Heatcraft KIRBY DROP-IN User manual

Document No.: CL276A.DOC

Page No.: 1of 19

Issue: C

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717

KIRBY DROP-IN HANDBOOK

MEDIUM TEMP R134a (& s/seded R22), LOW TEMP R404A

THANK YOU FOR CHOOSING THE HEATCRAFT KIRBY DROP-IN UNIT.

TO ENSURE TROUBLE FREE INSTALLATION AND COMMISSIONING, PLEASE REFER TO THE

CONTENTS OF THIS HANDBOOK.

IMPORTANT INFORMATION -

REFER TO THE SECTIONS ON “WARNINGS AND SAFEGUARDS”, AND

“INSTALLATION INSTRUCTIONS” BEFORE ATTEMPTING TO COMMISSION THIS

PRODUCT.

CONTENTS

End User Notes................................................................................................................................2

Warnings and Safeguards ...............................................................................................................3

Purpose....................................................................................................................................................5

Standard Design Conditions...................................................................................................................5

Installation Instructions .................................................................................................................6

General Commissioning & Decommissioning Guide.....................................................................8

Material Safety Data Sheets –M.S.D.S................................................................................................9

Important Notes.....................................................................................................................................9

General Schematic Drawing & Outline Drawings......................................................................10

Schematic Drawings .........................................................................................................................11

General Outline Drawing .................................................................................................................15

.

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 2of 19

End User Notes

General Notes

Kirby Drop-In units fall under the requirements for commercial electrical equipment as per

Standards Australia guidelines. Installation and major service of this unit must be carried out

by a licensed contractor and in accordance with local regulatory guidelines.

Kirby Drop-In units are supplied with a prewired connection cord for both single and three

phase units.

Under no circumstances should anyone other than a qualified person attempt to

gain access to the interior of the unit without first ensuring electric power is

disconnected.

Kirby Drop-In units have been designed for use in an outdoor (with a suitable cover) or indoor

environment. Kirby Drop-In units are not suitable for mobile and explosion-proof applications.

Auto Start-Up

Kirby Drop-In units may start automatically without any warning.

Auto Reset

Kirby Drop-In units use fans and compressors that are thermally protected. When tripped,

these components will not operate. Once sufficiently cooled however, the component will

automatically reset and may operate without warning.

The unit is equipped with a High/Low pressure switch as standard. The standard switch is a

universal manual or auto-reset type on both high and low sides. Factory setting is auto-reset on

both sides.

Routine Maintenance of Unit

Condenser:

Condenser should be cleaned at 3 monthly intervals.

System operation:

System operation should be checked every 6 months. Checks should include:

Operating conditions such as condensing and evaporating temperatures,

compressor discharge temperature, superheat and sub-cooling, etc.

Electrical connections, current draw and voltage level, etc.

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 3of 19

Warnings and Safeguards

Heatcraft Australia is very conscious of safety issues when designing and manufacturing these

products, but it is essential that the end user, installer or service personnel also exercises care when

working with the units.

Important Notes

Do NOT remove access panels without isolating power.

Do NOT operate unit with access panels removed due to the

presence of rotating equipment.

All controls are 230/240V.

No Smoking

Heatcraft Australia recommends No Smoking within a distance of 15 metres of the unit.

Warning –Electrical Hazard

A qualified Electrician must carry out all electrical work. All field wiring must conform to the

requirements of the equipment and all applicable National and Local Codes.

Always isolate the power to the unit before checking and / or diagnosing the units. Never work

on any electrical item without isolating or disconnecting the power supply.

Caution –Unit Pressurized

All units are supplied pre-charged with the working refrigerant. Do not vent any refrigerant to

the atmosphere as this is illegal. If for any reason the unit needs to be altered engage the

services of a qualified refrigeration mechanic.

Caution –Refrigerant Type

All units are designed to work effectively with HFC refrigerants R134a (MT units from July

2011) & R404A (LT). Medium temp units made prior to July 2011 used R22 (HCFC)

refrigerant. Under no circumstances can a refrigerant such as Ammonia, Hydrocarbon, Water

or Glycol be used in this product. Do not change the refrigerant type as the performance of the

unit will be affected.

Refrigerant can be harmful if it is inhaled and/or makes contact with exposed skin.

Refrigerant must be used and recovered responsibly. Extreme care must be taken when

handling refrigerant, as personnel injury or death may occur.

Warning

This indicates contents for which, if disregarded, the possibility of human death

or severe injury can be assumed.

Caution

This indicates contents for which, if disregarded, the possibility of human injury

or the possibility of material damage can be assumed.

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 4of 19

Caution –Lubricant Oil Type

All compressors are charged with PolyolEster (POE) oil. POE can be used with HCFC

refrigerants, such as R22 (s/seded MT units), and HFC refrigerants, such as R404A and R134a

(MT units from July 2011). Use ONLY POE oil, do NOT mix POE with other oils, when using

HFC refrigerants.

Caution –Sharp Edges

All units are manufactured with sheet metal and in this process all care is taken to ensure the

edges are concealed. Avoid contact with sheet-metal edges and the coil fins. They can be sharp

and are a potential personal injury hazard. Please take care when accessing in or around the

unit.

Warning –Qualified Personnel

All units may only be installed, commissioned, decommissioned and serviced by qualified and

trained personnel (refrigeration mechanics and/or electricians) who have sufficient knowledge

in this type of equipment. It is the purchaser’s responsibility to co-ordinate with qualified

personnel as required.

Personal Protective Equipment

Heatcraft Australia recommends as a secondary safety precaution that all personnel working

with the unit wear appropriate Personal Protective Equipment (PPE) such as gloves, eyewear

and footwear.

Caution –Lifting of Unit

Units are shipped in either timber crates or cardboard cartons depending on the size of the

unit. These units are generally considered to be heavy and may require special lifting

equipment. Units are fitted with either handles or eye bolts for lifting. Do not lift units by pipe work or

electrical cable etc. Refer to table 2 in General Outline Drawings for specific unit weights

Always take care to ensure a proper weight balance before lifting and moving unit.

Caution –High and Low Temperatures

Compressor housing and discharge line temperatures may reach 150°C due to failure of system

components. Wiring and other materials which could be damaged by these temperatures should

not come into contact with the housing or discharge line.

Moreover, even in normal working operation, the unit can generate very high (may exceed

100°C) and very low (below -40°C) temperatures on compressor housing and tubing surfaces

resulting in the possibilities of severe contact burns. Special caution must be taken when

working around the unit.

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 5of 19

Caution –Motor Protection

WARNING: Do not insert any object into operating fans. Ignoring this warning may

result in personal injury and/or severe equipment damage and consequences.

Hermetic compressors, and external rotor motor fans, are fitted with inherent internal or

external line break motor protection. After opening, the protector may not reset for several

hours until the motor cools sufficiently. Do not assume that the motor has suffered an open

circuit failure without first allowing it to cool.

Caution –Internal Pressure Relief (IPR) Valve

Some hermetic compressors include an IPR valve. The IPR valve will open when the discharge

pressure exceeds the suction pressure by a certain value, which is set by the compressor

manufacturer. When it has opened, the compressor sump will become warm and the

compressor will trip out on the motor protector. The unit may take 2 to 3 hours to reset and

restart automatically if this happens. “AW” compressors have an IPR valve.

Do NOT assume that a compressor that is running, but not pumping, is faulty.

Stop the compressor and allow the pressures to balance, and then start the compressor

again.

Purpose

Kirby Drop-In units are standard OEM products of Heatcraft Australia including all “high”,

“medium” and “low” temperature application ranges. They are designed for continuously

supplying and receiving the refrigerant to and from the evaporator(s), and rejecting the heat

extracted from the cold space to surrounding atmosphere where the units are installed.

Kirby Drop-In units are intended for installing in a typical ventilated indoor or outdoor ( with

suitable covers) environment (Refer to the General Arrangement Drawing section for details)

with the ambient temperature between 10 and 43°C and compressor return vapour temperature

no greater than 20°C.

They are not intended for environments that may have harmful, corrosive or flammable

atmospheres. Marine environments are considered corrosive; please consult Heatcraft before

installing in this environment.

Standard Design Conditions

From July 2011, Medium / High temperature Kirby Drop-In units are designed for refrigerant

R134a, to be used in commercial cool room applications ranging from 0°C to +10°C saturated

suction. Previous models used R22 refrigerant, and those models MUST not be used with any

other refrigerant. The refrigerant used is CLEARLY marked on the unit serial plate.

Low temperature Kirby Drop-In units are designed, for primary refrigerant R404A, to be used

in commercial freezer room applications ranging from -35°C to -10°C saturated suction.

Please refer to sales data sheet CL247 for standard Kirby Drop-In unit configurations, options

offered and other detailed information such as capacity variations for other refrigerants.

For special design requirements (non standard conditions and/or refrigerants), please inquire with your

local representatives and/or Heatcraft Australia local branches, or call our national telephone number 13

23 50 for your nearest available information resources.

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 6of 19

Installation Instructions

Kirby Drop-In Units are designed to be installed from the top of the cool/freezer room. As

such they should be inserted into the appropriate hole cut in the roof of the room. A roof gasket

is provided, to be used between the unit and the roof. Take care to install this gasket correctly

otherwise there will be excessive moisture ingress into the room causing reduced operating

efficiencies and increased running costs.

Unpacking of Unit

When unpacking, check for any damage to packing material or the unit itself which may affect

the unit’s performance. If any such damage is evident, please contact your local Heatcraft

branch.

When the unit has been removed from the packaging under no circumstances is the unit

allowed to rest on the evaporator drain tray/covers. Leave the unit on the supporting

packaging until ready to install.

Unpacking Timber Crate Units

To remove the unit from the timber crate proceed as follows

1. Remove the top of the timber crate

2. Attach the appropriate lifting equipment to the two (2) eye bolts located at either end of

the blue plastic plug.

3. Lift the unit straight up and position in the cool room. Do not allow the unit to rest on the

evaporator housing.

Unpacking Cardboard Carton Units

To remove the unit from the cardboard box proceed as follows

1. Open the top of the box

2. Lift the unit straight up using the two (2) handles provided, one at either end of the unit.

3. Position the unit in the cool room. Do not allow the unit to rest on the evaporator

housing.

Prior to installing the unit in the cool/freezer room ensure there is sufficient clearance

above the room to accommodate the full height of the unit. These units are intended to be

dropped-in to the cool room.

Installation Location (Refer to the General Arrangement Drawing section)

If the unit is to be located in close proximity to a wall or similar obstruction, the minimum

distance from the condenser coil face to the obstruction must be greater than 400 mm.

It is particularly important for the condensing unit section to allow sufficient

unobstructed air-discharge space around the unit to prevent warm air recirculation to

the condenser.

Coolroom units-

Coolroom units are induced draft discharging into the cooled space. The evaporator coil face

should be maintained at least 300mm from the nearest wall.

Evaporator section should be installed as far as possible from any room access door(s),

preferably discharging air towards the access door.

Cabinet Units-

Cabinet unit evaporators are forced draft discharge to the rear of the cabinet. The construction

of the unit prevents the evaporator from being installed too close to cabinet walls etc.

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 7of 19

Electrical Connection

Kirby Drop-In units are supplied fitted with either a single phase or

three phase connecting plug. Single phase units may be fitted with

either a 10 Amp or a 15 Amp plug depending on the specific unit.

All three phase units are fitted with a 15 Amp three phase and neutral plug.

Pressure Settings

Kirby Drop-In units have a maximum operating pressure of 32 Bar(g) determined on

pressure vessels (such as liquid receivers). Pressure limiting device settings such as the

HP control must be 29 Bar(g) or lower in accordance with AS1677.2 that the pressure

limiting device setting is no greater than 0.9 times the maximum operating pressure.

In general, Heatcraft Australia sets the HP control to allow a maximum condensing

temperature of 60°C. The corresponding saturation pressures for the respective refrigerants

cut-out points for safety protection purpose are approximately 28 Bar(g) for R404A, 23 Bar(g)

for R22 (s/seded MT models), and 16 bar for R134a (MT models from July 2011).

Heatcraft Australia also recommends the LP switch to be used as a safety protection device.

Depending on the application and compressor, LP cut-in and differential points should be set

with the following considerations:

Set the cut-out points at 3–5 K below the respective minimum design saturated suction

temperatures (Refer to the Standard Design Conditions section for saturated suction

temperature ranges).

Set the differential to no more than 2 Bar.

The cut-out pressure shall be in the positive pressure region.

When the unit is installed in a cold ambient, the cut-out pressure shall be lower than the

pressure corresponding to the ambient temperature.

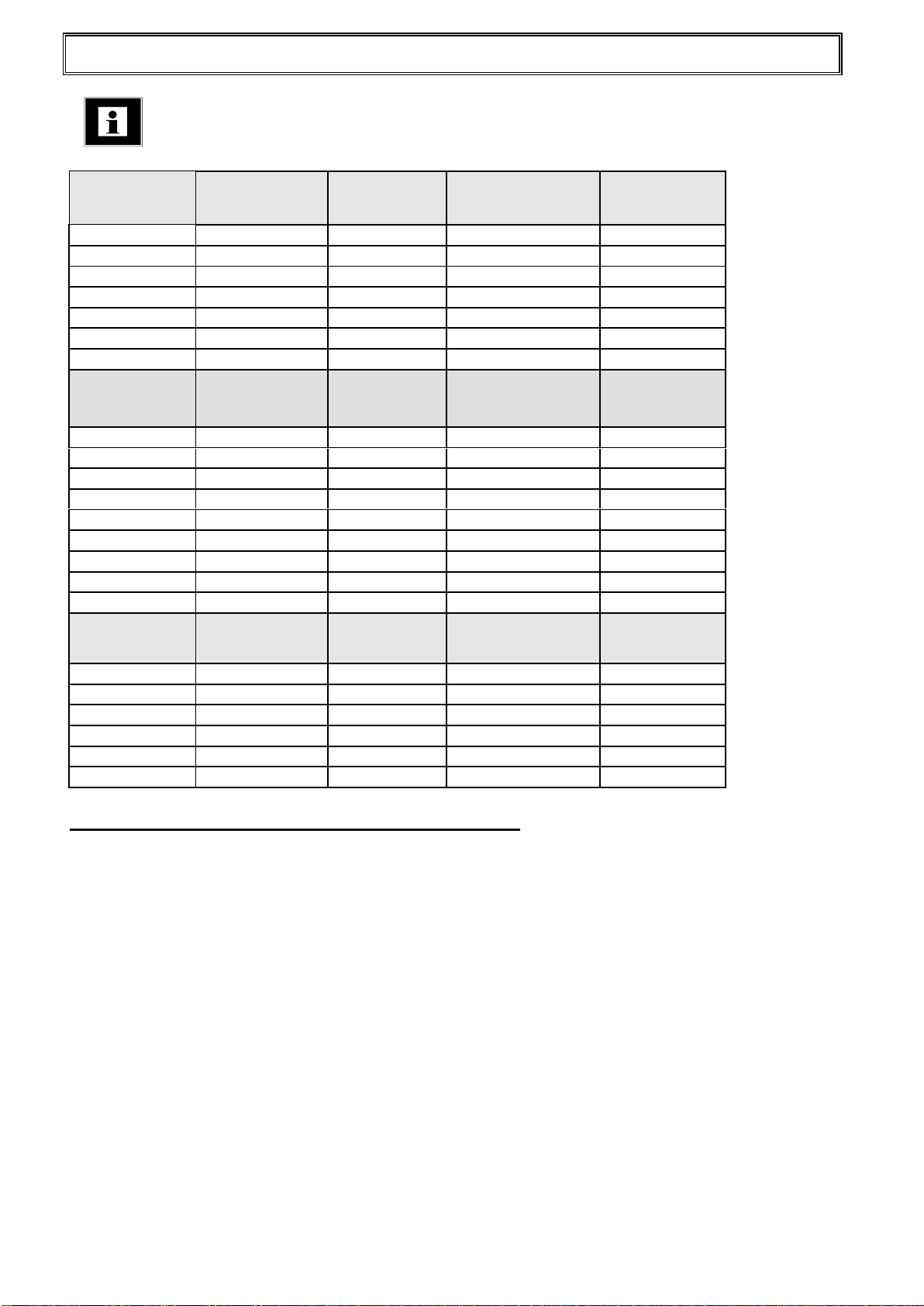

Dixell Control Settings

Dixell controls are supplied with factory default setting as listed in the Dixell instruction

manual, supplied with individual units. Heatcraft alters some of these setting as listed in the

table below.

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 8of 19

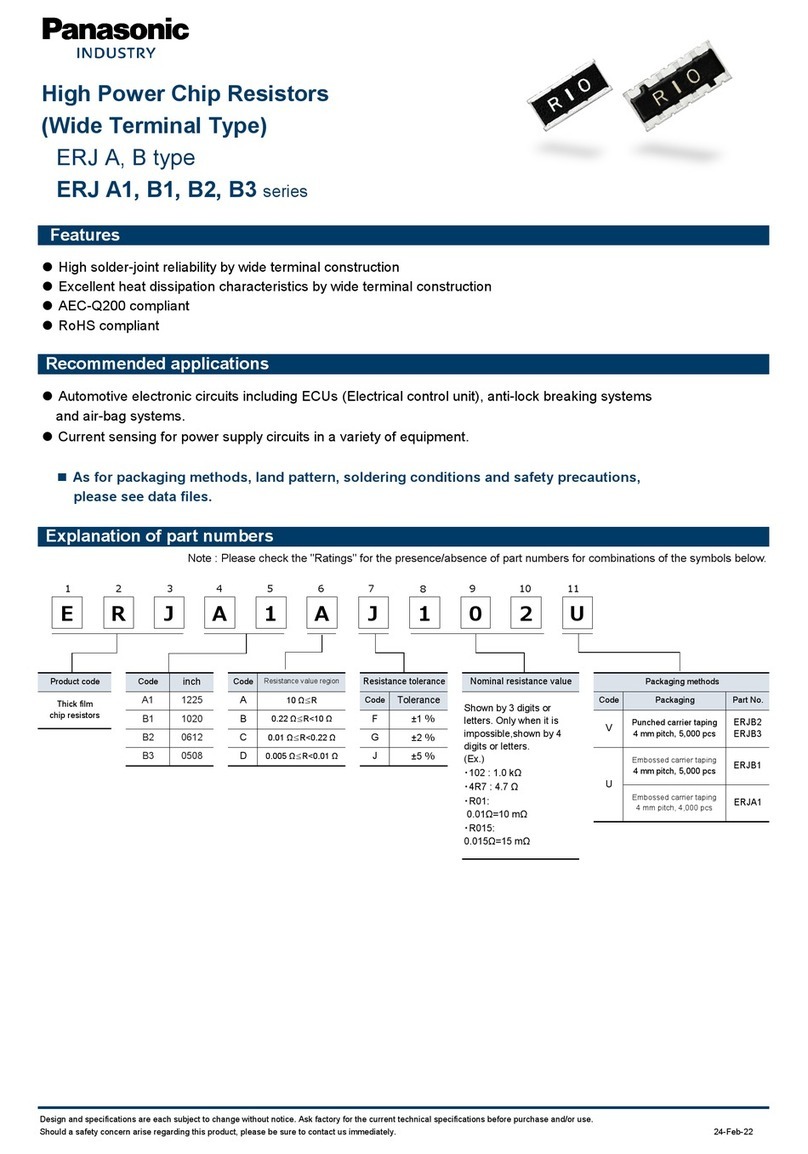

TEMPERATURE

New R134a MT

Models from July

2011

Superseded R22

MT Models (prior to

July 2011)

CONTROL

SET POINT

(Cut In)

Cut

Out

DEFROST

TERMINATION

FANS

STOP

DEFROST

TIME

KPC800-6

KPC800-4

XR03CX

3° C

1° C

KPC1000-6

KPC1000-4

XR03CX

3° C

1° C

KPC1200-4

XR03CX

3° C

1° C

KPC1400-6

KPC1400-4

XR03CX

3° C

1° C

KPC1700-6

KPC1700-4

XR03CX

3° C

1° C

KSC1800-4

XW60K

3° C

1° C

KSC2000-6

KSC2000-4

XW60K

3° C

1° C

KSC2700-6

KSC2900-4

XW60K

3° C

1° C

KSC3500-6

KSC4100-4

XW60K

3° C

1° C

LT R404A models

KPF1000-4

XW60K

-15° C

-17° C

2° C

11° C

20 MIN

KPF1200-4

XW60K

-15° C

-17° C

2° C

11° C

20 MIN

KSF1500-4

XW60K

-15° C

-17° C

2° C

11° C

20 MIN

KSF2000-4

XW60K

-15° C

-17° C

2° C

11° C

20 MIN

KSFT2600-4

XW60K

-15° C

-17° C

2° C

11° C

20 MIN

Table 1. Dixell Control Setting

General Commissioning & Decommissioning Guide

Warning –Commissioning

Medium Temp Units from July 2011 use R134a refrigerant, with TX valve refrigerant control.

Variation of TX valve setting from factory set up is possible. Changes should ONLY be made

by a qualified refrigeration mechanic.

LT units use Capillary refrigerant control and cannot be altered from factory set up.

During commissioning please check the following for correct operation

Compressors starting and stopping –the compressor should start quickly and take no

than 0.5 second to achieve running speed. If the start is slow and the compressor

sounds to be “labouring” or the relay “chatters” please investigate to determine the

problem. On stopping, the compressor should stop within 1 second, without any

knocking noises.

Temperature Setting –check the unit is cycling on and off as expected.

Water Drains –check to ensure that water is draining away correctly. A “P” trap should

be installed in the drain tube on the outside of the room.

TX valve and bulb (R134a medium temp units from July 2011)- ensure the TX valve

insulation is firmly in place (KPC models), and the sensor bulb is firmly in place on the

suction line (all R134a MT models).

TX valve setting (R134a medium temp units from July 2011)- Superheat setting is

factory set at 4K in normal operating condition (+2°C air on). Some adjustment may be

necessary depending on the conditions during initial pulldown of the space. Always

return to 4K for normal operation.

Defrost Heater (LT Units) –manually activate the defrost cycle to make sure the

heaters are working correctly.

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 9of 19

Warning –Decommissioning

If the unit should need to be decommissioned please proceed as follows

Remove the unit from the room.

Have the refrigerant removed from the unit by a licensed refrigeration mechanic.

Dispose of the unit in an appropriate recycling centre.

Material Safety Data Sheets –M.S.D.S.

These are available from your nearest Heatcraft Branch for all refrigerants that Kirby Drop-In

units are approved for, and for oils and other materials as needed.

Important Notes

To ensure Kirby Drop-In units operate efficiently and for a long working life, always obtain

genuine replacement parts from your local Heatcraft Wholesale Branch. Genuine replacement

parts are covered by the warranty. Refer to the Standard Terms & Conditions of Sale in the

Price Guide for warranty statements.

Continuous product improvement is our company policy. Heatcraft Australia reserves the right

to make changes in product specifications and/or this instruction manual without notice.

Heatcraft Australia is dedicated to providing safe products and protecting the environment by complying

with all applicable national laws and regulations governing environmental protection. New and used

refrigerants cannot be vented into atmosphere. Reclaim all used refrigerants. EPA regulations are

constantly updated. Ensure your refrigerant handling procedure complies with the relevant regulations.

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 10 of 19

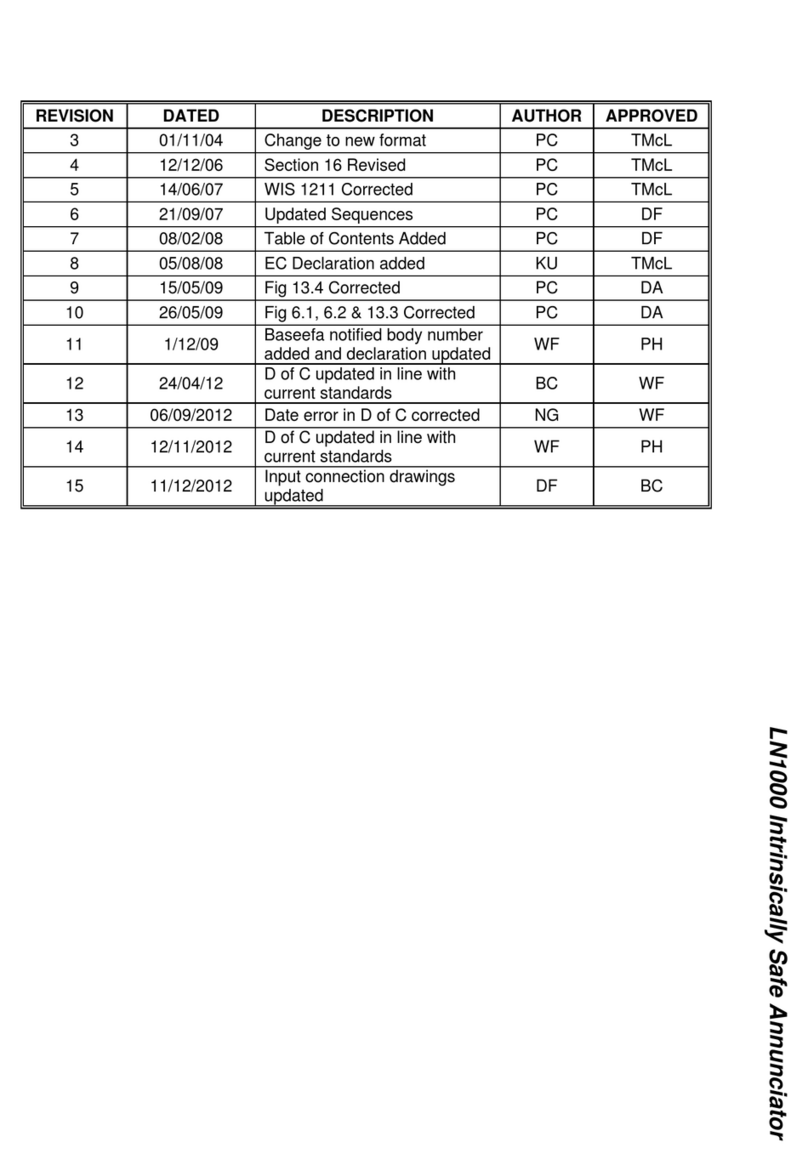

General Schematic Drawing & Outline Drawings

New R134a MT

Models from July

2011

Schematic

Outline

Hole Size

Unit Weight

W x D

Kg

KPC800-6

MS793-8

SK696-2

825X435

31

KPC1000-6

MS793-8

SK696-4

1040X435

33

KPC1400-6

MS793-9

SK696-4

1045X435

50

KPC1700-6

MS793-9

SK696-4

1045X435

58

KSC2000-6

MS793-10

SK696-9

660X550

90

KSC2700-6

MS793-10

SK696-10

1085X665

128

KSC3500-6

MS793-10

SK696-11

1085X665

135

Superseded R22

MT Models (prior to

July 2011)

Schematic

Outline

Hole Size

W x D

Unit Weight

Kg

KPC800-4

MS793-6

SK696-2

825X435

33

KPC1000-4

MS793-6

SK696-2

825X435

33

KPC1200-4

MS793-6

SK696-4

1045X435

46

KPC1400-4

MS793-7

SK696-4

1045X435

50

KPC1700-4

MS793-7

SK696-4

1045X435

58

KSC1800-4

MS793-1

SK696-8

660X550

88

KSC2000-4

MS793-2

SK696-9

660X550

90

KSC2900-4

MS793-2

SK696-10

1085X665

128

KSC4100-4

MS793-2

SK696-11

1085X665

135

LT R404A

Models

Schematic

Outline

Hole Size

W x D

Unit Weight

Kg

KPF1000-4

MS793-4

SK696-13

1045X435

64

KPF1200-4

MS793-4

SK696-13

1045X435

68

KSF1500-4

MS793-4

SK696-9

660X550

92

KSF2000-4

MS793-4

SK696-10

1085X665

135

KSFT2600-4

MS793-5

SK696-18

1085X665

155

Table 2 - Electrical Schematics and General Information

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 11 of 19

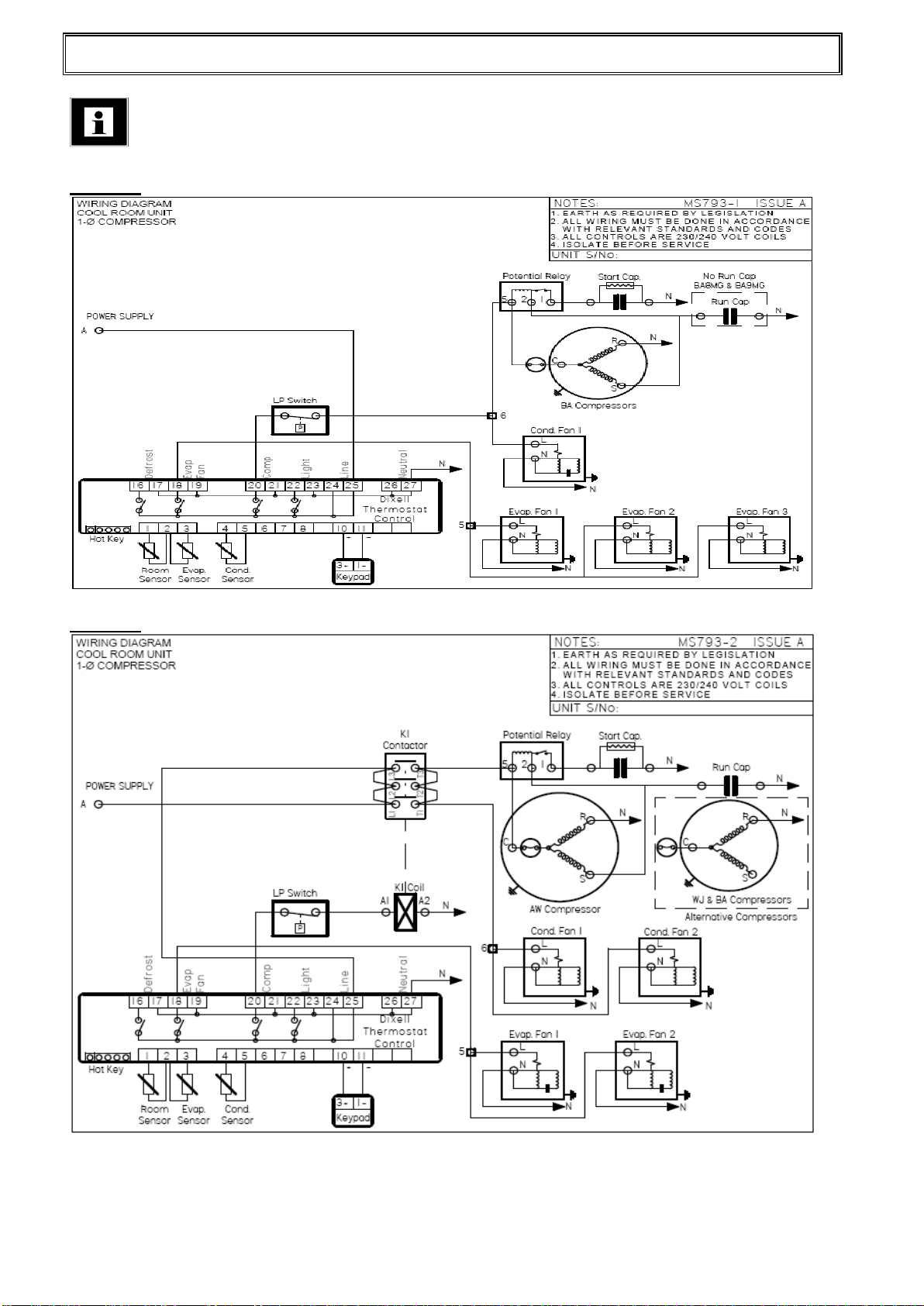

Schematic Drawings

MS793-1

MS793-2

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 12 of 19

MS793-4

MS793-5

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 13 of 19

MS793-6

MS793-7

MS793-8

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 14 of 19

MS793-9

MS793-10

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 15 of 19

General Outline Drawing

SK696-2

SK696-4

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 16 of 19

SK696-8

SK696-9

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 17 of 19

SK696-10

SK696-11

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 18 of 19

SK696-13

SK696-18

Manufactured for Heatcraft Australia Pty Ltd ACN 000 056 717 Document No.: CL276A.DOC

Page No. 19 of 19

COMMISSIONING NOTES

Table of contents

Other Heatcraft Industrial Equipment manuals