Rohde Spray Booth SK 66 User manual

Instruction Manual

Spray Booth SK 66

SK 66

Page 1

1. IMPORTANT SAFETY INSTRUCTIONS

1.1. General information

Please make sure that you understand both the safety instructions and the safety icons,

in order to eliminate potential danger. It is in your own interest to read through the

following safety instructions very carefully before you start operating your spray booth.

Always keep your instruction manual in a safe place. For your own safety use only

ROHDE spare parts!

1.2. Safety instructions

The ROHDE spray booth his an electrically operated device of Safety Class I according to

DIN VDE, which should exclusively be used for painting ceramics, glass and porcellain with

glaze.

1.3. Safety instructions for operation

The safe operation of a ROHDE spray booth will only be possible by adhering to the

following safety instructions:

•For your own safety you should wear an appropriate respirator, as well as protective

glasses in order to protect yourself against stone dust, etc. Ignoring these safety

instructions can result in damage to persons and health. The manufacturer does not

assume any liability for such cases!

•For industrial use, a qualified electrician must check the spray booth in proper and

perfect condition prior to first operation and in periods of 4 years.

•Repair and maintenance of electric components must be carried out by a

qualified electrician.

•For safety reasons the power plug must be disconnected before carrying out

maintenance or repair work.

Page 2

2. INITIAL OPERATION

2.1. Delivery / removal of packing material

If the ROHDE Spray booth is delivered on pallet by a freight forwarding, please check the

delivery immediately for damages. Should you find any damages on the packing, unpack

the pallet together with the driver and check the product for any damages. Write down

any damages found on the delivery note and do not forget to have the note

countersigned by the driver. Keep a copy of the damage complaint. Notify the forwarding

agent immediately about the damage. We regret that later claims cannot be accepted.

2.2. Disposal of packing material

Please contribute to a clean environment by disposing of the wood, cardboard and

plastic packing material in your nearest recycling centre. For further information on the

disposal of packing material please contact your retailer or community council.

2.3. Operation environment / place of operation

When you choose a suitable place for your Spray booth, please take note of the following

guidelines and prepare the spray booth accordingly:

Place the spray booth on an even surface.

The distance to the walls should be at least 25 cm on each side.

Floor, insulations of the ceiling, walls, dividing walls, panelling, etc have to be

made of material which is not easily flammable.

Make sure that the environment of the spray booth can be aired properly. If

this is not the case a ventilation system has to be installed. Please consult a

qualified ventilation specialist to find out if a ventilation system is necessary.

Page 3

2.4. Mounting of spray booth

2.4.1. Accessories of spray booth

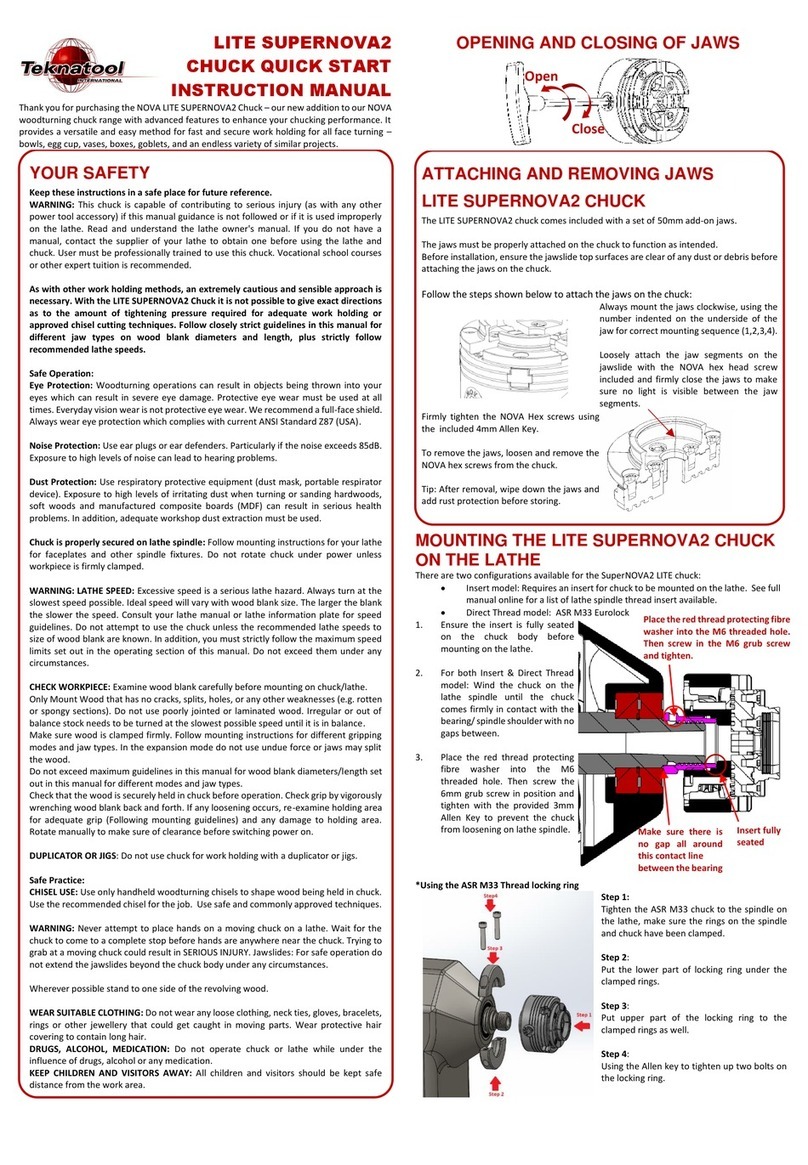

At first you should check the enclosed accessories (Picture 1) :

4 pieces of metal legs

8 pieces of wing nuts

8 pieces of spring nuts

8 pieces of washers

8 pieces of carriage bolts

1 piece of drain plug

Picture 1

2.4.2. Mounting the spray booth on its legs

Place the body of the spray booth flat on one side, in order to facilitate assembly. Make

sure, that all drill holes for fixing the legs are accessible.

Place the legs on the spray booth body in a way, that the drill holes in the body and the

legs are visible.

Now insert the carriage bolts (picture 2) into the drill holes and fasten each of them with

a washer, a spring ring and the wing nut.

Attach the remaining legs in the same way.

With the help of another person lift the spray booth and place it onto its legs. Ensure that

it is in a stable position. You might have to tighten the wing nut again.

Page 4

Picture 2Picture 3

2.4.3. Drain plug

Finally you have to install the drain plug in the provided drain hole (picture 4). For this

purpose, please push the plug slightly into the hole (picture 5) and then press it in firmly.

Picture 4Picture 5

The purpose of the drain hole is to enable you to clean the spray booth. Rinsing or

cleaning liquid can drain out through it.

2.4.4. Switching the suction motor ON/OFF

After you have assembled the spray booth and placed it in its final position, you can

connect it to the power supply.

The ON/OFF switch for the suction motor unit is located on the cealing (picture 6) of

the spray booth. By turning the switch to the position ON or OFF, the suction motor can be

switched on or off (picture 7).

Picture 6Picture 7

Page 5

As an optional equipment we provide a connection reduction to ø 150mm for onward

piping.

CAUTION: Always disconnect the power plug from the mains before

carrying out any assembly operations!

Remove the safety guard of the suction motor for the assembly operation. Then screw

the connection reduction onto the suction motor.

3. MAINTENANCE / CLEANING

CAUTION: Always disconnect the power plug from the mains before

carrying out any cleaning operations!

The spray booth naturally is exposed to contamination, which can be kept to a minimum

by cleaning the spray booth regularly.

3.1. Preparation

In order to facilitate removing dried glazes, it is necessary to wet he spray booth with

regular water.

You should therefore spray the booth with clean water several times. This should be

done with water only, do not use any detergents!

Wipe the inside of the booth with a wet sponge. You might have to repeat this

procedure.

The filter must be cleaned immediately after use.

If you open the drain hole (picture 8) during the cleaning process, you can drain the

waste water into a water bucket.

Picture 8

Do not forget to insert the drain plug again after the cleaning process!

Page 6

3.2. Exchanging the filter foam

Lift the rear wall with both hands upwards out of the anchorage (picture 9) and then pull it

away towards the front. The rear wall will be pulled out of the upper support automatically

(picture 10).

Picture 9Picture 10

Place the rear wall flat in front of you (picture 11) and you can detach the filter foam

easily.

Picture11 Picture12

Remove the dirty filter and replace it with a new, clean one. Clamp it in the rims of the

filter foam as demonstrated in picture 12. Further fixation is not necessary!

After you have exchanged the filters you can remount the rear wall to the spray booth.

Lift the wall into the upper support and push it into the direction of the motor.

The lower anchorage locks automatically, you can now let go of the rear wall.

Page 7

4. CIRCUIT DIAGRAM

Page 8

5. GUARANTEE REGULATIONS

We guarantee the faultless workmanship and function of the delivered spray booth and

grant a 36-month guarantee.

In addition the the filter material (wearing parts) the following points are exempt from the

guarantee:

Damages which have been caused by the customer.

Damage caused by the customer, e.g. unsuitable, aggressive detergents.

Damage caused by inappropriate transport(s).

Damage caused by inadequate applications for which the spray booth was not

intended by the manufacturer.

The manufacturer is not liable

What to do in the event of guarantee/damage:

Please notify your retailer - before any costs arise. Your retailer will then talk to us, the

manufacturer, how to proceed.

In the case of a reclamation, please state the spray booth type, product number and

the date of purchase or the year of construction (see type plate on the spray booth

side).

Page 9

6. PROPERTY RIGHTS / TRADE NAMES / DISCLAIMER

The content of the instruction manual are purely informative. It may be changed without

prior notice and may not be seen as a liability of Helmut Rohde GmbH. We do not

guarantee or take over responsibility for the correctness or precision of the contents in

this instruction manual.

We mention names, trade names, product identifications etc. without special

identification, as they are commonly known. Those names and identifications, however,

may be the property of companies or institutes.

7. SPARE PARTS

8. SERVICE

We hope you will enjoy working with your new ROHDE spray

booth and wish you much success at all times!

Your ROHDE-Team

Page 10

Should you have any questions left regarding your kiln, spare parts or additional equipment

please contact your retailer.

When ordering spare parts please have your invoice of purchase ready at any time.

For your own safety, only use ROHDE spare parts!

20220824-02

Table of contents

Other Rohde Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Leister

Leister WELDPLAST 200-i operating instructions

InterPuls

InterPuls ACR Smart MMV Instruction Manual, Operation and Maintenance original instructions

Interpack

Interpack RSA 20-B user manual

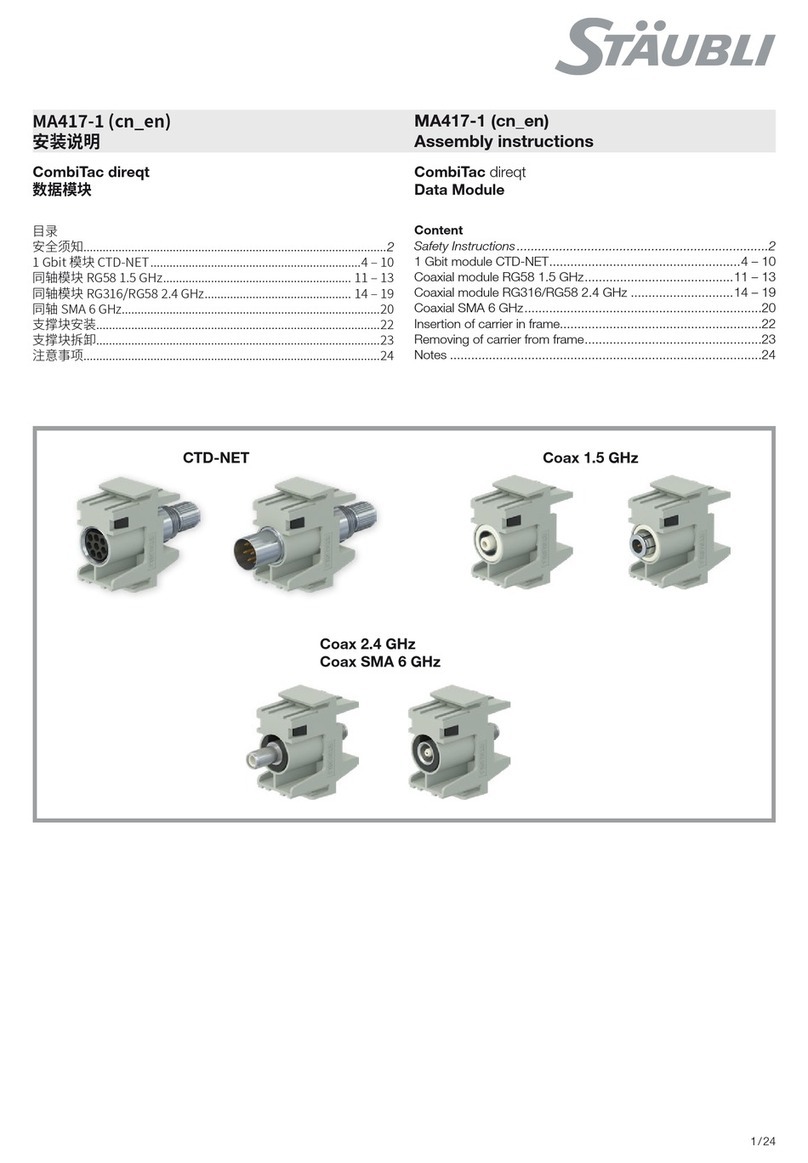

Staubli

Staubli MA417-1 Assembly instructions

Wavetronix

Wavetronix Click 516 user guide

Arrow

Arrow 1200 DIGITAL operating instructions