration Products, was

thoroughly cleaned and dehydrated at the factory. Foreign matter may enter the

system by way of the evaporator to condensing unit piping. Therefore, care must

be used during installation of the piping to prevent entrance of foreign matter.

Install all refrigeration system components in accordance with applicable local and

national codes and in conformance with good practice required for the proper

operation of the system.

The refrigerant pipe size should be selected from the tables on pages 15-21. The

interconnecting pipe size is not necessarily the same size as the stub-out on the

condensing unit or the evaporator.

The following procedures should be followed:

(a) Do not leave dehydrated compressors or filter driers open to the

atmosphere.

(b) Use only refrigeration grade copper tubing, properly sealed against

contamination.

(c) Suction lines should slope 1/4" per 10 feet towards the compressor.

(d) Suitable P-type oil traps should be located at the base of each

suction riser to enhance oil return to the compressor.

(e) For desired method of superheat measurement, a pressure tap

should be installed in each evaporator suction line in the proximity of

the expansion valve bulb.

(f) When brazing refrigerant lines, an inert gas should

be passed through the line at low pressure to prevent

scaling and oxidation inside the tubing. Dry nitrogen is

preferred.

(g) Use only a suitable silver solder alloy on suction and liquid lines.

(h) Limit the soldering paste or flux to the minimum required to prevent

contamination of the solder joint internally. Flux only the male portion

of the connection, never the female. After brazing, remove excess flux.

(i) If isolation valves are installed at the evaporator,full port ball valves

should be used.

(j) Do not install liquid/suction line heat exchangers.

Refrigerant Pipe Support

1. Normally, any straight run of tubing must be supported in at least two locations

near each end of the run. Long runs require additional supports. The refrigerant

lines should be supported and fastened properly. As a guide, 3/8 to 7/8 should be

supported every 5 feet; 1-1/8 and 1-3/8 every 7 feet; and 1-5/8 and 2-1/8 every

9 to 10 feet.

2. When changing directions in a run of tubing, no corner should be left

unsupported. Supports should be placed a maximum of 2 feet in each direction

from the corner.

3. Piping attached to a vibrating object (such as a compressor or compressor base)

must be supported in such a manner that will not restrict the movement of the

vibrating object. Rigid mounting will fatigue the copper tubing.

4. Do not use short radius ells. Short radius elbows have points of excessive stress

concentration and are subject to breakage at these points.

5. Thoroughly inspect all piping after the equipment is in operation and add

supports wherever line vibration is significantly greater than most of the other

piping. Extra supports are relatively inexpensive as compared to refrigerant loss.

Piping

Example of Pipe Support Condensing Unit / Compressor to Wall Support.

13

Piping

The following are examples of proper piping layout for typical system configurations

14

Piping

15

Pipe size example:

Given: -10°F Freezer with one system having (2) evaporators

• One condensing unit rated at 24,000 BTUH’s @ -20°F SST R404A refrigerant.

• Two evaporators each rated at 12,000 BTUH’s @ 10°F TD.

• 75 feet of actual line run between condensing unit to first evaporator and 20 feet

of actual line run between the first evaporator and the second evaporator (see

figure below).

How to figure line sizes:

1. Determine equivalent line run = actual run + valves and fitting allowances.

2. Use Line Sizing Tables on pages 16-21 to size lines.

3. Note any special considerations.

Fittings in this system:

• (6) 90° elbows in main line plus a 90° turn through a tee.

• (5) addtional 90° elbows to first evaporator.

• (4) additional 90° elbows to second evaporator.

Determine line size 1 (main line from condensing unit):

1. Main line from the condensing unit to be sized for the total capacity (balance) of

the whole system of 24,000 BTUH’s (Table 3 and 3A).

2. Refer to 24,000 @75 feet at -20°F SST R404A on the chart.

You will find the suction line to be 1 1/8" and 1/2" liquid line.

3. Refer to Table 5A. For every 1 1/8" 90° elbow you must add 3 equivalent feet of

pipe and 2 equivalent feet of pipe for each 1 1/8" tee.

Therefore, total equivalent line run =

Actual line run 75 feet

+ (6) 1 1/8" elbows @ 3' 18 feet

+ (1) 1 1/8" tee @ 2' 2 feet

Total equivalent line run 95 feet

4. Refer to Table 3A. For 95 total equivalent feet, the suction line size should be 1

3/8" and the liquid line stays at 1/2" line.

Note: The gray shaded areas on Table 2. For 24,000 BTUH’s, the maximum suction

riser is 1 1/8" to insure proper oil return and pressure drop from the bottom p-trap

to the top p-trap.

Determine line size 2 (evaporators):

1. Line sizing to each evaporator is based on 12,000 BTUH’s and equivalent

run from condensing unit. First evaporator has an 80 ft. run and the second

evaporator has a 95 ft. run.

2. Table 3 indicates 7/8" suction for the first evaporator and Table 3A indicates 1

1/8" suction for the second evaporator.

3. Refer to Table 5A. Each 7/8" 90° elbow adds 2 equivalent feet of pipe. Each

1 1/8" 90° elbow adds 3 equivalent feet and a 90° turn through a 1 1/8" tee

adds 6 equivalent feet.

4. Actual line run (evap 1) 80 feet

+ (5) 7/8" elbows @ 2' 10 feet

+ (1) 90° turn through tee @ 6' 6 feet

Total equivalent line run 96 feet

Actual line run (evap 2) 95 feet

+ (4) 1 1/8" elbows @ 3' 12 feet

Total equivalent line run 107 feet

5. Table 3A indicates 1 1/8" suction line and 3/8" liquid line from main line to

both evaporators.

Unit Cooler Piping

Evap. 1

Evap. 2

Piping

NOTE: This is a line sizing example. Use diagrams on page

13-14 for piping orientation.

16

System

Capacity

+40

˚F

Equivalent Lengths

+20

˚F

Equivalent Lengths

+10

˚F

Equivalent Lengths

25' 50' 75' 100' 150' 200' 25' 50' 75' 100' 150' 200' 25' 50' 75' 100' 150' 200'

1,000 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8

3,000 3/8 3/8 3/8 3/8 1/2 1/2 3/8 3/8 3/8 1/2 1/2 1/2 3/8 3/8 1/2 1/2 1/2 1/2

4,000 3/8 3/8 1/2 1/2 1/2 1/2 3/8 1/2 1/2 1/2 5/8 5/8 3/8 1/2 1/2 5/8 5/8 5/8

6,000 3/8 1/2 1/2 1/2 5/8 5/8 1/2 1/2 1/2 5/8 5/8 5/8 1/2 1/2 5/8 5/8 5/8 5/8

9,000 1/2 1/2 5/8 5/8 5/8 5/8 1/2 5/8 5/8 7/8 7/8 7/8 1/2 5/8 5/8 7/8 7/8 7/8

12,000 1/2 5/8 5/8 7/8 7/8 7/8 5/8 5/8 7/8 7/8 7/8 7/8 5/8 7/8 7/8 7/8 7/8 7/8

15,000 5/8 5/8 7/8 7/8 7/8 7/8 5/8 7/8 7/8 7/8 7/8 7/8 5/8 7/8 7/8 7/8 7/8 7/8

18,000 5/8 7/8 7/8 7/8 7/8 7/8 5/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 1 1/8 1 1/8

24,000 5/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 7/8 1 1/8 1 1/8 7/8 7/8 7/8 1 1/8 1 1/8 1 1/8

30,000 7/8 7/8 7/8 7/8 1 1/8 1 1/8 7/8 7/8 7/8 1 1/8 1 1/8 1 1/8 7/8 7/8 1 1/8 1 1/8 1 1/8 1 1/8

36,000 7/8 7/8 7/8 1 1/8 1 1/8 1 1/8 7/8 7/8 1 1/8 1 1/8 1 1/8 1 1/8 7/8 1 1/8 1 1/8 1 1/8 1 1/8 1 3/8

42,000 7/8 7/8 1 1/8 1 1/8 1 1/8 1 1/8 7/8 7/8 1 1/8 1 1/8 1 1/8 1 1/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8

48,000 7/8 7/8 1 1/8 1 1/8 1 1/8 1 1/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8

54,000 7/8 1 1/8 1 1/8 1 1/8 1 1/8 1 3/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8

60,000 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8

66,000 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8

72,000 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8

78,000 7/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 5/8 1 1/8 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8

84,000 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8

90,000 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8

120,000 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8

150,000 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8

180,000 1 3/8 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 2 1/8

210,000 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 2 5/8

240,000 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 2 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8

300,000 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 2 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8

360,000 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 2 5/8

480,000 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 2 1/8 2 5/8 2 5/8 3 1/8 3 1/8 3 1/8

600,000 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 3 1/8 2 1/8 2 5/8 3 1/8 3 1/8 3 1/8 3 5/8

Table 1. Recommended Line Sizes for R-407*

* NOTES:

1. Sizes that are highlighted indicate maximum suction line sizes that should be used for risers. Riser size should not exceed horizontal size. Properly placed suction traps must also be used for

adequate oil return. All sizes shown are for O.D. Type L copper tubing.

2. Suction line sizes selected at pressure drop equivalent to 2˚F. Reduce estimate of system capacity accordingly.

3. If system load drops below 40% of design, consideration to installing double suction risers should be made.

4. R407A, R407C, R407F

Line Sizing

SUCTION LINE SIZE

SUCTION TEMPERATURE

17

Line Sizing

Table 1A. Recommended Line Sizes for R-407 (continued)*

LIQUID LINE SIZE

Receiver to

Expansion Valve

Expansion Valve

25' 50' 75' 100' 150' 200'

3/8 3/8 3/8 3/8 3/8 3/8 1,000

3/8 3/8 3/8 3/8 3/8 3/8 3,000

3/8 3/8 3/8 3/8 3/8 3/8 4,000

3/8 3/8 3/8 3/8 3/8 3/8 6,000

3/8 3/8 3/8 3/8 3/8 3/8 9,000

3/8 3/8 3/8 3/8 3/8 3/8 12,000

3/8 3/8 3/8 3/8 3/8 3/8 15,000

3/8 3/8 3/8 3/8 1/2 1/2 18,000

3/8 3/8 3/8 1/2 1/2 1/2 24,000

3/8 1/2 1/2 1/2 1/2 5/8 30,000

3/8 1/2 1/2 1/2 5/8 5/8 36,000

3/8 1/2 1/2 1/2 5/8 5/8 42,000

1/2 1/2 1/2 5/8 5/8 5/8 48,000

1/2 1/2 1/2 5/8 5/8 5/8 54,000

1/2 1/2 5/8 5/8 5/8 5/8 60,000

1/2 1/2 5/8 5/8 5/8 7/8 66,000

1/2 5/8 5/8 5/8 5/8 7/8 72,000

1/2 5/8 5/8 5/8 7/8 7/8 78,000

1/2 5/8 5/8 5/8 7/8 7/8 84,000

1/2 5/8 5/8 7/8 7/8 7/8 90,000

5/8 5/8 7/8 7/8 7/8 7/8 120,000

5/8 7/8 7/8 7/8 7/8 7/8 150,000

7/8 7/8 7/8 7/8 1 1/8 1 1/8 180,000

7/8 7/8 7/8 7/8 1 1/8 1 1/8 210,000

7/8 7/8 7/8 1 1/8 1 1/8 1 1/8 240,000

7/8 7/8 7/8 1 1/8 1 1/8 1 1/8 300,000

7/8 1 1/8 1 1/8 1 1/8 1 1/8 1 3/8 360,000

7/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 480,000

1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 3/8 600,000

* NOTES:

1. All sizes shown are for O.D. Type L copper tubing.

2 .R407A, 407C, R407F

18

* NOTES:

1. Sizes that are highlighted indicate maximum suction line sizes that should be used for risers. Riser size should not exceed horizontal size. Properly placed suction traps must also be used for

adequate oil return. All sizes shown are for O.D. Type L copper tubing.

2. Suction line sizes selected at pressure drop equivalent to 2˚F. Reduce estimate of system capacity accordingly.

3. If system load drops below 40% of design, consideration to installing double suction risers should be made.

4. R407A, R407C, R407F

Line Sizing

System

Capacity

BTU/H

SUCTION LINE SIZE

SUCTION TEMPERATURE

+20

˚F

Equivalent Lengths

+10

˚F

Equivalent Lengths

-10

˚F

Equivalent Lengths

25' 50' 75' 100' 150' 200' 25' 50' 75' 100' 150' 200' 25' 50' 75' 100' 150' 200'

1,000 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 1/2 3/8 3/8 3/8 1/2 1/2 1/2

3,000 3/8 3/8 1/2 1/2 1/2 5/8 3/8 1/2 1/2 1/2 5/8 5/8 1/2 1/2 5/8 5/8 5/8 7/8

4,000 3/8 1/2 1/2 1/2 5/8 5/8 1/2 1/2 1/2 5/8 5/8 7/8 1/2 5/8 5/8 5/8 7/8 7/8

6,000 1/2 1/2 5/8 5/8 7/8 7/8 1/2 1/2 5/8 5/8 7/8 7/8 1/2 5/8 5/8 7/8 7/8 7/8

9,000 5/8 5/8 7/8 7/8 7/8 7/8 5/8 5/8 7/8 7/8 7/8 7/8 5/8 7/8 7/8 7/8 7/8 1 1/8

12,000 5/8 7/8 7/8 7/8 7/8 7/8 5/8 7/8 7/8 7/8 7/8 1 1/8 7/8 7/8 7/8 7/8 1 1/8 1 1/8

15,000 5/8 7/8 7/8 7/8 7/8 1 1/8 7/8 7/8 7/8 7/8 1 1/8 1 1/8 7/8 7/8 7/8 1 1/8 1 1/8 1 1/8

18,000 7/8 7/8 7/8 7/8 1 1/8 1 1/8 7/8 7/8 7/8 1 1/8 1 1/8 1 1/8 7/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8

24,000 7/8 7/8 7/8 1 1/8 1 1/8 1 1/8 7/8 1 1/8 1 1/8 1 1/8 1 1/8 1 3/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8

30,000 7/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8

36,000 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8

42,000 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8

48,000 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8

54,000 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8

60,000 1 1/8 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8

66,000 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 1 5/8

72,000 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 1 1/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 1 5/8

78,000 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 2 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8

84,000 1 1/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8

90,000 1 3/8 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8 2 5/8

120,000 1 3/8 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 1 3/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8

150,000 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 2 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8

180,000 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 2 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8

210,000 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 2 1/8 2 1/8 2 5/8 2 5/8 3 1/8 3 1/8

240,000 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 2 5/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8

300,000 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 3 5/8

360,000 2 1/8 2 1/8 2 5/8 2 5/8 3 1/8 3 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 2 5/8 2 5/8 3 1/8 3 1/8 3 5/8 3 5/8

480,000 2 1/8 2 5/8 2 5/8 3 1/8 3 1/8 3 5/8 2 5/8 2 5/8 2 5/8 2 5/8 3 5/8 3 5/8 2 5/8 3 1/8 3 1/8 3 5/8 3 5/8 4 1/8

600,000 2 5/8 2 5/8 3 1/8 3 1/8 3 5/8 3 5/8 2 5/8 2 5/8 3 1/8 3 1/8 3 5/8 3 5/8 3 1/8 3 1/8 3 1/8 3 5/8 4 1/8 4 1/8

Table 2. Recommended Line Sizes for R-448A/R-449A

19

Line Sizing

System

Capacity

BTU/H

SUCTION LINE SIZE

SUCTION TEMPERATURE

-20

˚F

Equivalent Lengths

-30

˚F

Equivalent Lengths

-40

˚F

Equivalent Lengths

25' 50' 75' 100' 150' 200' 25' 50' 75' 100' 150' 200' 25' 50' 75' 100' 150' 200'

1,000 3/8 3/8 1/2 1/2 1/2 1/2 3/8 3/8 1/2 1/2 1/2 5/8 3/8 1/2 1/2 1/2 5/8 5/8

3,000 1/2 1/2 5/8 5/8 7/8 7/8 1/2 1/2 5/8 5/8 7/8 7/8 1/2 1/2 5/8 5/8 7/8 7/8

4,000 1/2 5/8 5/8 7/8 7/8 7/8 5/8 5/8 5/8 7/8 7/8 7/8 1/2 5/8 5/8 7/8 7/8 7/8

6,000 5/8 5/8 7/8 7/8 7/8 7/8 5/8 5/8 7/8 7/8 7/8 7/8 5/8 5/8 7/8 7/8 7/8 1 1/8

9,000 5/8 7/8 7/8 7/8 1 1/8 1 1/8 5/8 7/8 7/8 7/8 1 1/8 1 1/8 5/8 7/8 7/8 7/8 1 1/8 1 1/8

12,000 7/8 7/8 7/8 1 1/8 1 1/8 1 1/8 7/8 7/8 7/8 1 1/8 1 1/8 1 1/8 7/8 7/8 7/8 1 1/8 1 1/8 1 1/8

15,000 7/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 7/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 7/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8

18,000 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 7/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8

24,000 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8

30,000 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 5/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8

36,000 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 3/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8

42,000 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8

48,000 1 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8 1 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8

54,000 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8 2 1/8 1 3/8 1 3/8 1 3/8 1 5/8 1 5/8 2 1/8

60,000 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 3/8 1 5/8 1 5/8 1 5/8 2 1/8

66,000 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8

72,000 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8 1 3/8 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8

78,000 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8 1 5/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8

84,000 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 1 5/8 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8

90,000 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 1/8 2 5/8 1 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8

120,000 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 1 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8

150,000 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 2 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 2 5/8

180,000 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 2 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8

210,000 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8

240,000 2 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 3 5/8 2 5/8 2 5/8 2 5/8 3 1/8 3 1/8 3 5/8

300,000 2 5/8 2 5/8 2 5/8 3 1/8 3 5/8 3 5/8 2 5/8 2 5/8 3 1/8 3 1/8 3 5/8 4 1/8 2 5/8 2 5/8 3 1/8 3 5/8 3 5/8 4 1/8

360,000 2 5/8 2 5/8 3 1/8 3 5/8 3 5/8 4 1/8 2 5/8 3 1/8 3 5/8 3 5/8 3 5/8 4 1/8 2 5/8 3 1/8 3 5/8 3 5/8 4 1/8 4 1/8

480,000 2 5/8 3 1/8 3 1/8 3 5/8 3 5/8 4 1/8 3 1/8 3 5/8 3 5/8 4 1/8 4 1/8 4 1/8 3 1/8 3 5/8 3 5/8 4 1/8 4 1/8 4 1/8

600,000 3 1/8 3 1/8 3 1/8 3 5/8 3 5/8 4 1/8 3 1/8 3 5/8 3 5/8 4 1/8 4 1/8 5 1/8 3 1/8 3 5/8 3 5/8 4 1/8 4 1/8 5 1/8

Table 2. Recommended Line Sizes for R-448A/R-449A (continued)*

20

Table 2A. Recommended Line Sizes for R-448A/R-449A

LIQUID LINE SIZE

Receiver to

Expansion Valve

Expansion Valve

25' 50' 75' 100' 150' 200'

3/8 3/8 3/8 3/8 3/8 3/8 1,000

3/8 3/8 3/8 3/8 3/8 3/8 3,000

3/8 3/8 3/8 3/8 3/8 3/8 4,000

3/8 3/8 3/8 3/8 3/8 3/8 6,000

3/8 3/8 3/8 3/8 3/8 3/8 9,000

3/8 3/8 3/8 3/8 3/8 3/8 12,000

3/8 3/8 3/8 3/8 3/8 1/2 15,000

3/8 3/8 3/8 3/8 1/2 1/2 18,000

3/8 3/8 1/2 1/2 1/2 1/2 24,000

3/8 3/8 1/2 1/2 1/2 1/2 30,000

3/8 1/2 1/2 1/2 1/2 1/2 36,000

3/8 1/2 1/2 1/2 1/2 5/8 42,000

1/2 1/2 1/2 1/2 1/2 5/8 48,000

1/2 1/2 1/2 1/2 5/8 5/8 54,000

1/2 1/2 1/2 5/8 5/8 5/8 60,000

1/2 1/2 5/8 5/8 5/8 5/8 66,000

1/2 1/2 5/8 5/8 5/8 5/8 72,000

1/2 1/2 5/8 5/8 5/8 7/8 78,000

1/2 5/8 5/8 5/8 5/8 7/8 84,000

1/2 5/8 5/8 5/8 7/8 7/8 90,000

5/8 5/8 5/8 7/8 7/8 7/8 120,000

5/8 7/8 7/8 7/8 7/8 7/8 150,000

5/8 7/8 7/8 7/8 7/8 1 1/8 180,000

7/8 7/8 7/8 7/8 7/8 1 1/8 210,000

7/8 7/8 7/8 7/8 1 1/8 1 1/8 240,000

7/8 7/8 1 1/8 1 1/8 1 1/8 1 1/8 300,000

7/8 7/8 1 1/8 1 1/8 1 1/8 1 1/8 360,000

1 1/8 1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 480,000

1 1/8 1 1/8 1 1/8 1 3/8 1 3/8 1 3/8

600,000

Line Sizing

Table of contents

Other Heatcraft Industrial Equipment manuals